Mixed cooling flame tube used for low-pollution gas turbine

A gas turbine, mixed cooling technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of reducing the outlet temperature of the combustion chamber, unstable tempering and combustion, easy over-temperature of the wall, etc., to reduce NOx pollutants, The effect of reducing the average outlet temperature and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

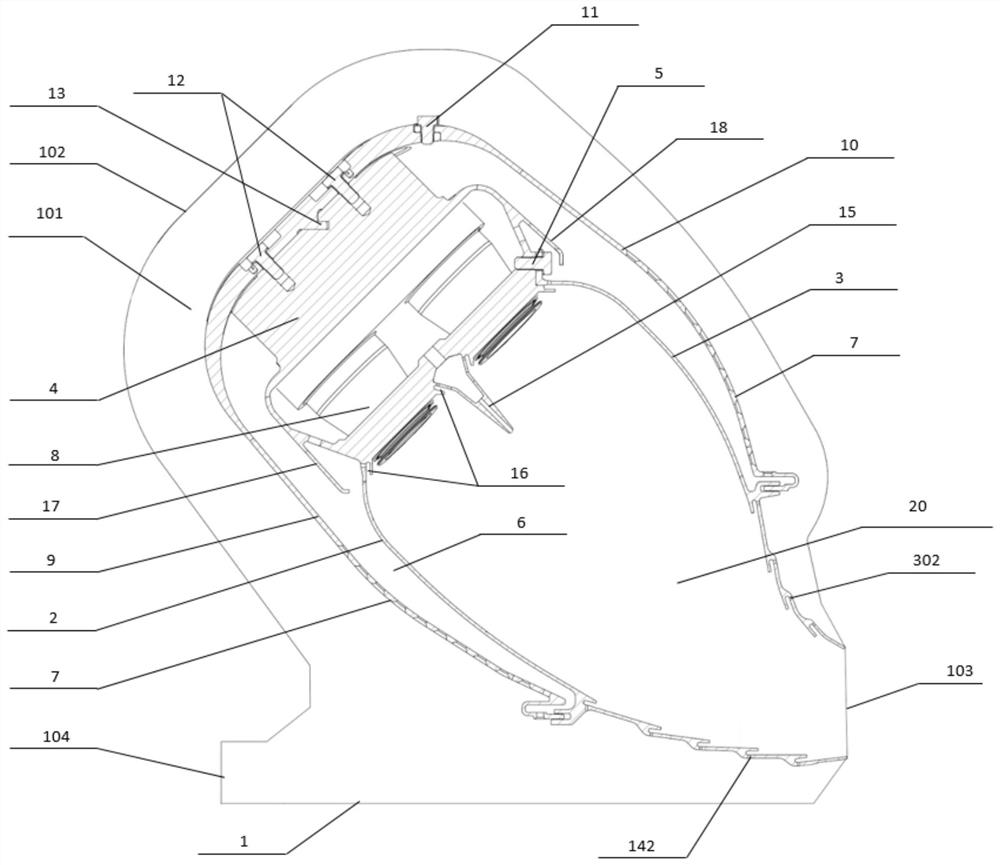

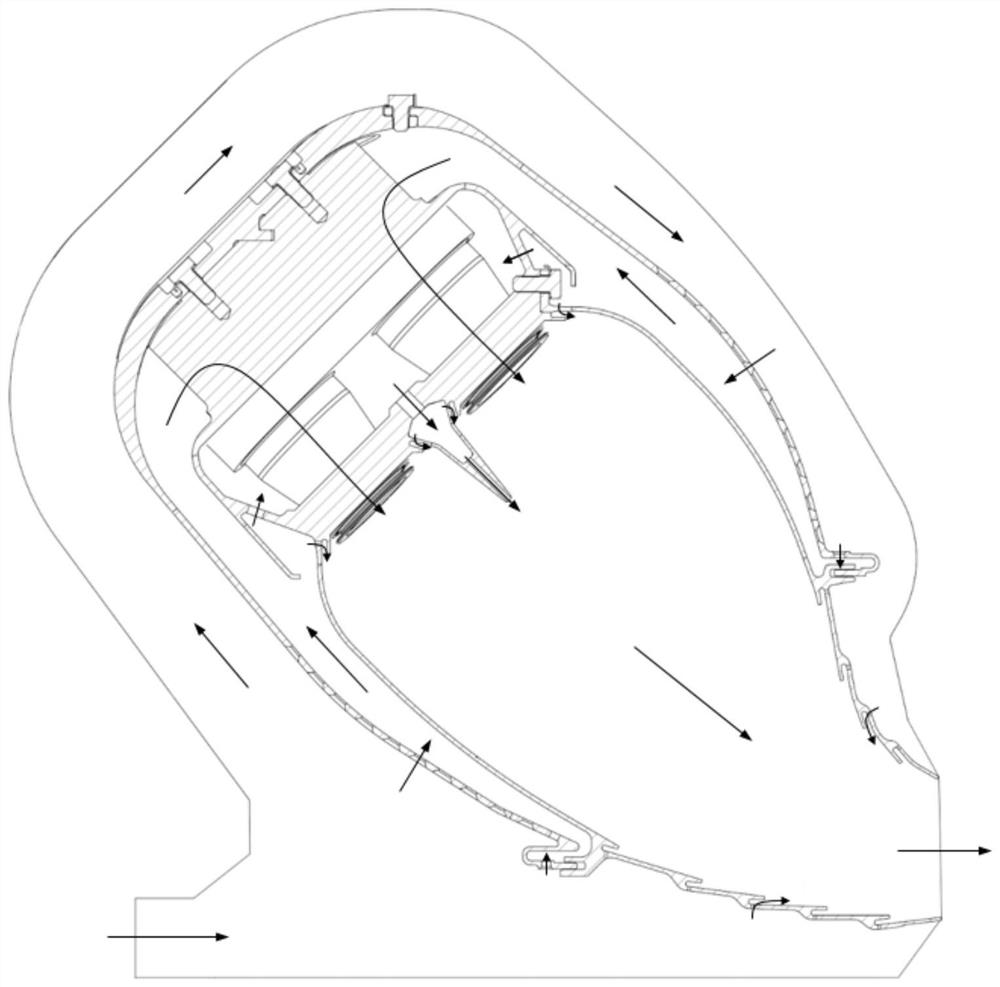

[0037] Such as Figure 1-4As shown, the present embodiment provides a mixed cooling flame cylinder for low-pollution gas turbines, which is arranged in the combustion chamber 1 and includes a fairing, an inner wall 2, an outer wall 3 and a head structure 4, and the fairing is arranged in the combustion chamber 1 A gas circulation channel 101 is formed between the inner wall and the inner wall of the combustion chamber 1; the inner wall 2, the outer wall 3 and the head structure 4 are all installed in the fairing, and the head structure 4 is close to the combustion chamber 1 outside the combustion chamber 102 Set on one side; one end of the inner wall 2 and one end of the outer wall 3 are connected to the head structure 4, the inner wall 2 is arranged on the side close to the combustion chamber inlet 104, and the inner wall 2, the outer wall 3 and the head structure 4 are formed. Inner cavity 20, the end of inner cavity 20 away from head structure 4 is the opening end correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com