Novel low-nitrogen-emission cold flame combustion integrated steam boiler

A technology for steam boiler and nitrogen emission, applied in steam boilers, boiler water pipes, combustion methods, etc., can solve the problems of high smoke temperature, short service life, small water capacity, etc., to achieve simple quality control management, easy capacity expansion and maintenance , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] The specific embodiments of each invention content of the present invention are as follows:

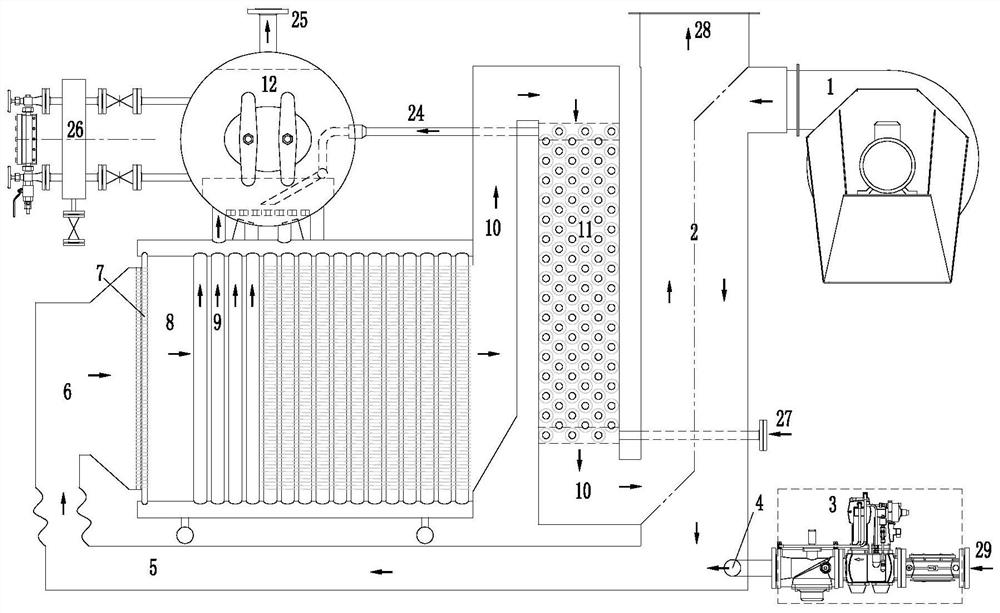

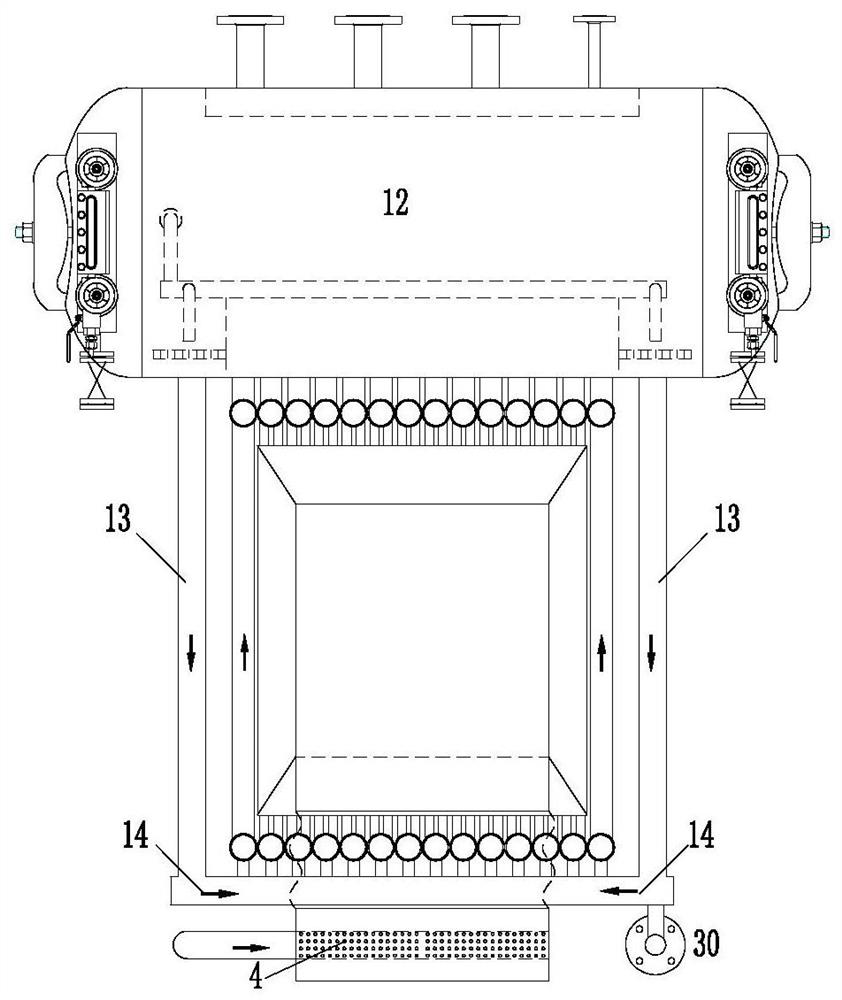

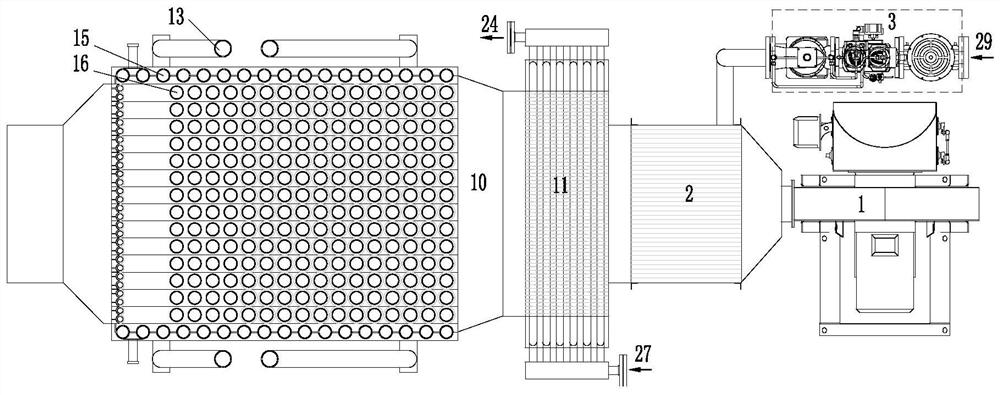

[0031] The invention relates to a novel low-nitrogen emission cold flame combustion integrated steam boiler, which mainly consists of a fan 1, an air preheater 2, a gas valve group 3, a gas distribution pipe 4, an air duct 5, an air distribution chamber 6, and a water-cooled grate 7. Furnace 8, convection area 9, flue 10, economizer 11, steam drum 12, downpipe 13, downcommunication pipe 14, water level controller 26, etc.

[0032] Smoke and air system: the fan 1 pressurizes the cold air and enters the air preheater 2 to preheat it into hot air; after the gas valve group 3 decompresses and the gas distribution pipe 4 diverts the natural gas and hot air, they are evenly mixed in the air duct 5 , into the air distribution chamber 6, and then the mixed gas passes through the water-cooled grate 7 and ignites to form a flame that burns in the furnace 8, and then the high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com