A liquid fuel porous medium burner with cold flame evaporation

A porous medium, liquid fuel technology, applied in the field of micro-energy, can solve the problems of poor separation, low pollutant discharge, high pollutant discharge, and achieve convenient fuel addition, low pollutant discharge, and low combustion pollutant discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

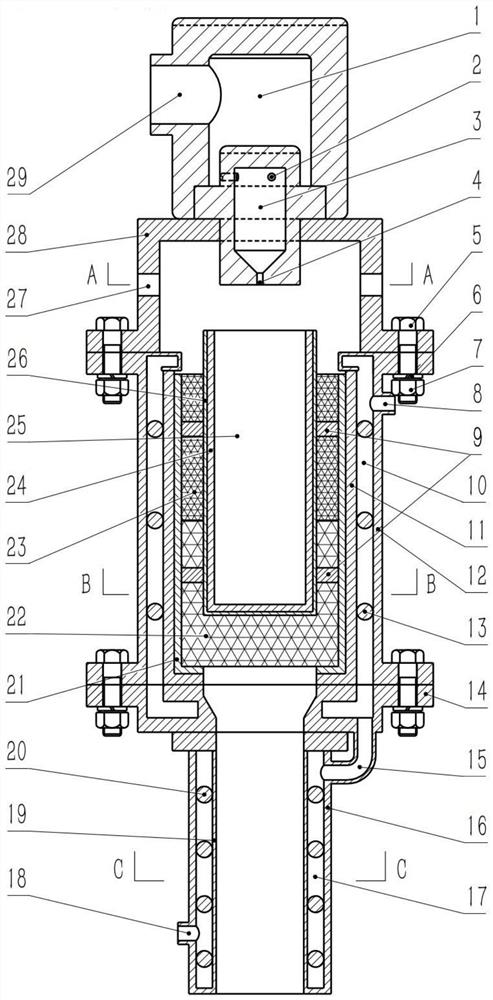

[0028] The liquid fuel porous medium burner of this embodiment uses liquid heptane as the fuel, such as figure 1 As shown, the liquid heptane fuel is supplied into the pressure swirl nozzle 1 through the pressure swirl nozzle liquid inlet 29, and then atomized and sprayed into the combustion device, only by adjusting the fuel supply pressure of the pressure swirl nozzle 1 to adjust the fuel supply. The power of the burner can be adjusted by entering the amount.

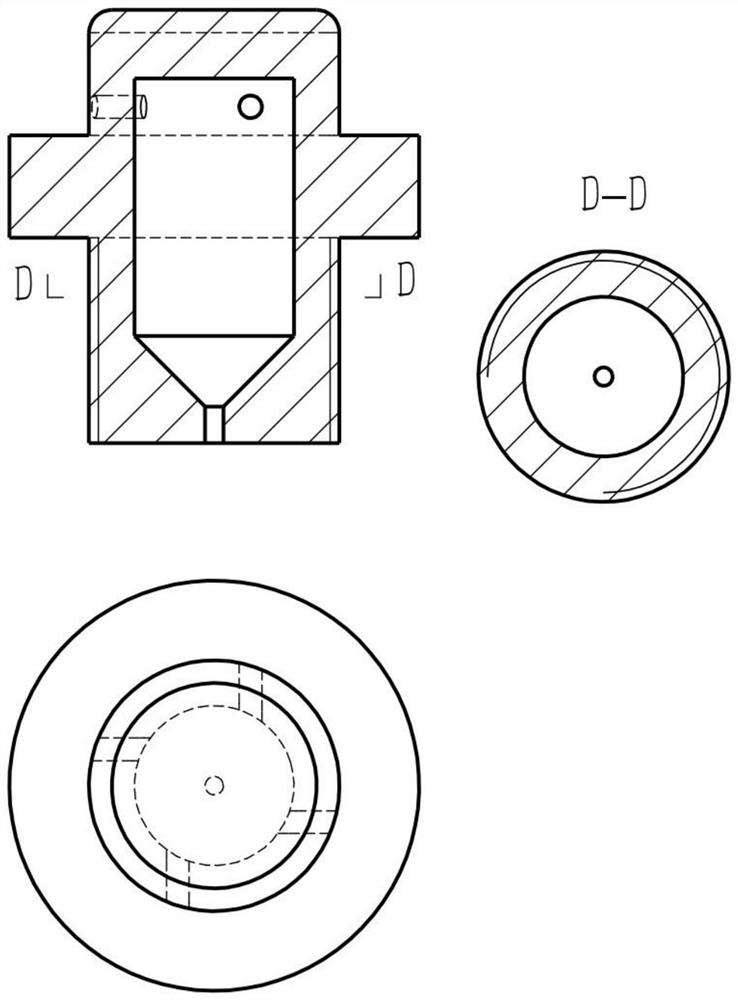

[0029] The present embodiment discloses a liquid fuel porous medium burner with cold flame pre-evaporation, such as figure 1 As shown, it includes a pressure swirl nozzle 1, a nozzle swirl chamber inlet 2, a swirl chamber 3, a nozzle outlet 4, a bolt 5, a washer 6, a nut 7, and a pressure swirl nozzle inlet 29. It also includes cooling water outlet 8, cold flame gasifier fixing ring 9, combustion chamber water cooling channel 10, combustion chamber shell 11, combustion chamber water cooling channel wall surface 12, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com