Annular surface cold flame ultralow-nitrogen combustor

A technology of annular surface and burner, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of inability to match boilers and low-nitrogen transformation of old-fashioned boilers, achieve stable combustion, prevent flame backfire, The effect of lowering the flame temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

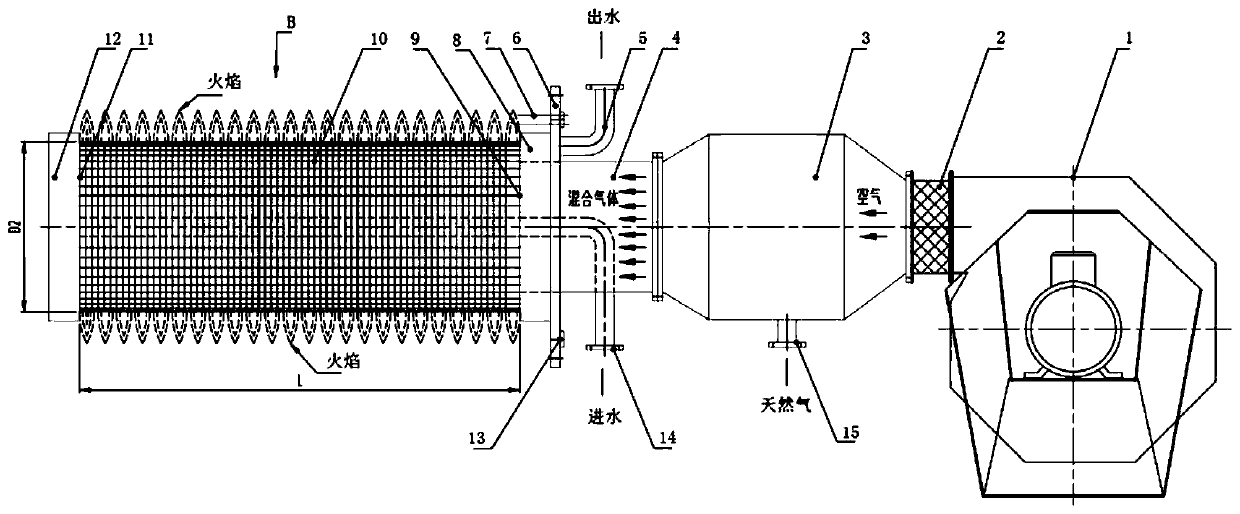

[0028] According to the attached Figure 1-8 The specific embodiment of the present invention is further described:

[0029] This embodiment provides an annular surface cold flame ultra-low nitrogen burner, which can achieve full combustion of natural gas through the uniform mixing of natural gas and air, and at the same time, the combustion flame is sprayed from the slit formed by the inner water pipe 17, the outer water pipe 16 and the perforated plate 19. When it is ignited, backfire can be prevented, and the flame temperature can be effectively controlled and reduced, which greatly reverses the generation of NOx. Such as figure 1 and figure 2 As shown, the annular surface cold flame ultra-low nitrogen burner of this embodiment has a plurality of inner water pipes 17 and outer water pipes 16 arranged in a circular arrangement (or fan-shaped according to local heating requirements), the outer water pipes 16 and the inner water pipes The centers of the adjacent gaps of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com