Cooling flame frontal surface device capable of inhibiting generation of NOx in hearth of gas-fired boiler

A gas-fired boiler and flame front technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as deterioration of combustion conditions, reduction of boiler efficiency, complexity, etc., to suppress the generation of NOx, improve combustion efficiency, and use control. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

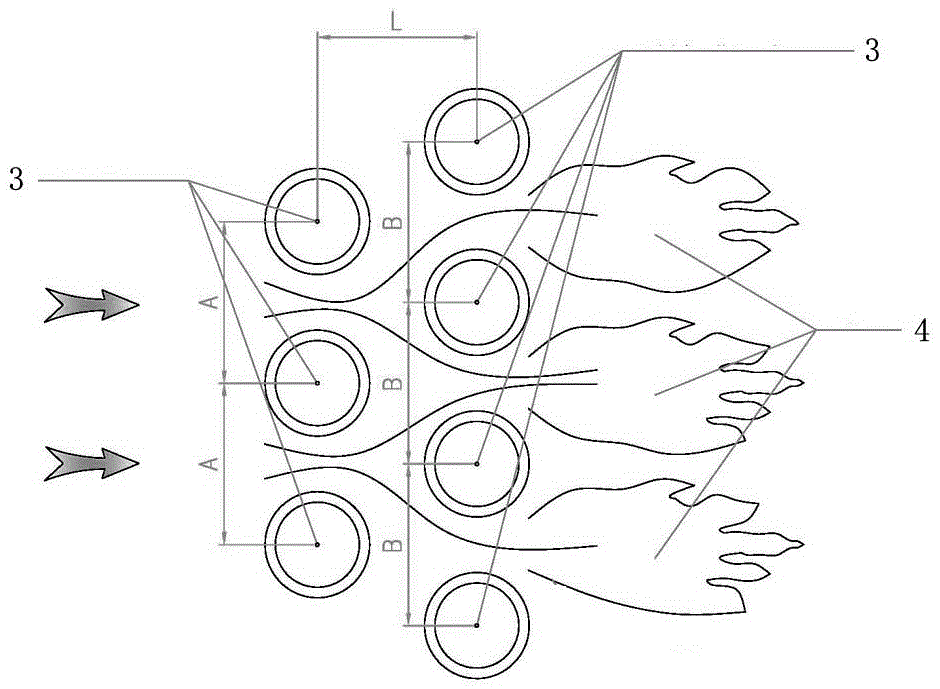

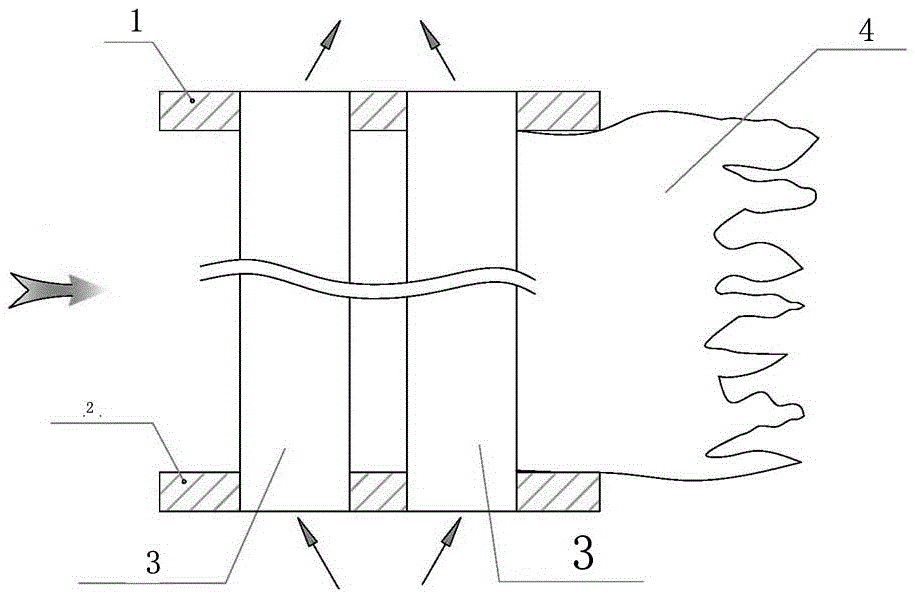

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a cooling flame front device used in the furnace of a gas-fired boiler that can suppress the formation of NOx according to the present invention mainly includes an upper tube sheet 1 and a lower tube sheet 2, and is installed on the upper tube sheet 1 and the lower tube sheet Two groups of cooling water pipes 3 leading to cooling water between 2, each of the two groups of cooling water pipes 3 are arranged in two rows adjacent to each other along the burning direction of the flame 4, and the cooling water pipes in the two rows are arranged in a staggered manner.

[0010] As shown in the figure, the gas flame 4 in the furnace of the boiler according to the present invention is in a horizontal direction, and the front and rear two rows of cooling water pipes 3 are arranged in front and rear perpendicular to the direction of the horizontal flame 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com