Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Tighter engagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

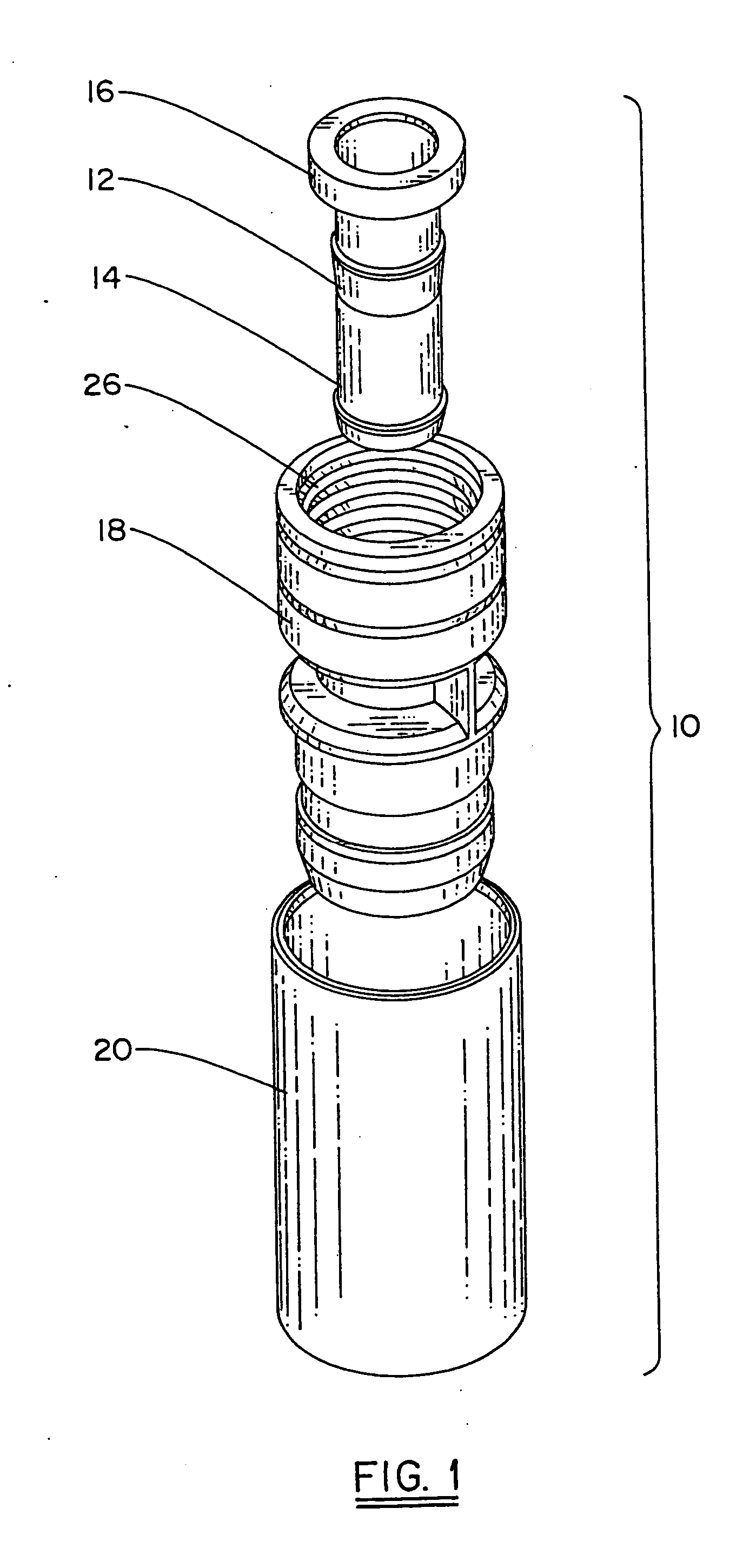

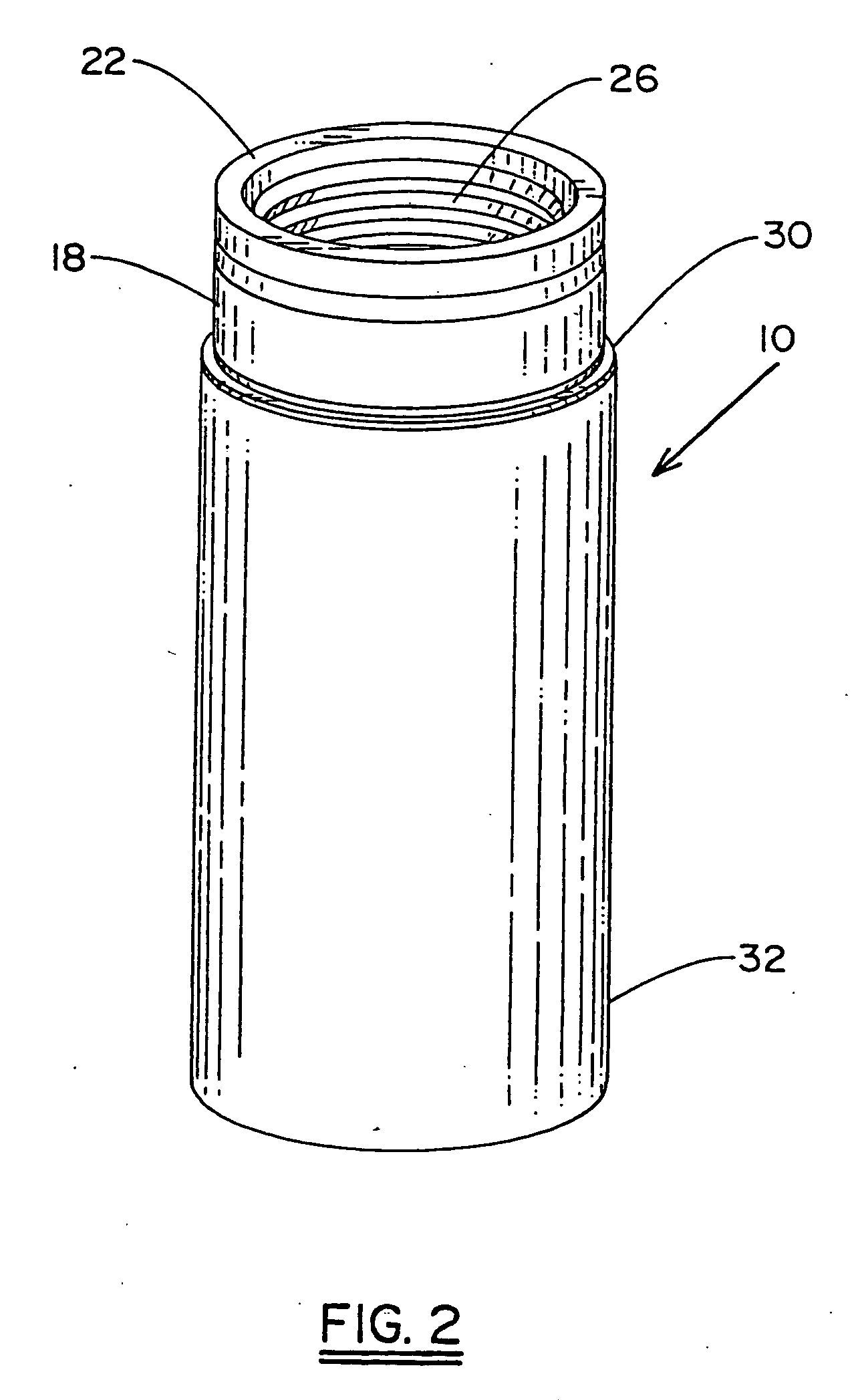

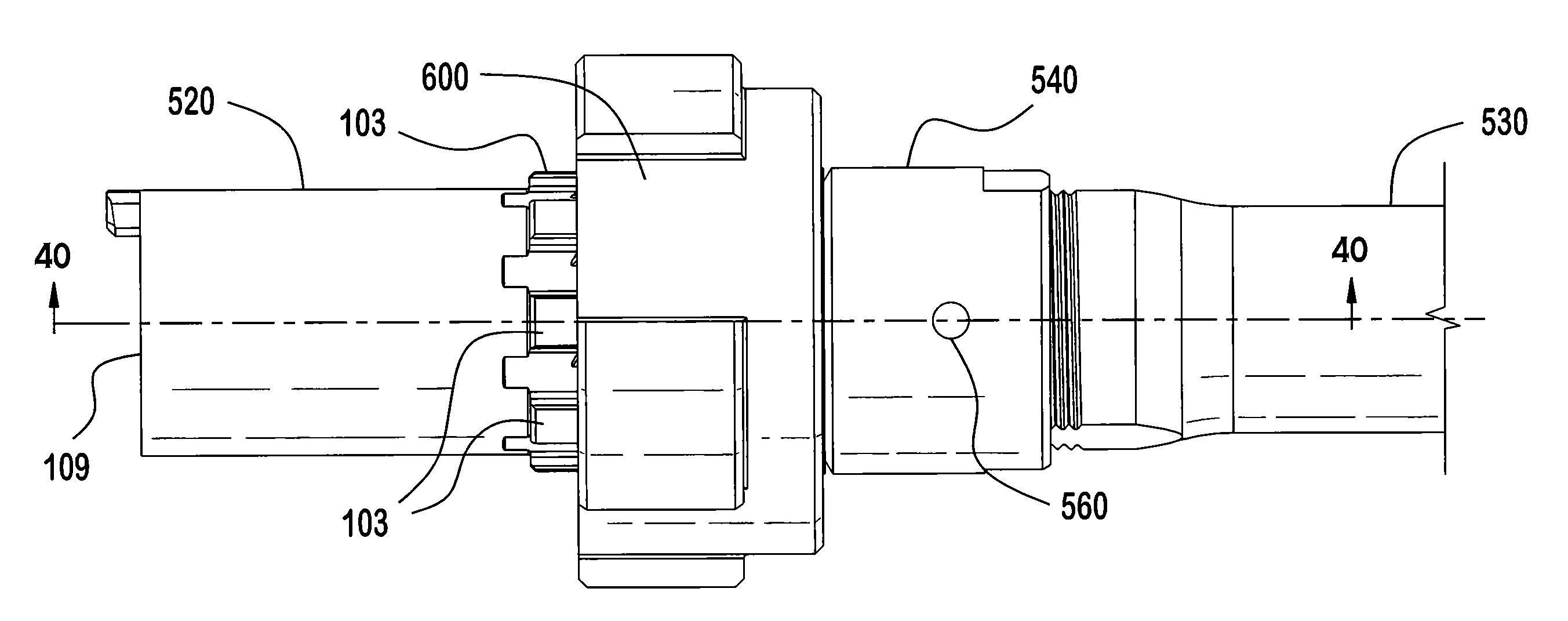

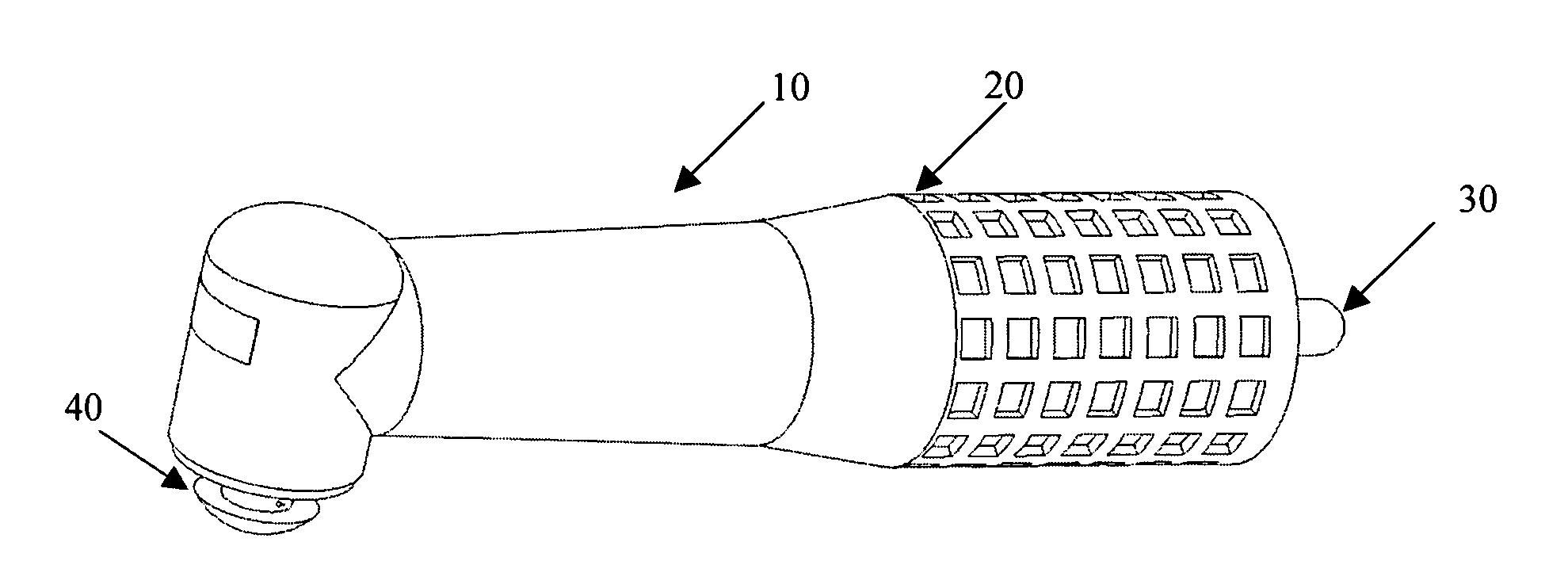

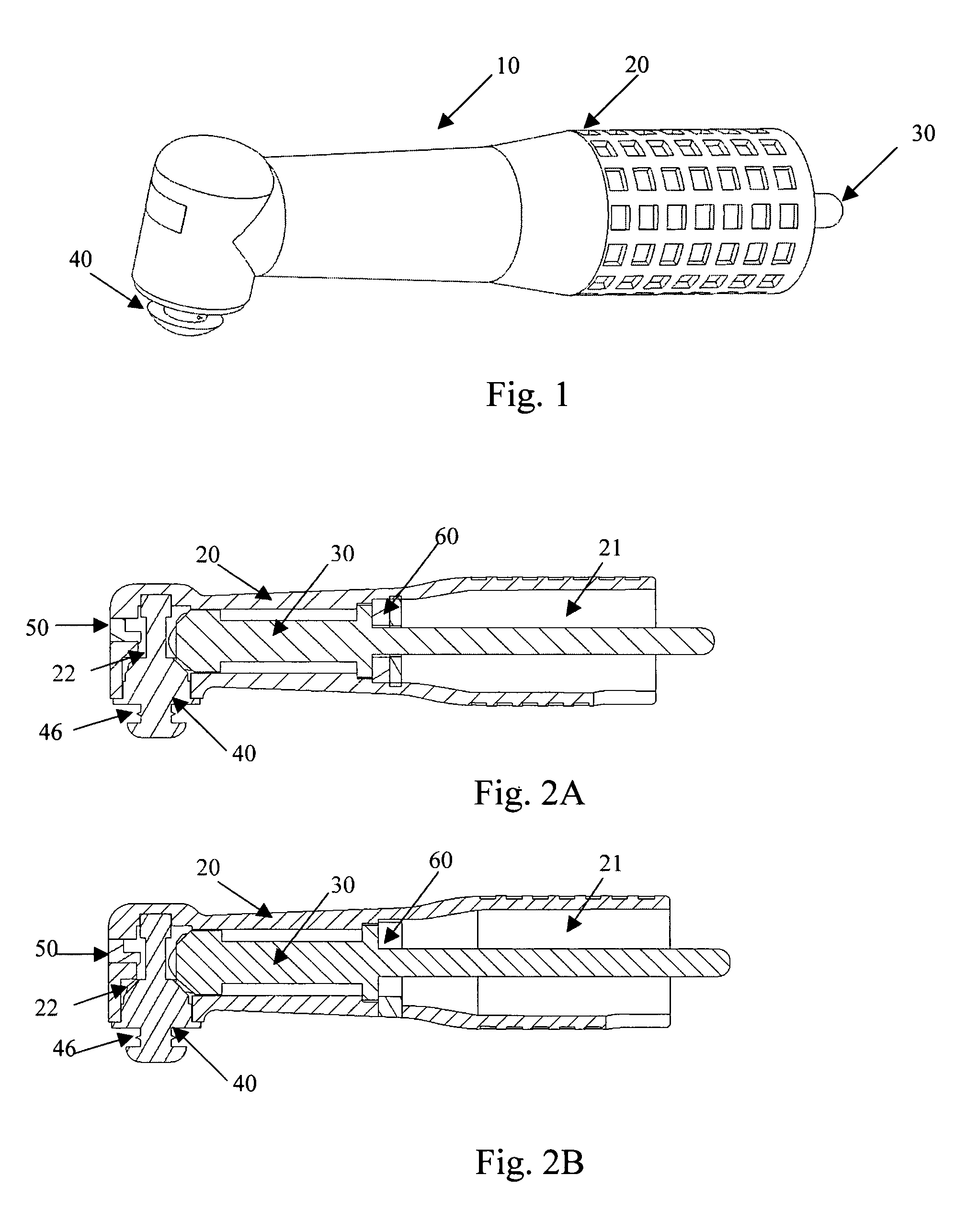

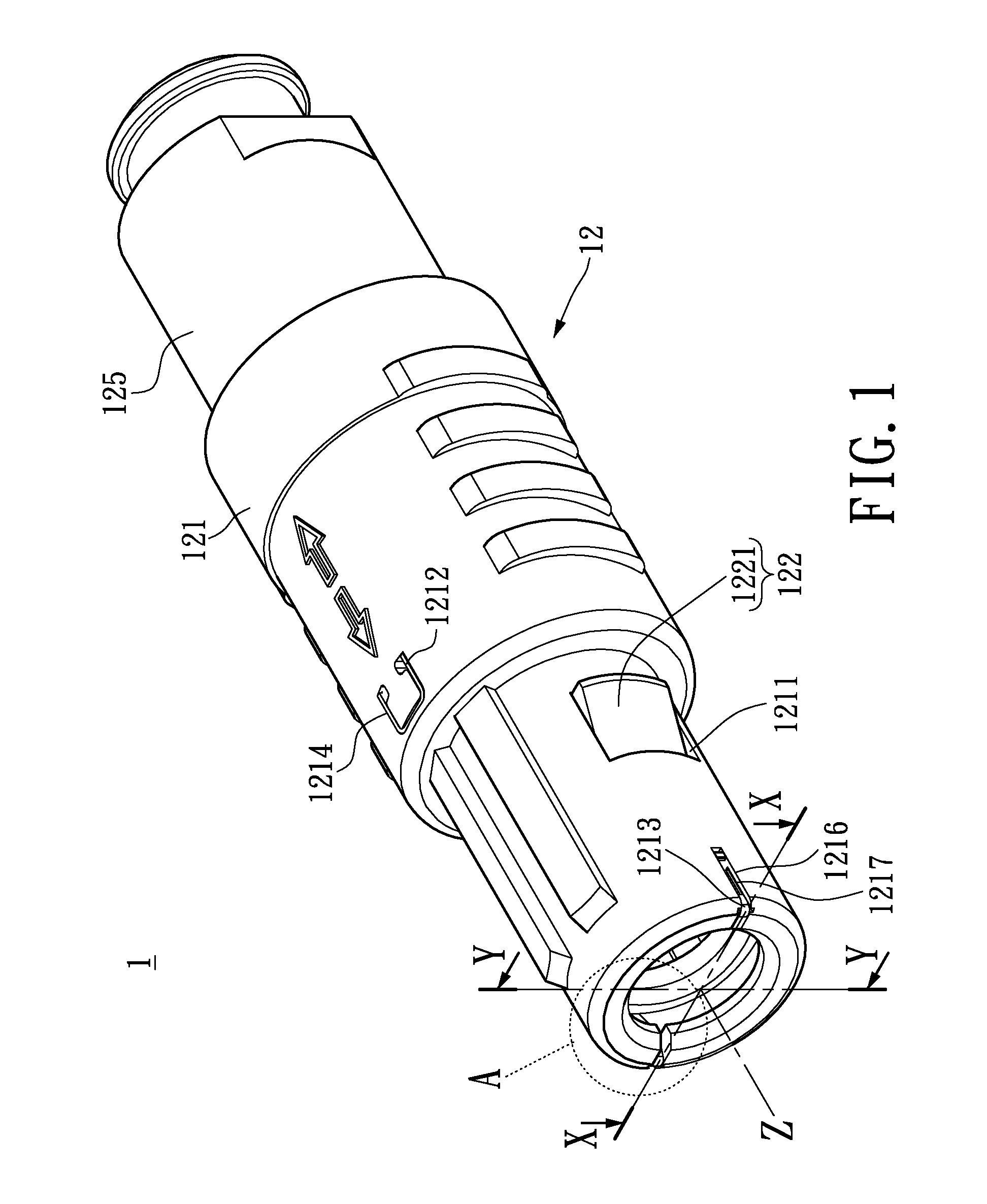

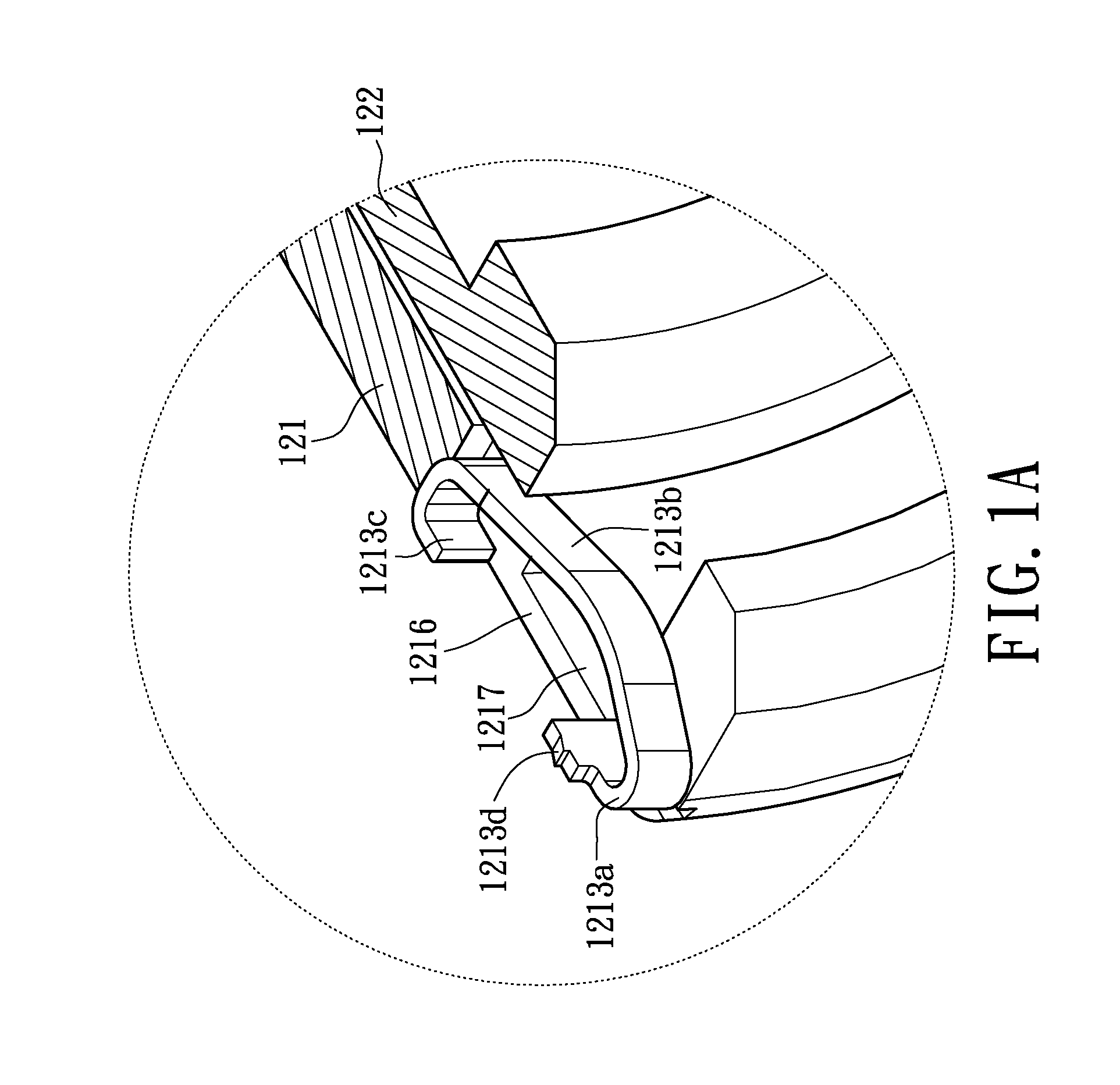

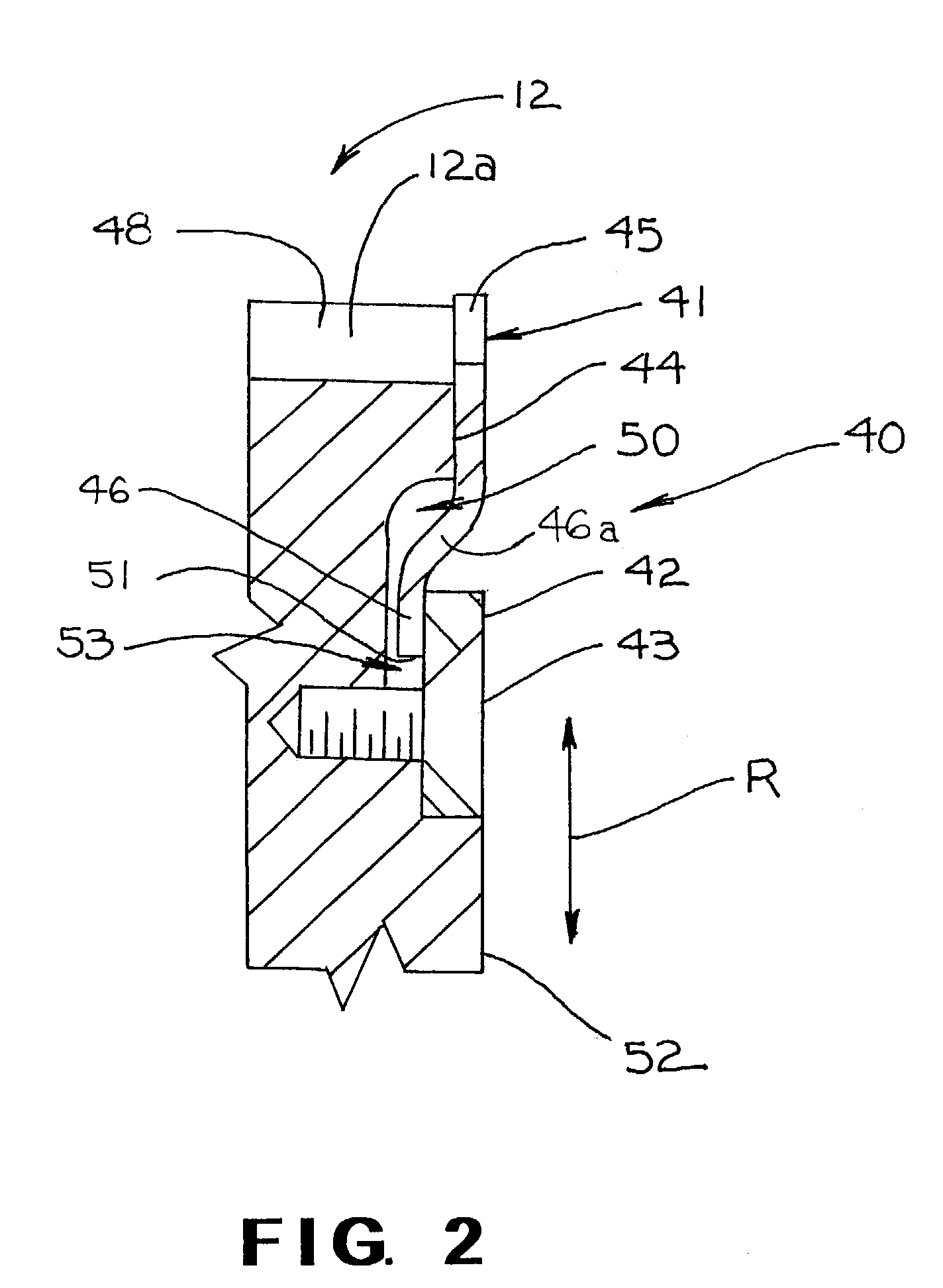

Environmentally protected and tamper resistant CATV drop connector

InactiveUS20050042919A1Avoid problemsLow costElectrically conductive connectionsCouplings bases/casesInterference fitEngineering

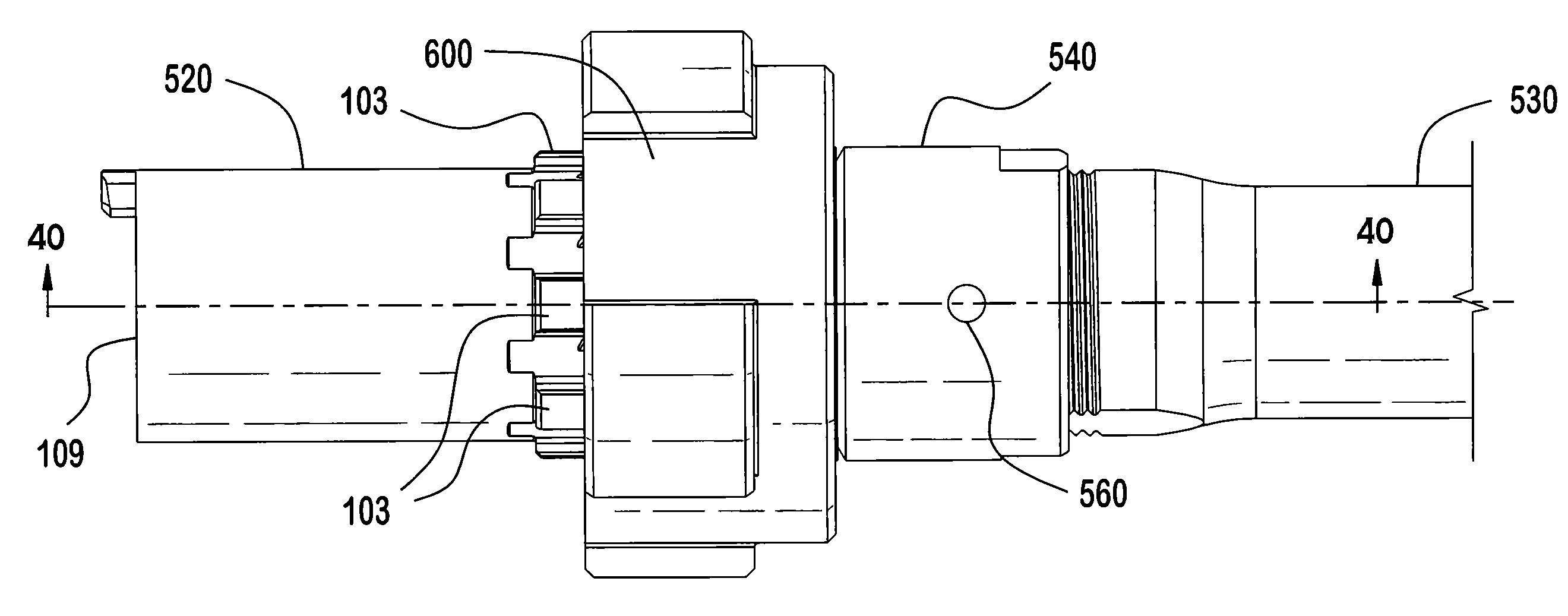

In addition to the single molded part incorporating features of the conventional nut, sealing member and body, the connector includes a post and a hollow compression sealing ring. The post includes an integrally formed stem and flange portions, with the compression ring axially movable upon the body and including a tapered surface which applies a radially inward force to the body, compressing the cable and providing tight frictional engagement of the connector and cable. When in its fully installed position, the axial length of the ring is sufficient to entirely enclose the unitary body and nut, preferably having an interference fit with the outer surface of the nut portion, thus locking and sealing the connector threads to the equipment port. The compression ring is preferably of metal to shield the internal plastic parts of the connector from UV rays.

Owner:PPC BROADBAND INC

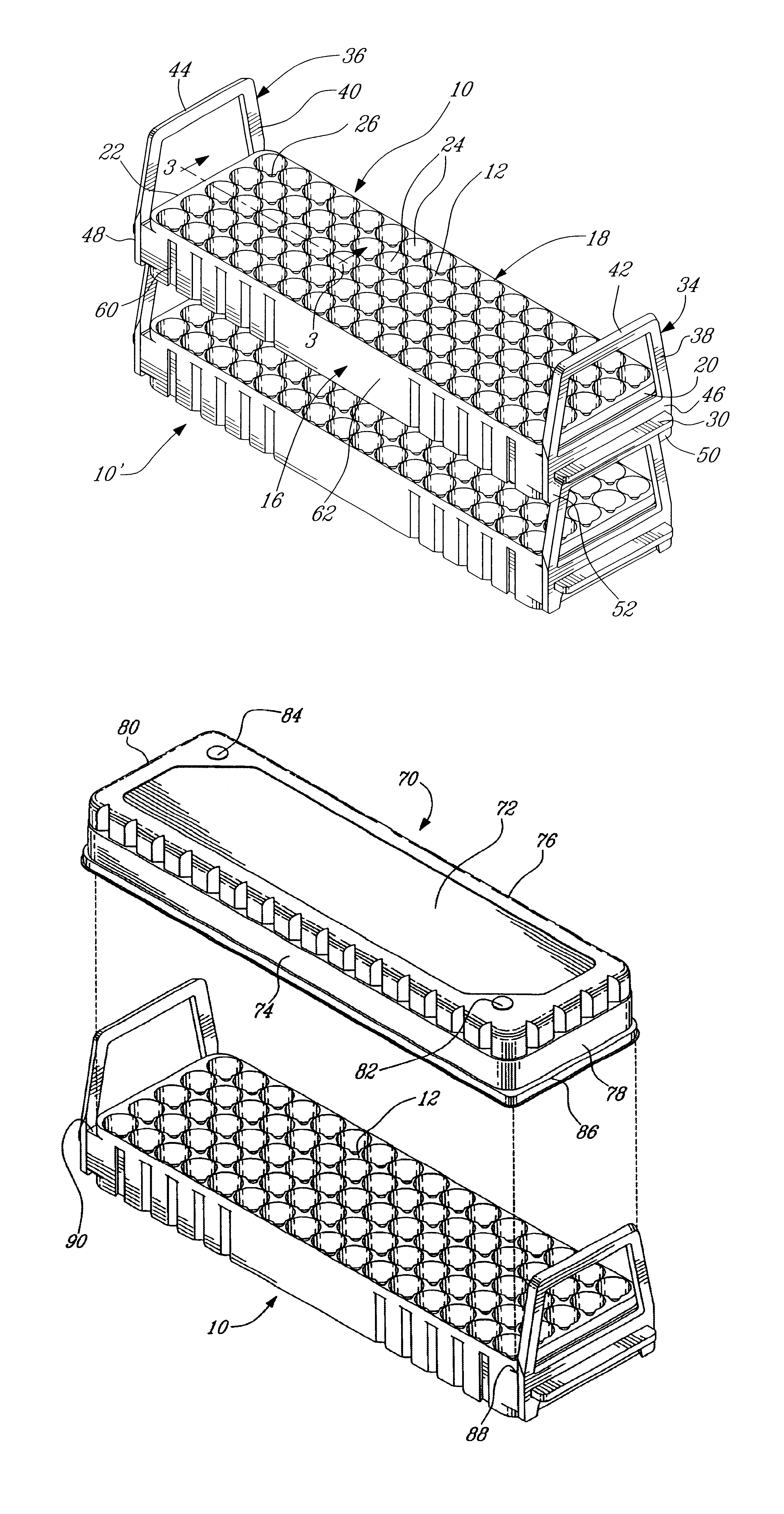

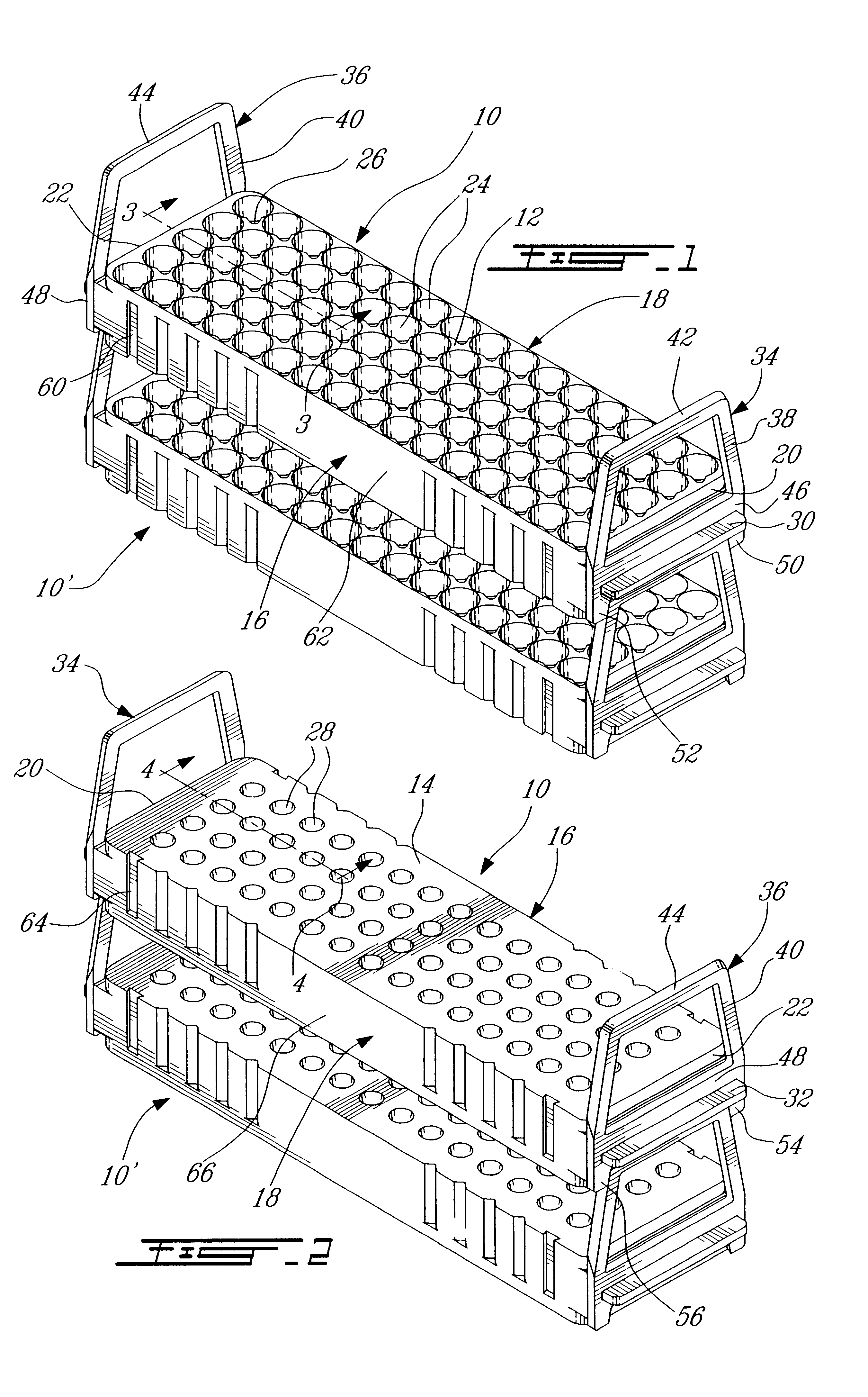

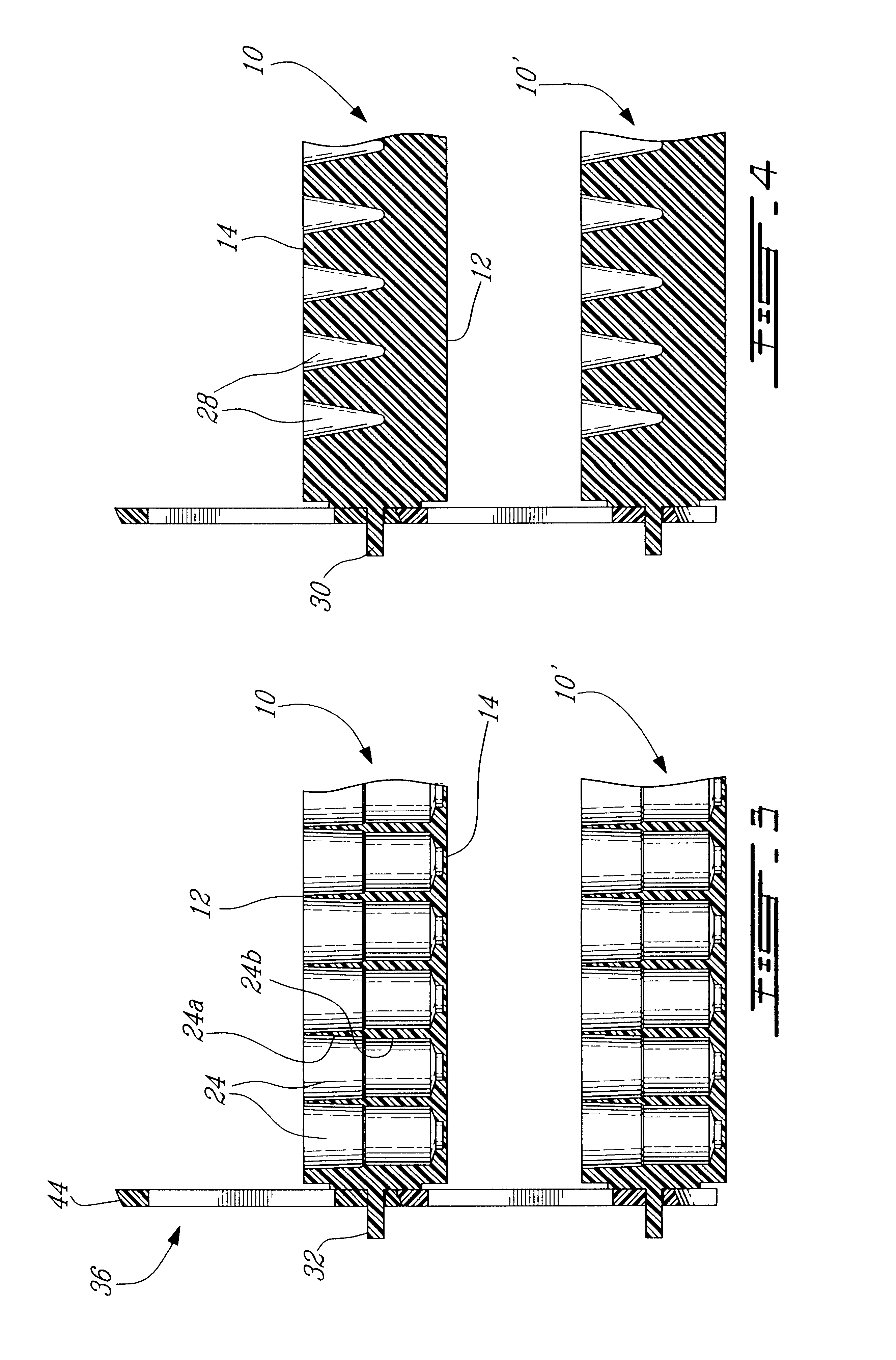

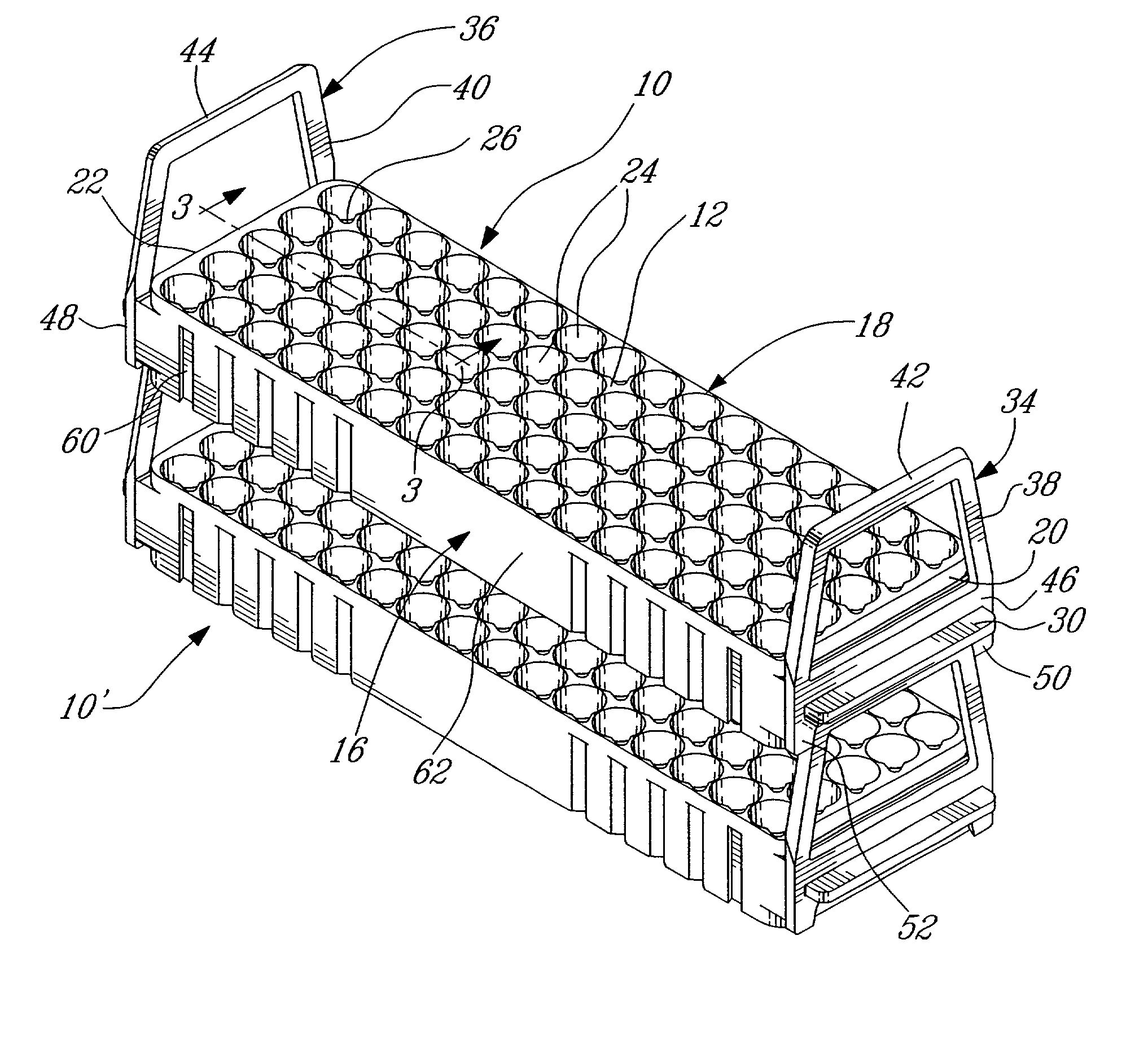

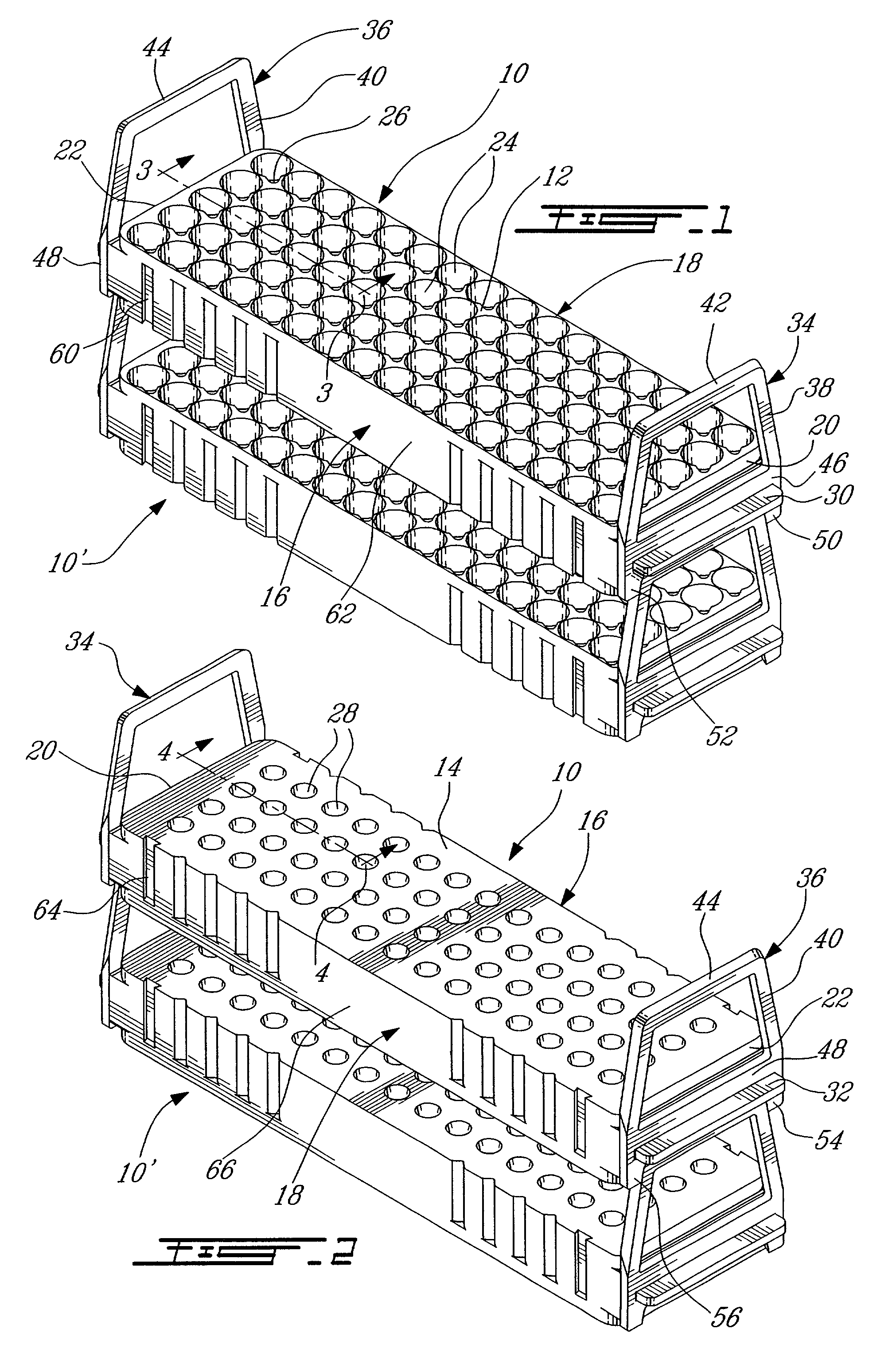

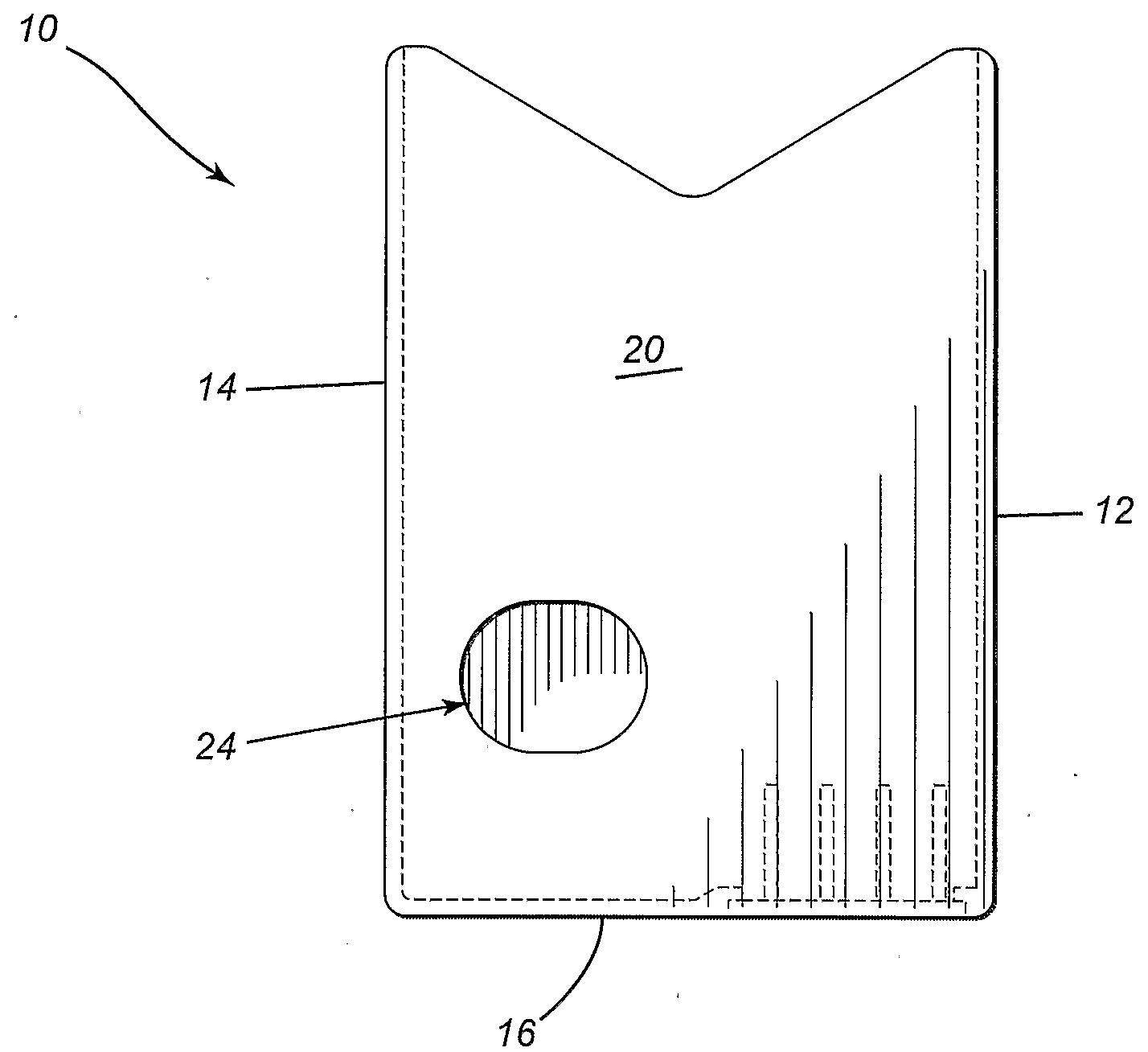

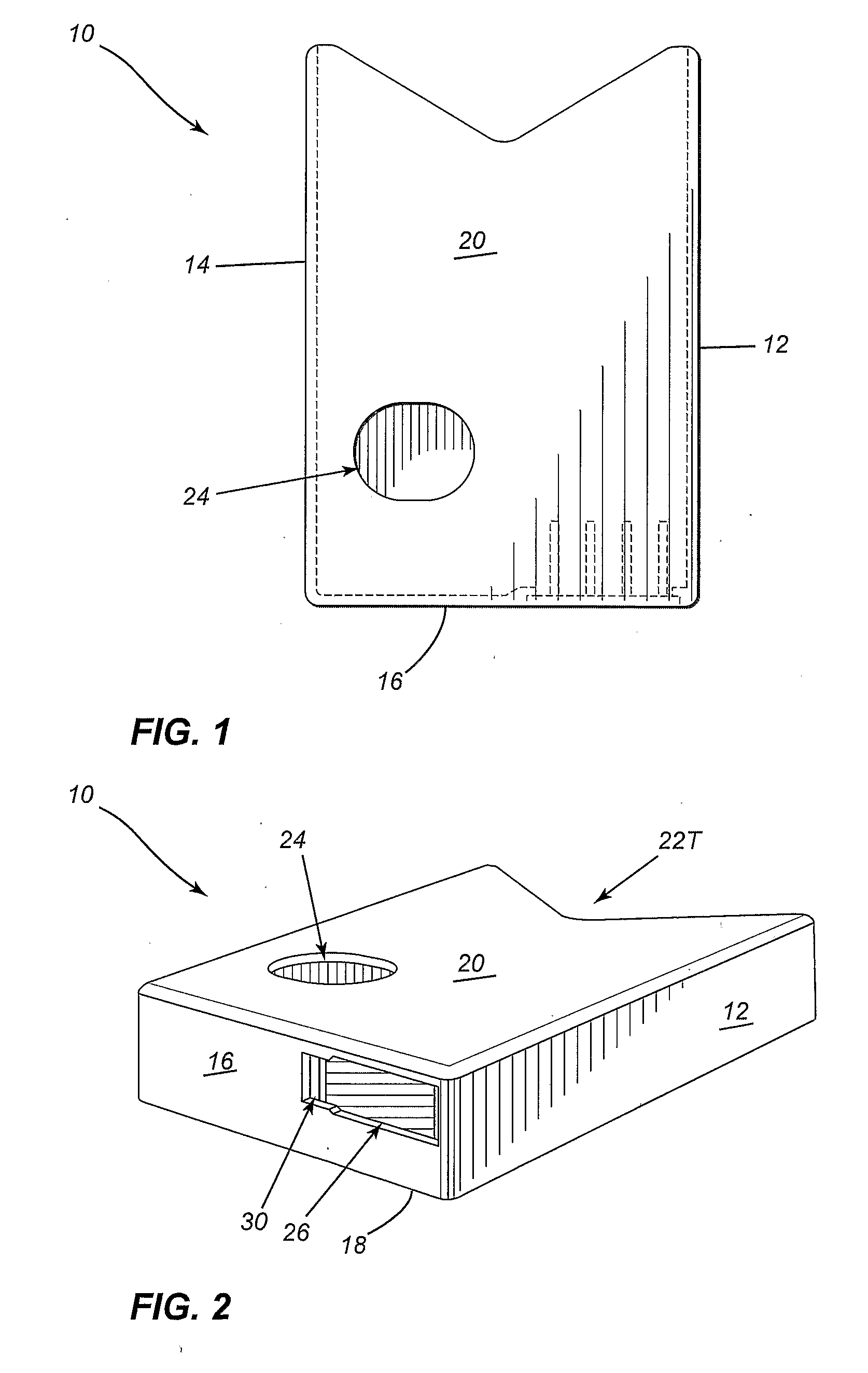

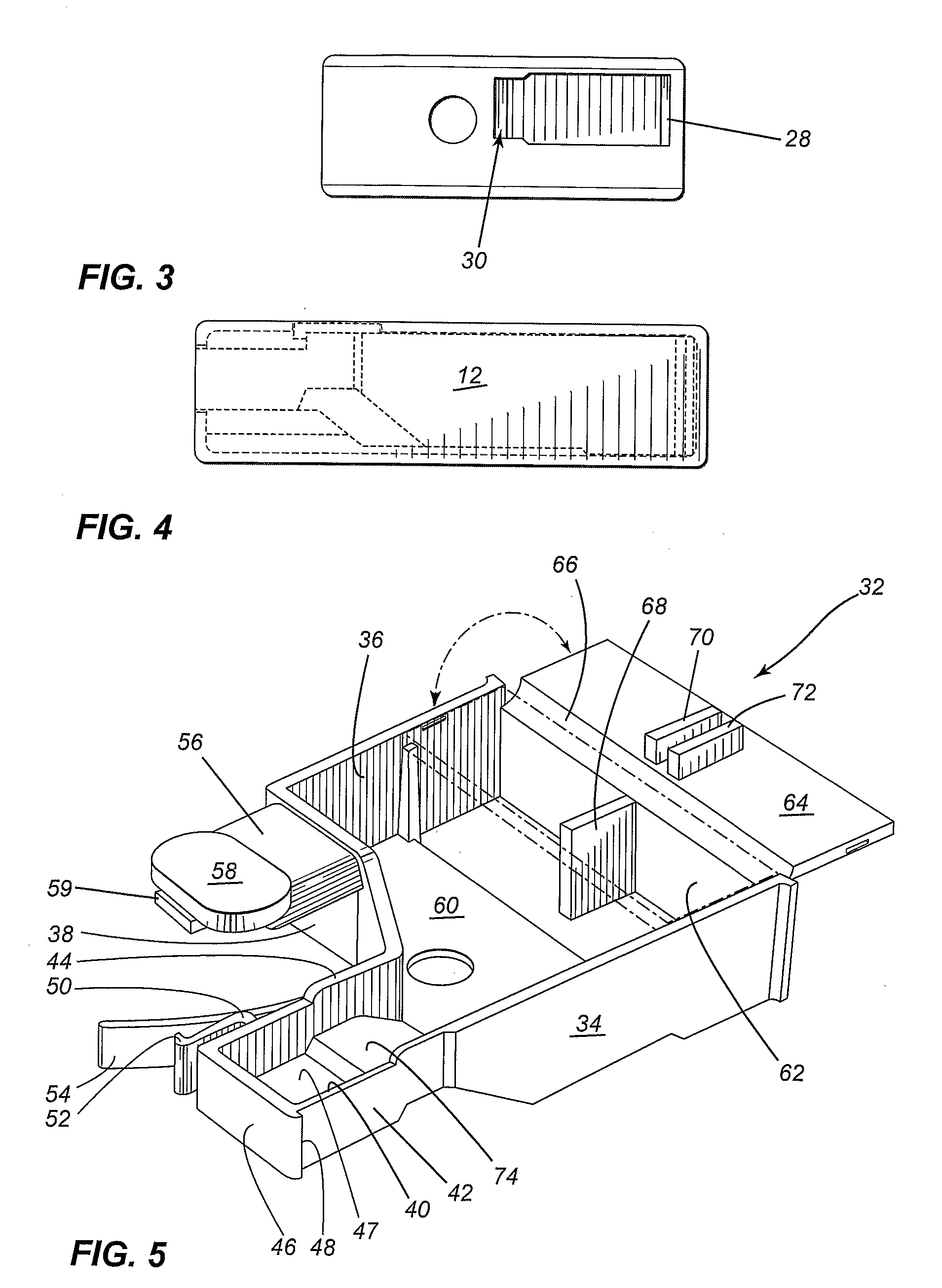

Modular test tube rack

A modular test tube rack for assembly with similarly constructed racks comprise a flat rectangular body displaying, in a first position, a series of wells extending from its top wall to its bottom wall and adapt to receive tubes therein. A pair of handles vertically extend at opposite end walls of the body, each handle having a lower portion adapted to tightly engage an extension on each end wall and a hand gripping upper portion. The lower portion has a bottom edge configured to anchor with the top edge of the handle of an underposed similarly constructed rack to thereby enable a stacking of two more of these racks. In one embodiment, the body displays a second series of wells extending from the bottom wall to the top wall whereby the body, when in a second position reversed relative to the first position, may also receive test tubes, the handles being reversably mountable to the end wall extension to still enable a stacking of racks in the second position.

Owner:3088081 CANADA

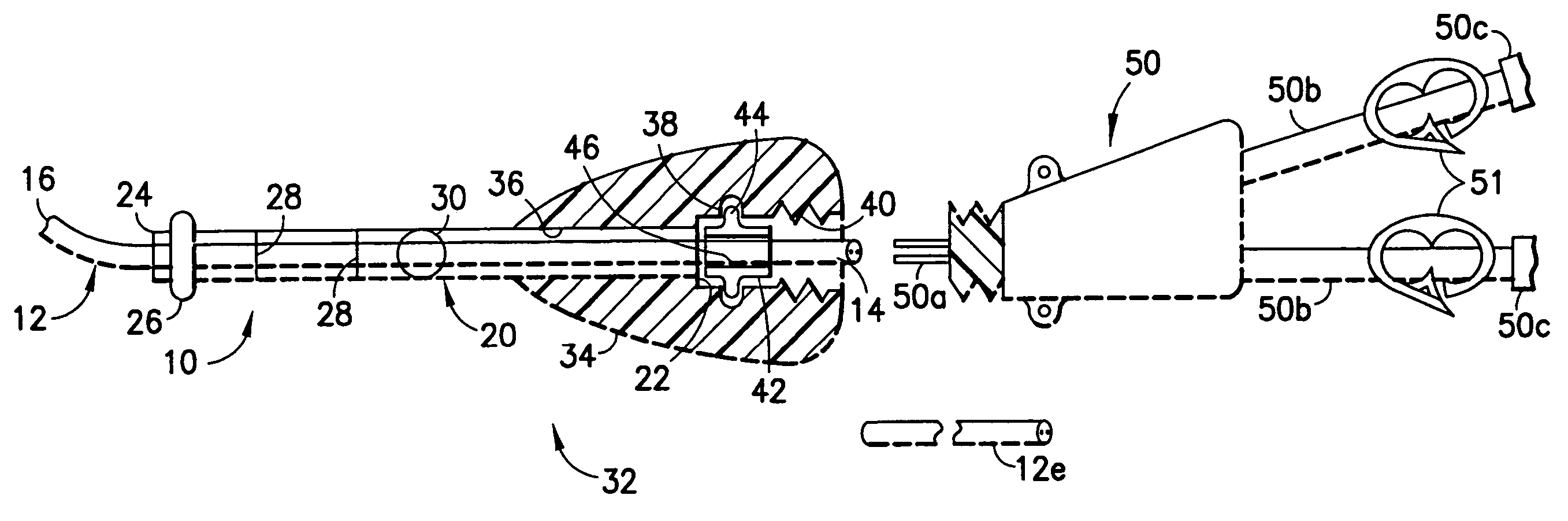

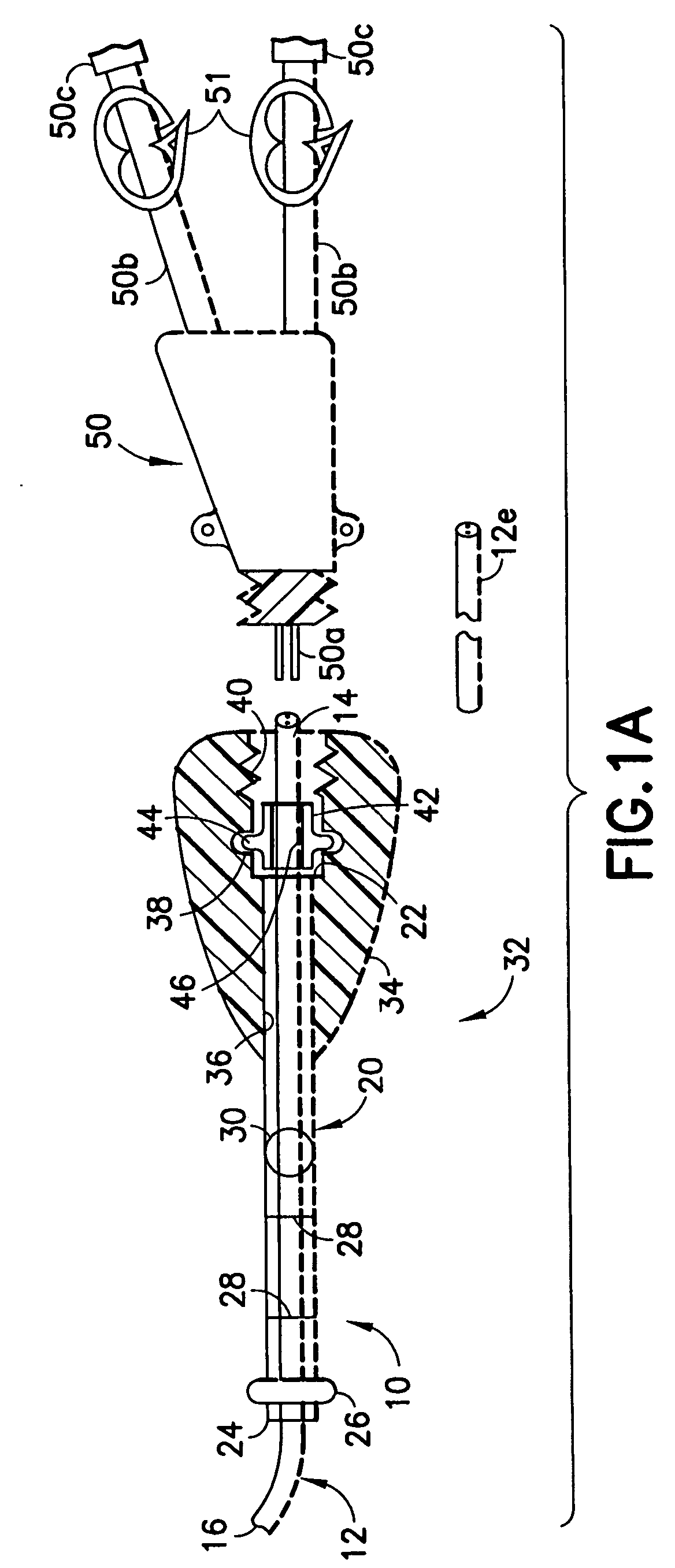

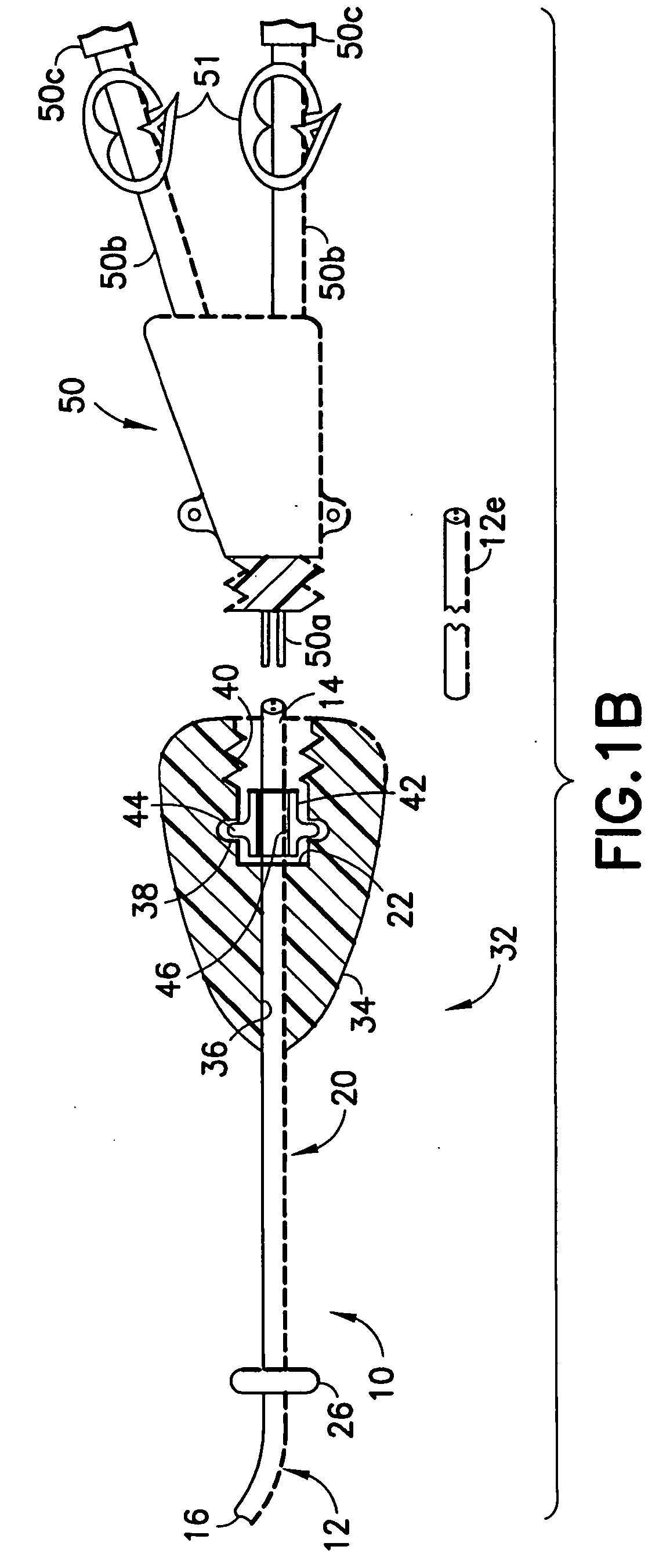

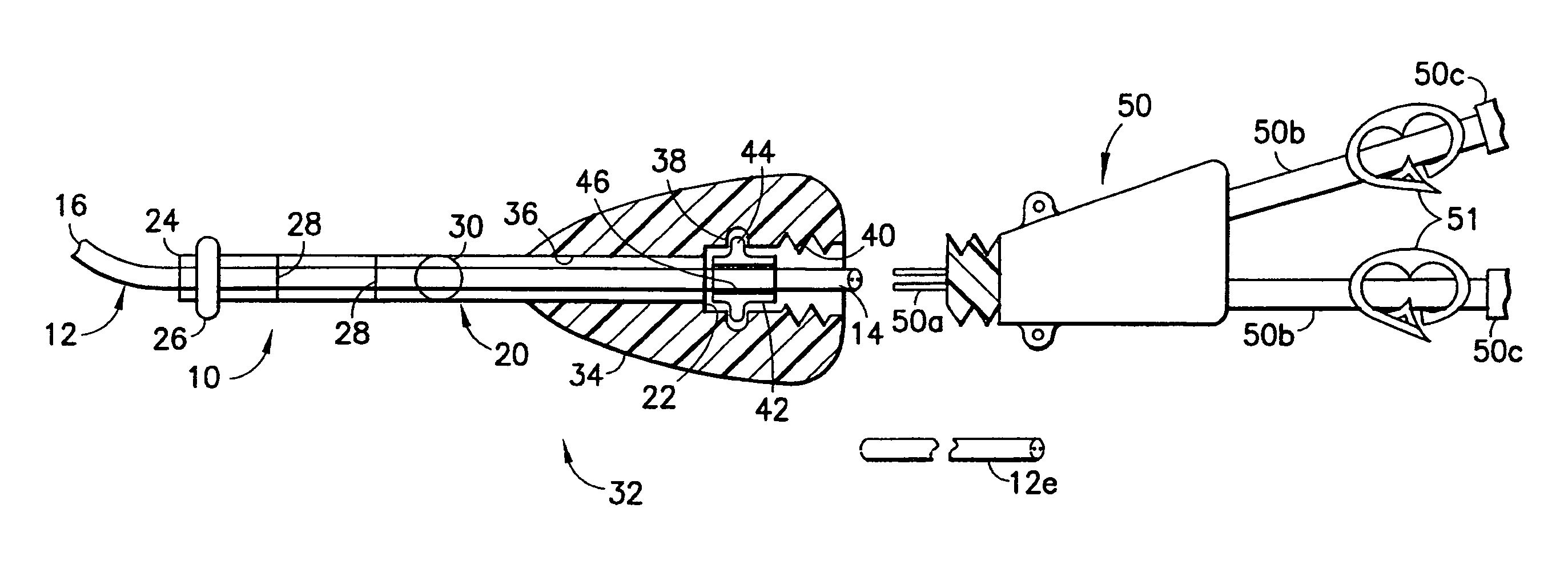

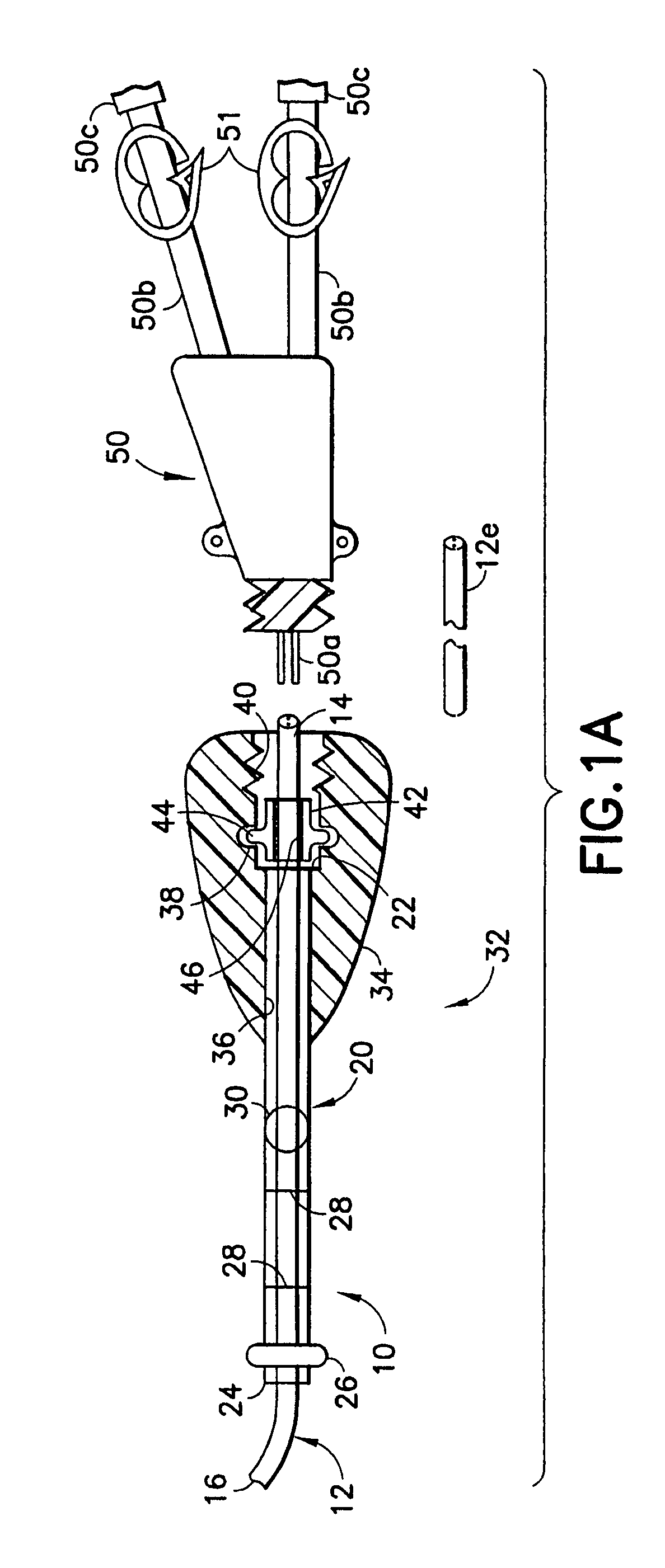

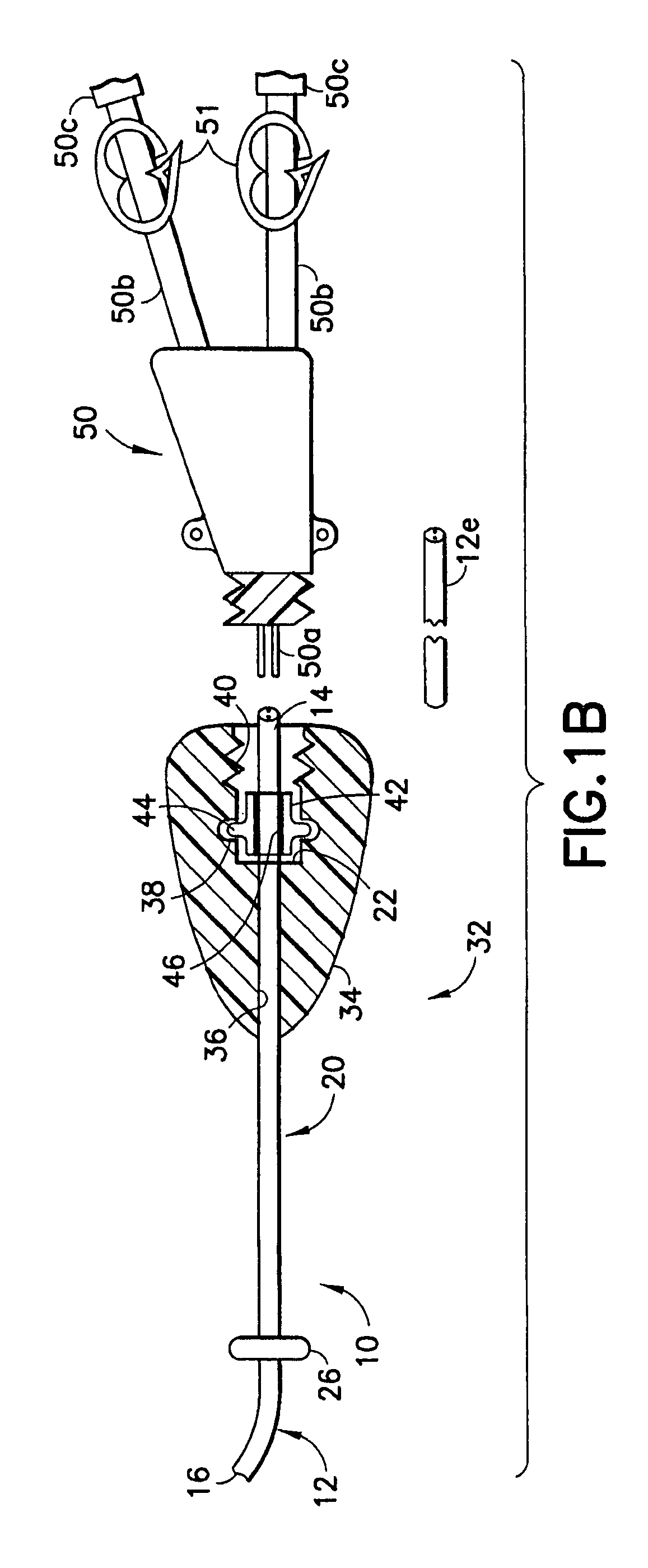

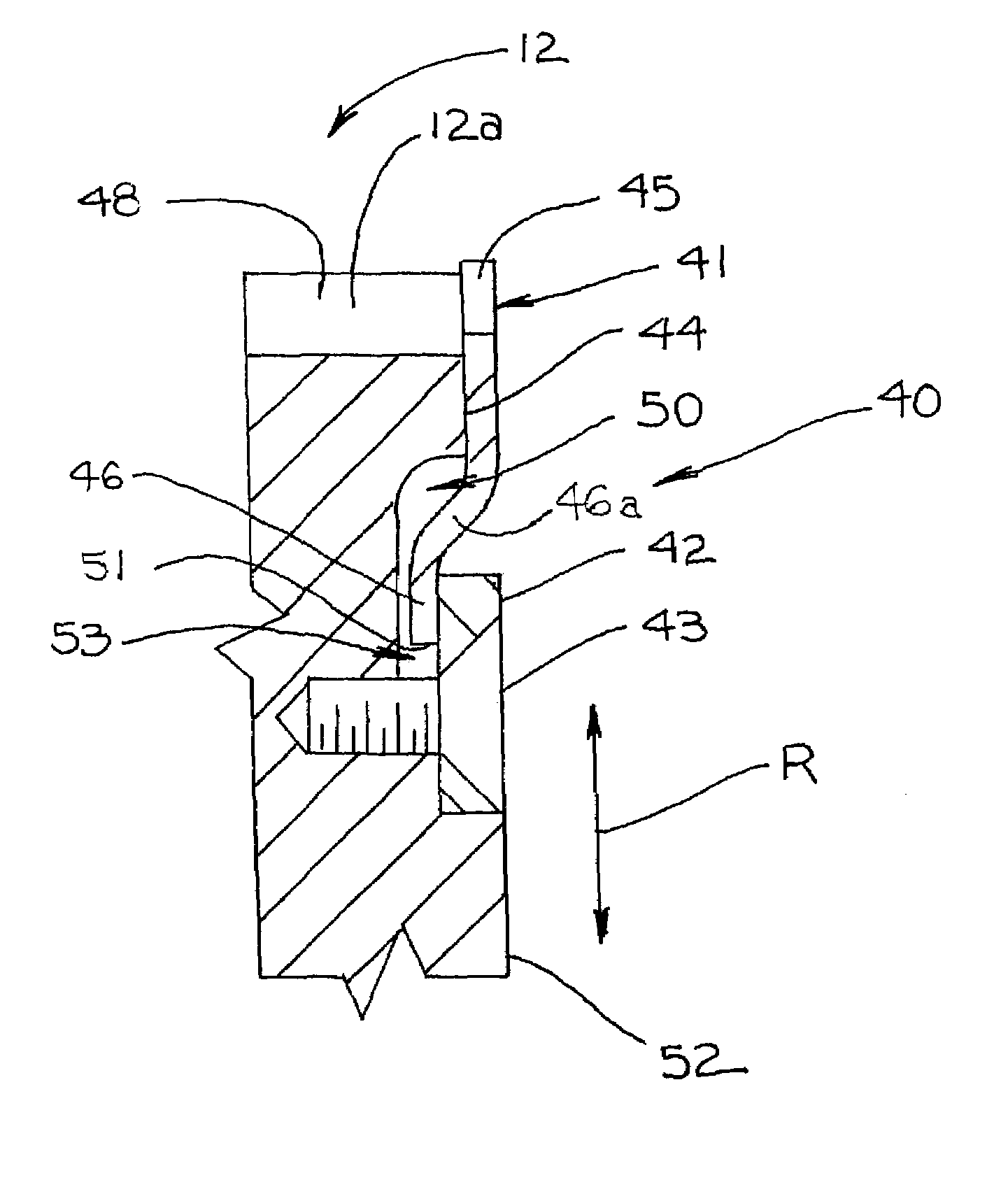

Dialysis catheter

InactiveUS20060129134A1Easy accessAvoid bleedingMulti-lumen catheterExcision instrumentsCatheters dialysisCuff

A catheter assembly includes catheter having proximal and distal ends and at least one lumen extending between the ends. At least one end of the catheter is formed from a material that can be trimmed to achieve a selected length for the catheter. A tubular connector is telescoped over the catheter and a hub is joined to the tubular connector. Proximal portions of the hub are configured for connection to a medical apparatus. A cuff is mounted around the tubular connector or the catheter. The cuff is formed from a material that will permit or promote the growth of scar tissue for anchoring the catheter device at least on a semi-permanent basis in a patient.

Owner:KERR ANDREW

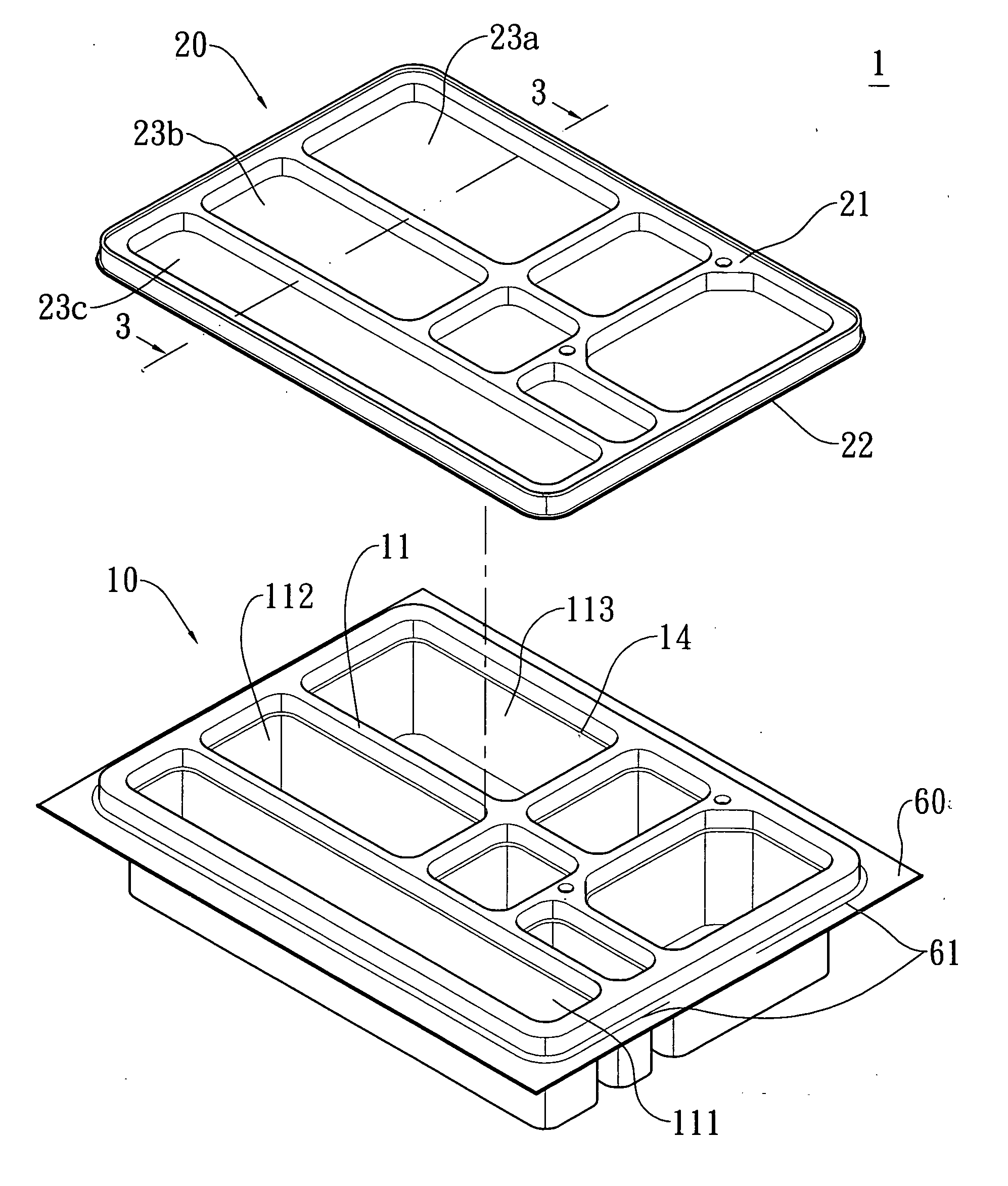

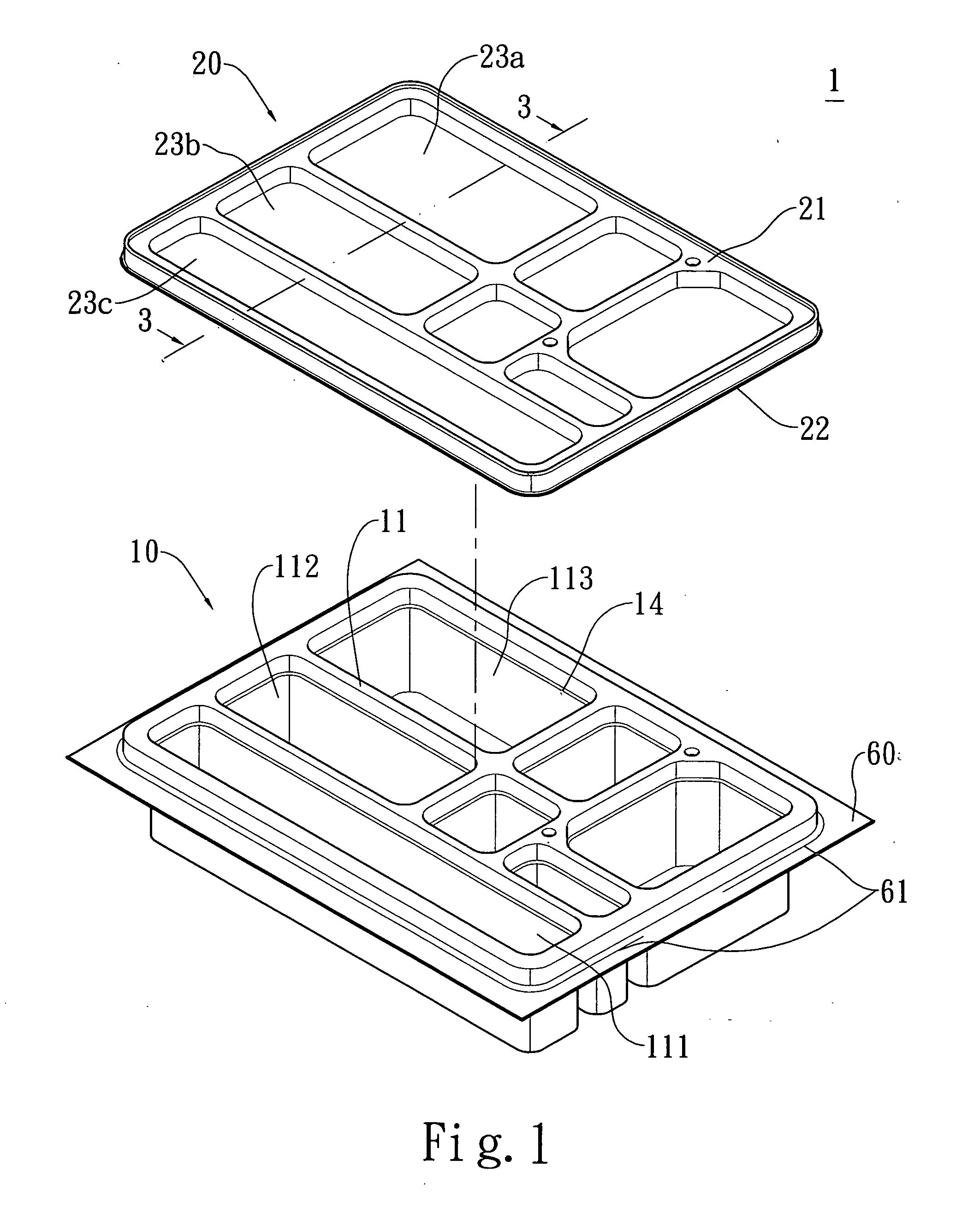

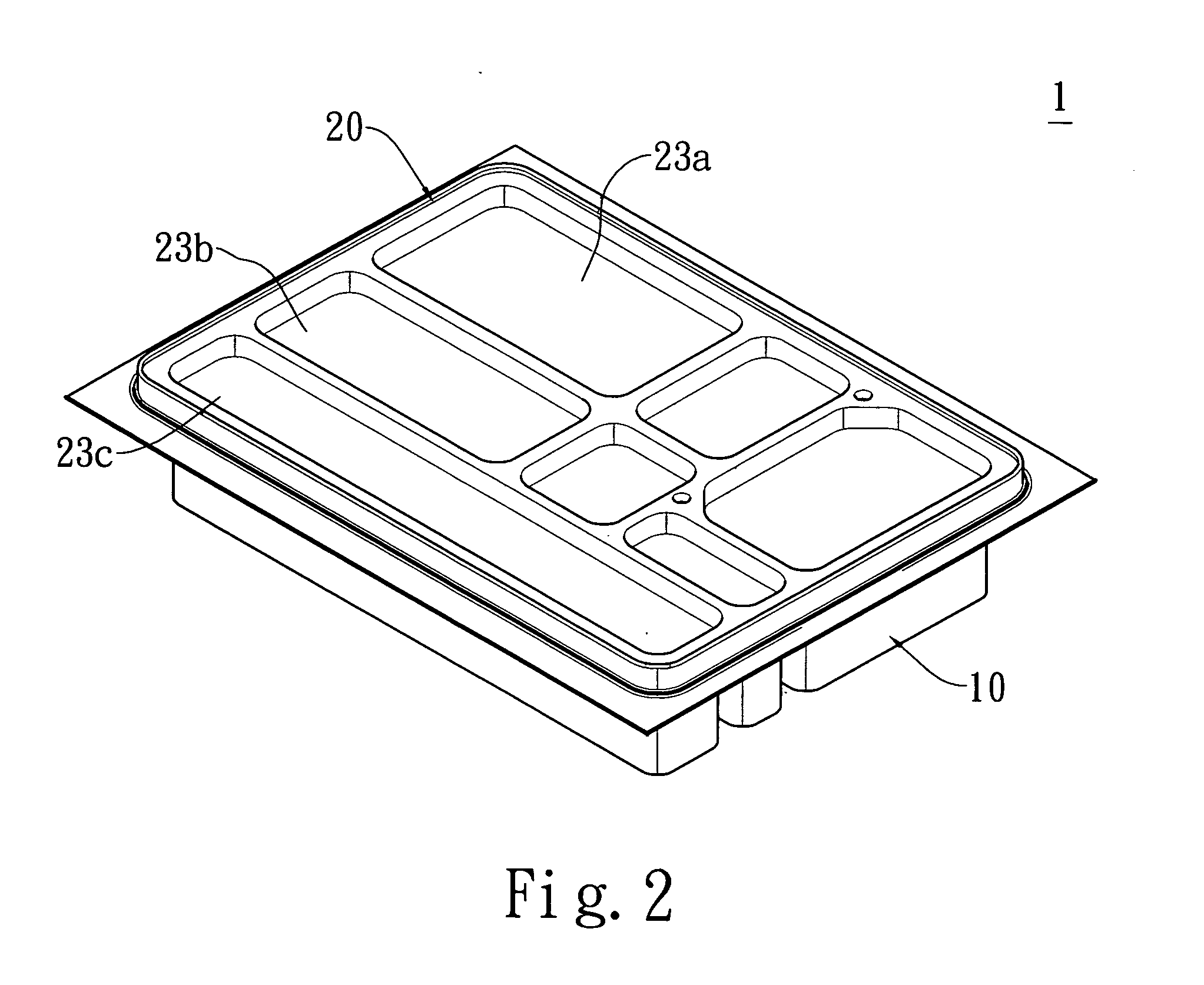

Lunch box

Owner:LIU WEN TAO

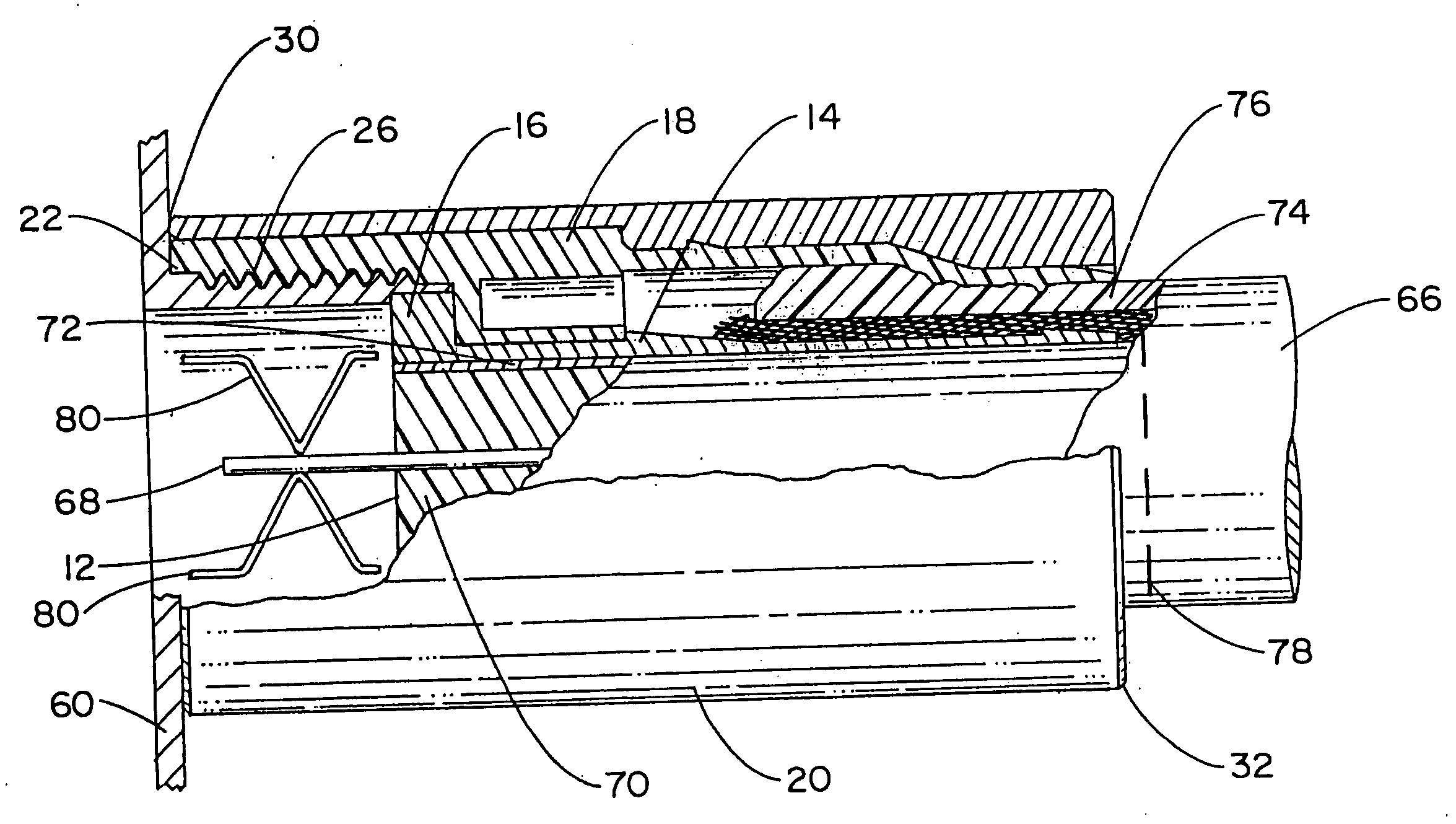

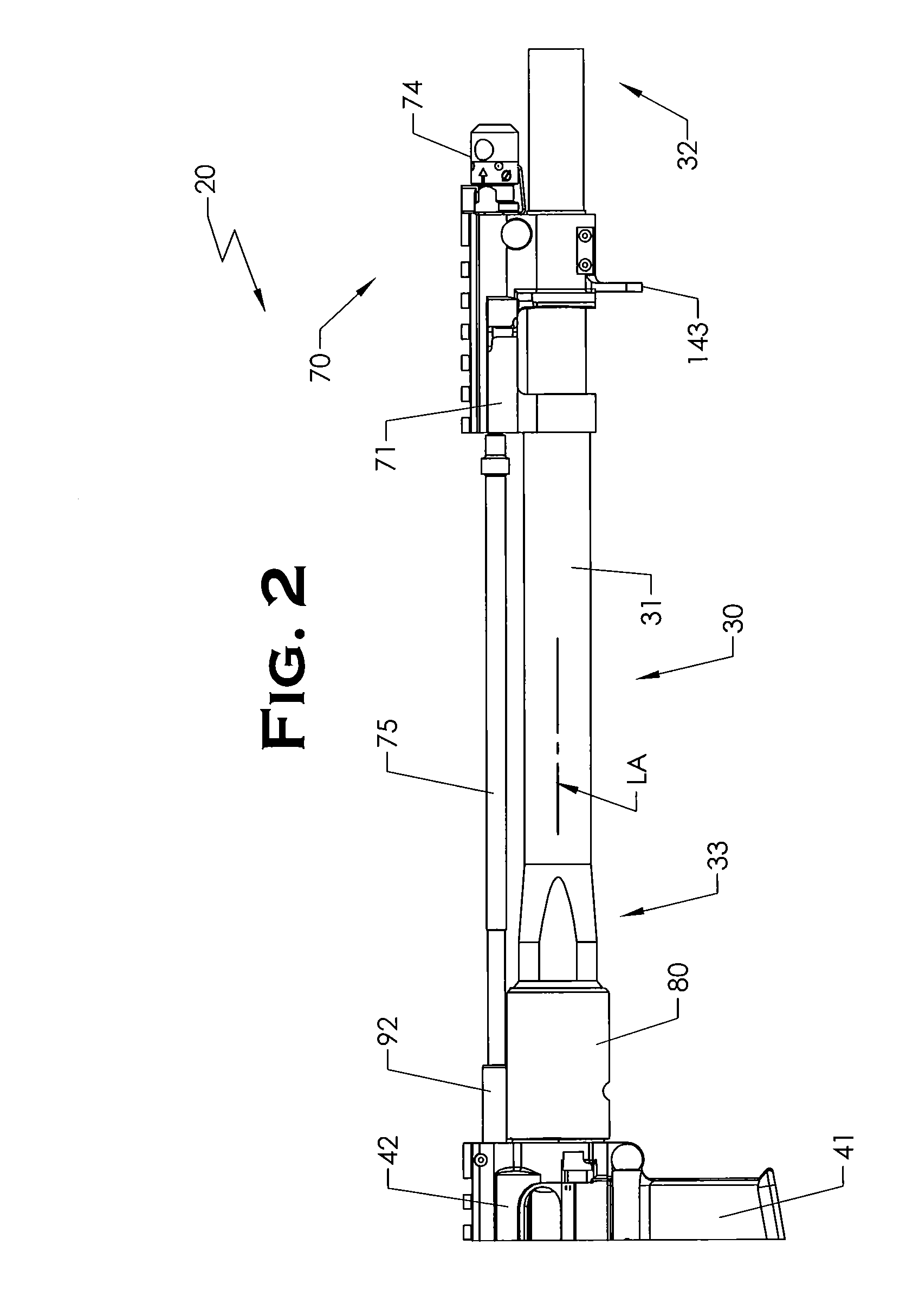

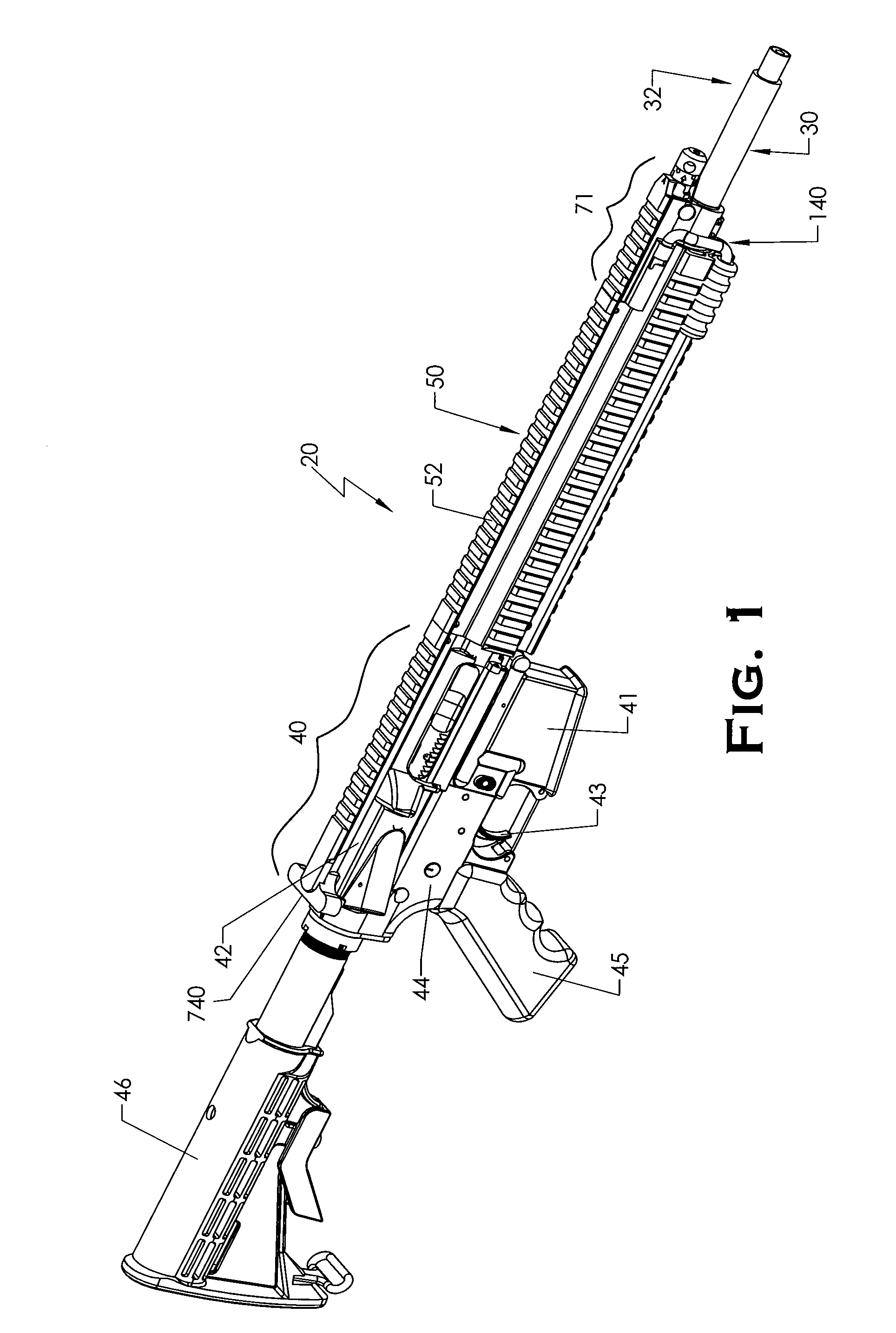

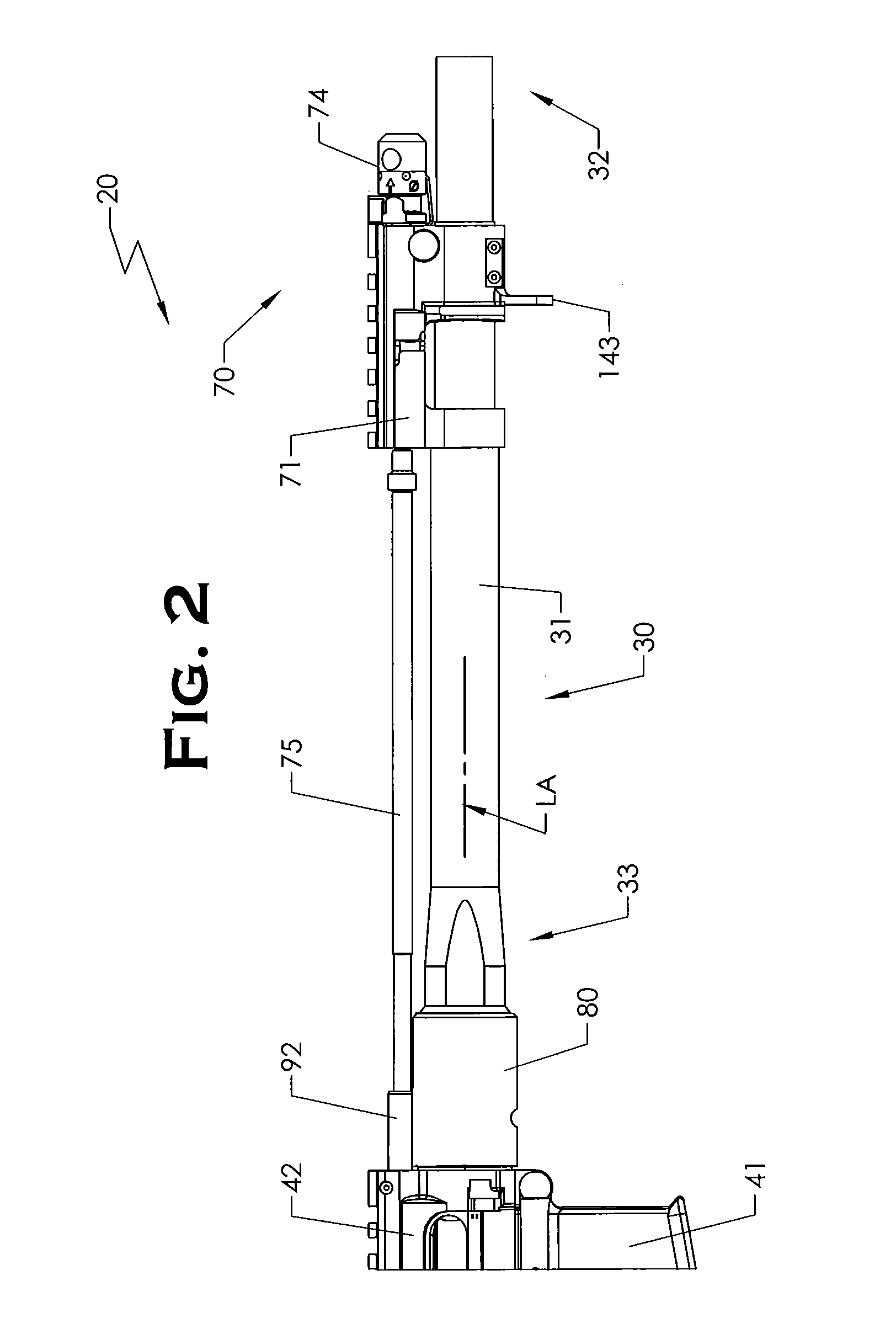

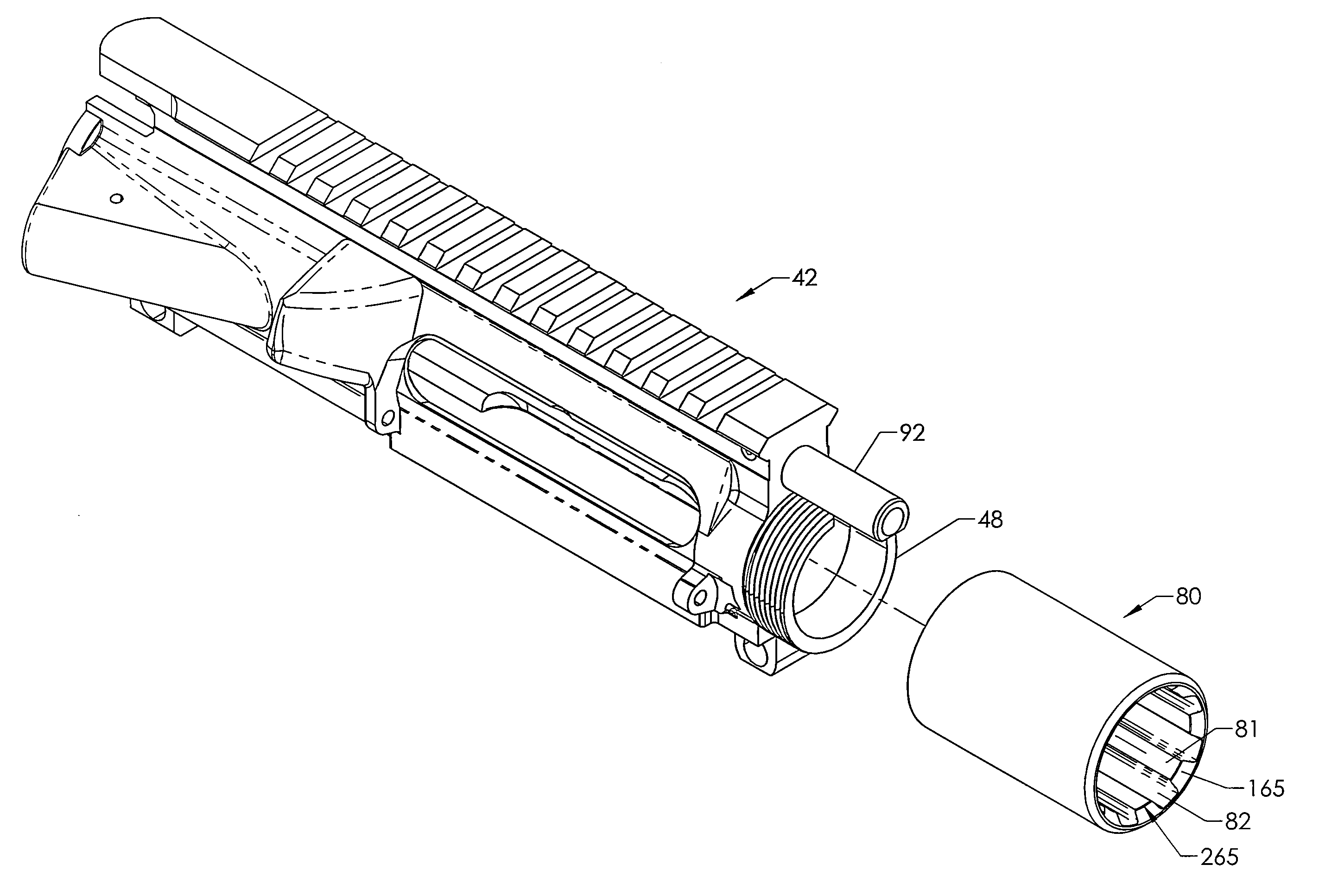

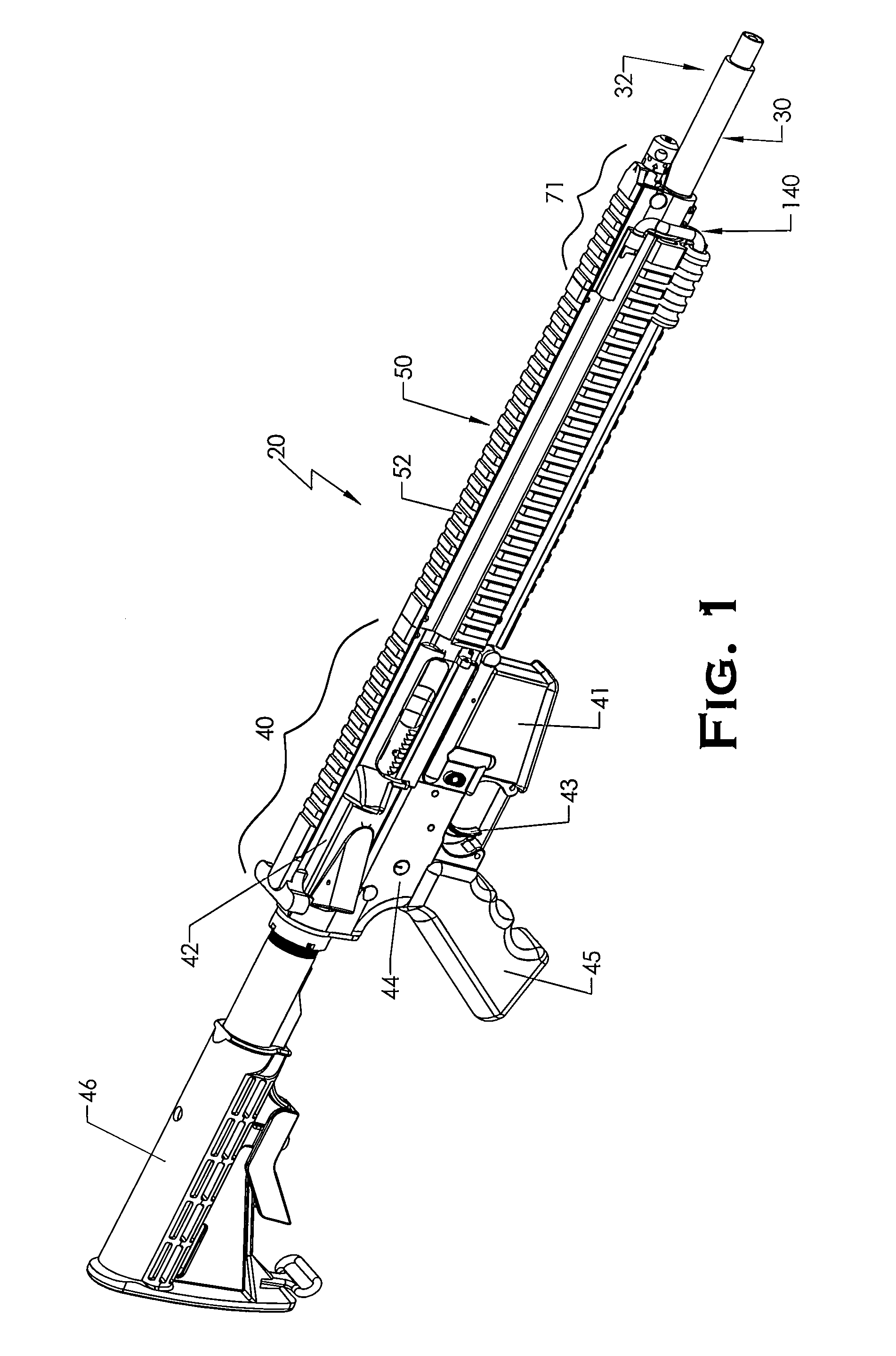

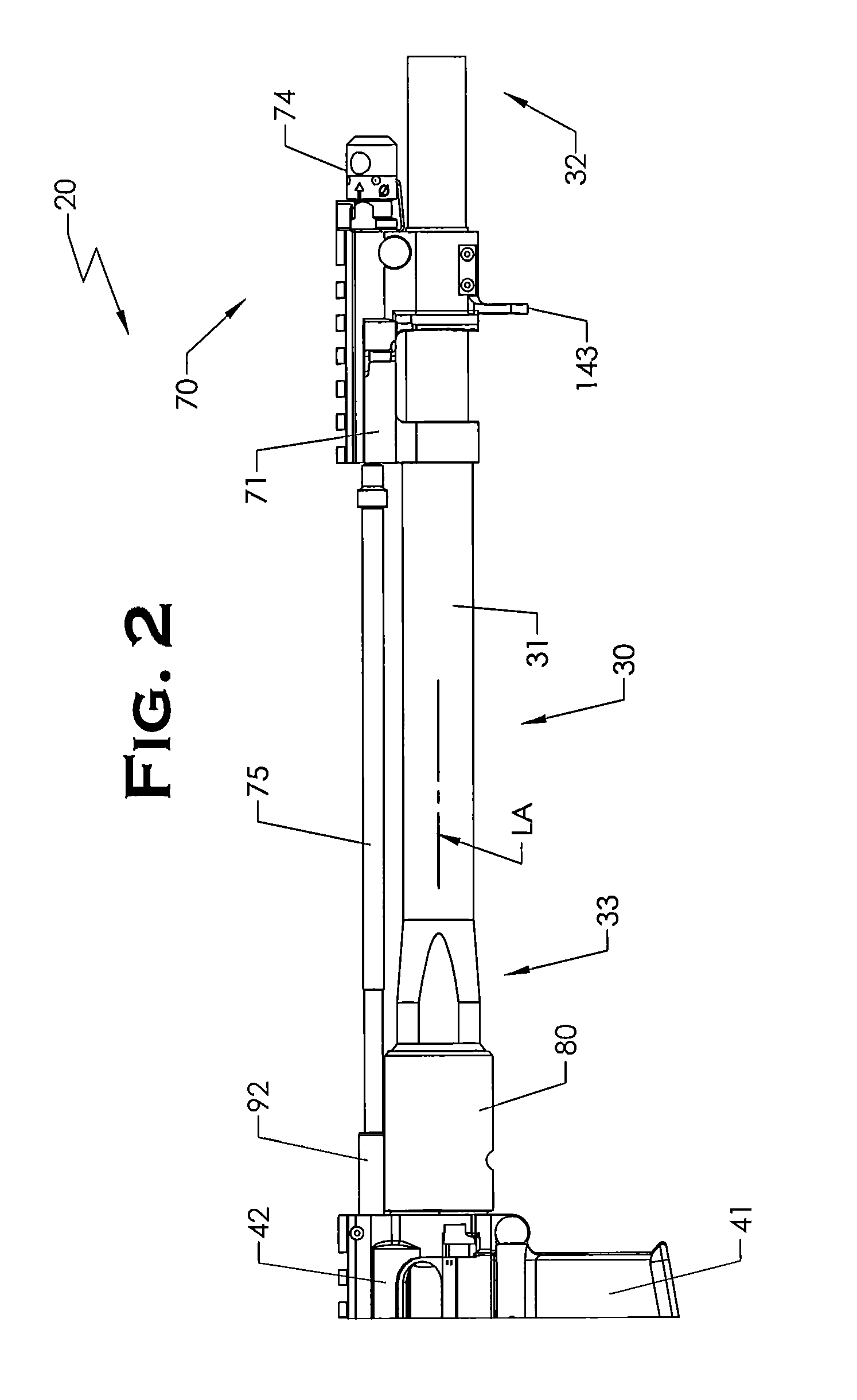

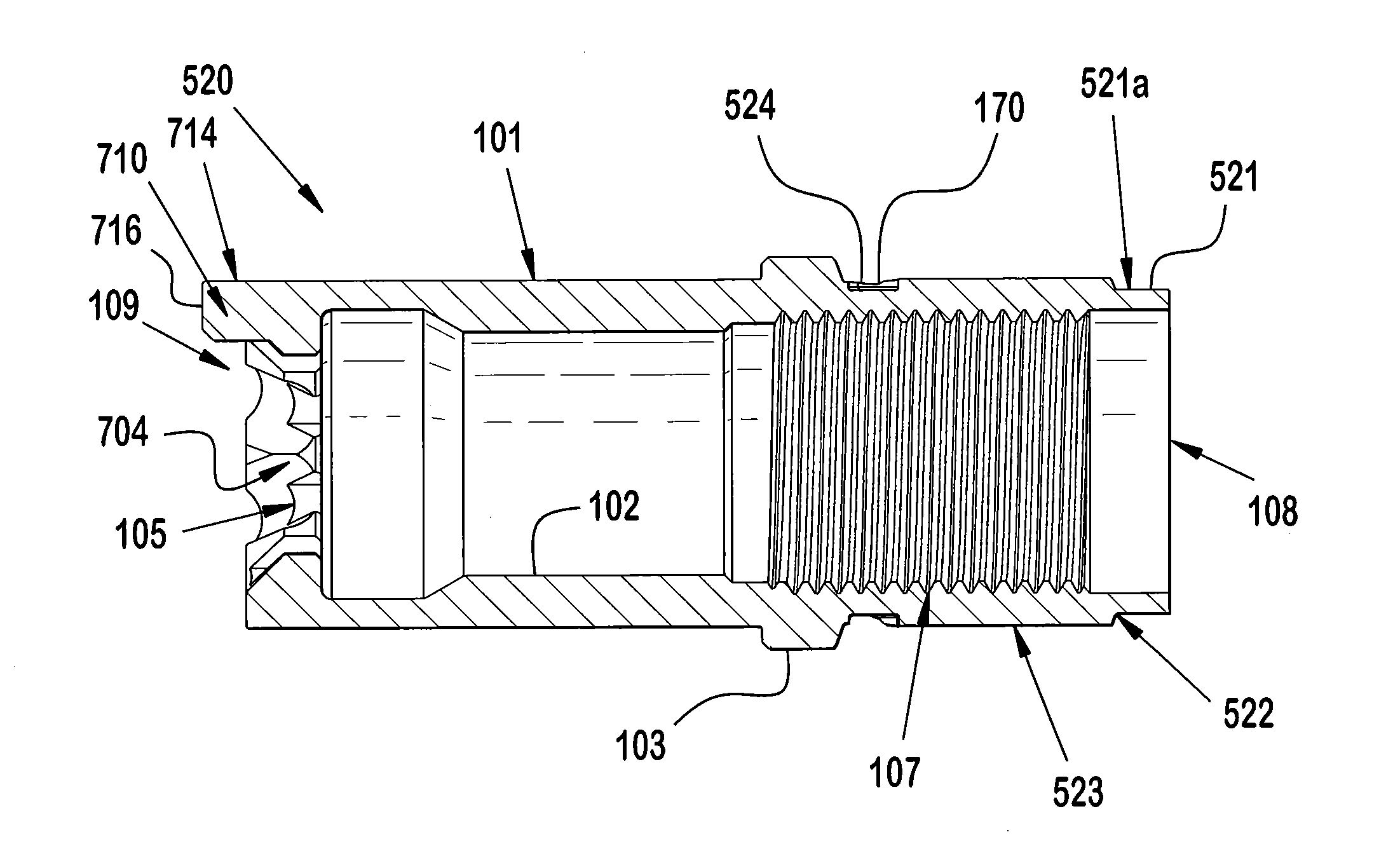

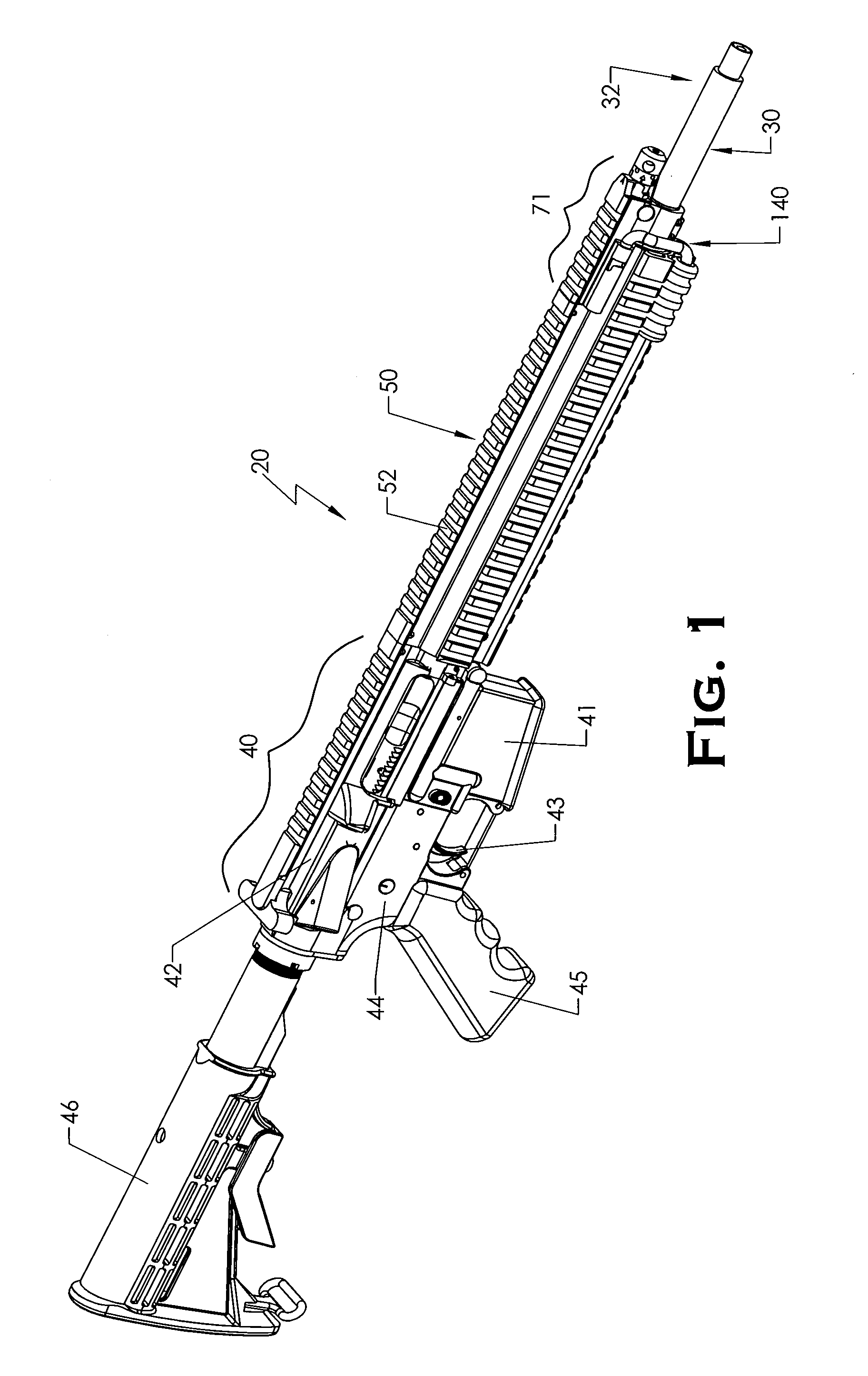

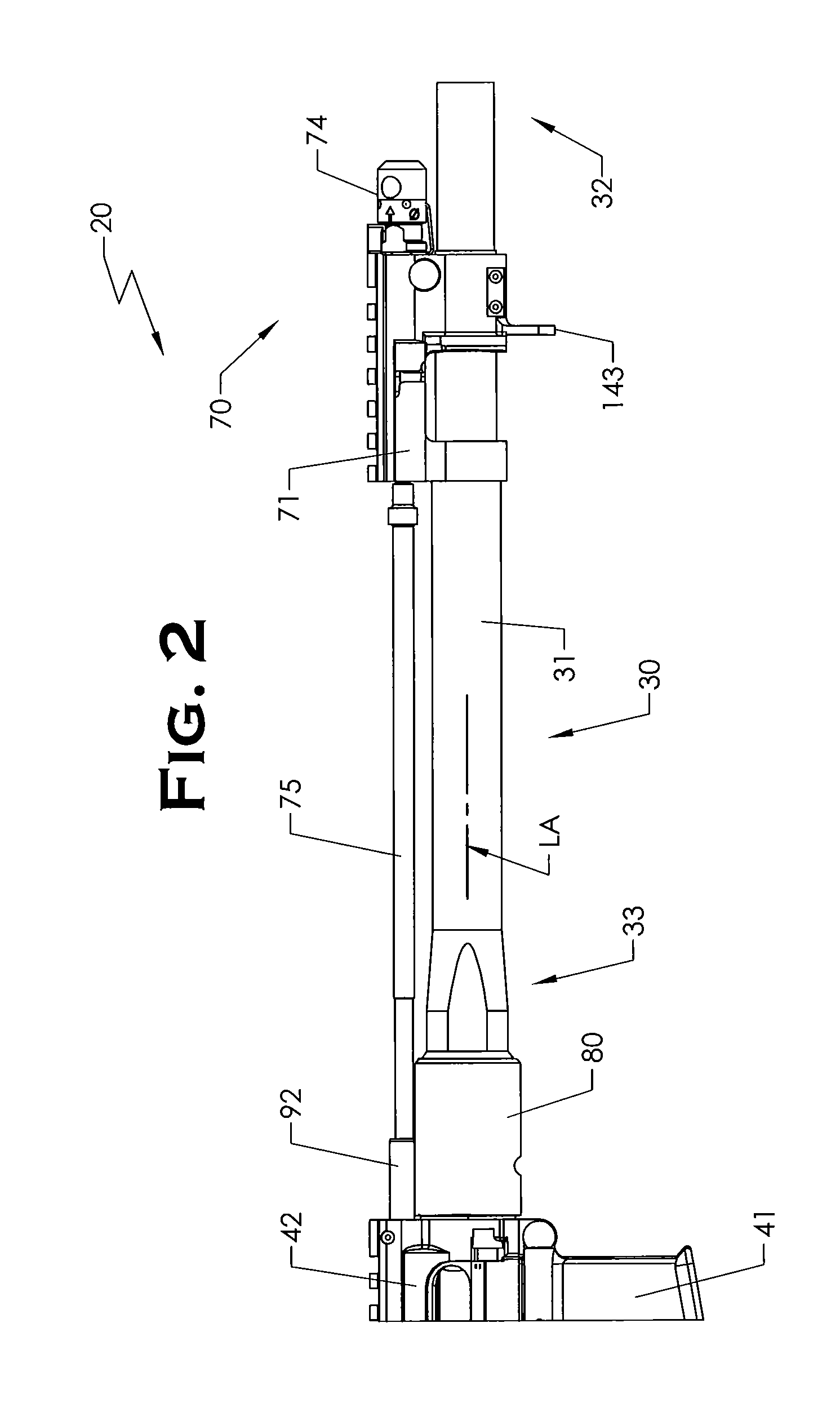

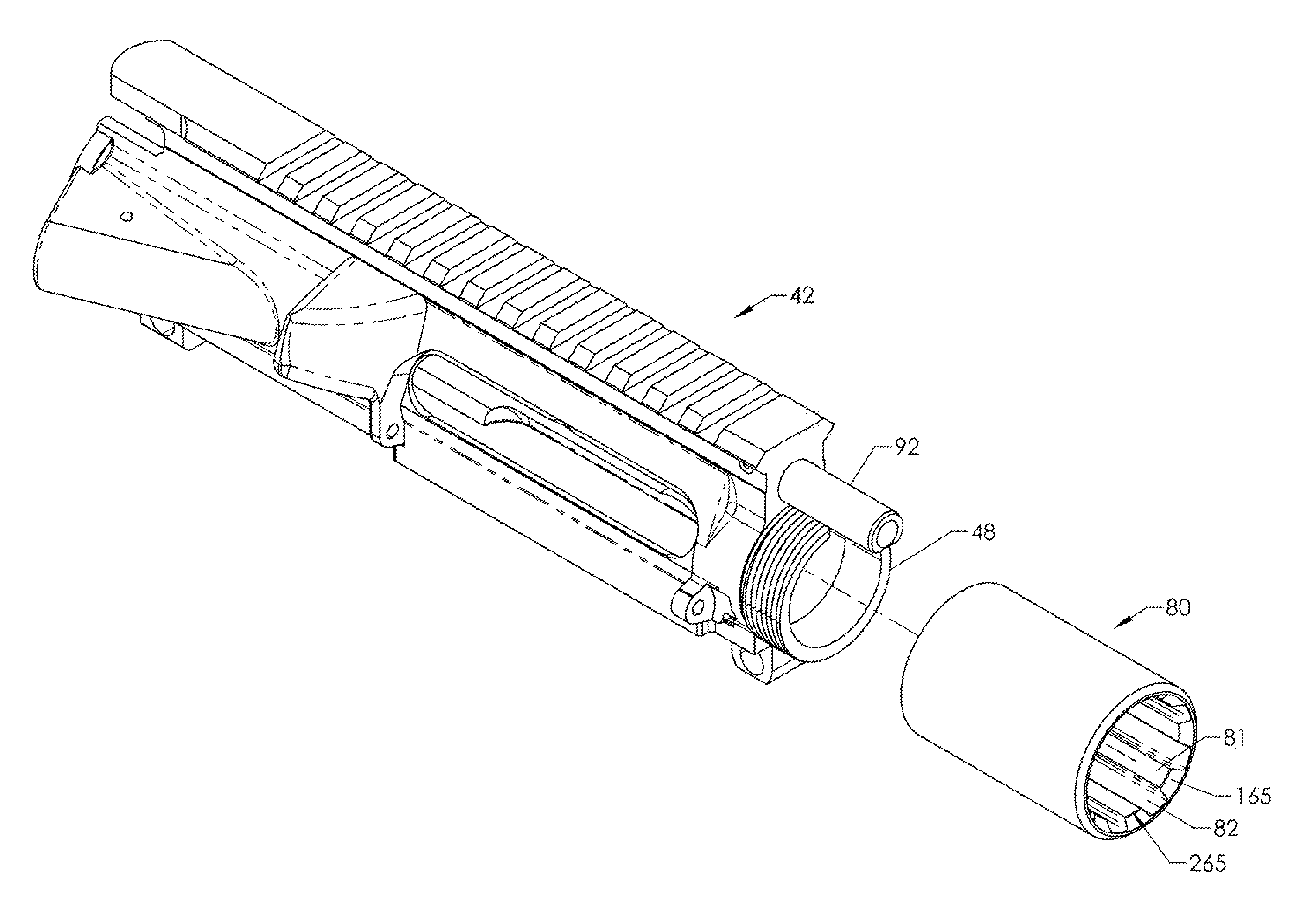

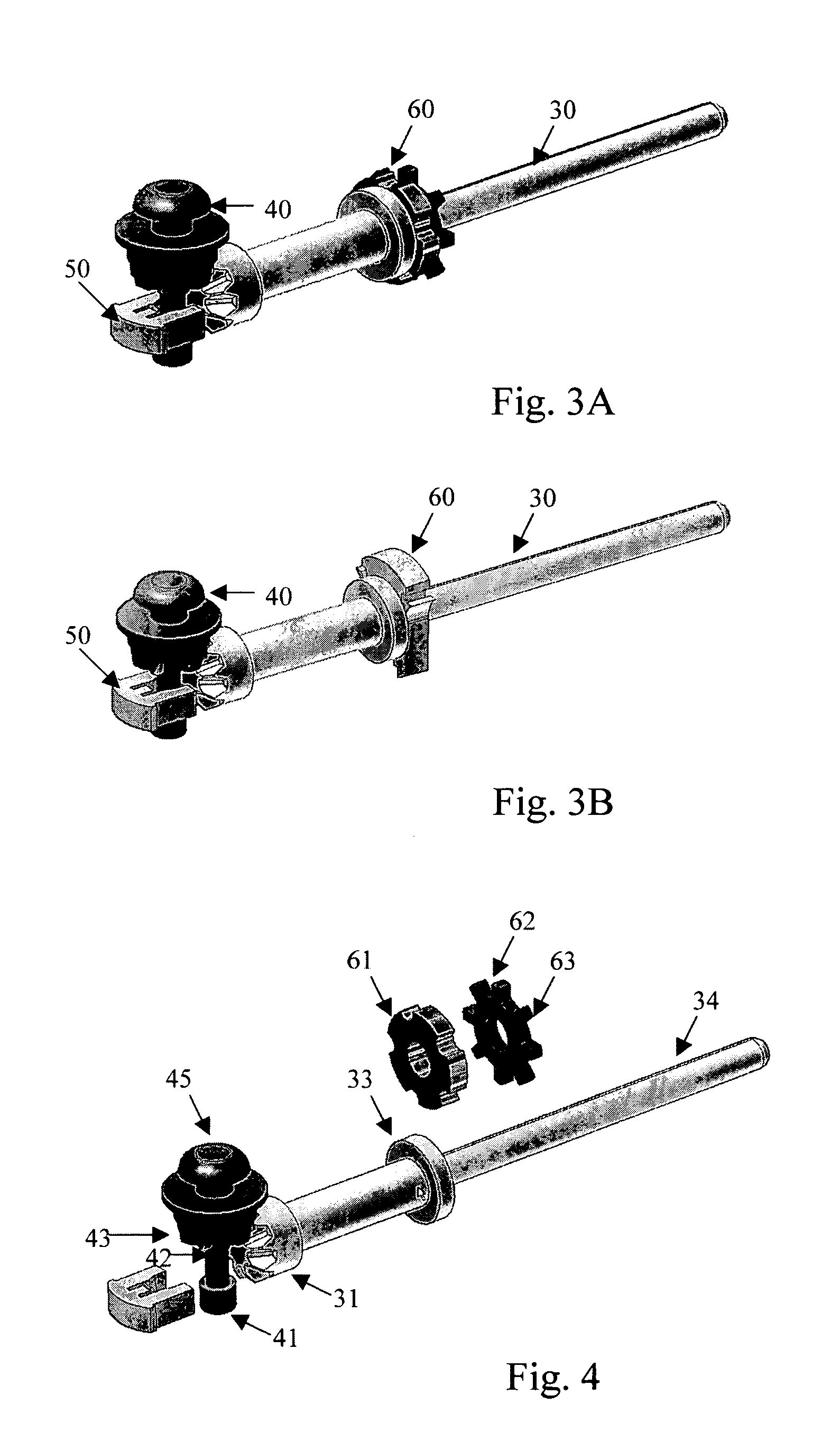

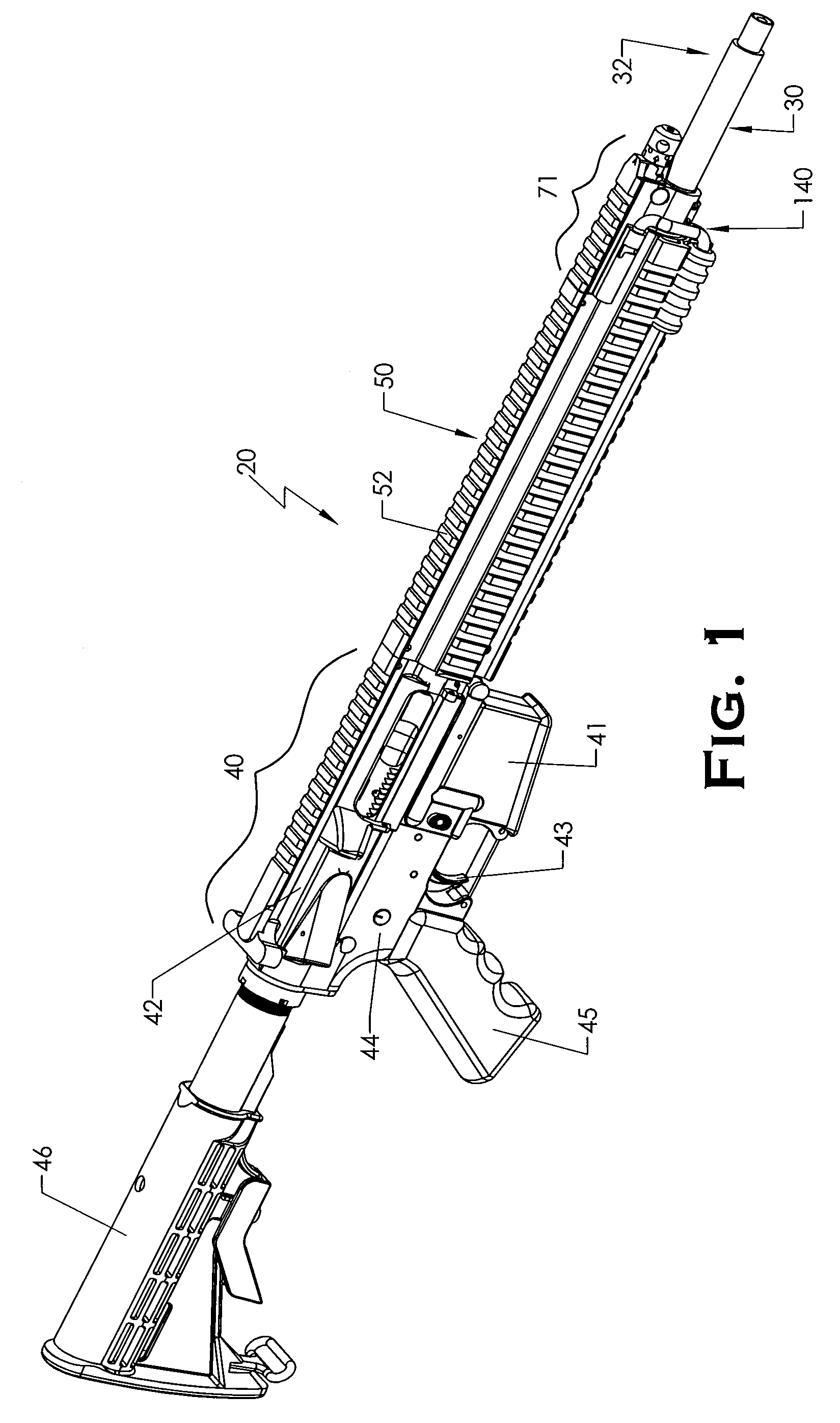

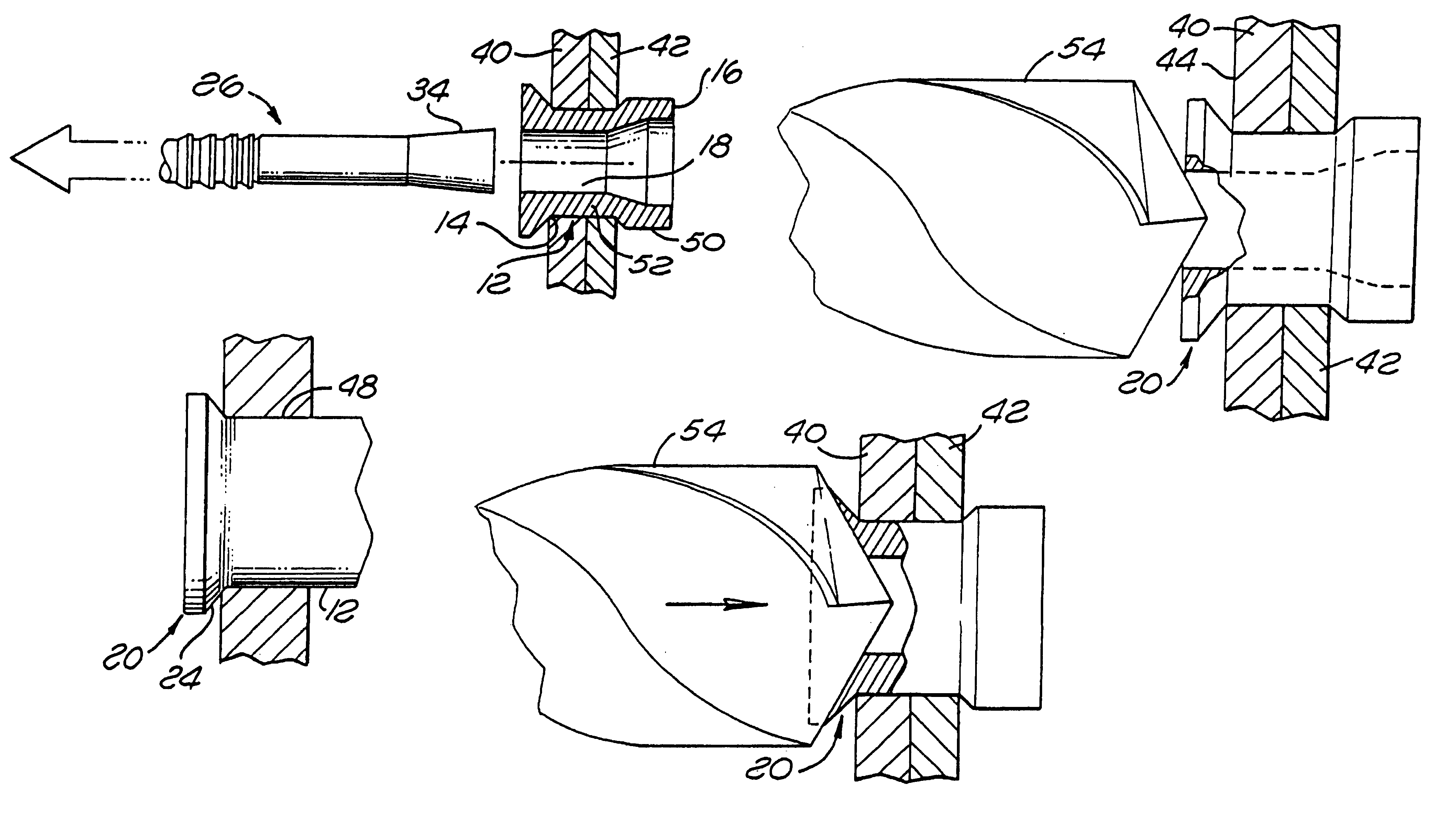

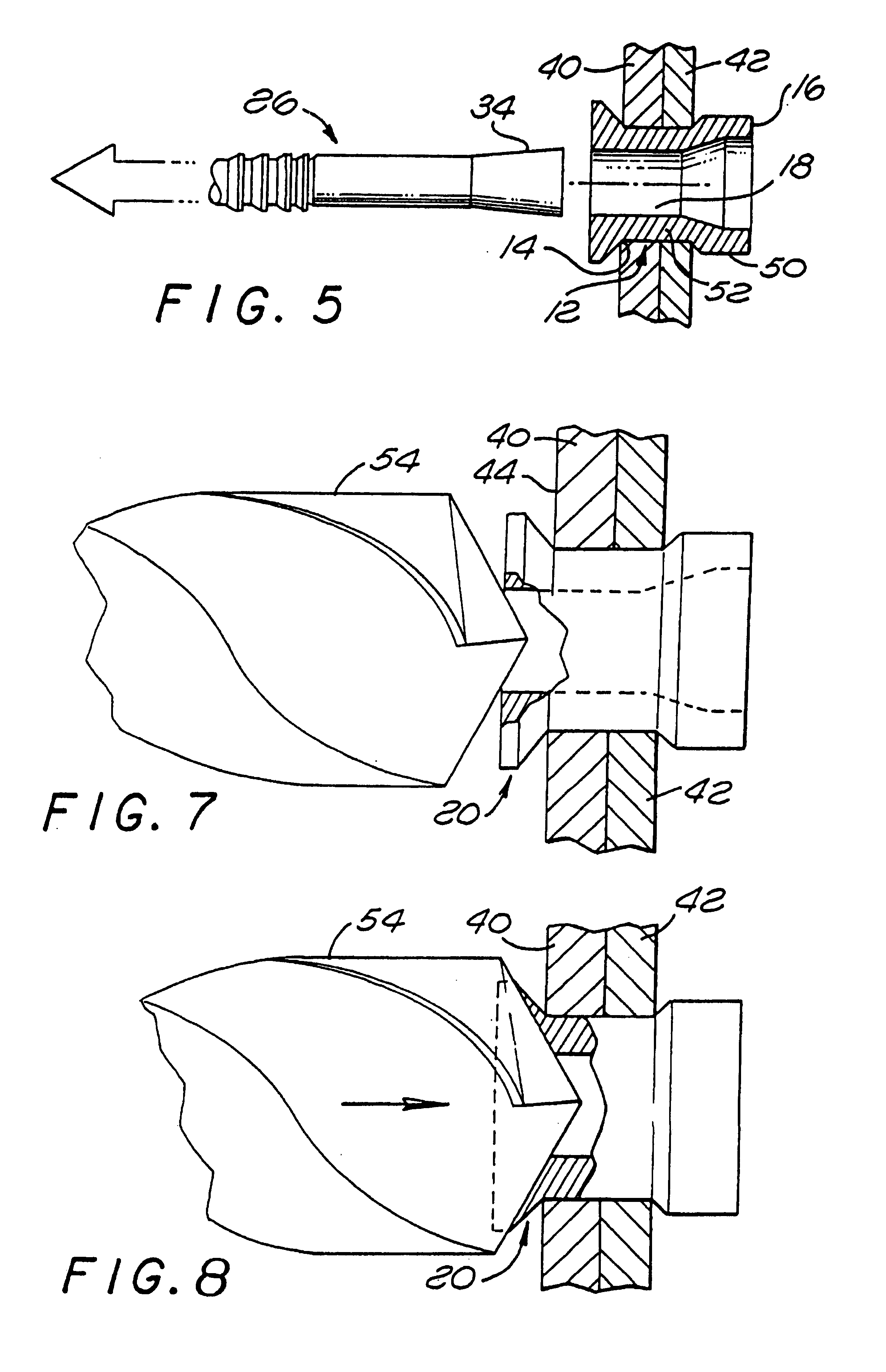

Quick coupling barrel system for firearm

ActiveUS20120131835A1Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

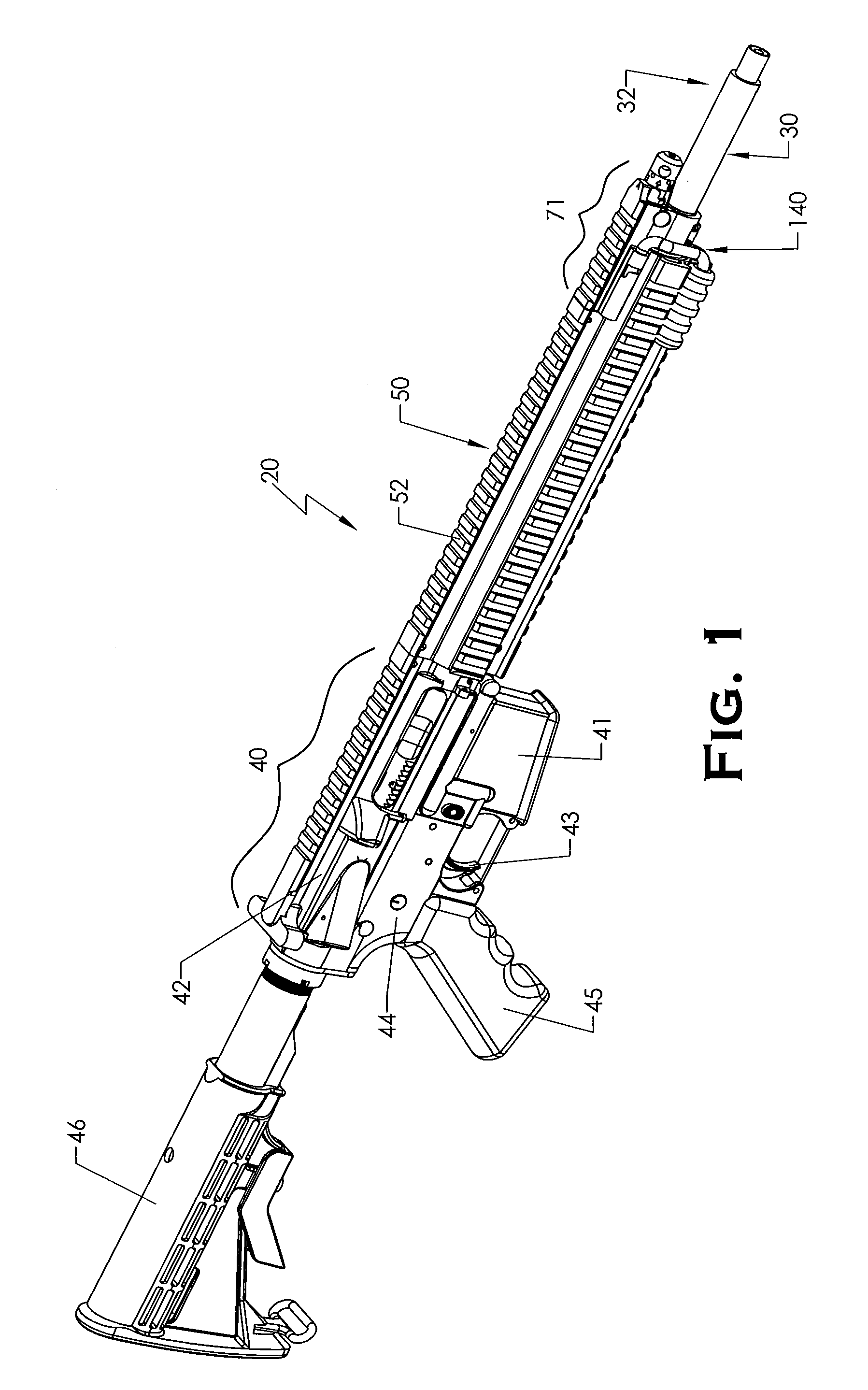

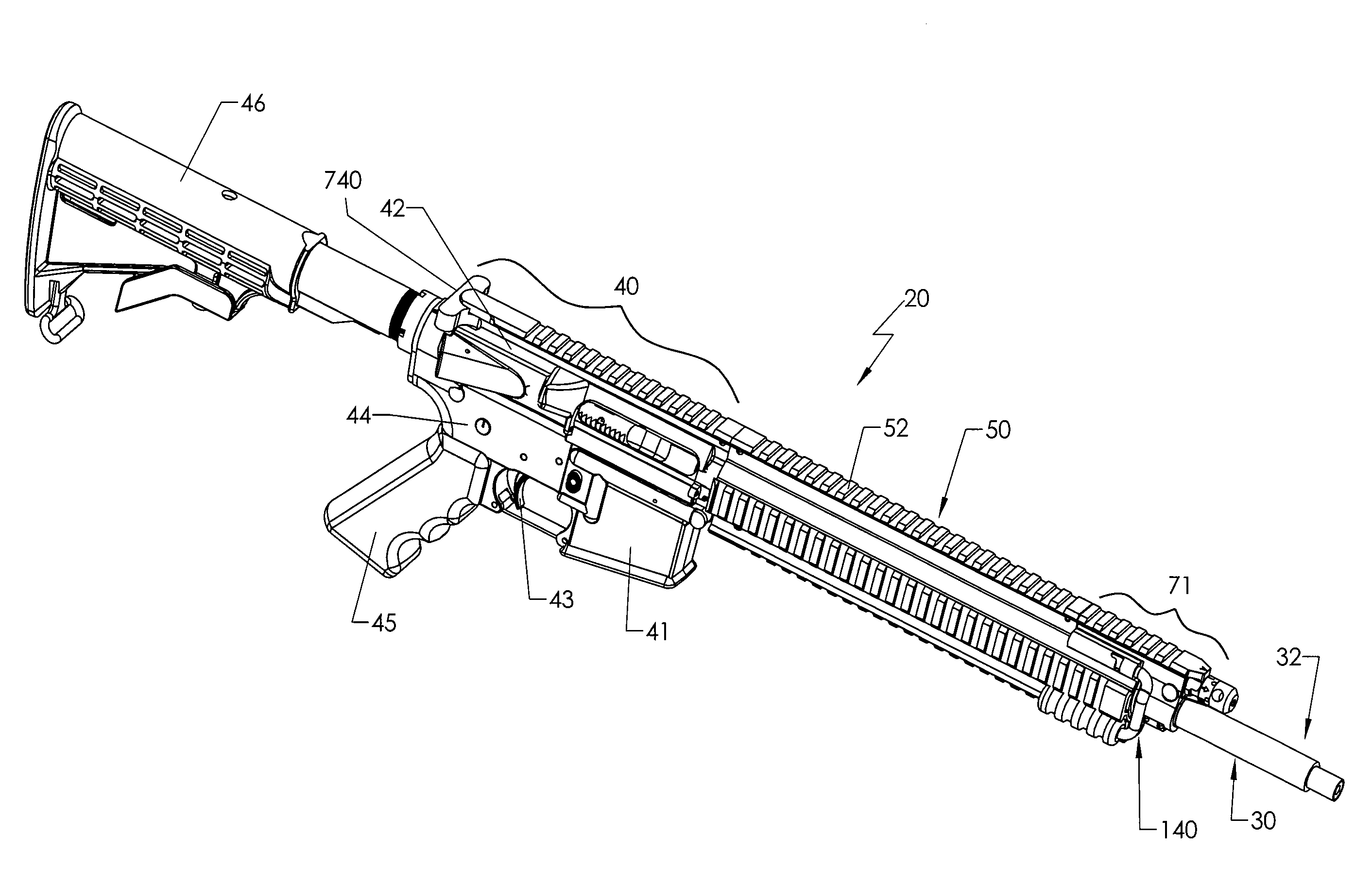

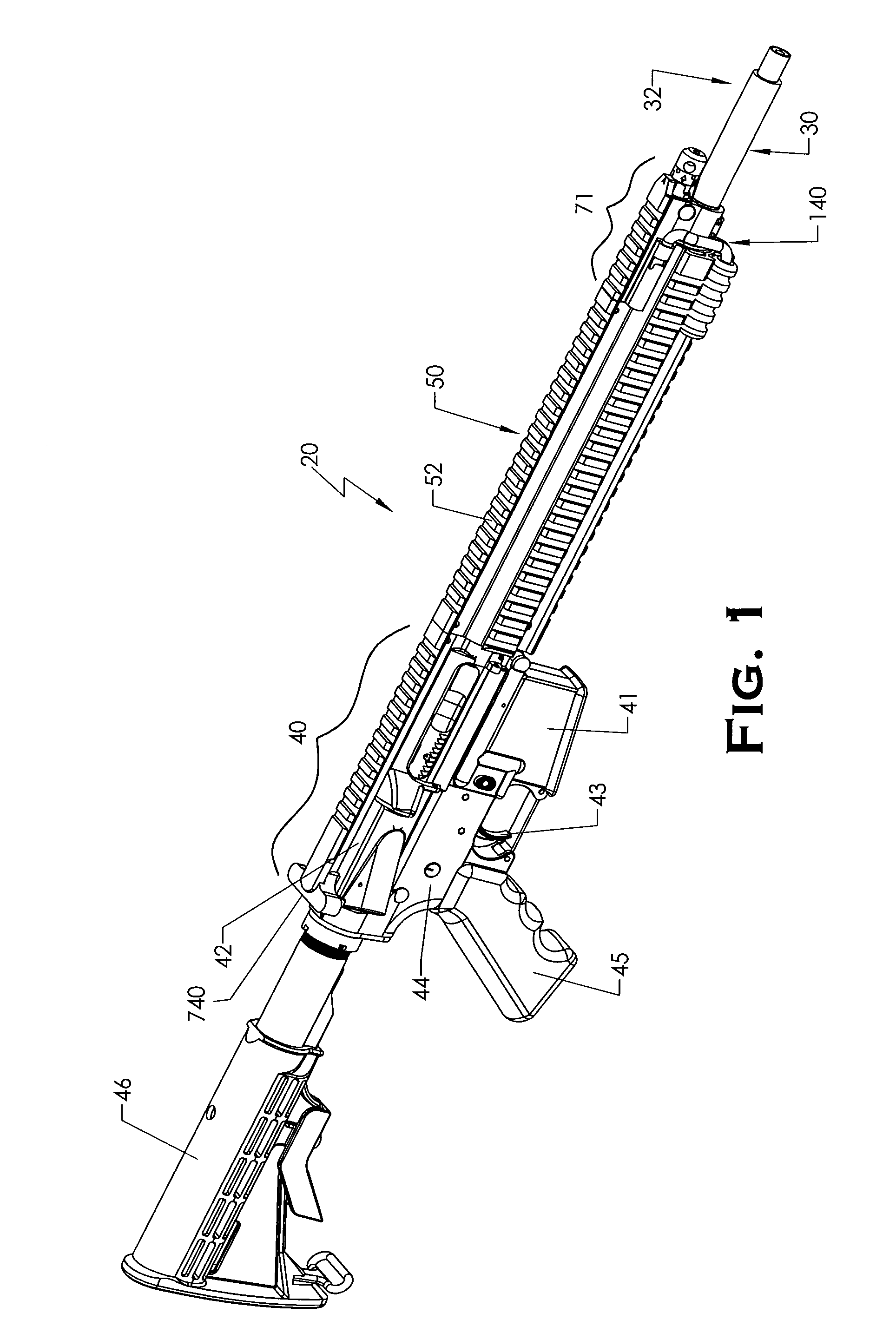

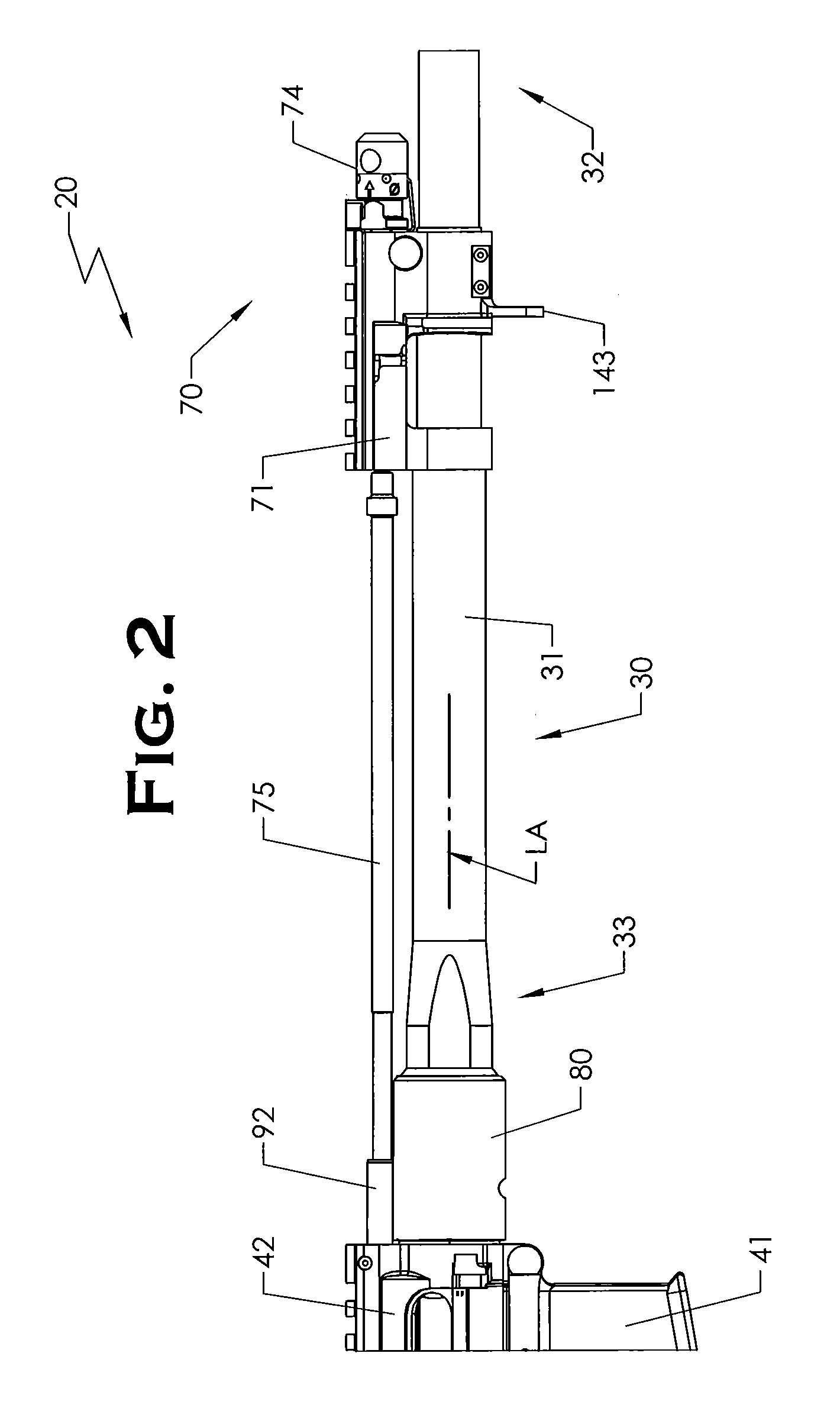

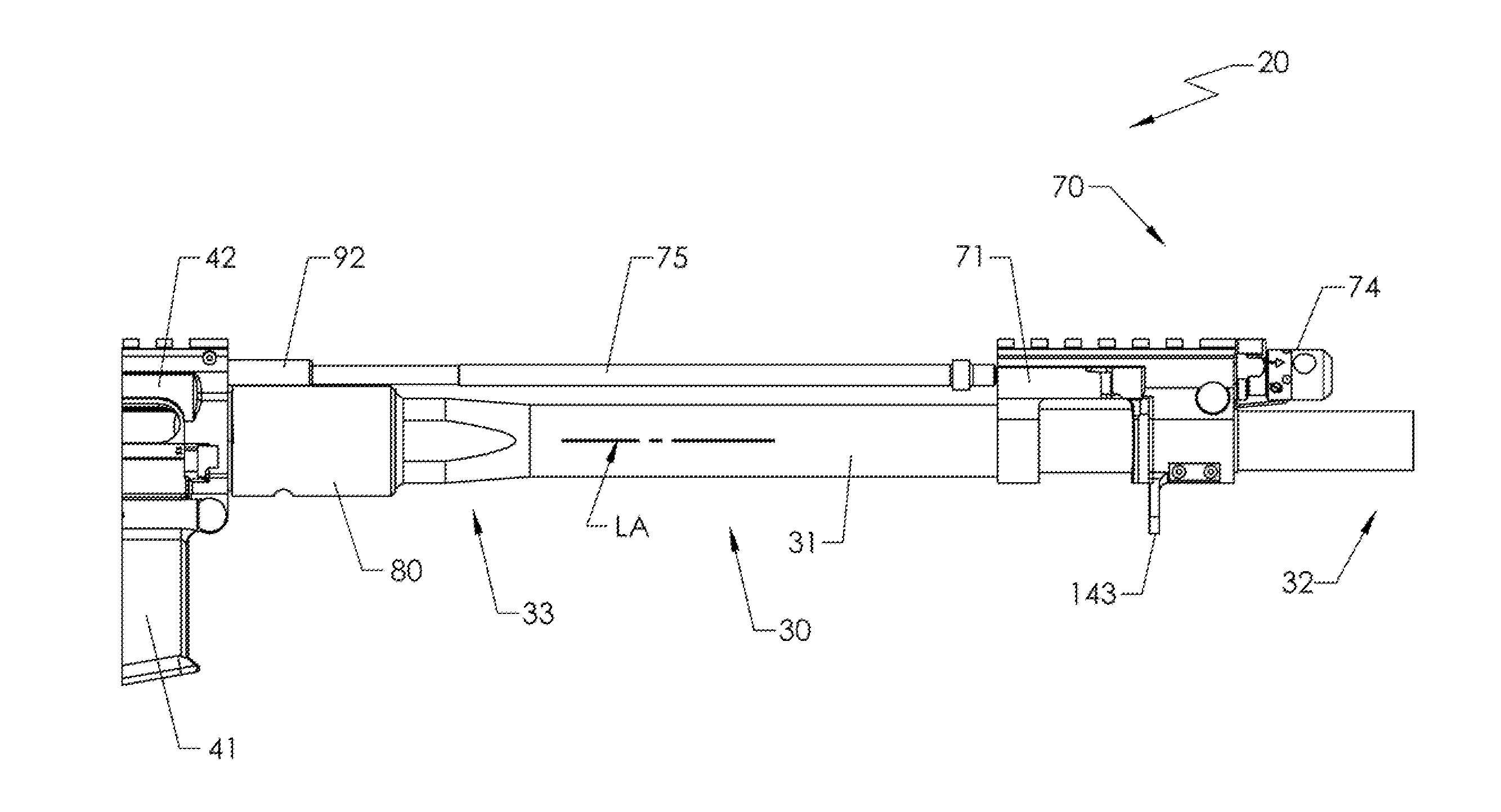

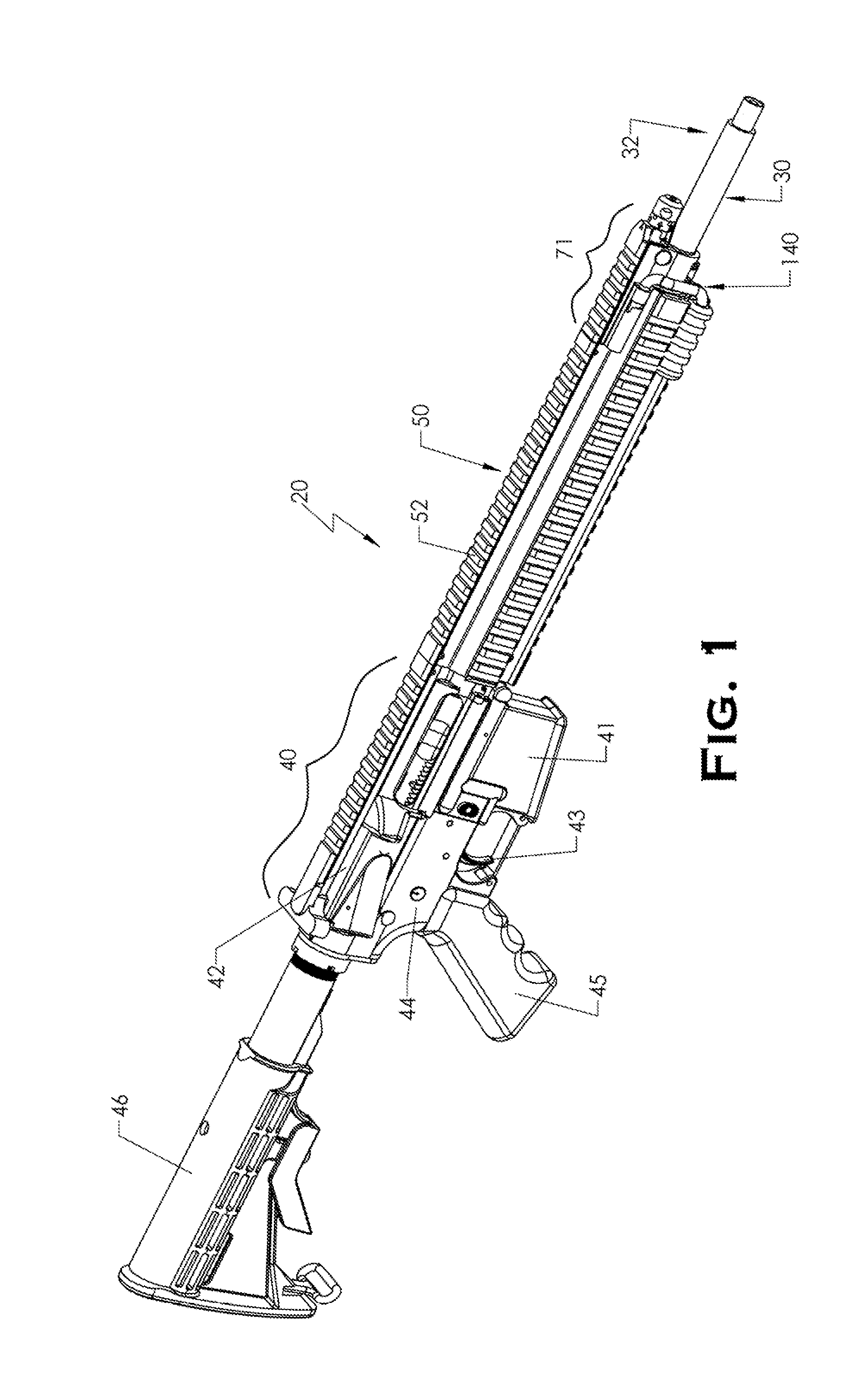

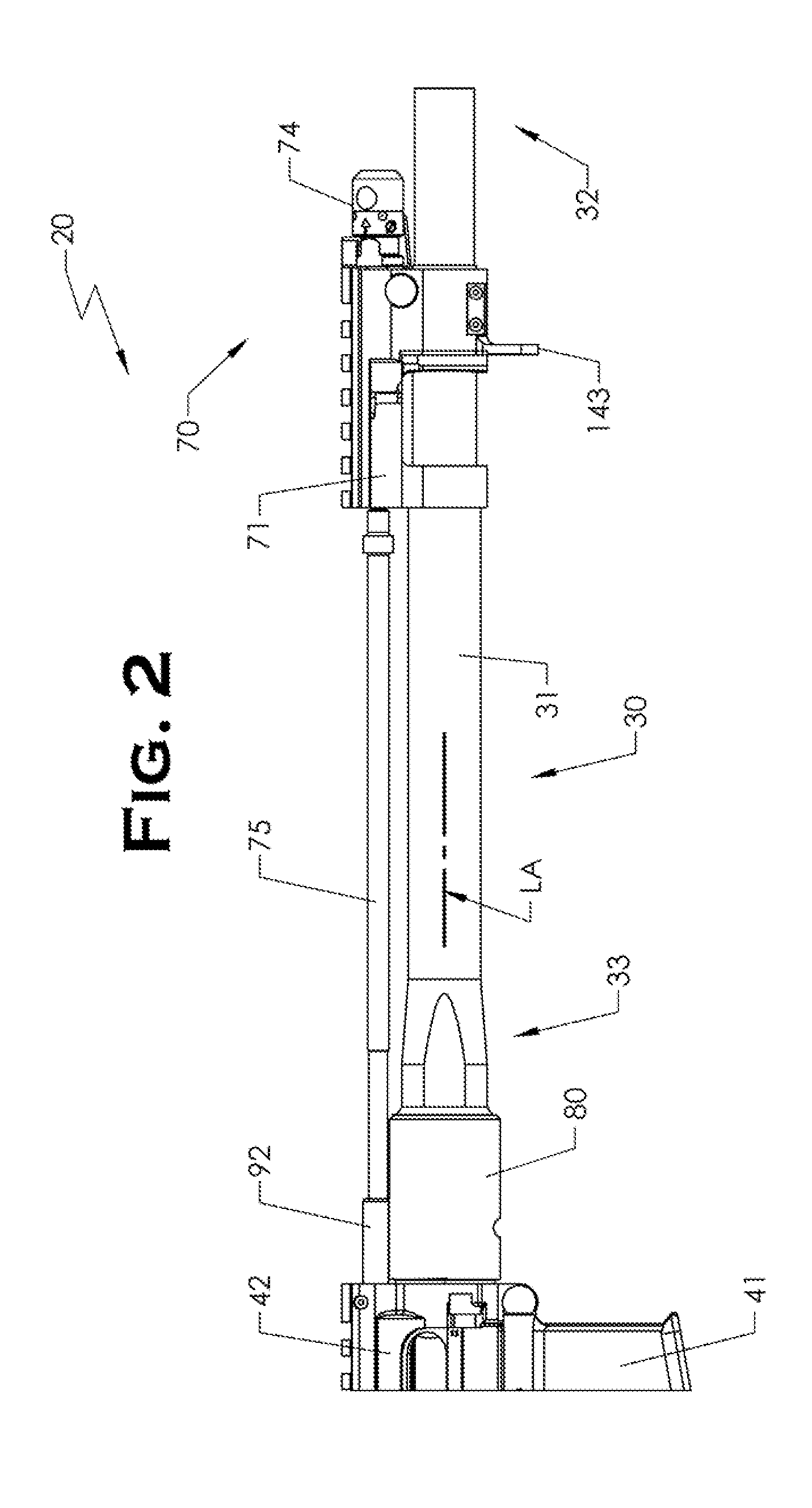

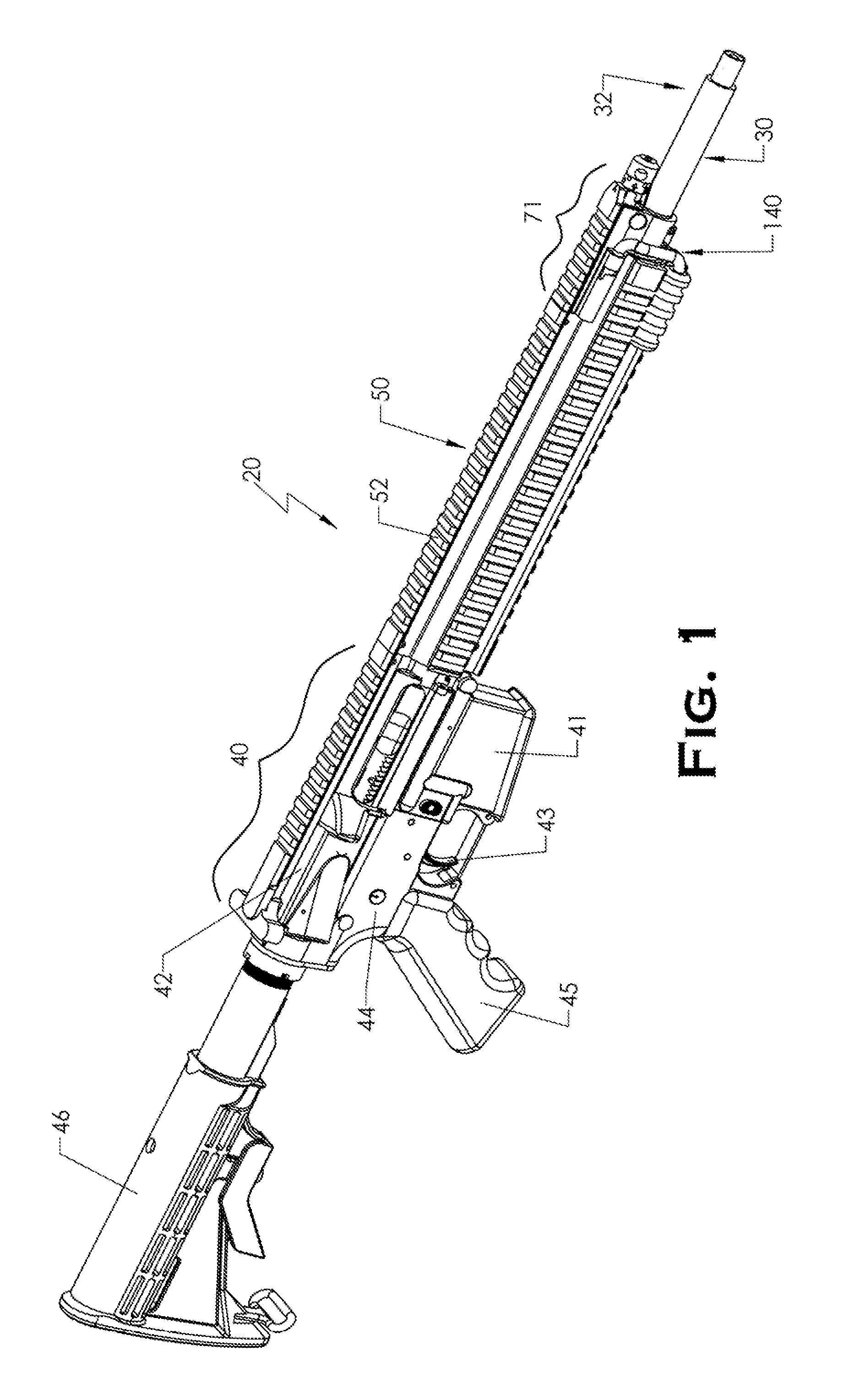

Firearm with quick coupling barrel interlock system

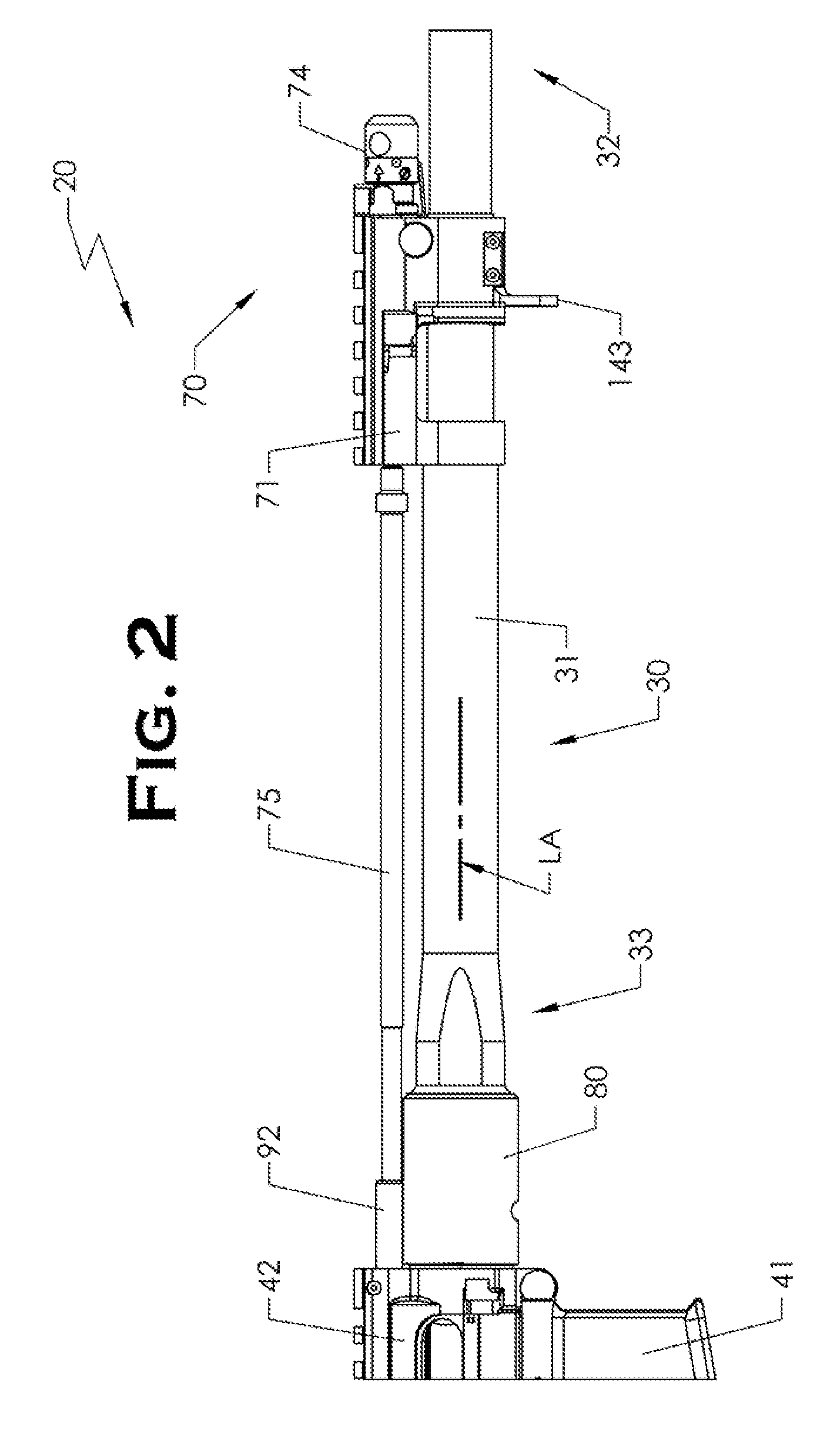

ActiveUS20120216439A1Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingEngineering

A firearm with barrel interlock system for a rotary mounted quick coupling barrel assembly. In one embodiment, the firearm includes a receiver and barrel assembly rotatably mounted thereto. A bolt carrier supporting a bolt is slidably disposed in the receiver and axially movable into and out of battery with the barrel assembly. The barrel interlock system may include a first barrel anti-rotation locking element disposed on the barrel assembly and a mating second barrel anti-rotation locking element disposed on the bolt carrier that is engageable with the first element. When mutually engaged, the first and second locking elements form a meshed relationship and prevent rotation and removal of the barrel assembly from the receiver. In some non-limiting embodiments, the locking elements may be in the form of a protrusion and complementary shaped recess.

Owner:STURM RUGER & CO INC

Firearm with quick coupling barrel system

ActiveUS8479429B2Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

Firearm with quick coupling barrel interlock system

ActiveUS8505227B2Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingEngineering

A firearm with barrel interlock system for a rotary mounted quick coupling barrel assembly. In one embodiment, the firearm includes a receiver and barrel assembly rotatably mounted thereto. A bolt carrier supporting a bolt is slidably disposed in the receiver and axially movable into and out of battery with the barrel assembly. The barrel interlock system may include a first barrel anti-rotation locking element disposed on the barrel assembly and a mating second barrel anti-rotation locking element disposed on the bolt carrier that is engageable with the first element. When mutually engaged, the first and second locking elements form a meshed relationship and prevent rotation and removal of the barrel assembly from the receiver. In some non-limiting embodiments, the locking elements may be in the form of a protrusion and complementary shaped recess.

Owner:STURM RUGER & CO INC

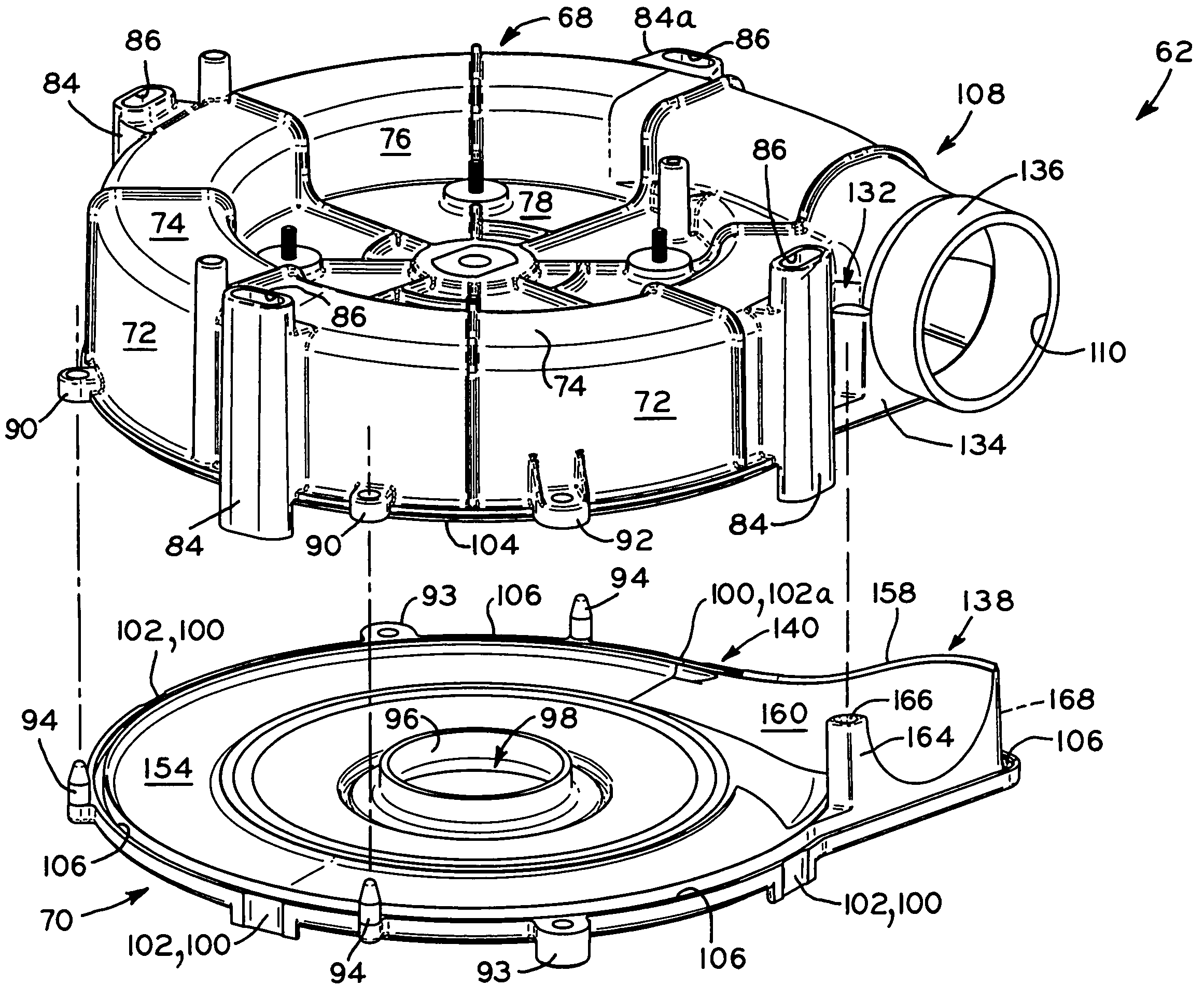

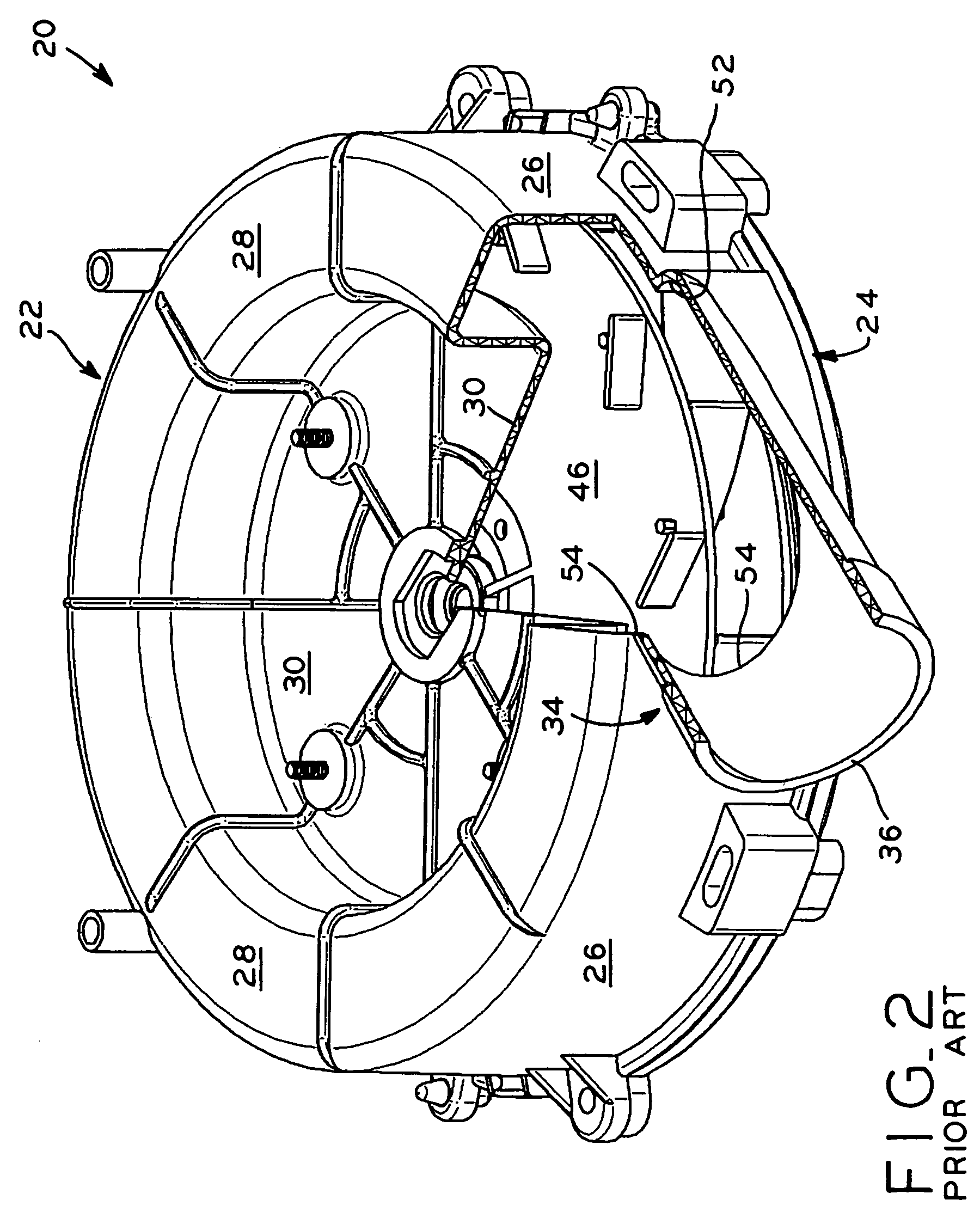

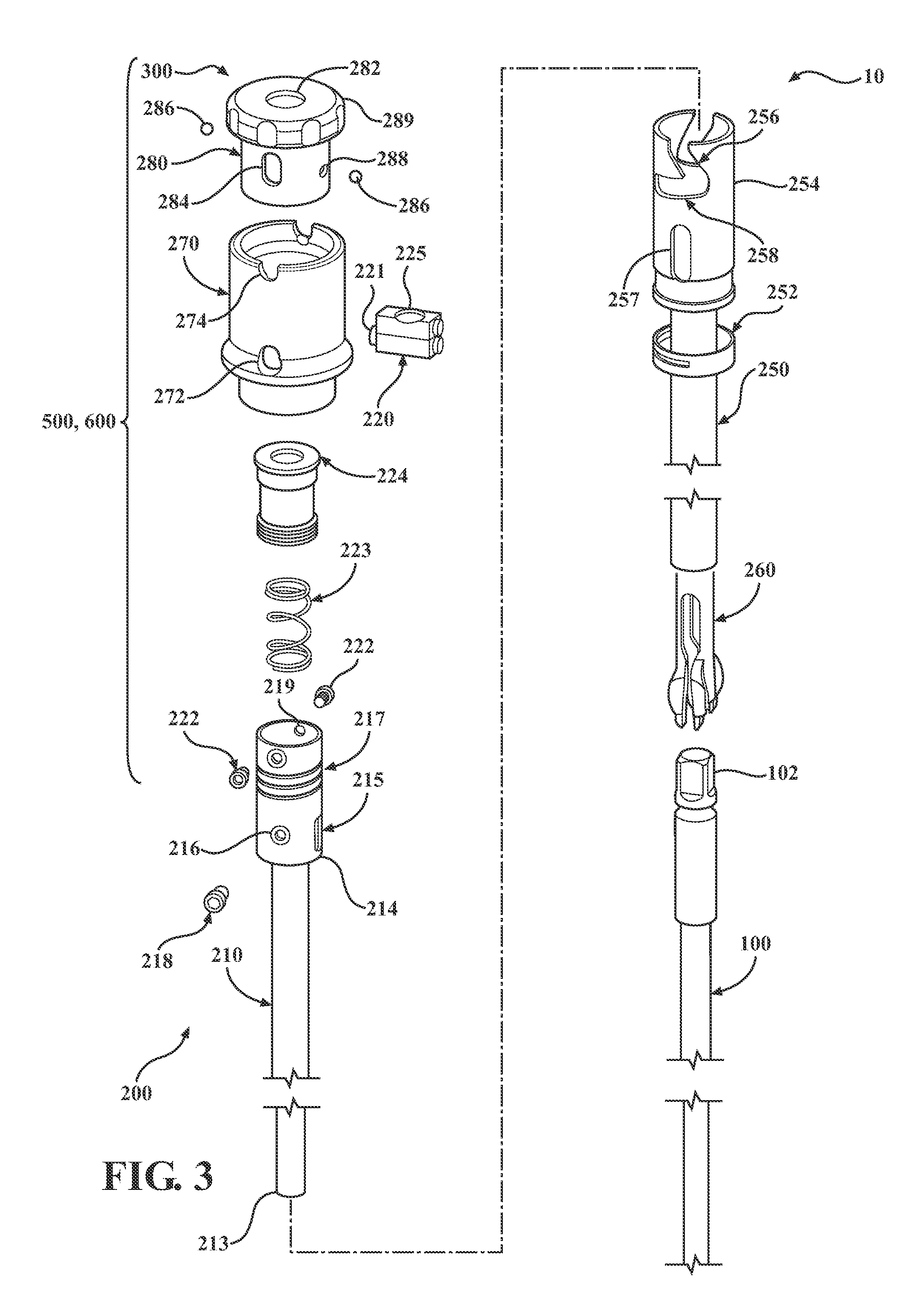

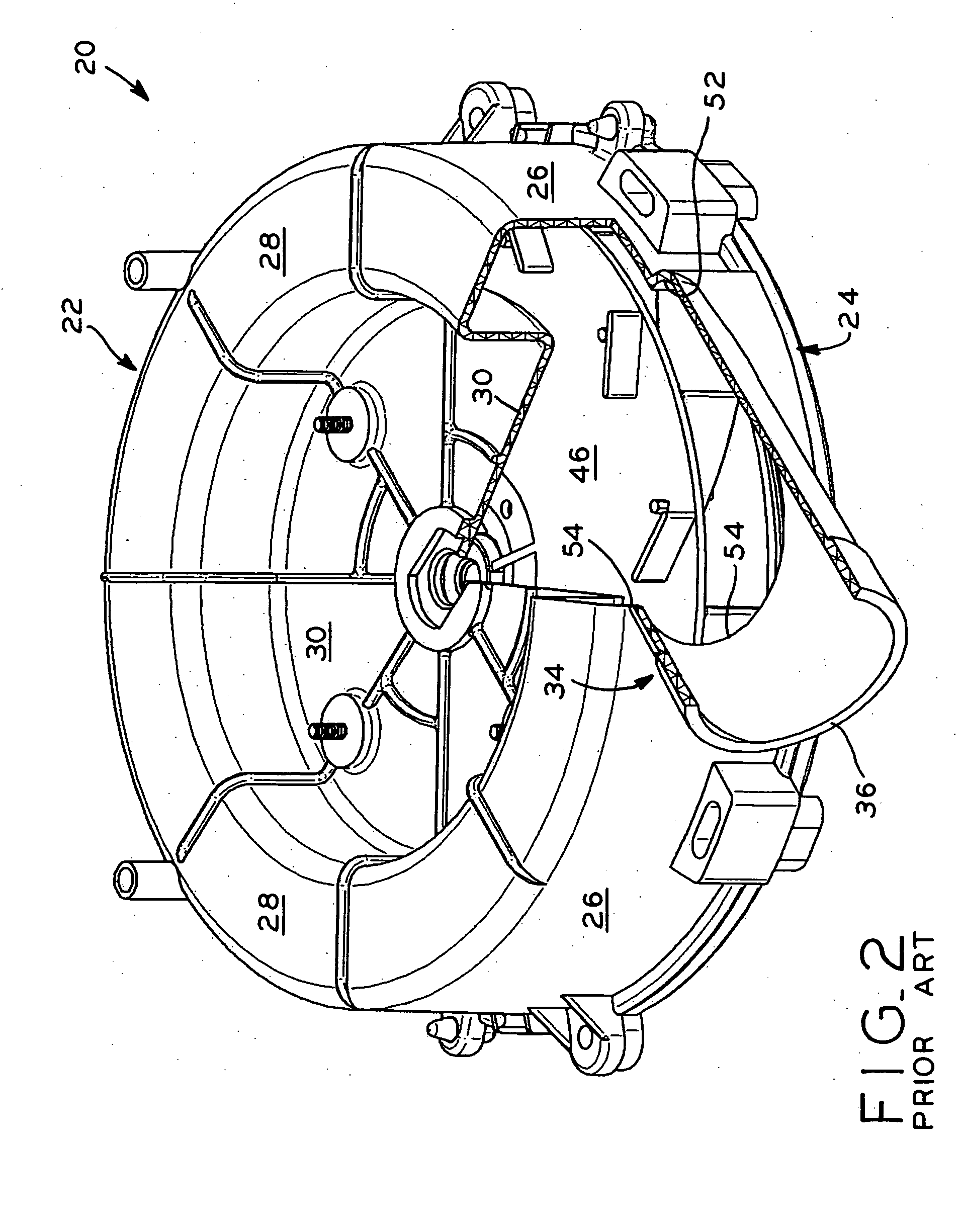

Lobed joint draft inducer blower

A draft inducer blower for high efficiency furnaces, including a blower housing which facilitates maximum air flow efficiency through the blower housing while reducing air flow noises. The blower housing generally includes a housing body and housing cover which define an exhaust transition therebetween, which transitions the air flow from the circular main cavity of the blower housing to the blower housing outlet. The housing body and housing cover are attached to one another via a lobed joint along the exhaust transition, and each include complementary, smoothly contoured inner surfaces to facilitate smooth air flow through the exhaust transition toward the outlet. Additionally, the housing body and housing cover include cooperating cutoff surfaces which form a broadly radiused cutoff within the blower housing to reduce or eliminate the blade pass noise associated with contact of the air flow from the impeller with the cutoff.

Owner:REGAL BELOIT AMERICA

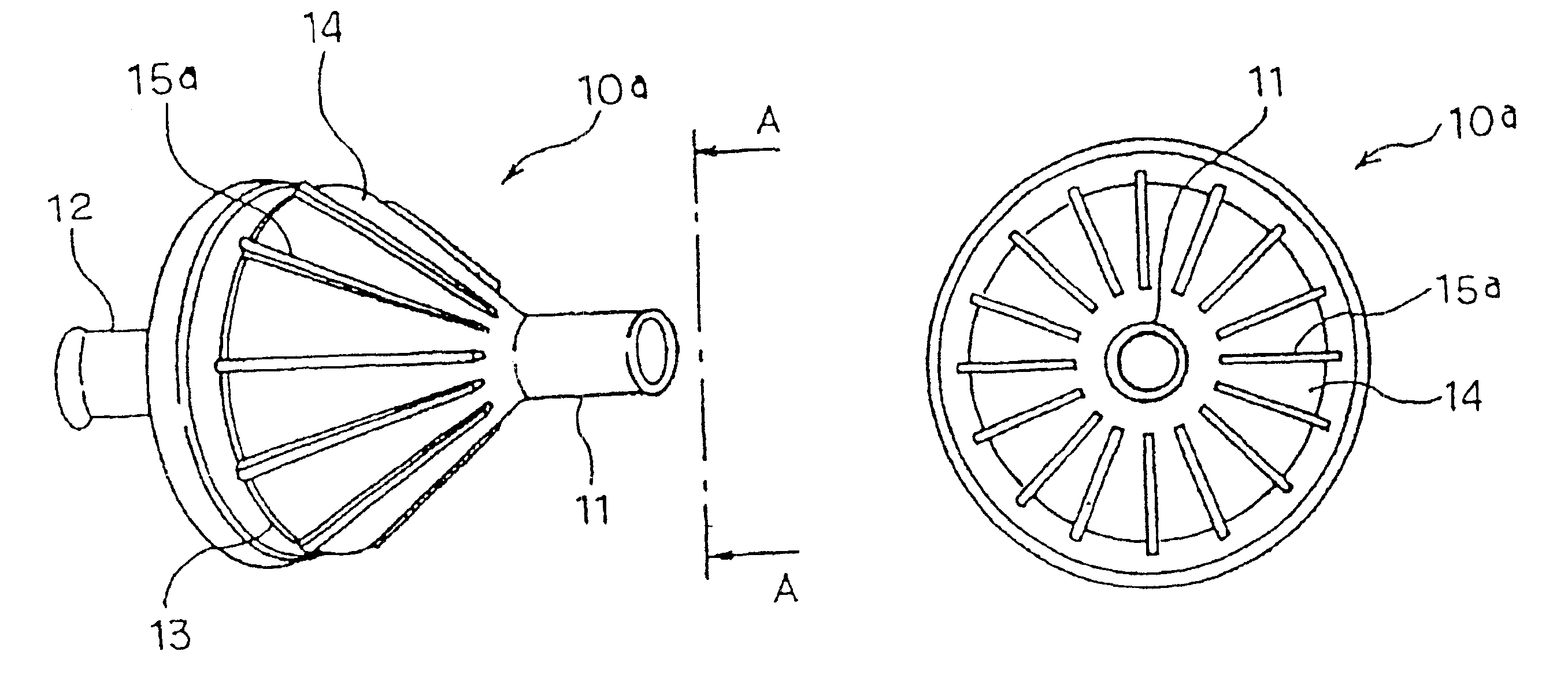

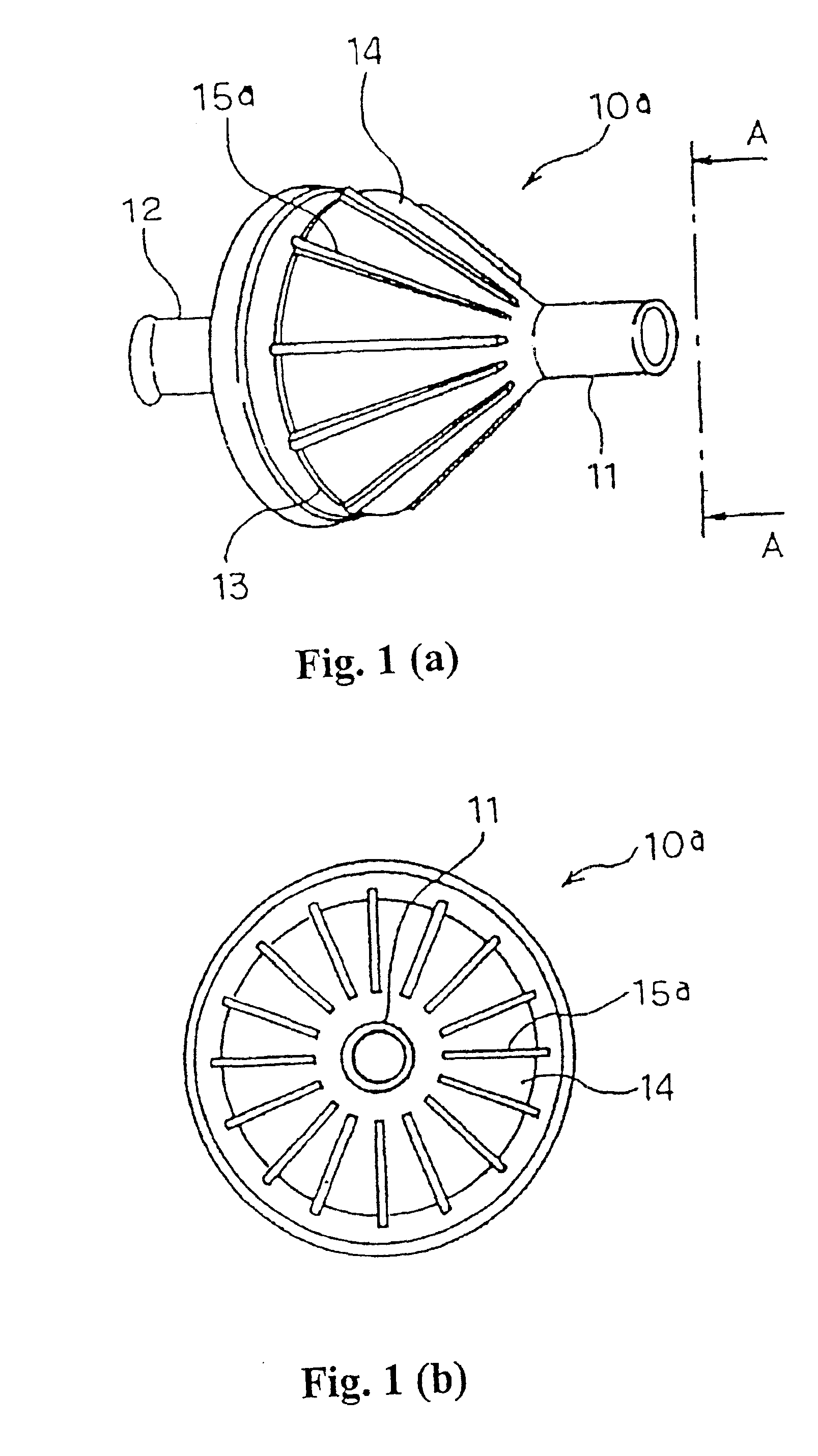

Grommet

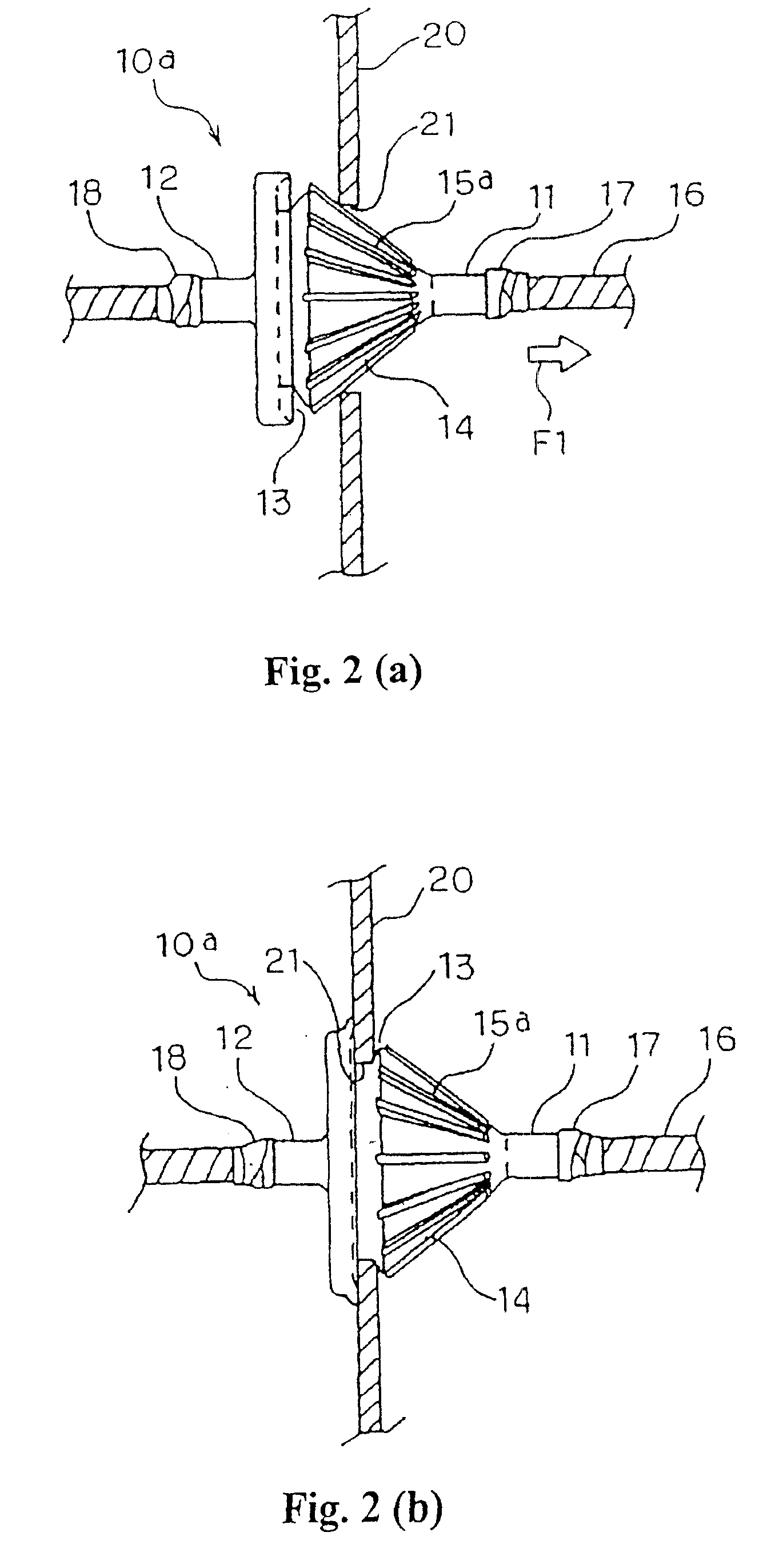

InactiveUSRE38788E1Complicated processShort processing timePipesMulti-purpose toolsEngineeringGrommet

The present invention relates to a grommet capable of easy installation by reducing an insertion resistance when conducting an insertion of the grommet into an opening of a vehicle panel. The configuration of the grommet allows molds for forming the grommet to have reduced processing costs, and molding and installation time can also be decreased. The grommet includes wire harness holding areas for tightly engaging around the periphery of the wire harness and an engagement area which fixedly engages an opening provided on a vehicle panel. A tapered area connects a wire harness holding area and an engagement area with a near-conical tapered surface extending over the outer surface of a tapered area, and a plurality of linear convex areas are provided to extend from a wire harness holding area to the engagement area, in an insertion direction of the grommet over the entire periphery on the tapered area.

Owner:SUMITOMO WIRING SYST LTD

Firearm with quick coupling barrel system

ActiveUS20150007478A1Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such as splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

Firearm with quick coupling barrel system

ActiveUS20120131834A1Quick changeImprove tightness and reliabilityBreech mechanismsMetal working apparatusCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

Dispensing closure with automatic sealing valve of single body

ActiveUS7128245B2Tighter engagementImprove sealingCapsClosure capsAutomatic balancing valvesManufacturing cost reduction

Owner:CHONG WOO

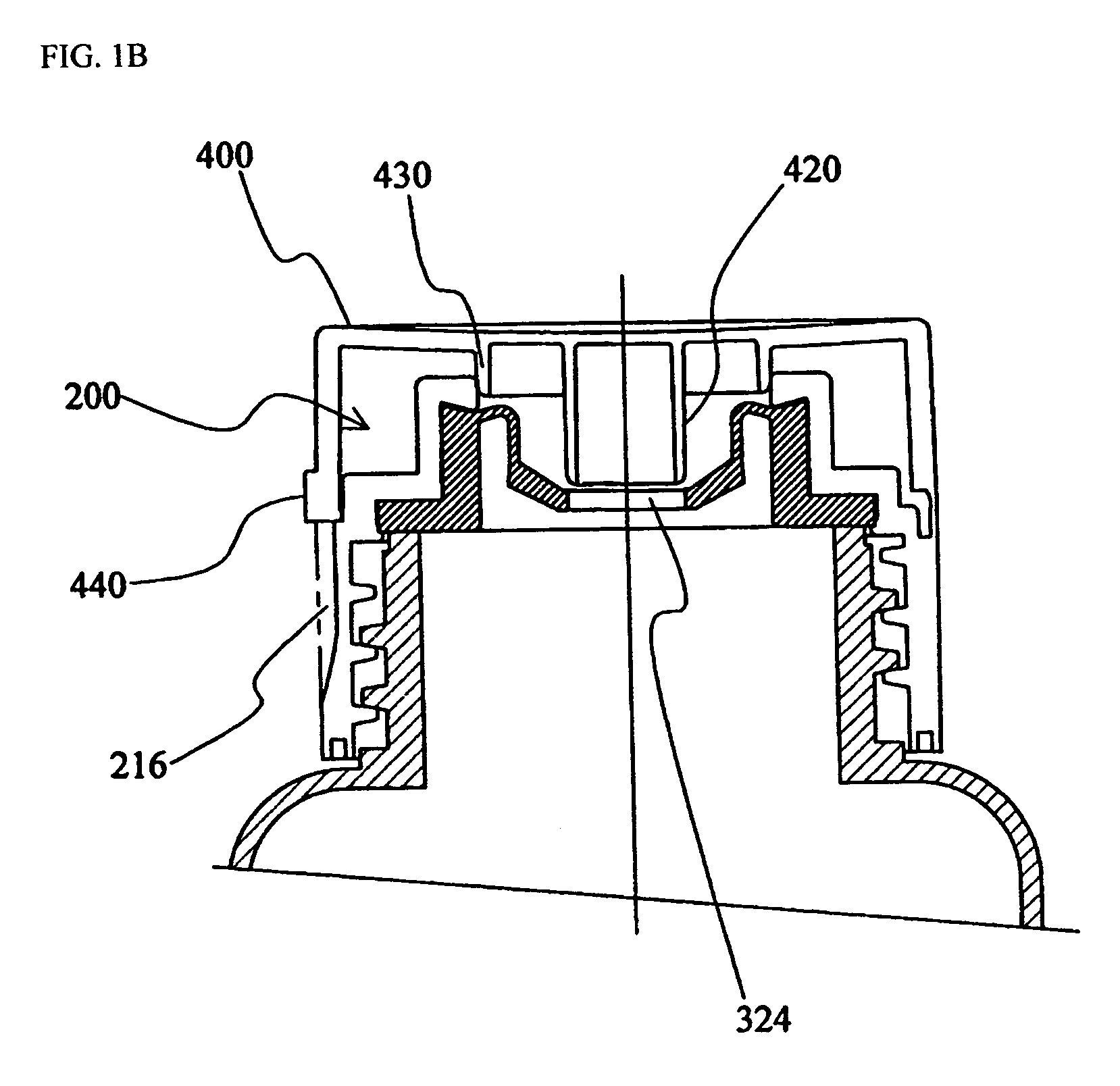

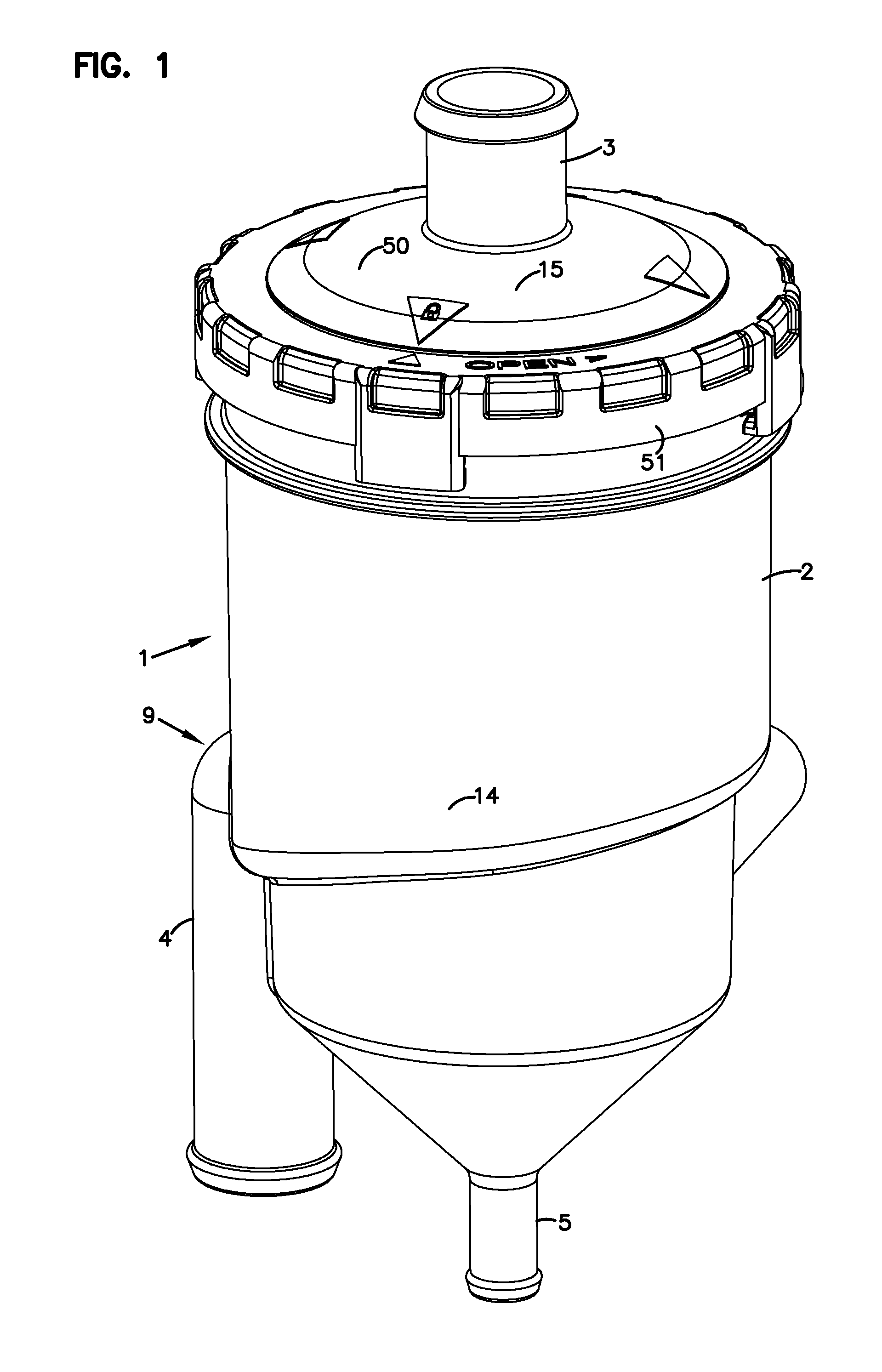

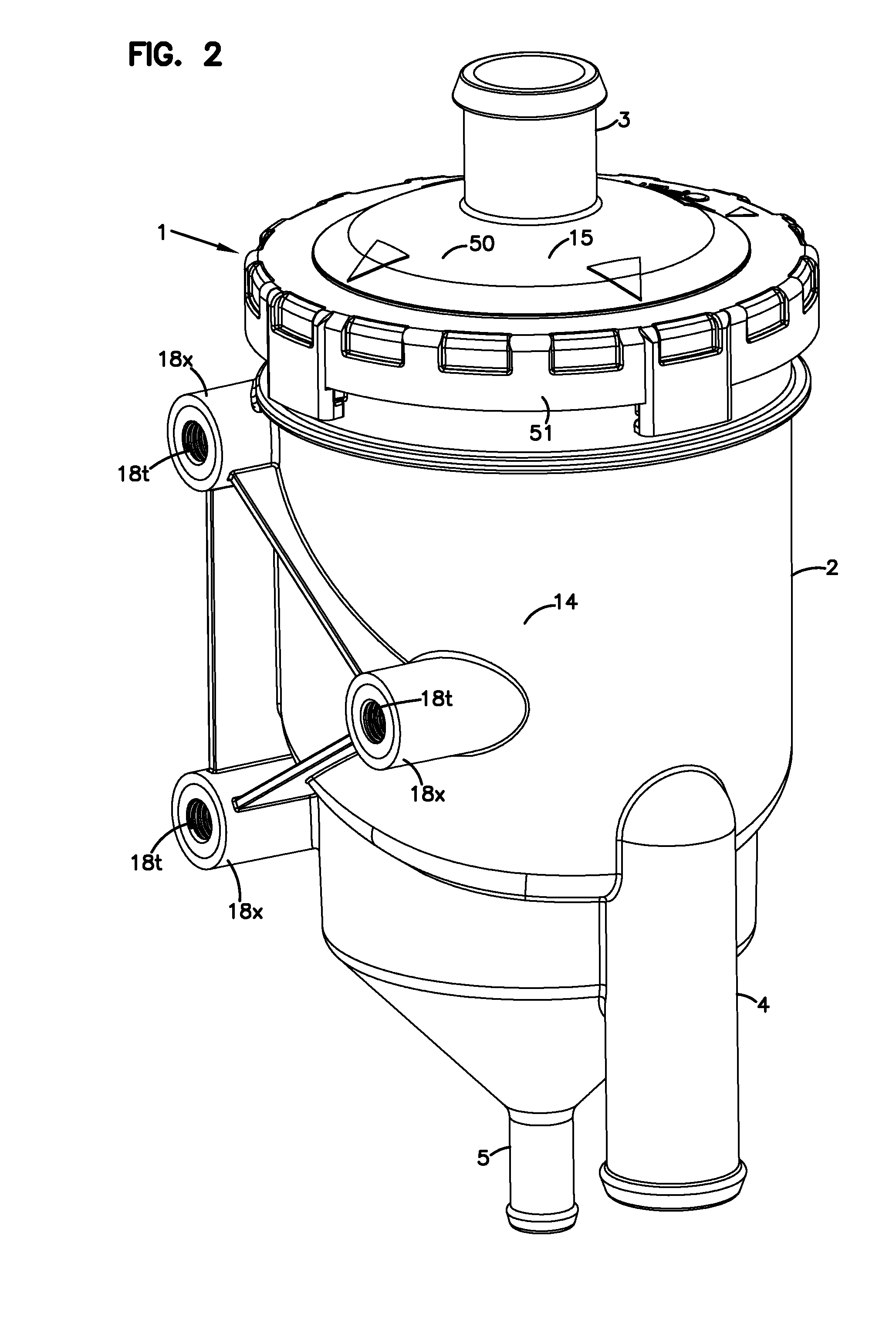

Crankcase ventilation filter systems; components; features; and, mehtods of assembly and use

ActiveUS20140215982A1Precise positioningTighter engagementGas treatmentDispersed particle filtrationFilter systemCrankcase

Crankcase ventilation filter assemblies are described and shown. Components, features and methods of assembly and use are described. Many of the principles relate to preferred cartridge configurations for engagement with selected housings. Selected optional features described can be used to provide indication to a service provider that a proper cartridge is not positioned appropriately in the housing for use.

Owner:DONALDSON CO INC

Dialysis catheter

InactiveUS7258685B2Tighter engagementAvoid the needMulti-lumen catheterExcision instrumentsCatheters dialysisScar tissue

A catheter assembly includes catheter having proximal and distal ends and at least one lumen extending between the ends. At least one end of the catheter is formed from a material that can be trimmed to achieve a selected length for the catheter. A tubular connector is telescoped over the catheter and a hub is joined to the tubular connector. Proximal portions of the hub are configured for connection to a medical apparatus. A cuff is mounted around the tubular connector or the catheter. The cuff is formed from a material that will permit or promote the growth of scar tissue for anchoring the catheter device at least on a semi-permanent basis in a patient.

Owner:KERR ANDREW

Modular test tube rack

A modular test tube rack for assembly with similarly constructed racks comprise a flat rectangular body displaying, in a first position, a series of wells extending from its top wall to its bottom wall and adapt to receive tubes therein. A pair of handles vertically extend at opposite end walls of the body, each handle having a lower portion adapted to tightly engage an extension on each end wall and a hand gripping upper portion. The lower portion has a bottom edge configured to anchor with the top edge of the handle of an underposed similarly constructed rack to thereby enable a stacking of two more of these racks. In one embodiment, the body displays a second series of wells extending from the bottom wall to the top wall whereby the body, when in a second position reversed relative to the first position, may also receive test tubes, the handles being reversably mountable to the end wall extension to still enable a stacking of racks in the second position.

Owner:3088081 CANADA

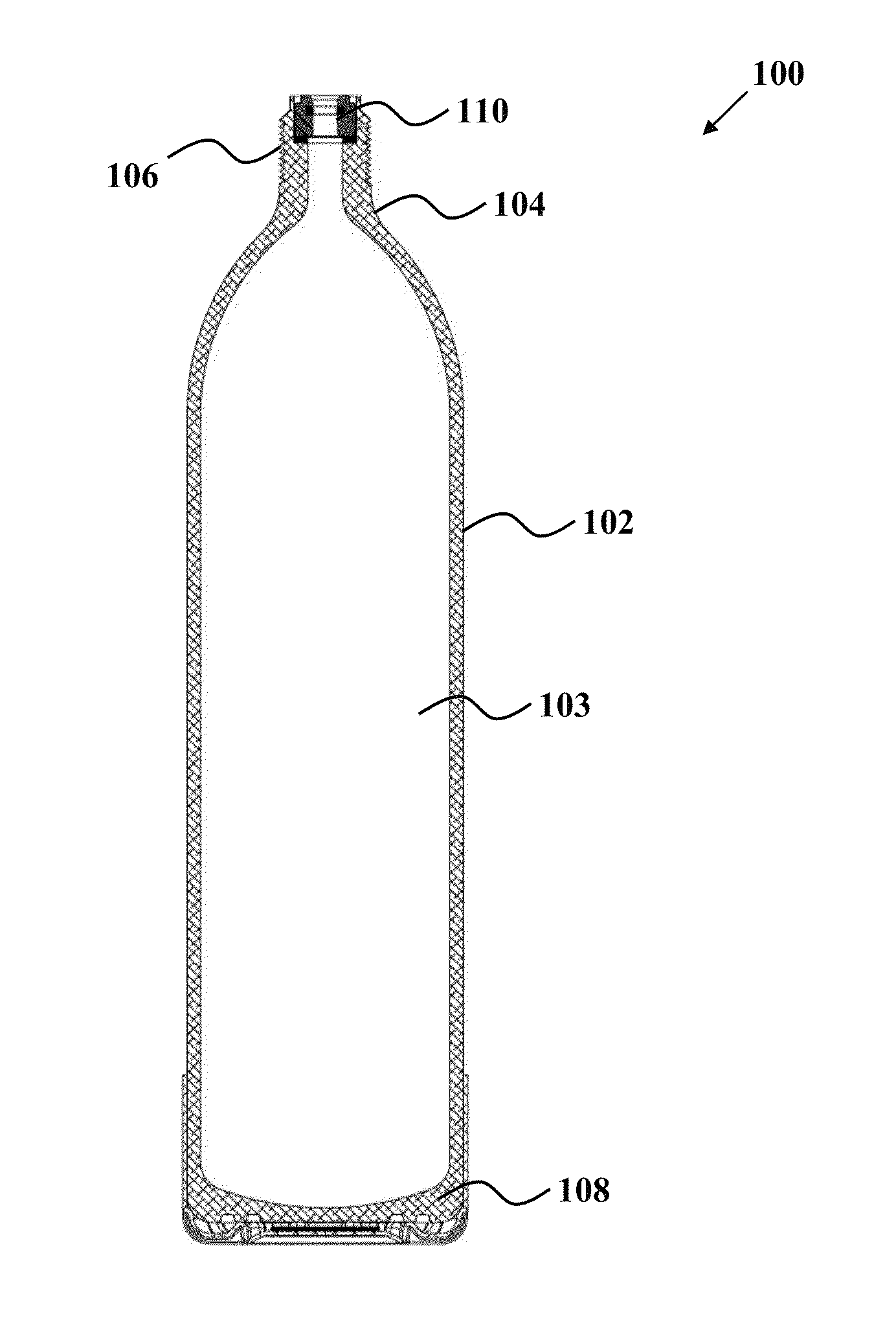

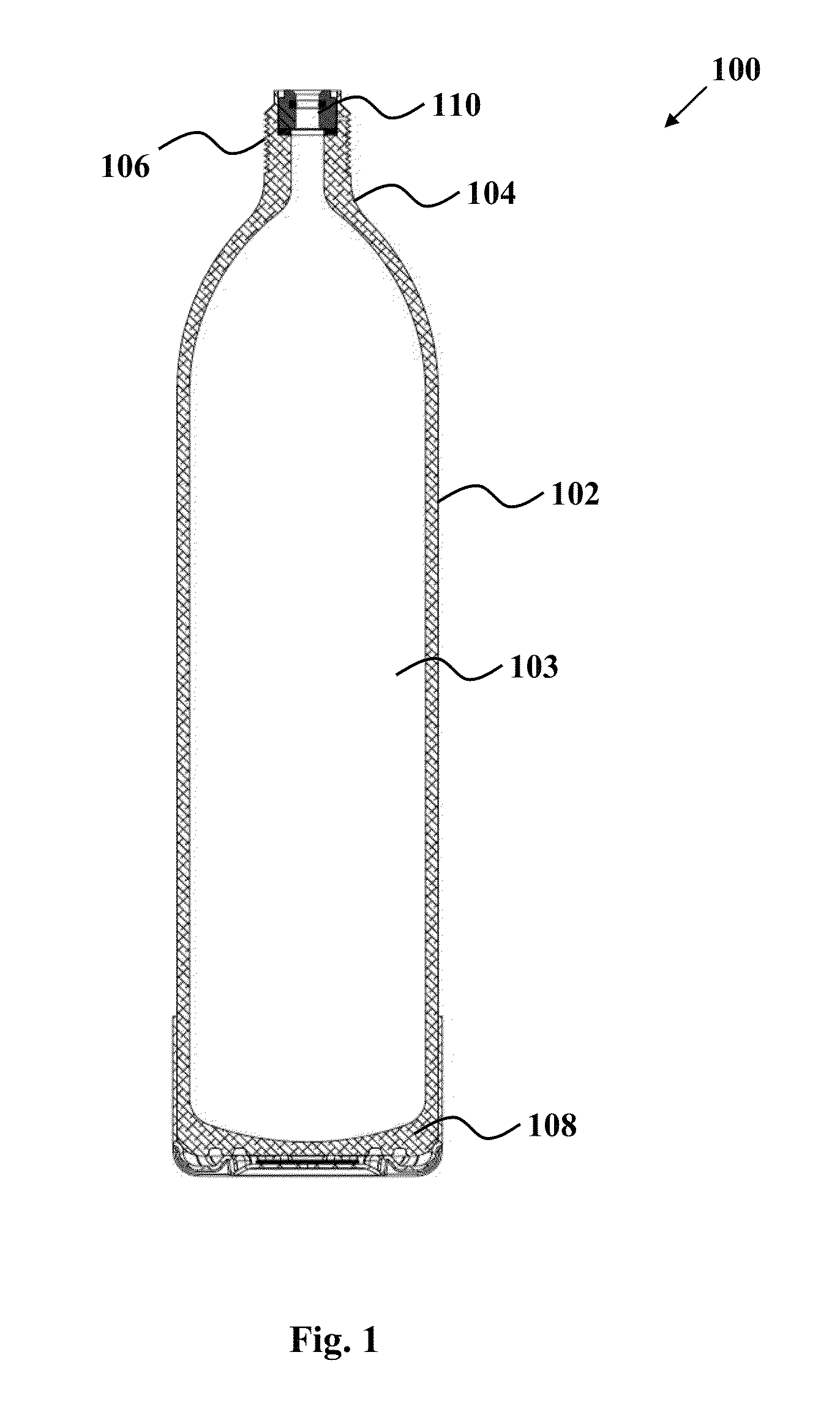

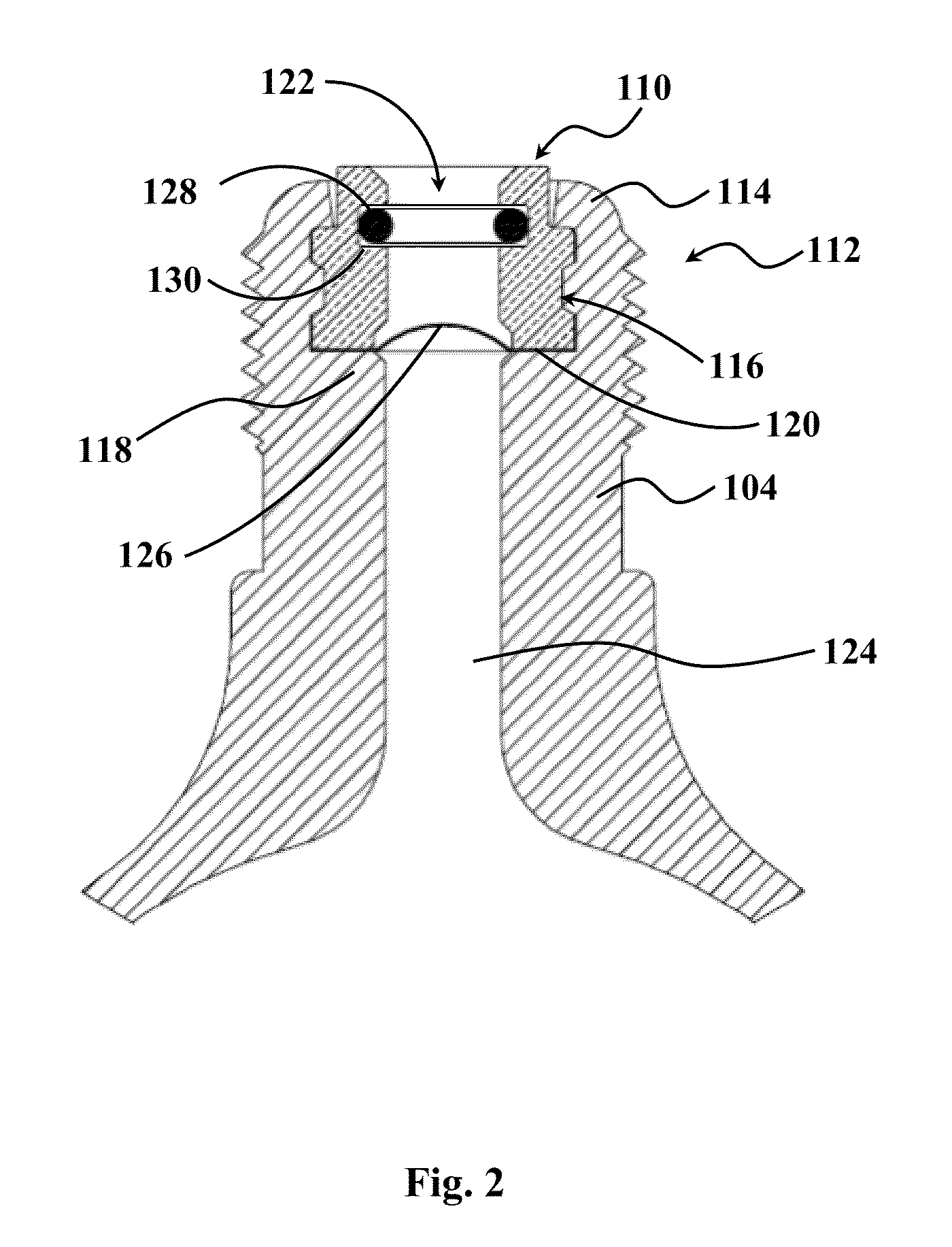

Pressurized Gas Container

InactiveUS20150329341A1High safety standardsLow costVessel mounting detailsVessel manufacturingProcess engineeringCarbonated drink

A pressurized gas container associates with and supplies gas to a pressurized gas port of an appliance, such as for supplying carbon dioxide for the preparation of a carbonated drink. The container has a plug at its opening that has a barrier element that seals the container and is configured to be non-reversibly ruptured by a shaft of a gas-channeling member. The plug also has one or more sealing elements that are distinct from the barrier element and are configured for forming a gas-tight association with the shaft of the gas-channeling member. A plurality of such pressurized containers may be carried by a holder rack in a multipack. An appliance adapted for preparing or dispensing carbonated drink includes an adapter for associating with such a pressurized carbon dioxide-containing canister and for receiving the pressurized carbon dioxide therefrom.

Owner:STRAUSS WATER LTD

Firearm with quick coupling barrel system

ActiveUS9057576B2Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such as splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

Disposable dental prophy angle with secure retention mechanism

ActiveUS7255559B2Improve convenienceImprove performanceTooth pluggers/hammersBoring toolsDrive shaftWood splinter

A disposable, securely retained dental angle is provided. The angle includes a one-piece hollow housing having a short leg at its front end, which is angled with respect to the long leg. Both the short and long legs have a through bore. The short leg has an aperture, which is connected to the bore of the long leg to allow insertion of a driving shaft through the short leg of the angle. A driven rotor is inserted in the short leg. A horse-shoe-like snap rotor retainer fits within the short leg over the driven rotor to retain the driven rotor in the angle. A paw-like or, alternately, a horse-shoe-like locking means fits within the long leg over the driving shaft to lock the driving shaft in the angle and to retain the angle together. In one embodiment, a pair of splinters on the driven rotor provides the function to retain the rubber prophy cup firmly while the driven rotor is in operation.

Owner:PAC DENT INC

Pluggable self locking connector

InactiveUS20140235085A1Avoid reentryTighter engagementCoupling device detailsSurgical instrument detailsSelf lockingEngineering

A pluggable self locking connector includes a socket having a socket case and a plug having a plug shell and a snap fit portion coupled thereto. The socket case is formed with a depression on the inner wall. The outer wall of the snap fit portion is formed with a deformable resilient rib and a bump. The plug shell is formed with an opening for receiving the resilient rib and a resilient latch corresponding to the bump. The front end of the plug shell has a resilient positioning member. When the socket and plug mate, the resilient rib slides into the depression. When the socket and the plug separate, the resilient rib is confined within the depression and the resilient latch and the bump are engaged. The front end of the snap fit portion presses the resilient positioning member and the resilient positioning member is partially exposed.

Owner:NEXTRONICS ENG CORP

Child Resistant Dispenser

InactiveUS20090200332A1Prevent removalTighter engagementRacksDispensing apparatusEngineeringPressure release

Owner:INTINI THOMAS D

Quick coupling barrel system for firearm

ActiveUS8490312B2Quick changeImprove tightness and reliabilityBreech mechanismsBarrel mountingCouplingSpring force

A spring-loaded quick coupling barrel retaining system for a firearm. The firearm includes a receiver, a barrel nut, and barrel assembly rotatably mounted thereto. In one embodiment, the barrel assembly may include barrel locking lugs which rotatably engage and interlock with corresponding locking elements disposed on the barrel nut such a splines. The barrel assembly further includes a spring member forming a flexible interface with the barrel nut. The spring member self-tensions and tightens the lockup between the barrel assembly and barrel nut to promote a tight fit. Some embodiments may include a lock nut and a setting tool for adjusting the spring force to promote consistently proper lockup from one replacement barrel assembly to the next.

Owner:STURM RUGER & CO INC

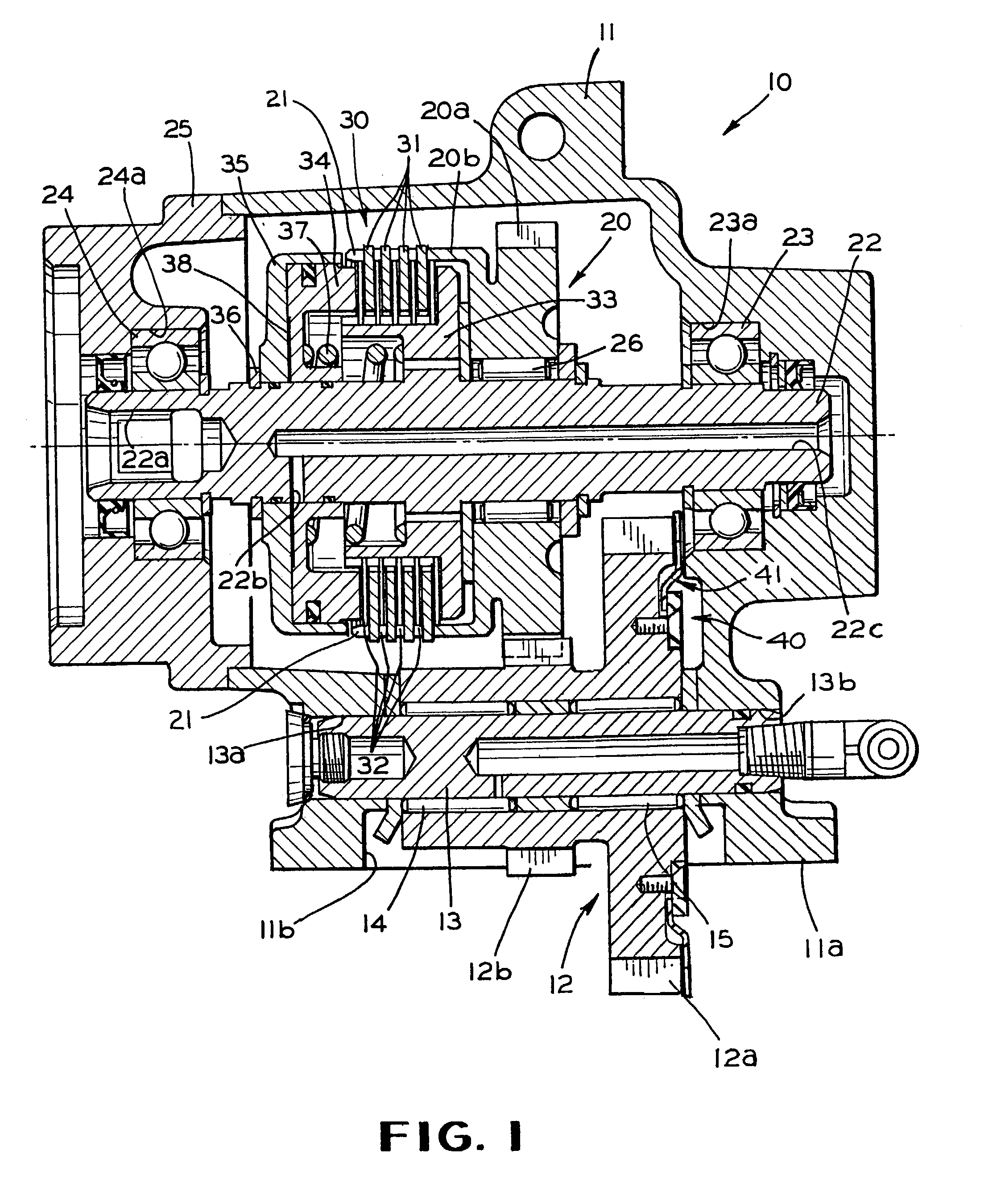

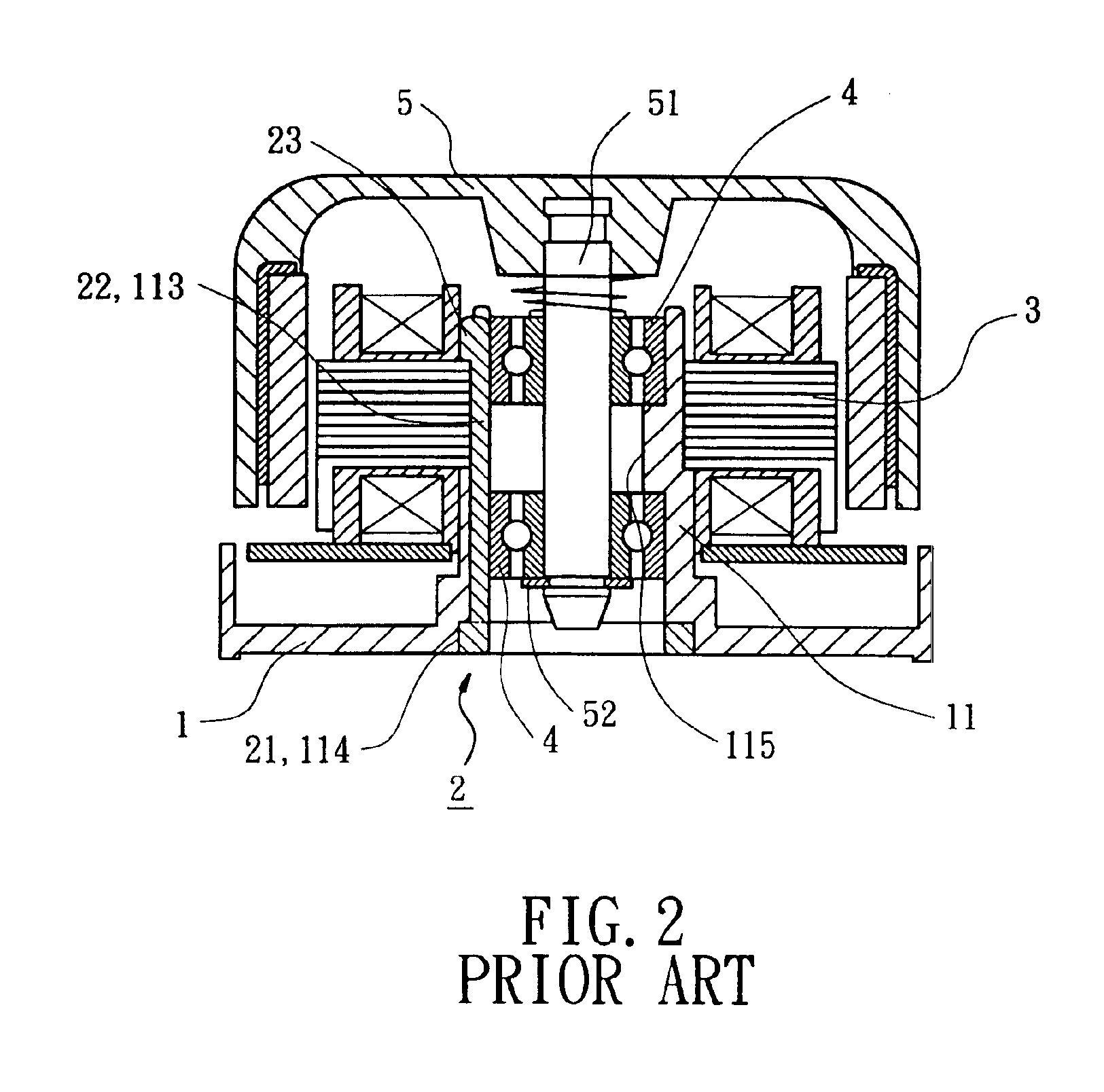

Gear assembly having noise-reduction structure and power take-off unit therewith

InactiveUS7007565B2Improved noise-reduction structureReduce the amount of noiseGear vibration/noise dampingPortable liftingNoise reductionPower take-off

A meshing gear assembly includes a toothed disk that is supported on a first gear so as to be frictionally engaged therewith, but rotationally and radially movable relative thereto. The circumferential width of each tooth formed on the toothed disk is preferably larger than the circumferential width of each tooth formed on the first gear, and the outer diameter of the toothed disk can be larger than the outer diameter of the first gear. The first gear and the toothed disk mesh with a second gear such that as the second gear rotates, the toothed disk and the first gear also rotate. However, the toothed disk and the first gear rotate at different speeds because the difference in the number of teeth formed thereon. Because the teeth formed on the toothed disk have a larger circumferential thickness and a larger outer diameter than the teeth formed on the first gear, a tight meshing engagement with the second gear is provided. This tight meshing engagement, in combination with the frictional engagement of the toothed disk with the first gear, takes up backlash between the first gear and the second gear.

Owner:PARKER INTANGIBLES LLC

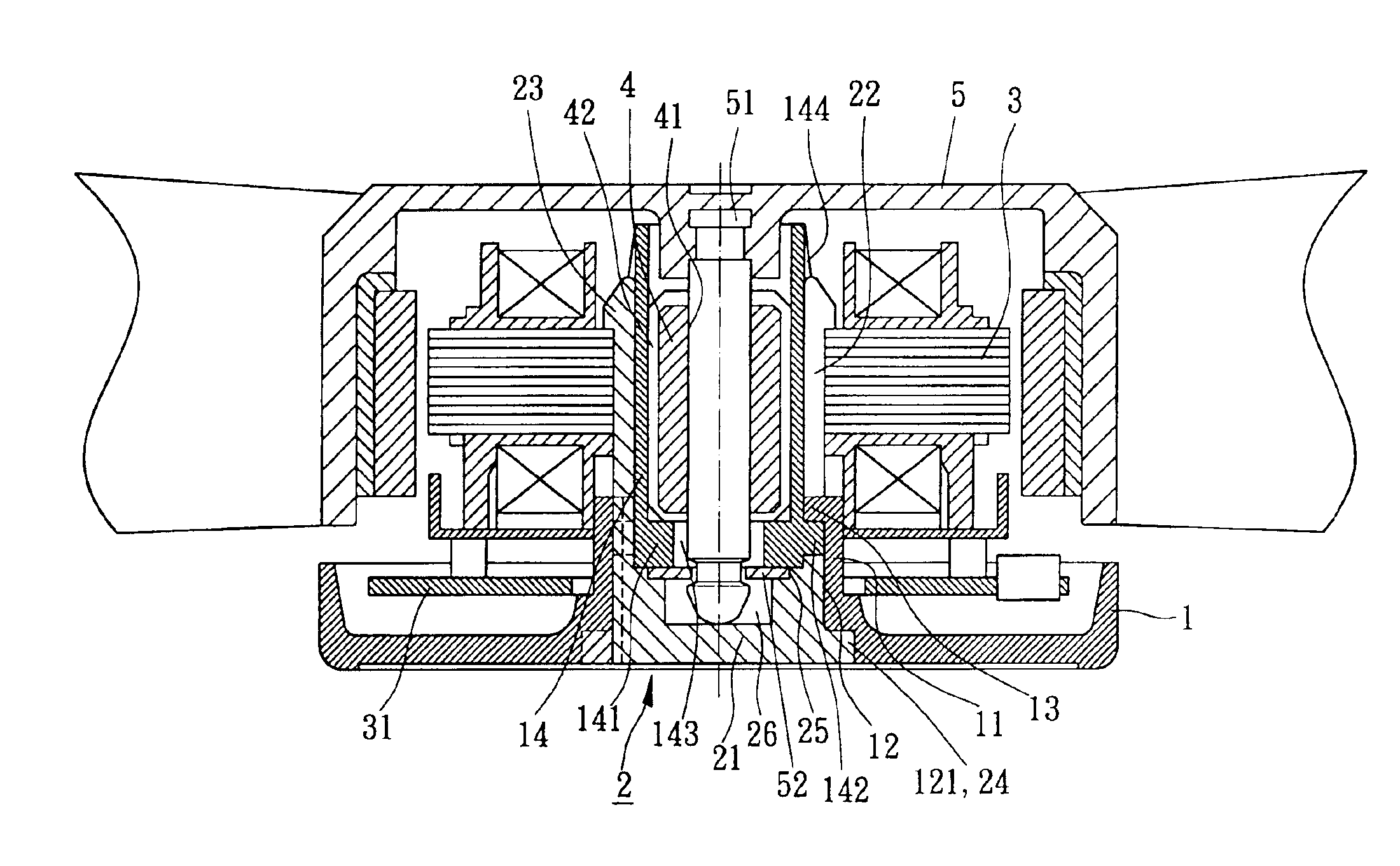

Axial tube assembly of a motor

ActiveUS6897586B2Firmly assembledImprove rotational stabilityRecord information storageMechanical energy handlingEngineeringElectric motor

An axial tube assembly of a motor includes an axial tube around which a stator assembly is mounted, an engaging member, and a sleeve in which a bearing is mounted. The engaging member includes a base and a plurality of resilient legs projecting from the base. Each resilient leg has a hook on a distal end thereof. The base of the engaging member is engaged with and thus seals a bottom end of an axial hole of the axial tube. The sleeve is mounted in the engaging member and has a base portion. The hook of each resilient leg is pressed outward to thereby retain the stator assembly in place when the sleeve and the engaging member are received in the axial tube, with the resilient legs of the engaging member together holding the sleeve to thereby allow tight engagement between the sleeve and the bearing.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Method for replacing a tacking fastener

InactiveUSRE39582E1Lower the volumeReduce the amount requiredRivetsShrinkage connectionsEngineeringBiomedical engineering

A temporary fastener that fastens two adjacent workpieces. The fastener includes a shank that extends through a hole of the workpieces. Extending from one end of the shank is a conical shaped head. The fastener also contains a pull stem which has a head located adjacent to the blind end of the shank. The stem head is pulled through the shank to expand and tightly fasten the shank to the workpieces. The fastener is removed by drilling through the head and the shank. The diameter of the conical shank head is smaller than the diameter of the drill so that part of the head does not become attached to the drill bit and scratch the workpiece. The conical shape of the head also reduces the volume of fastener material to further reduce the size and amount of chips produced during the drilling process. The tightly engaged shank prevents the fastener from rotating during the drilling operation.A method of replacing a tacking fastener that temporarily joins two adjacent workpieces with a permanent fastener to permanently join the workpieces. A drill bit is engaged with an inner channel of the temporary fastener at a head of the fastener. The drill bit has a diameter larger than the head diameter. The head, the shank, the first workpiece, and the second workpiece are drilled through to form a hole through the workpieces. The first workpiece and the second workpiece are joined with a permanent fastener through the hole.

Owner:ALLFAST FASTENING SYST

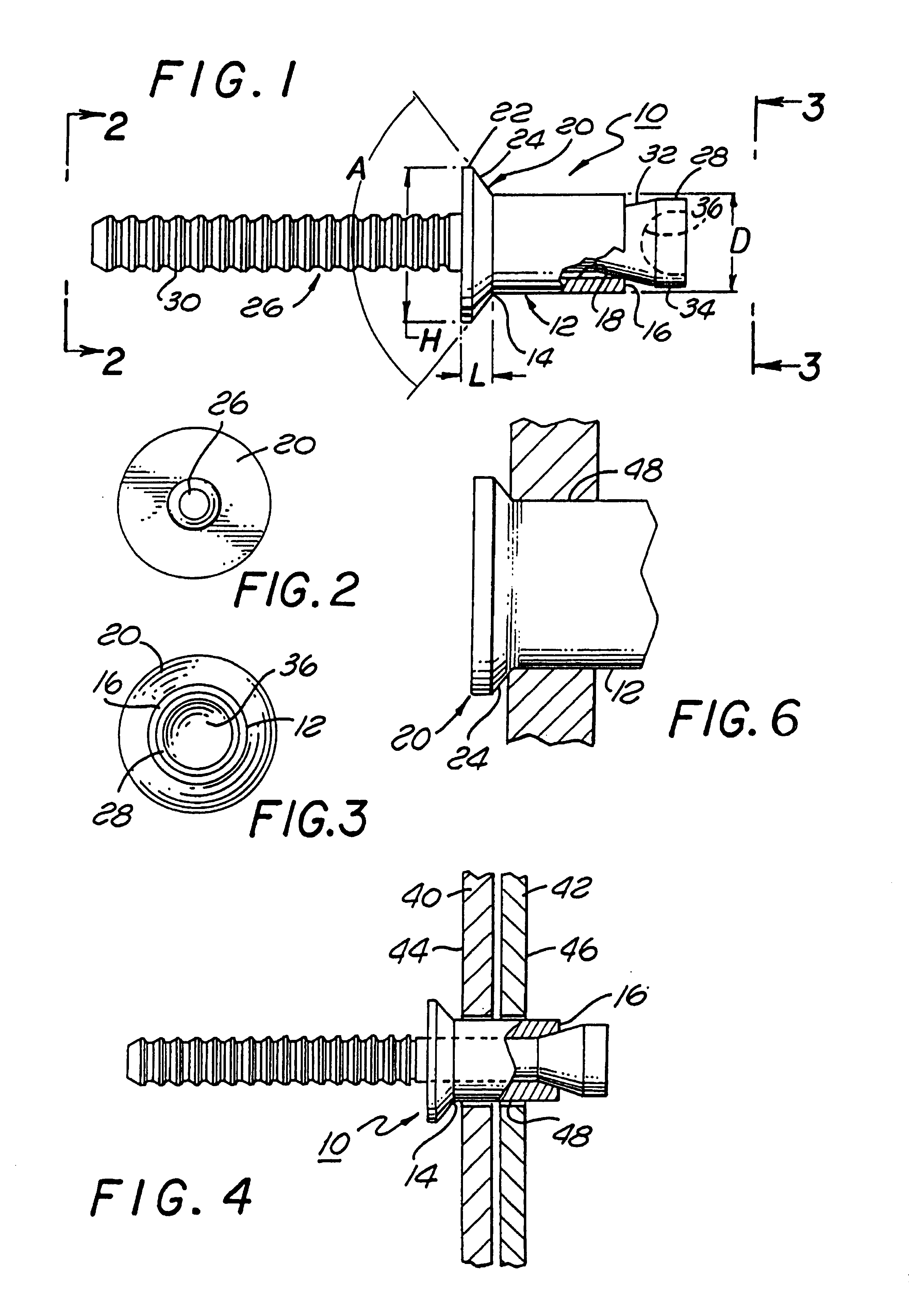

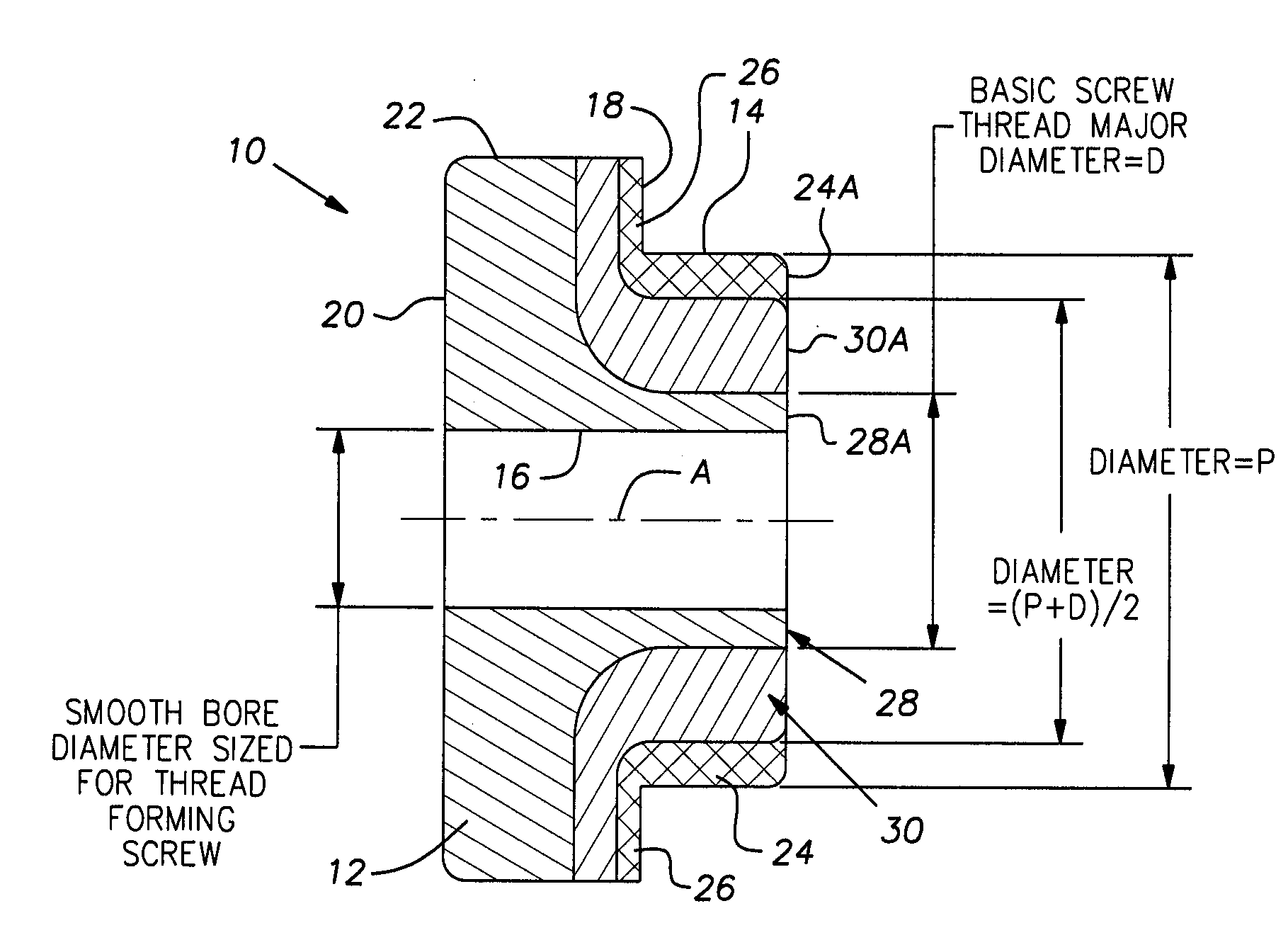

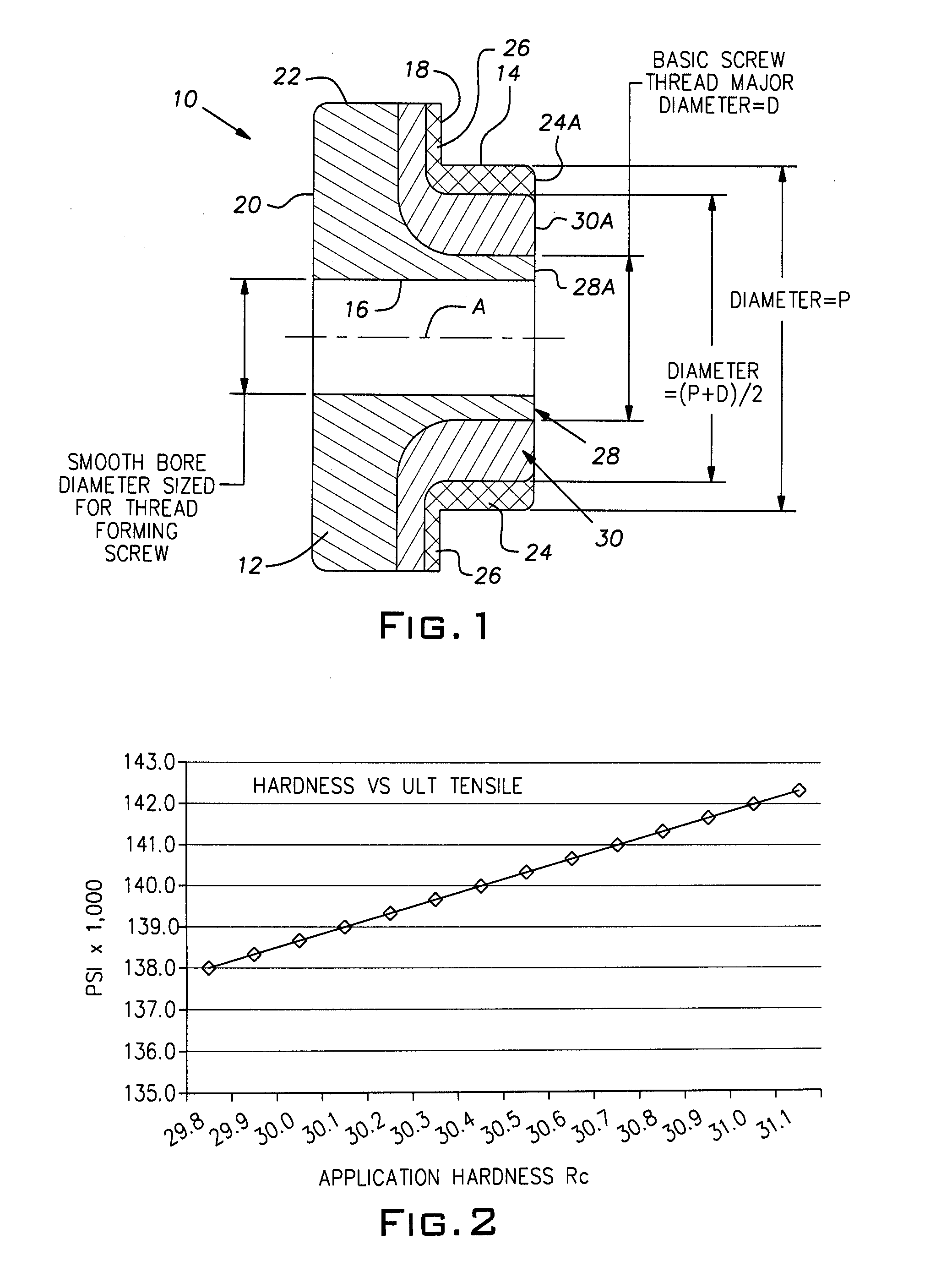

Clinch nut

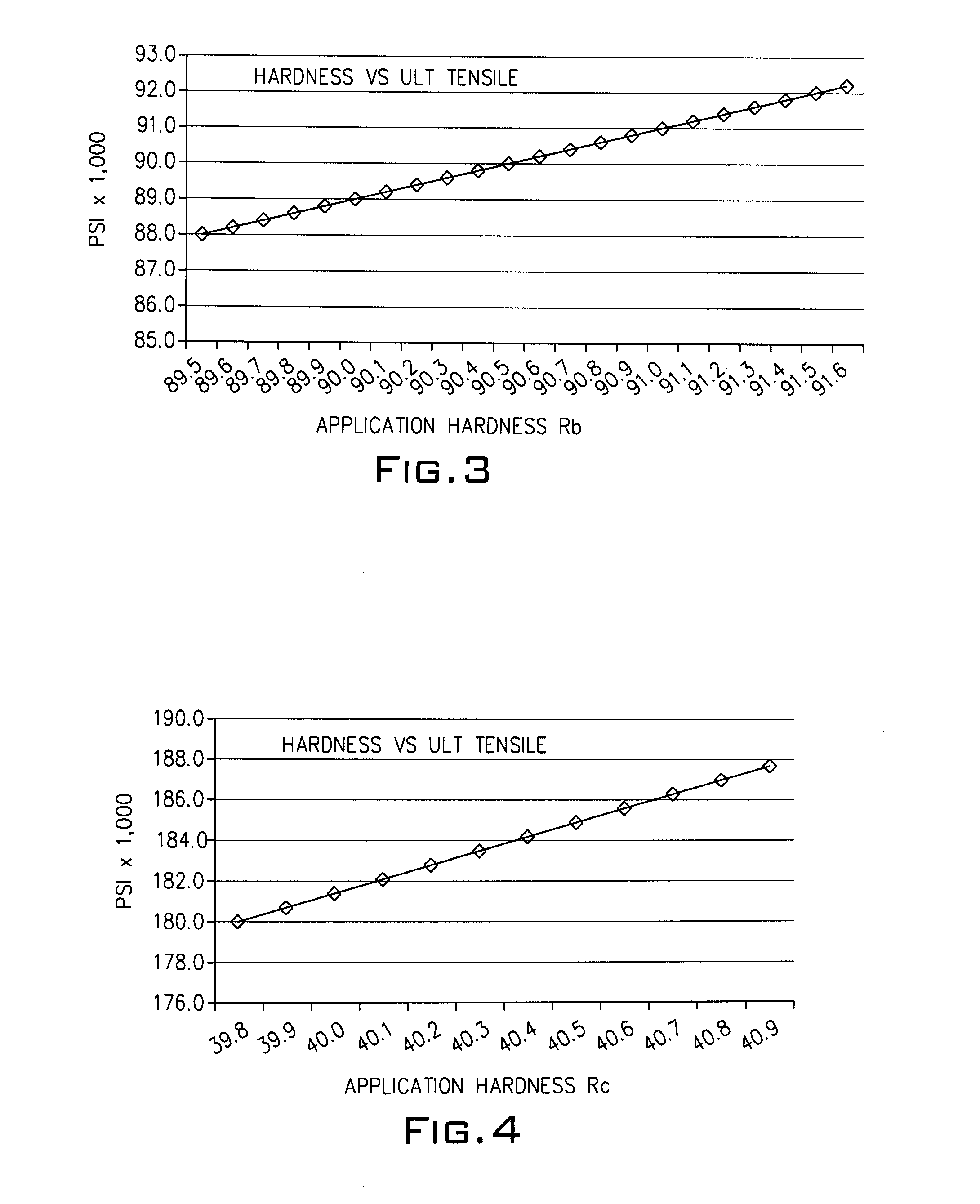

A metal clinch fastener has portions thereof selectively hardened to enable use of the fastener with metal members of differing hardness values. The selective hardening of the fastener enables mounting with application of required forces for piercing and / or plastic deformation of the metal member without undesirable deformation or distortion of the fastener. The screw thread region or zone of the fastener has a relatively lesser hardness suitable and may be pre-threaded or later threaded by engagement with a thread forming screw.

Owner:R B & W MFG

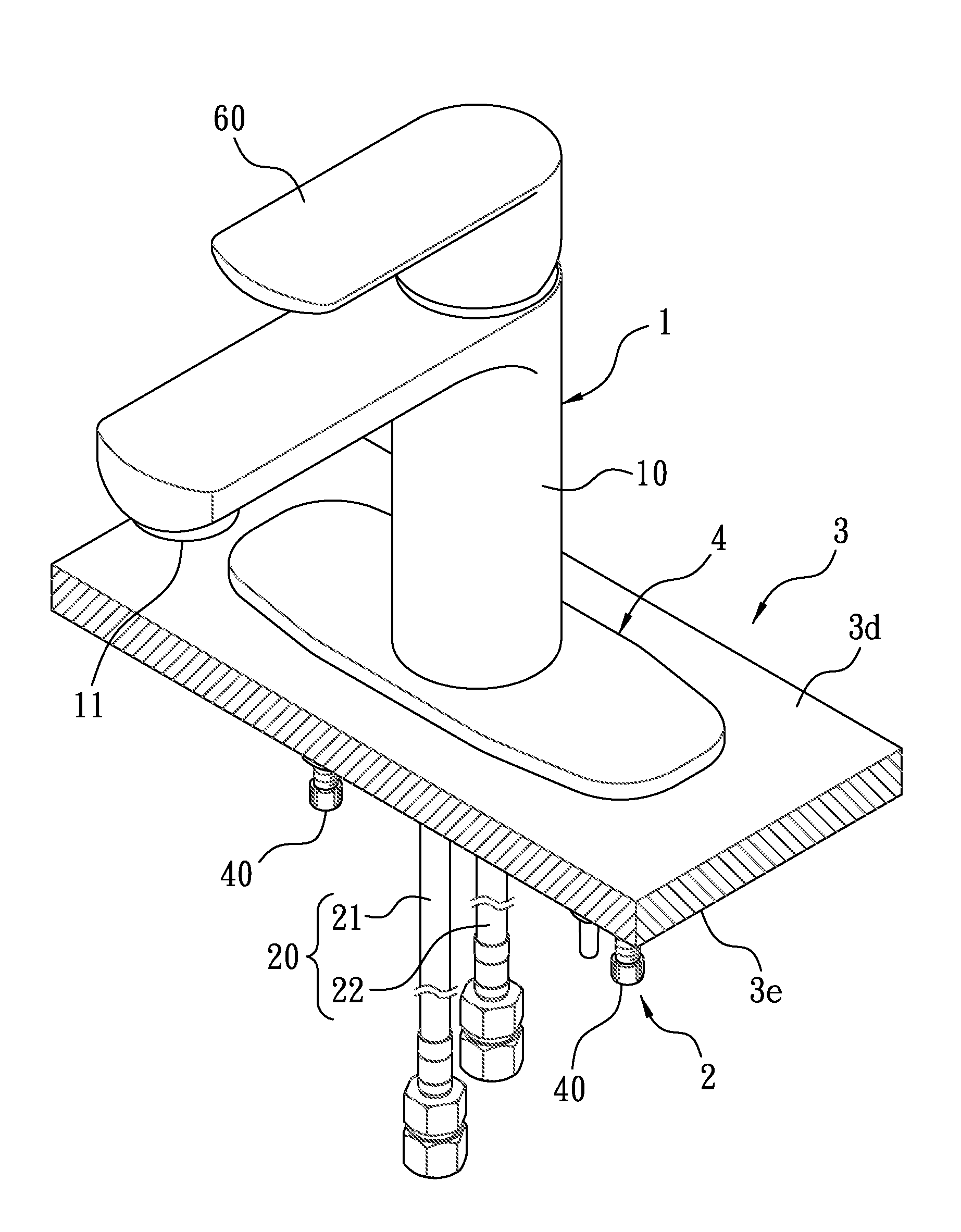

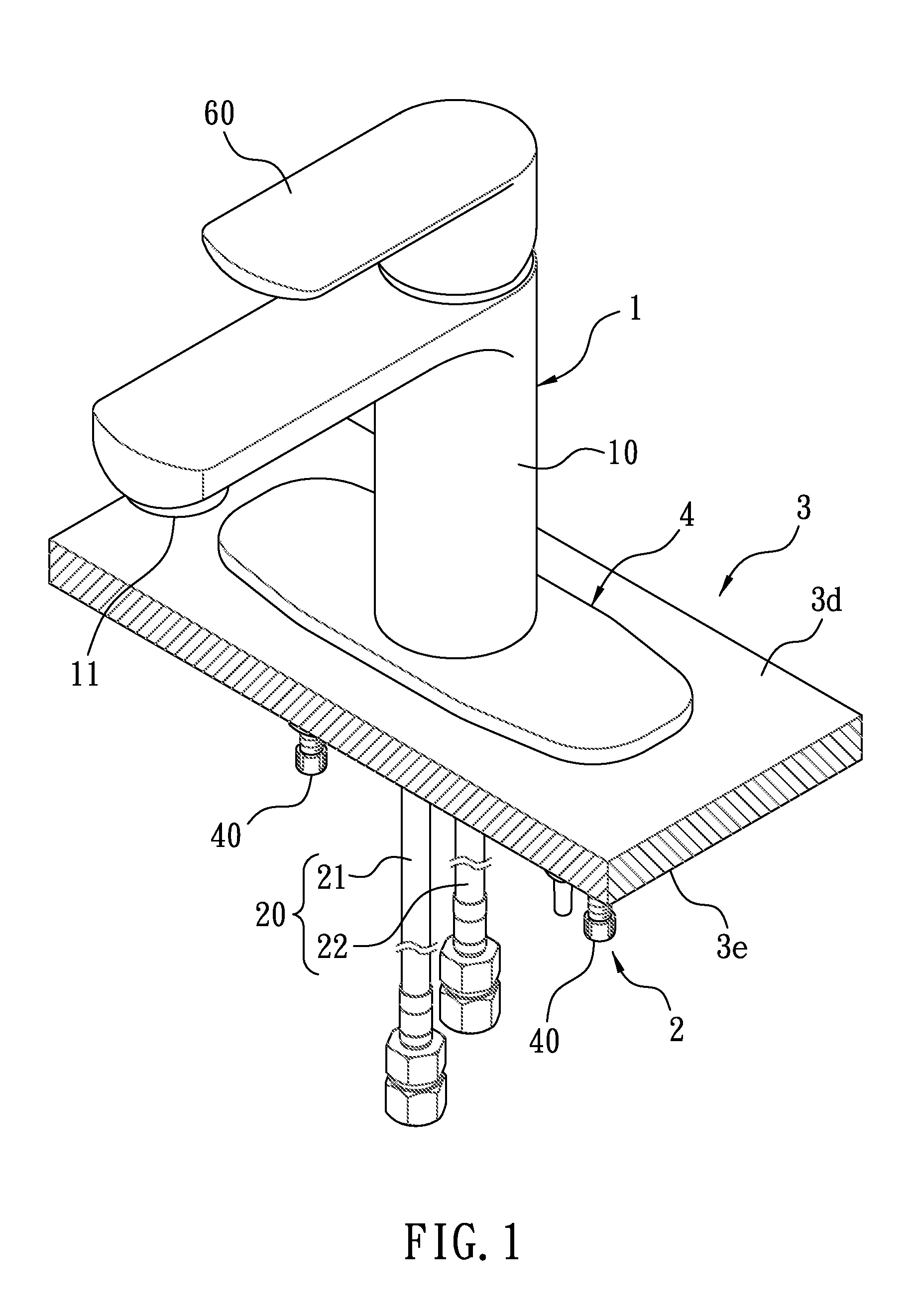

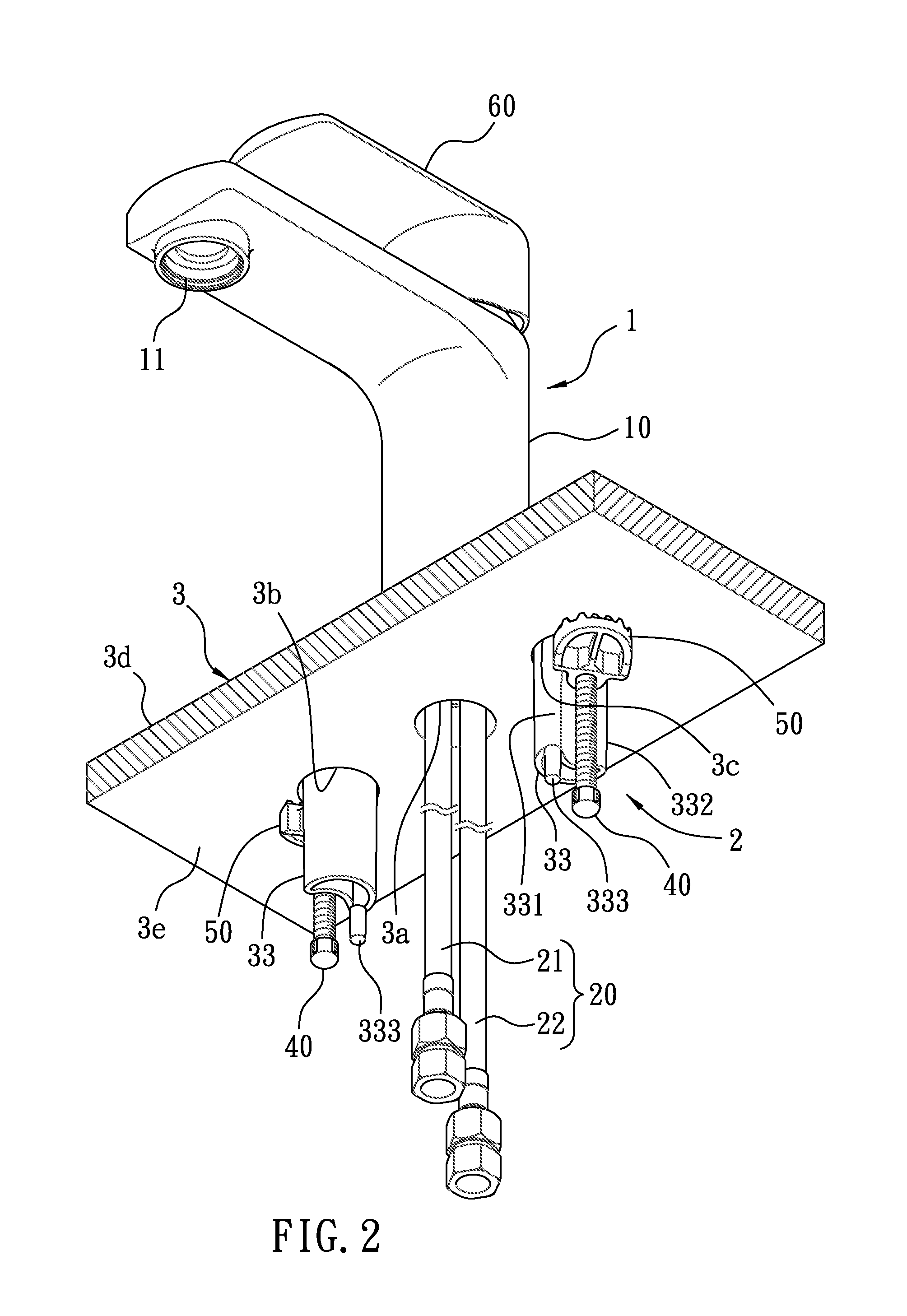

Lavatory faucet

InactiveUS20160024762A1Large caliberThe process is convenient and fastWash-standsDomestic plumbingEngineeringMechanical engineering

A lavatory faucet is fixed on a basin and contains: a body and a fixing device. The body includes a housing and a supply pipe assembly; the fixing device includes a mounting seat, two screw rods, and two clamping blocks; the basin includes a central orifice, a left orifice, and a right orifice. The mounting seat includes an upper fitting sleeve, two extending wings for abutting against a top face of the basin, and two support feet. The upper fitting sleeve has a channel defined therein relative to the central orifice, each extending wing has a through hole to insert each support foot, and each support foot has a first stopping fence. Each screw rod extends out of the through hole and is rotated above the mounting seat, each clamping block is screwed with each screw rod and is limited by the first stopping fence as rotating each screw rod.

Owner:GLOBE UNION INDAL

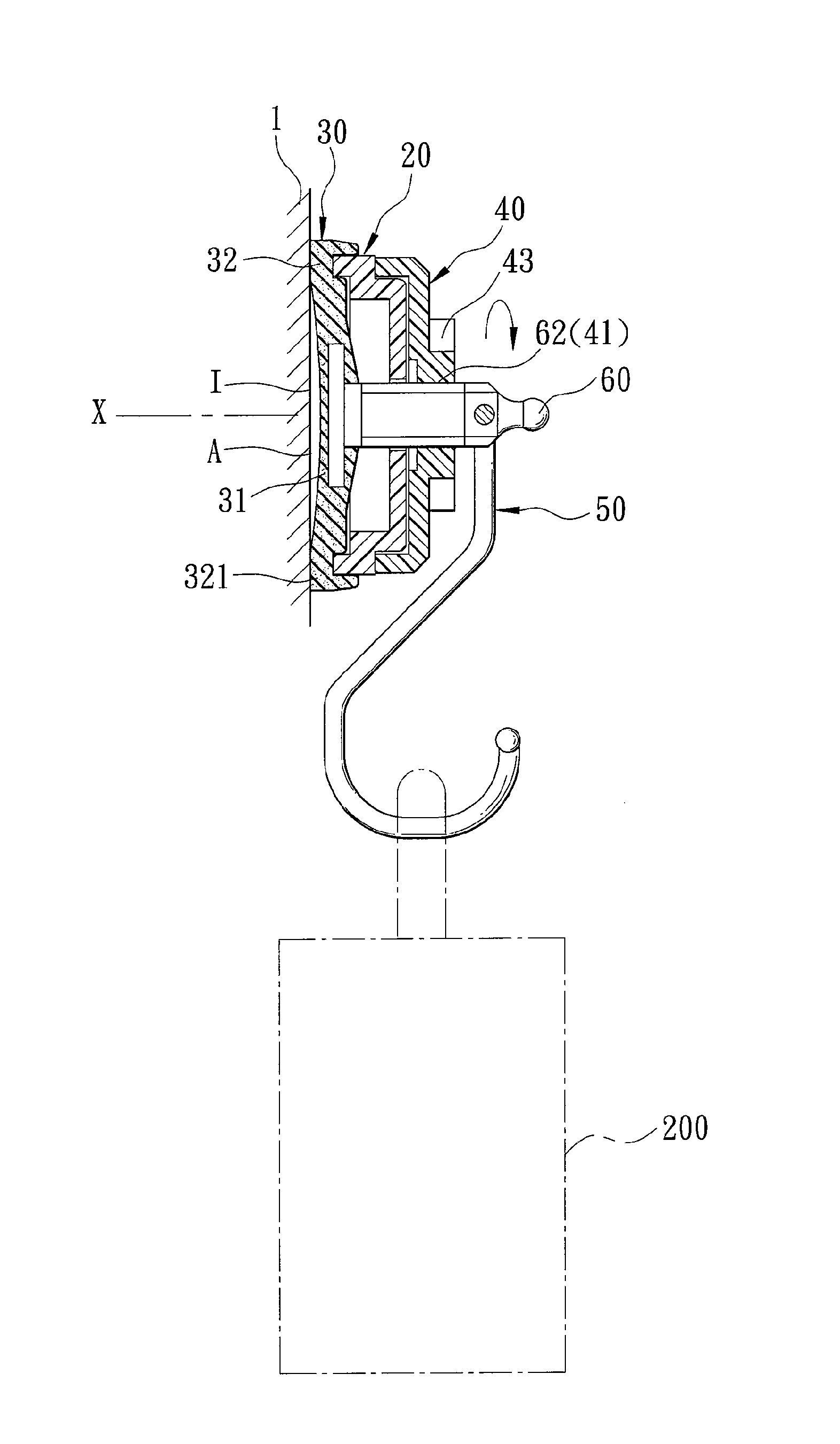

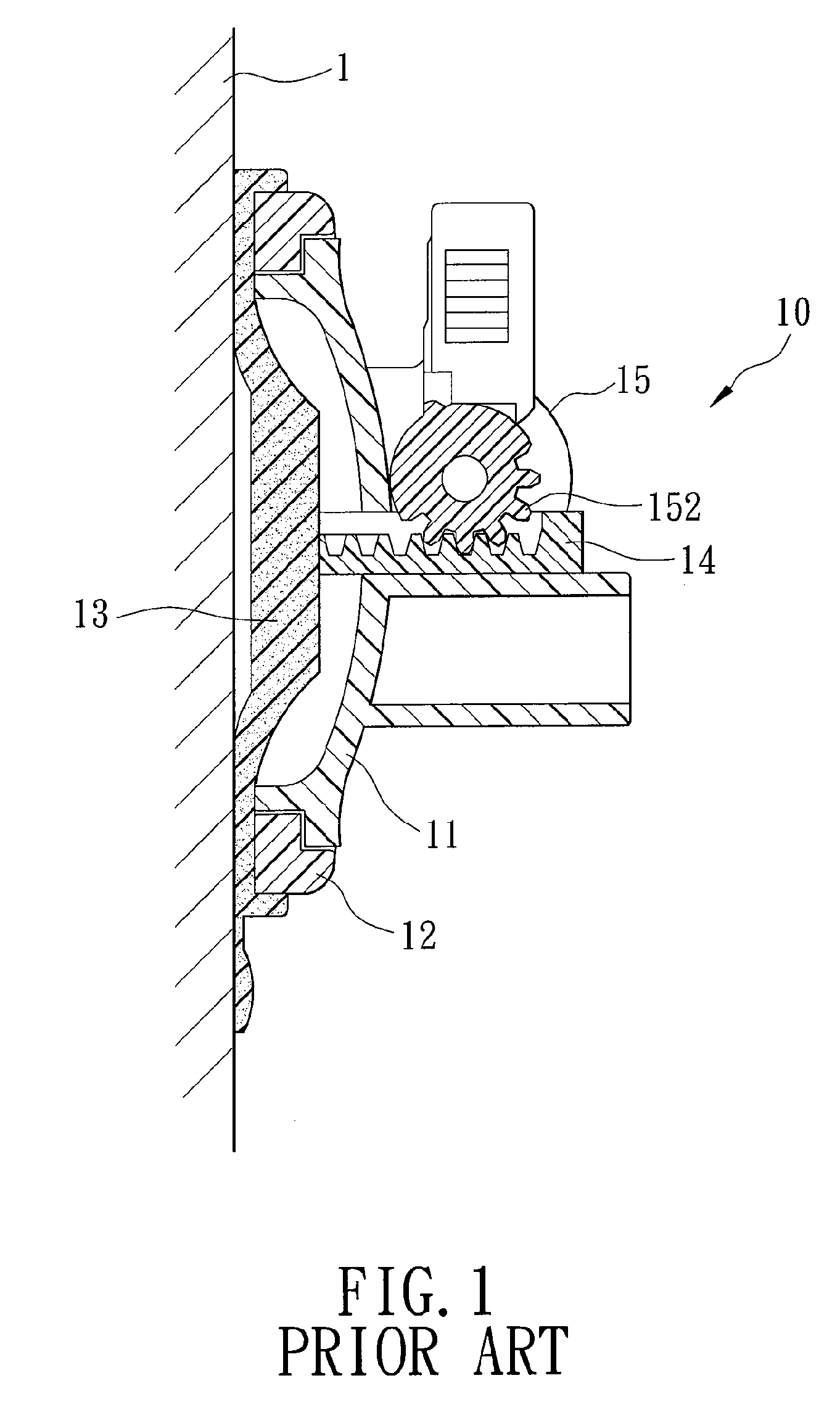

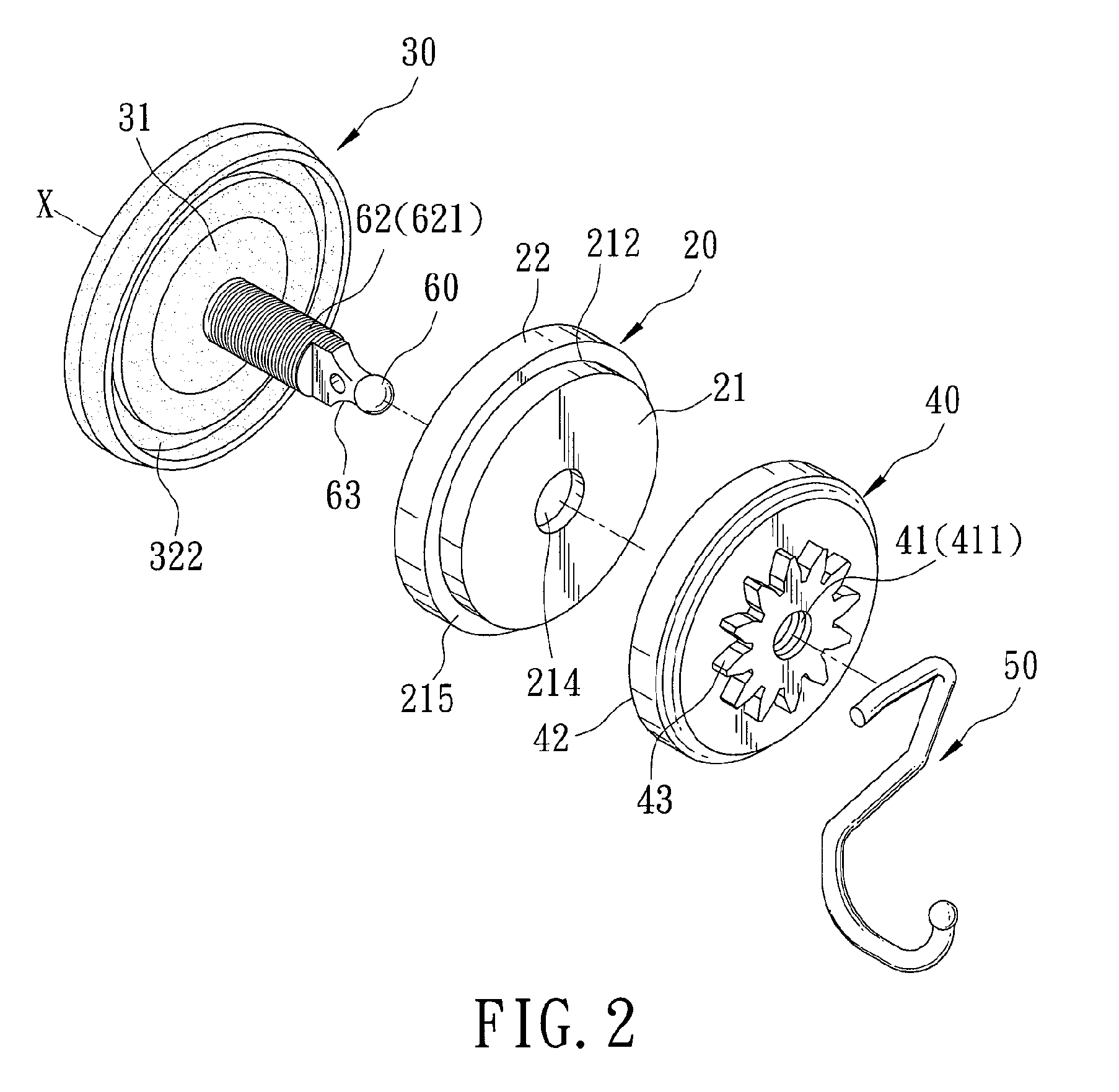

Suction cup device

InactiveUS8079557B2Reduce pressureTight with flat surfaceStands/trestlesKitchen equipmentTwisting movementsEngineering

A suction cup device includes a cup forming unit cooperating with a flat surface to create a volume-variable space, a liftable rod secured to a central portion of the cup forming unit, a bracing shell member having a force-transmitting surrounding wall in engagement with a peripheral portion of the cup forming unit, and a twistable cap member having a surrounding bottom wall in abutting against a circumferential abutment region of the bracing shell member and threadedly engaged with the liftable rod such that a manually twisted movement of the twistable cap member can result in axial movement of the rod so as to pull the central portion away from the flat surface to produce a reduced pressure in the volume-variable space and a biasing force to thereby ensuring fluid-tight engagement of the cup forming unit with the flat surface.

Owner:TU TSUNG TZONG +1

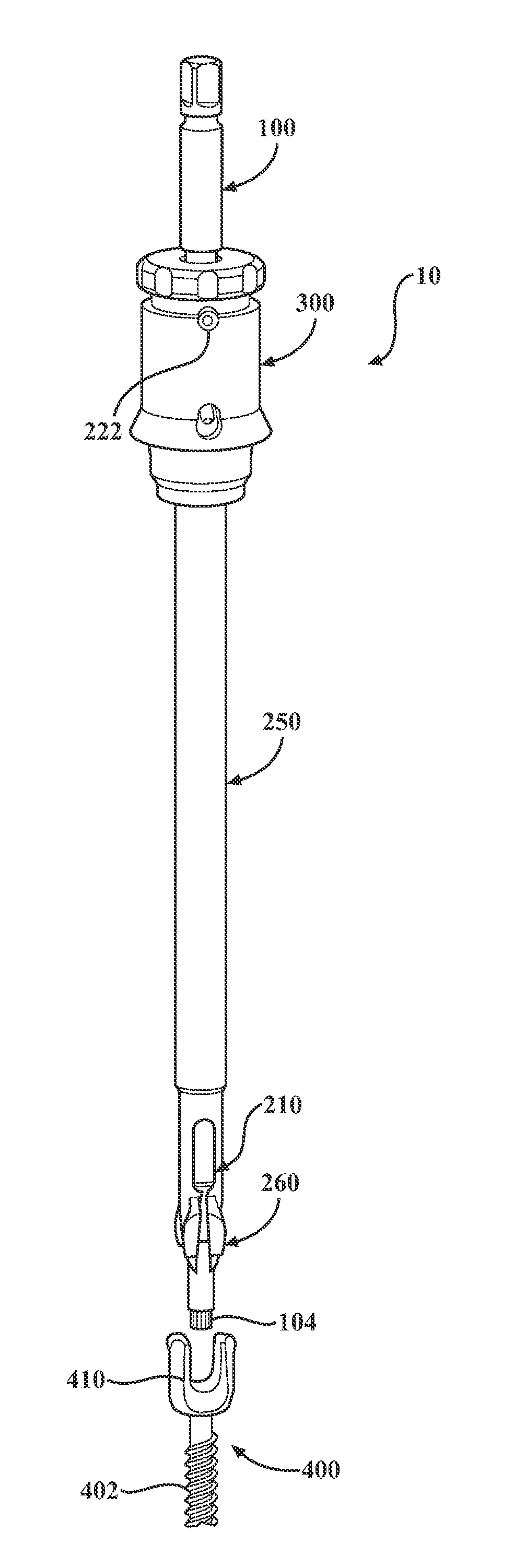

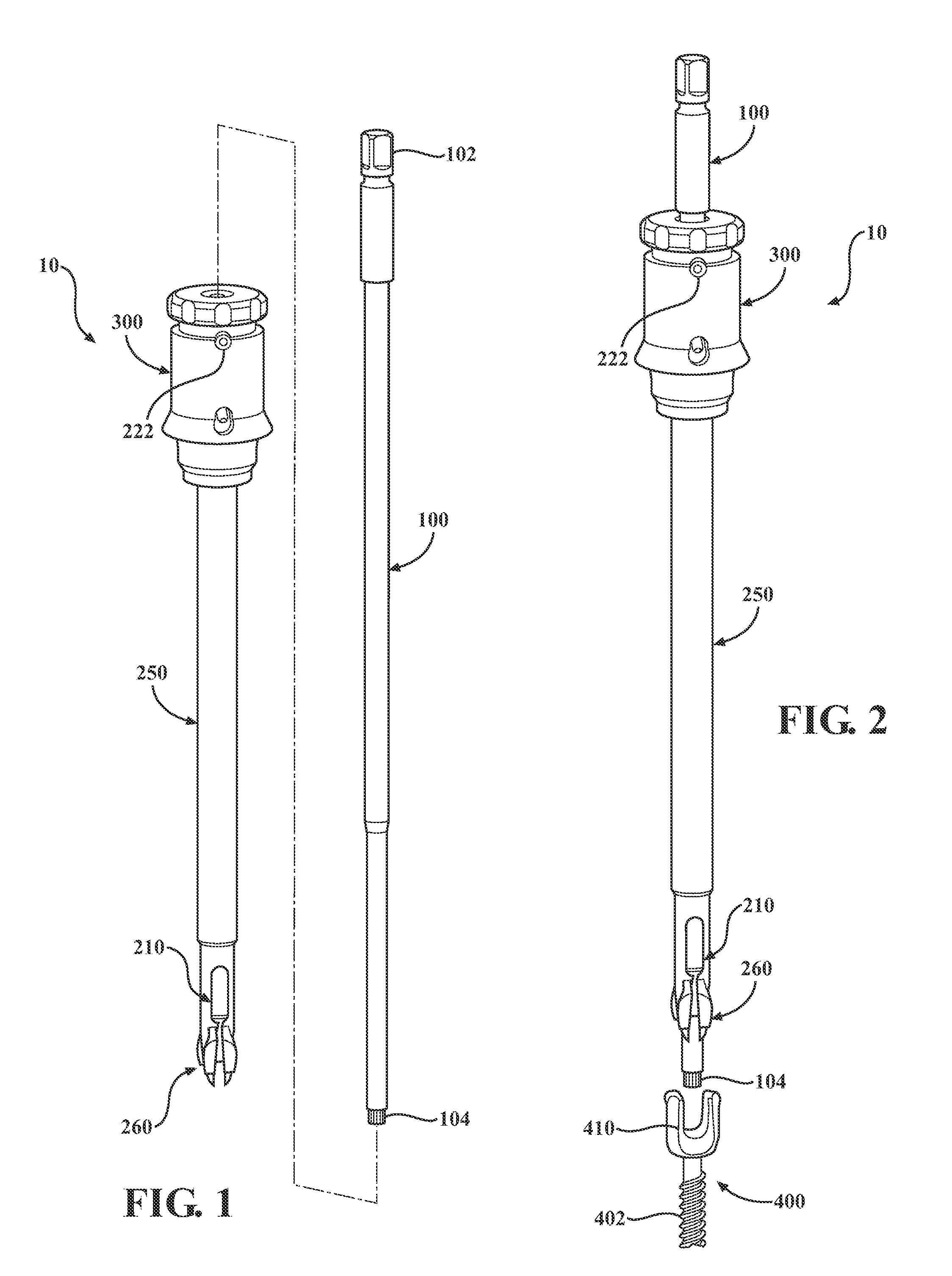

Single action locking pedicle screwdriver

ActiveUS20150359572A1Tighter engagementEliminate slackInternal osteosythesisProsthesisFixed positionLocking mechanism

Owner:ALPHATEC SPINE INC

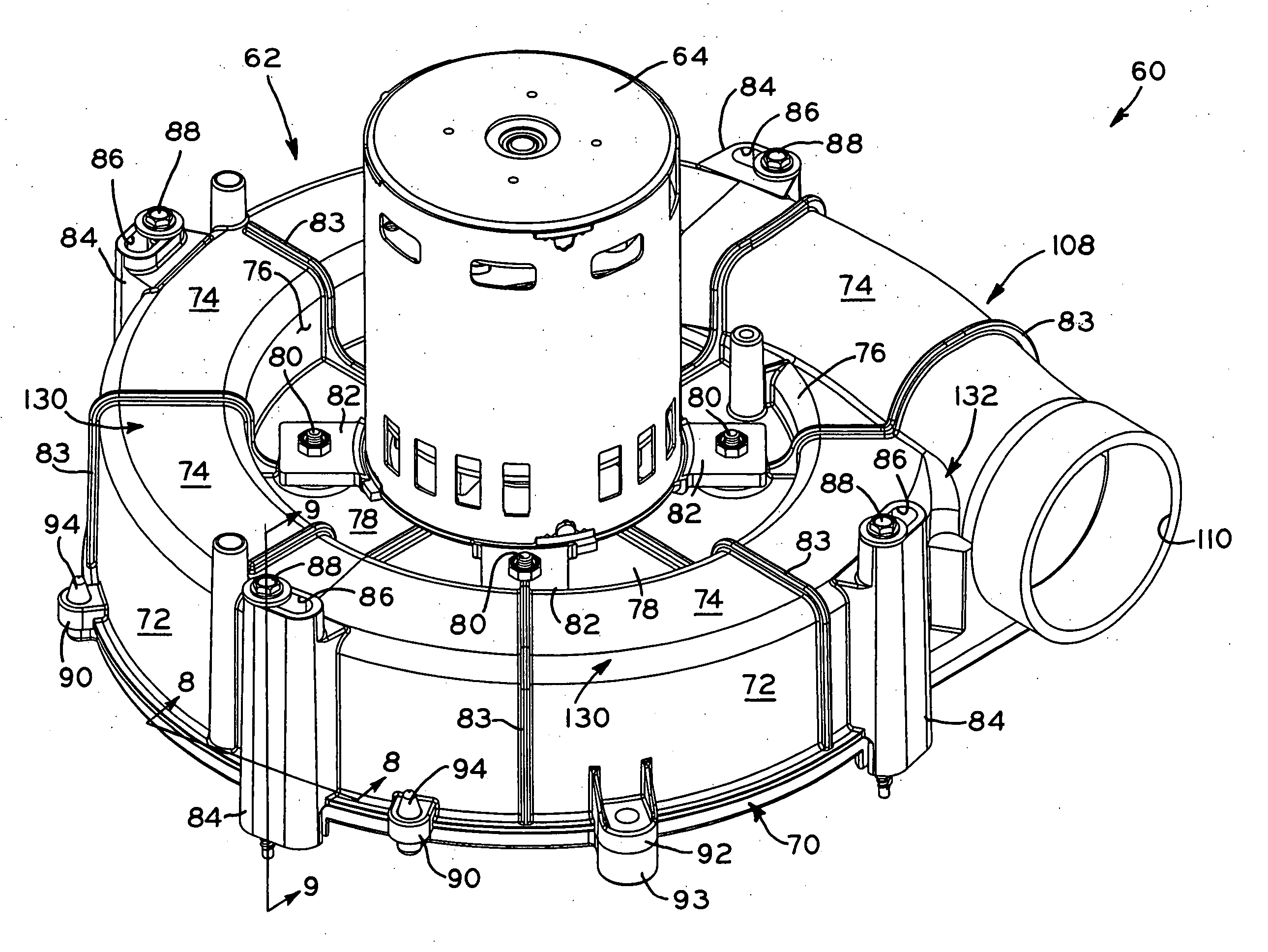

Lobed joint draft inducer blower

InactiveUS20060051204A1Facilitates maximum air flow efficiencyReduce airflow noisePump componentsStatorsEngineeringInducer

A draft inducer blower housing for high efficiency furnaces, including a housing body and housing cover which define an exhaust transition therebetween, which transitions the air flow from the circular main cavity of the blower housing to the blower housing outlet. A cutoff portion of the blower housing is formed as an insert member or third housing component, which is located within a recess defined within the housing body proximate the outlet. The cutoff insert member may be attached to the housing body and captured between the housing body and housing cover, and includes a broadly radiused cutoff portion defining the exhaust cutoff of the blower housing. The housing body includes reduced-height mounting lugs, and indentations provided in the outer wall of the housing body above each mounting lug. The reduced height mounting lugs reduce the amount of material needed to form the housing body, and allow the use of shorter fasteners to secure the blower housing to the wall of a furnace. The indentations in the outer wall of the blower housing facilitate easier access to the openings of the mounting lugs during installation of the fasteners.

Owner:FASCO IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com