Grommet

a technology of grommets and spherical plates, which is applied in the direction of insulating bodies, multi-purpose tools, basic electric elements, etc., can solve the problems of reducing the insertion resistance of grommets during installation, and achieve the effect of less complicated processing and shorter processing tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

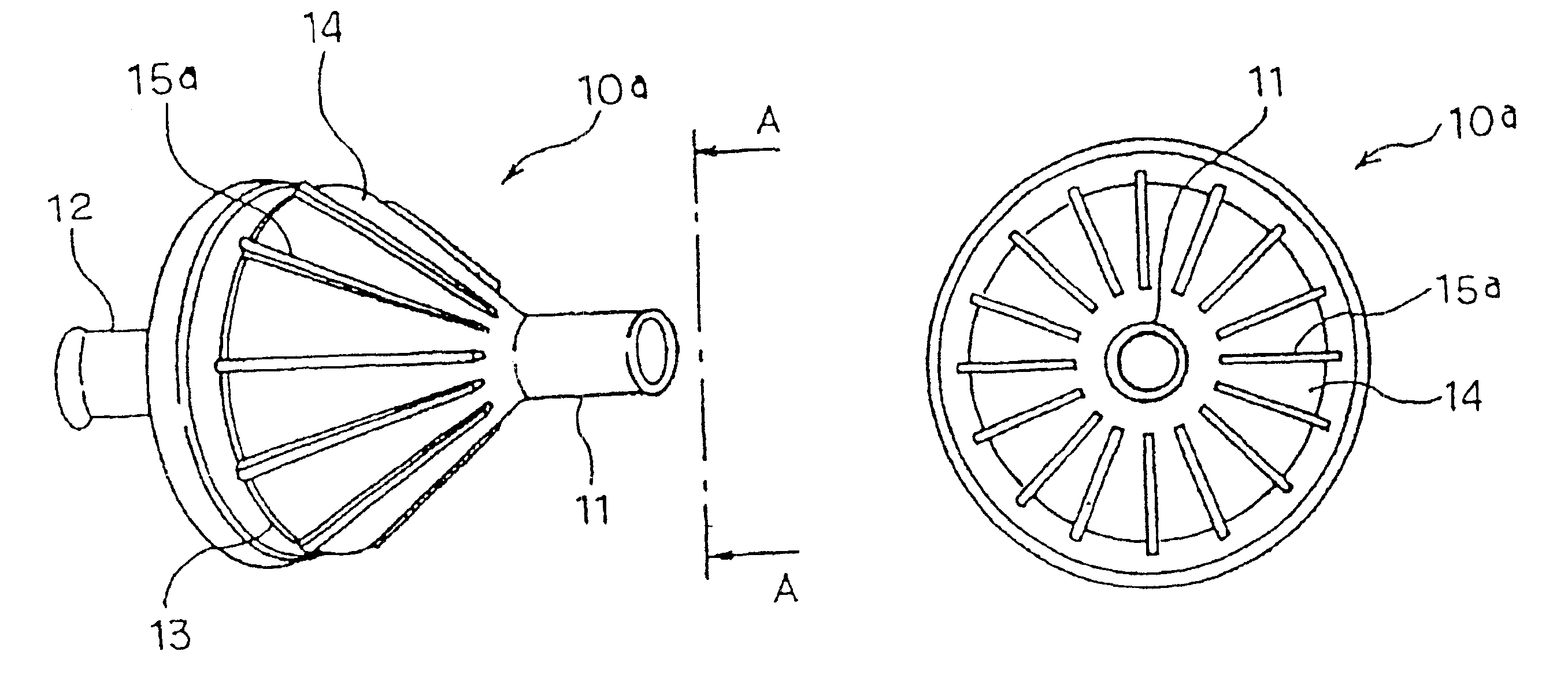

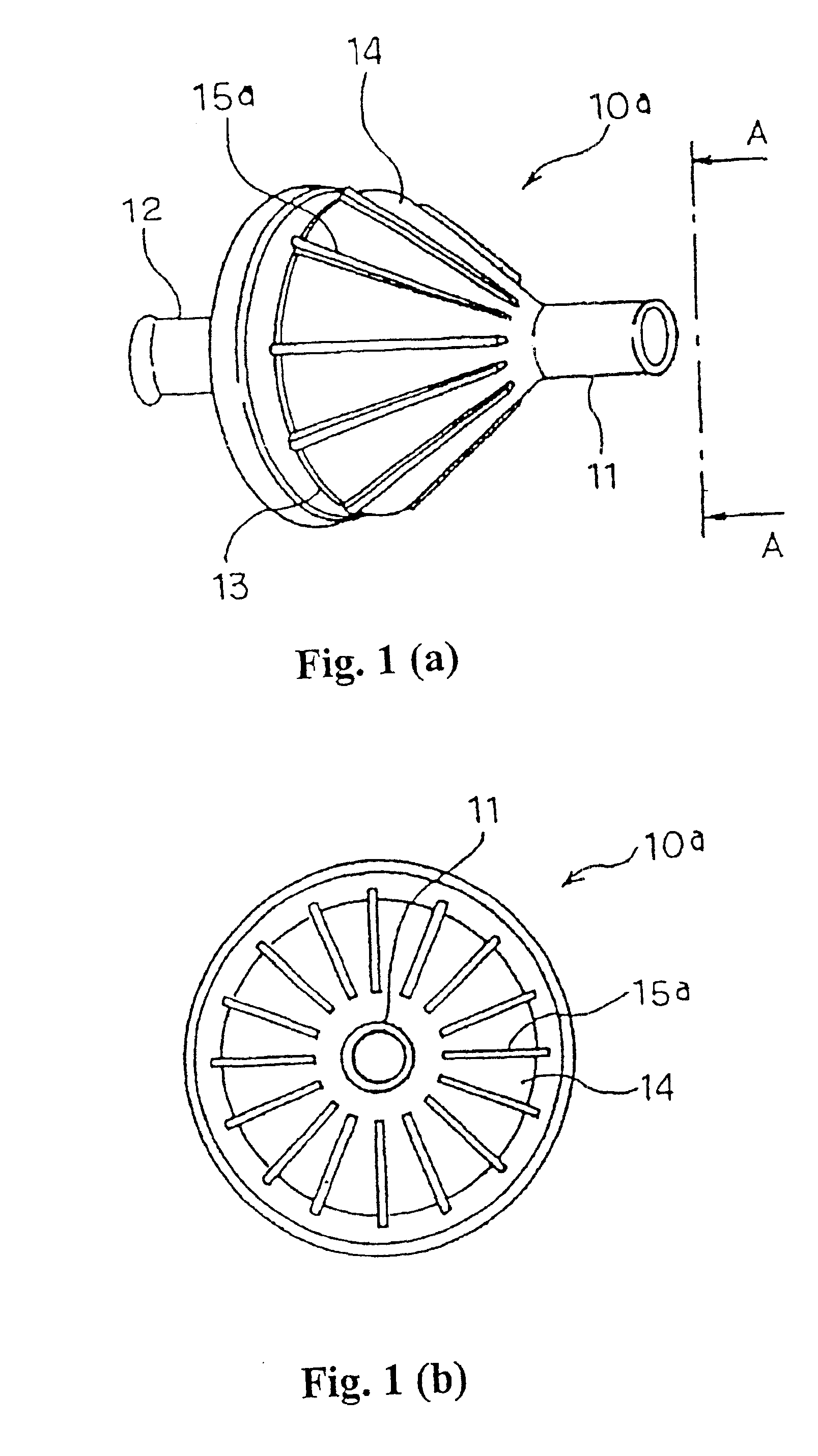

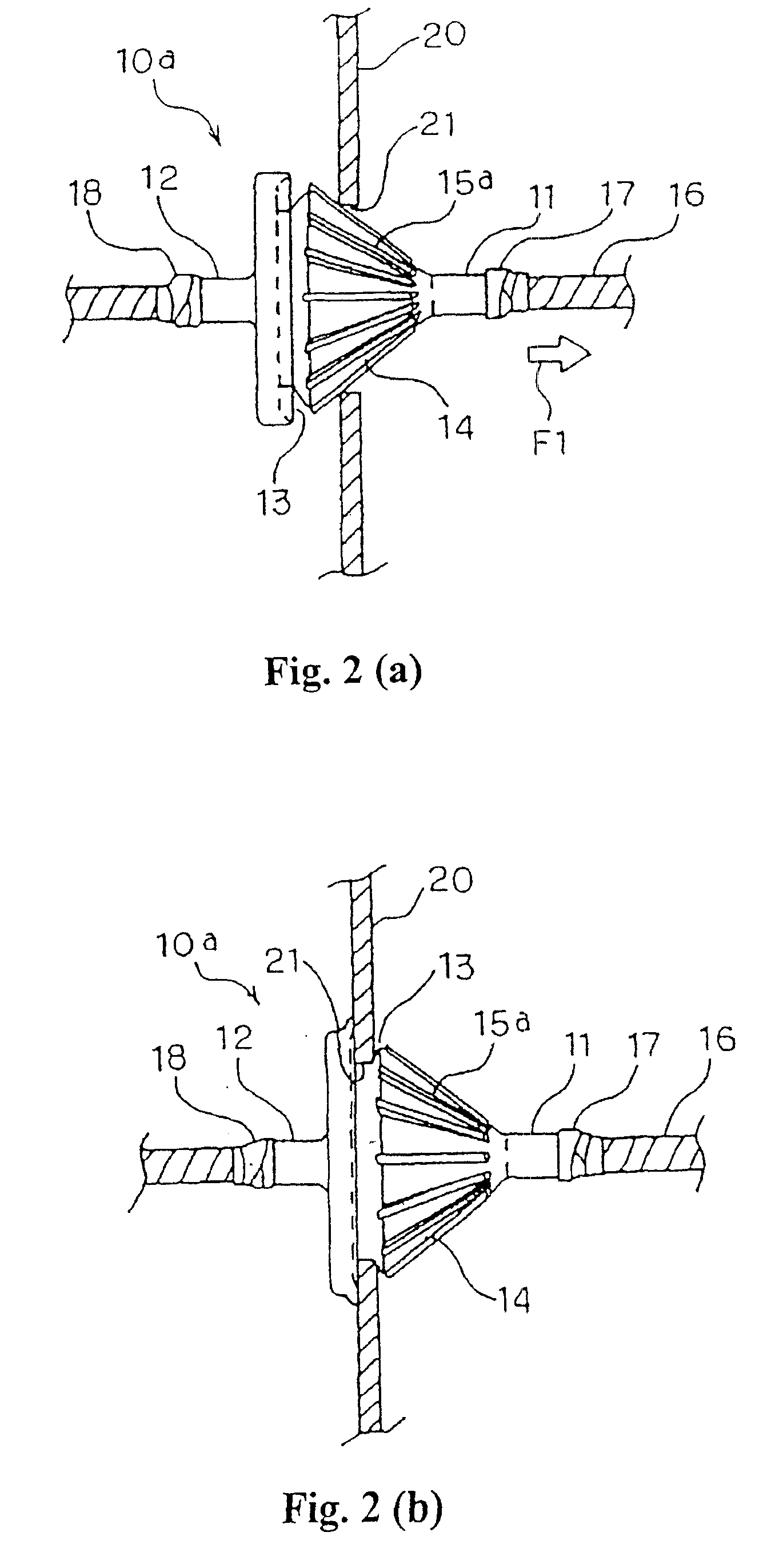

[0029]the grommet of the present invention will now be described with regard to the present invention in reference to FIGS. 1(a) and 1(b). As shown in FIG. 1(a) and FIG. 1(b), a grommet 10a includes wire harness holding areas 11 and 12 which tightly engage and hold the outer periphery of a wire harness. An engagement area 13 is provided to fixedly engage with an installation opening provided in a vehicle panel. A tapered area 14 having a near-conical tapered shape over a full periphery thereof extends between the wire harness holding area 11 and the engagement area 13, and plurality of spaced linear convex areas 15a are provided to extend from an engagement area 13 side toward a wire harness holding area side over the entire periphery of the tapered area 14, that is, in an inserted direction of the grommet.

[0030]The linear convex surfaces 15a are integrally formed with the grommet from the same material as that of the grommet, which is achieved by utilizing a machining process to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com