Energy-saving and efficient ash removal device of waste heat boiler

A waste heat boiler and ash cleaning device technology, which is applied to cleaning heat transfer devices, boiler water pipes, lighting and heating equipment, etc., can solve the problems of increasing labor intensity of workers, low ash cleaning efficiency, and long time period for boiler shutdown and ash cleaning , to achieve the effect of improving dust cleaning efficiency, reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

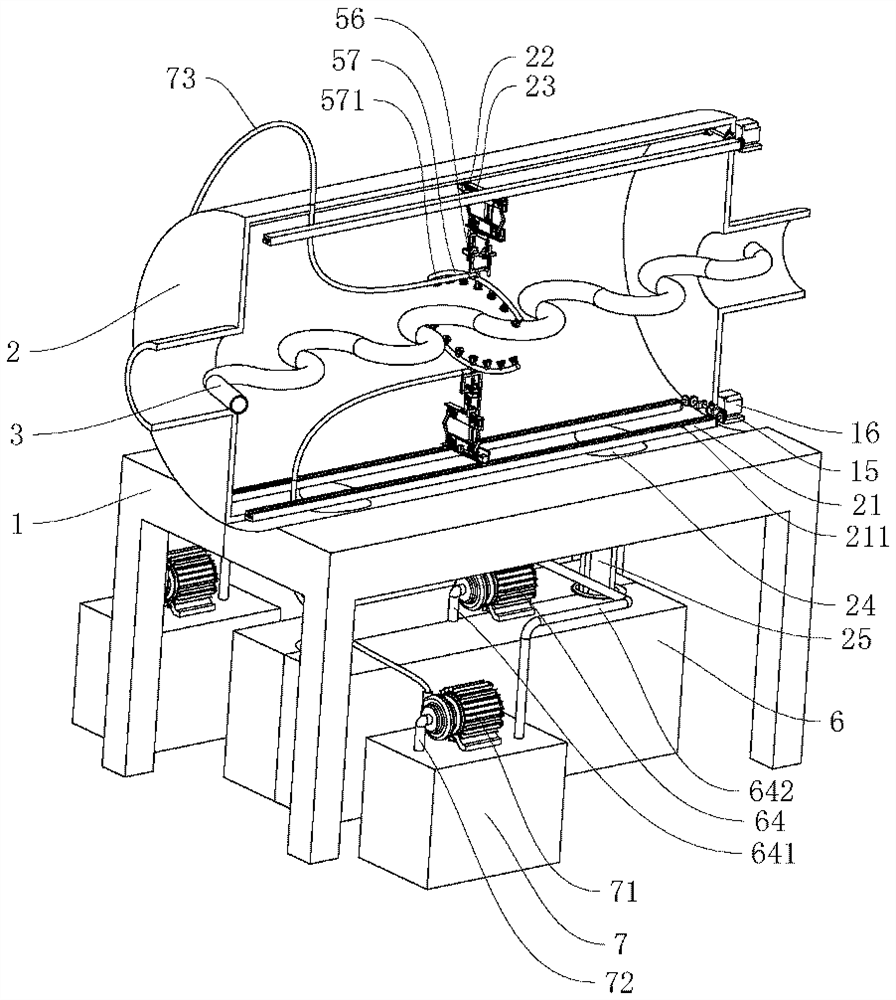

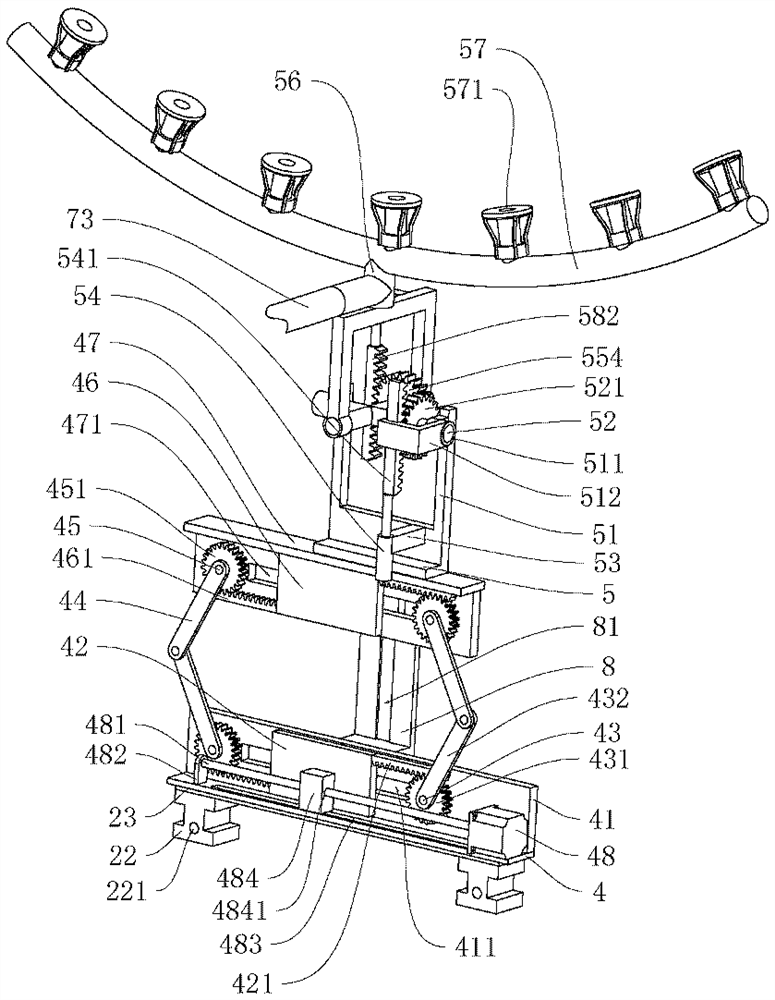

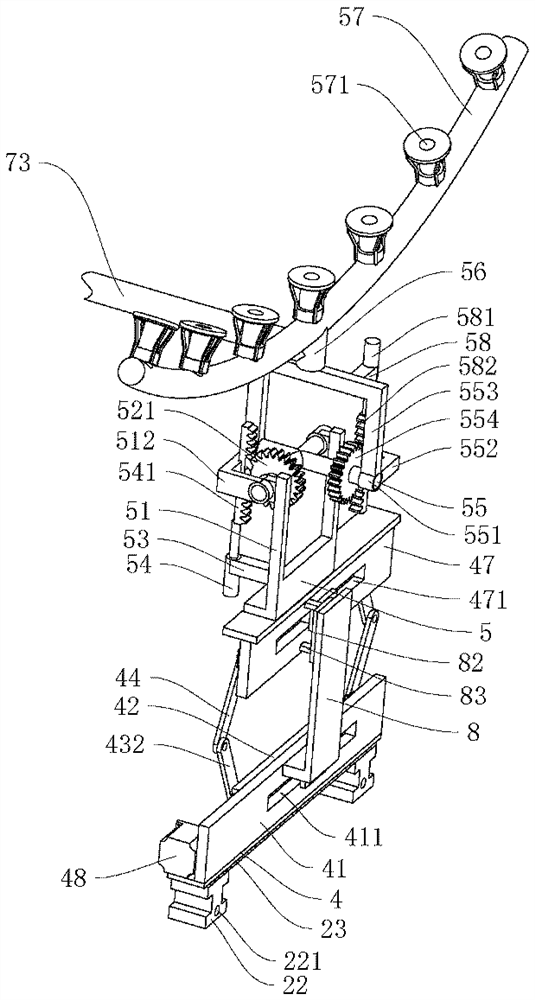

[0039] The following is attached Figure 1-7 The application is described in further detail.

[0040] The embodiment of the present application discloses an energy-saving and high-efficiency waste heat boiler dust cleaning device. refer to figure 1 The soot cleaning device includes a bottom frame 1, on which a boiler body 2 of horizontal structure is fixedly installed, and a plurality of water pipes 3 are installed in the boiler body 2, and these water pipes 3 all flow pure water to be heated. Water, when the pure water in the water pipe 3 needs to be heated, the high-temperature waste gas in the industrial production process is discharged into the boiler body 2, and the waste heat generated by the high-temperature waste gas effectively heats the pure water in the water pipe 3 .

[0041] The high-temperature exhaust gas is mixed with a large amount of dust and other impurities, and these dust and other impurities will adhere to the heating surface of the water pipe 3. In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com