Coal firing boiler with N-shaped fire tubes

A technology for coal-fired boilers and fire tubes, applied in the field of coal-fired boilers, can solve the problems of complex manufacturing process, difficult maintenance, large furnace body, etc., and achieve the effect of good application effect, low production cost and small furnace body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

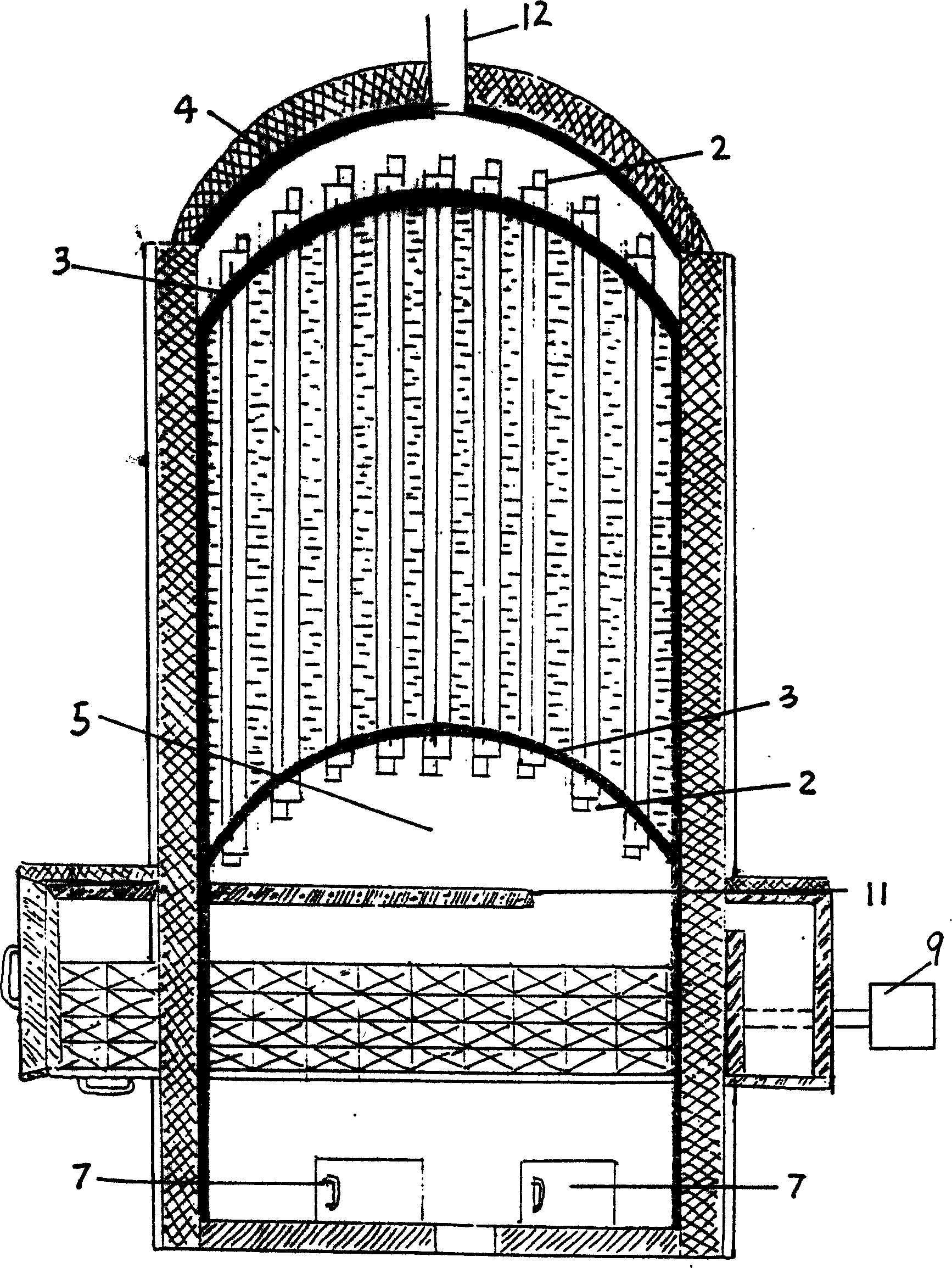

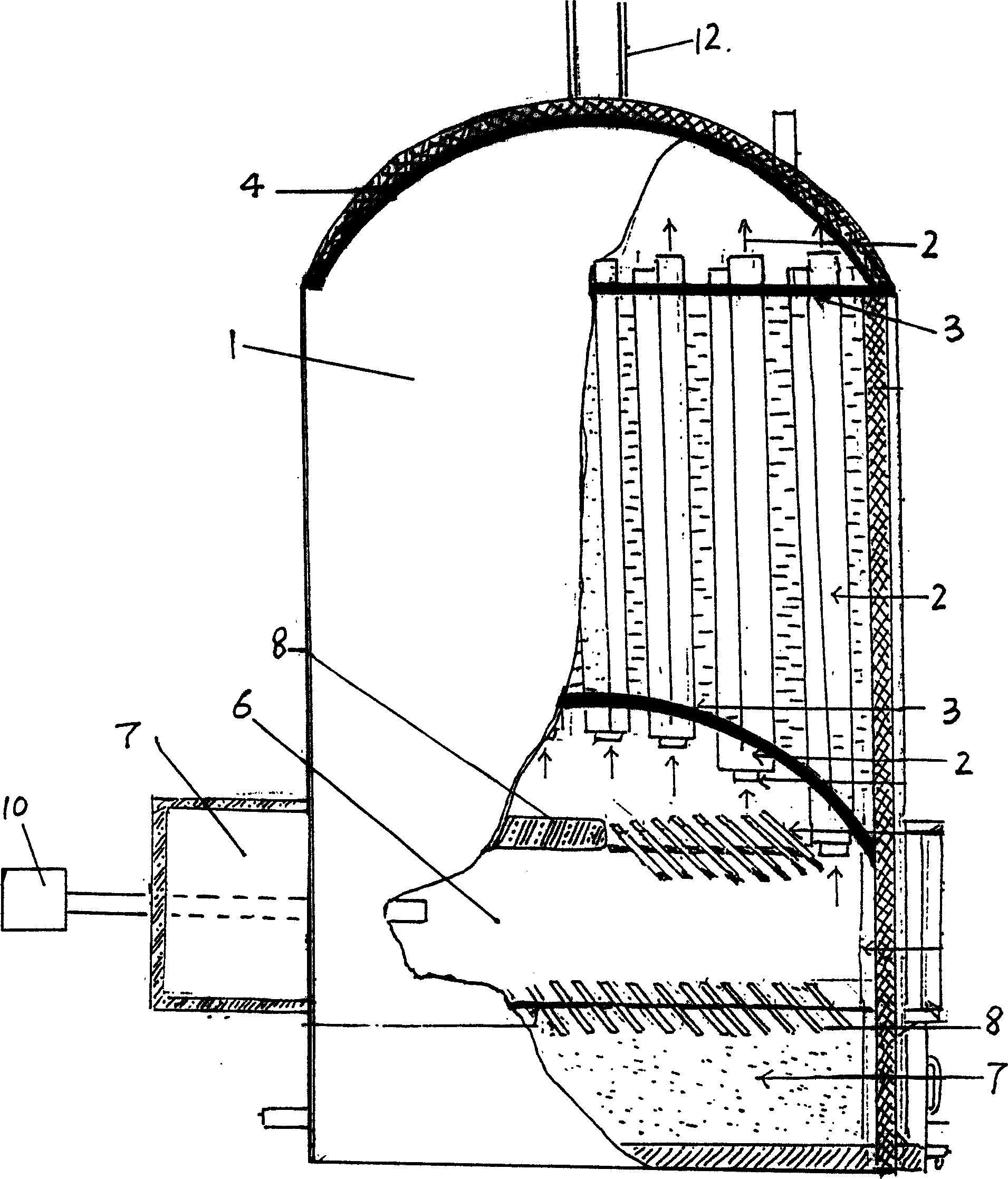

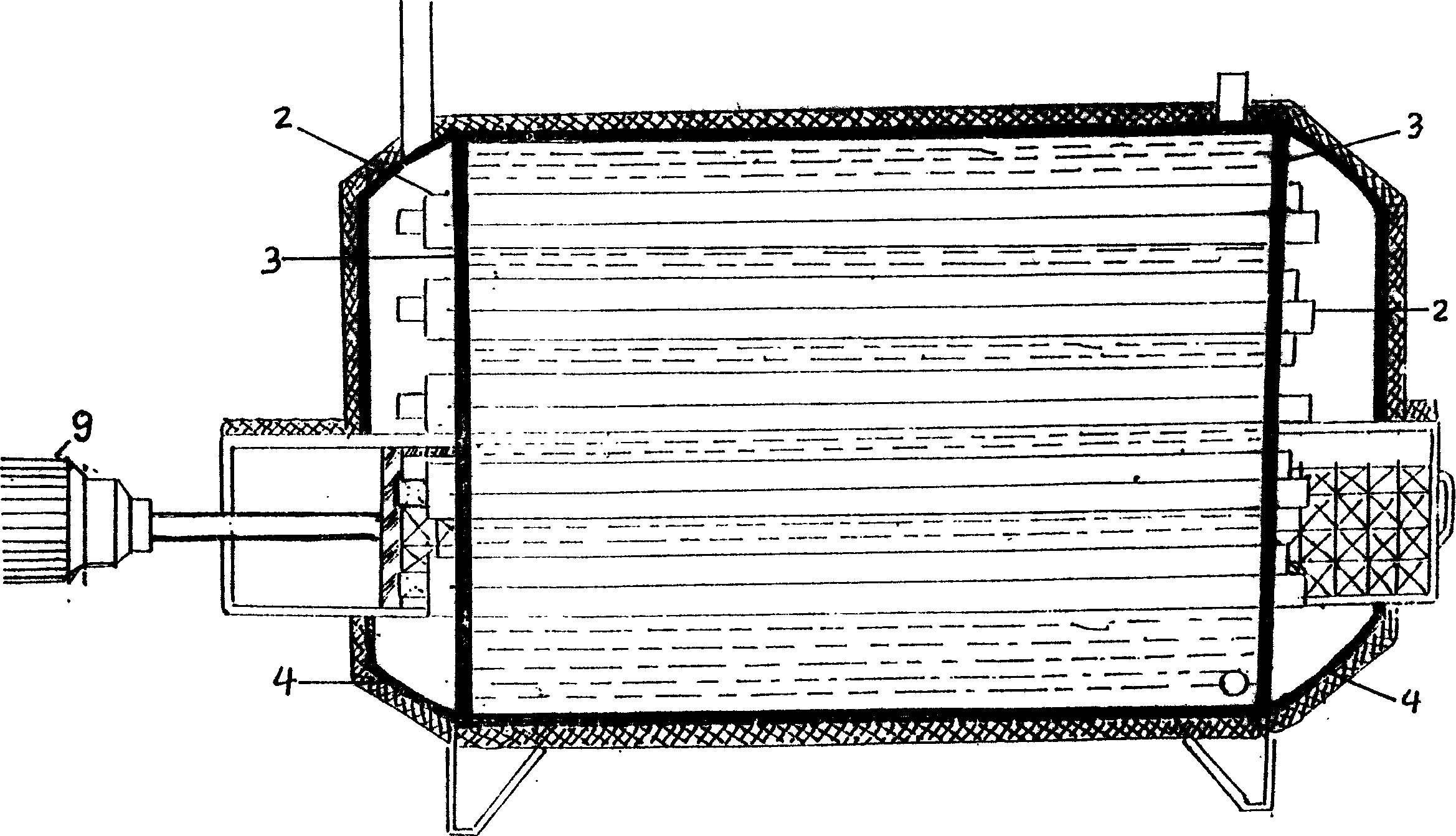

[0010] Example. As shown in accompanying drawing 1, the briquette (such as square briquette) coal-fired boiler of N-shaped fire tube, constitutes and comprises furnace body 1 in existing fire tube boiler structure, cover 4, chimney 12, ash chamber 7 , the fire pipe 2, the connecting head 3 arranged at the upper end and the lower end of the fire pipe 2, the connecting head 3 is preferably an arc-shaped connecting head, and a water storage bin is formed between the upper and lower heads; it also includes a briquette combustion chamber 5 , coal pushing device 9, briquette gas guide arch 11; then comprise pulverized coal combustion chamber 6, furnace inner dust shield 8, cyclone powder machine 10 (referring to accompanying drawing 2) for pulverized coal boiler. Regardless of whether it is a shaped coal boiler or a pulverized coal boiler, the characteristic of the N-shaped fire tube coal-fired boiler is that the fire tube 2 is an N-shaped fire tube composed of three or more section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com