Low-nitrogen combustion process and device combining direct flow with rotational flow and supplying air at multiple stages in hearth

A low-nitrogen combustion, swirl mixing technology, applied in combustion methods, control combustion, combustion equipment and other directions, can solve the problems of complex system, incomplete combustion, low combustion efficiency, etc., to reduce NOx emissions, reduce investment costs, furnace chamber compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Fuel gas is divided into base load gas and functional load gas; combustion air is also divided into two parts, primary combustion air and secondary combustion air.

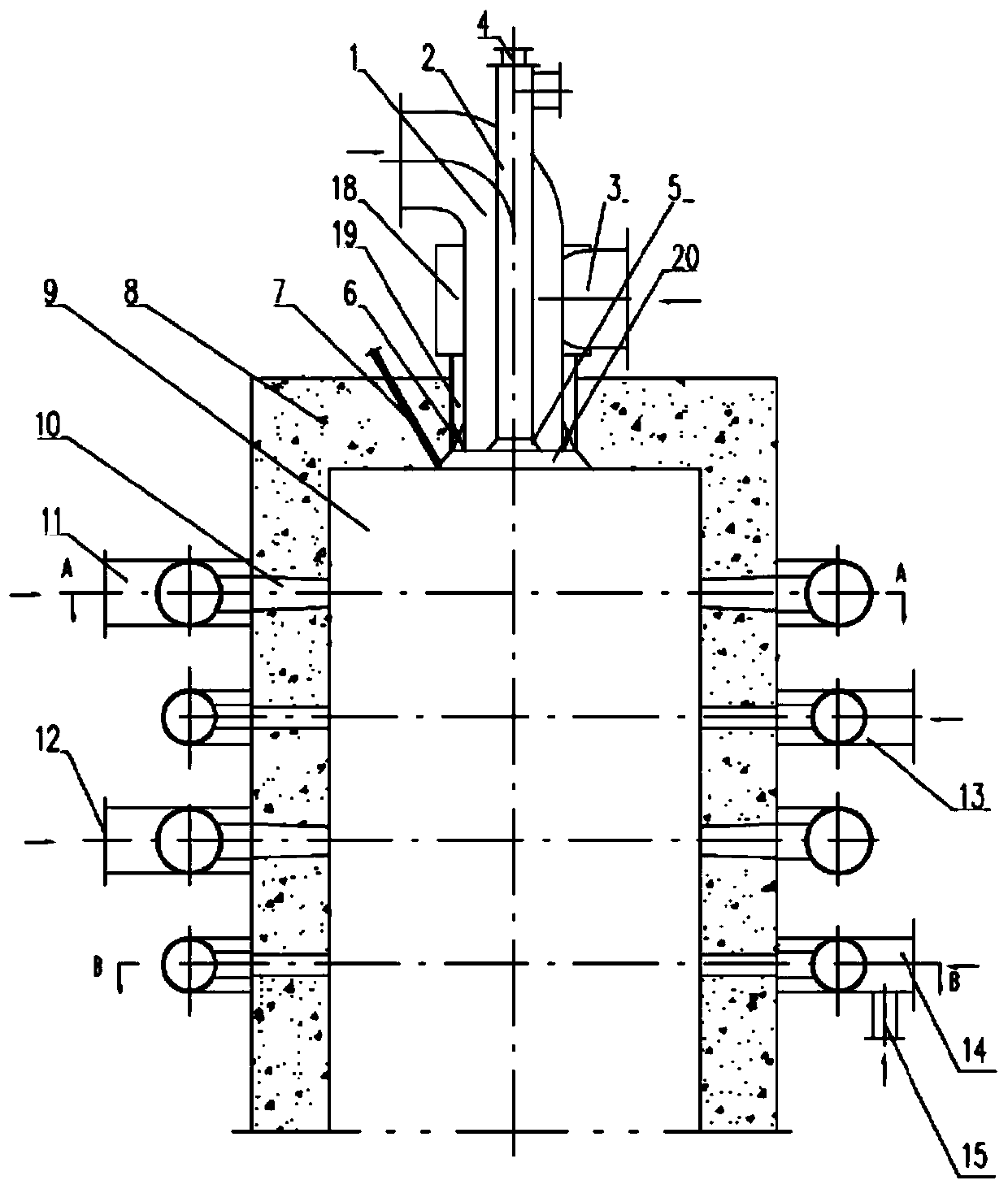

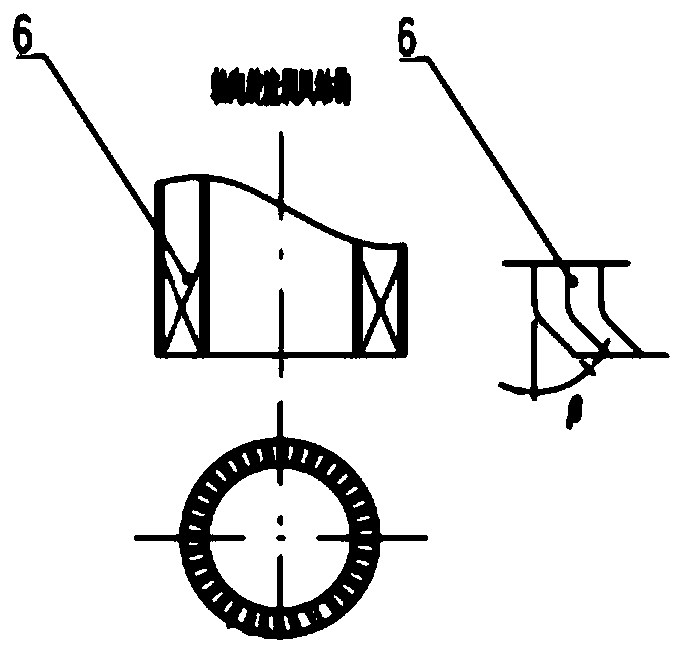

[0052] 40% of the total fuel gas is injected into the furnace from the base load gas pipe 1; 10% of the primary combustion air is passed into the central air pipe 2, and the central air outlet 5 is a tapered neck structure, which is conducive to mixing with the gas 50% of the primary combustion-supporting air enters the combustion-supporting air passage 19 through the volute type bellows 18, and the outlet of the combustion-supporting air passage 19 is provided with an axial swirl air regulator 6, which is in the shape of a curved blade. The blade inclination angle β is 45-60°, the coverage is 1.2-1.4; the flow velocity of the gas pipeline is 10-15m / s, and the air flow velocity is 8-10m / s; the flow velocity of the nozzle after the air and gas are mixed is 25-30m / s. The mixture is ignited by the igniter 7 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com