Combustion system suitable for flexible peak regulation of four-corner tangential boiler, and operation method thereof

A combustion system, four-corner tangential technology, applied in the direction of combustion method, combustion with multiple fuels, combustion with block fuel and powder fuel, etc., can solve the problems of high risk of boiler fire extinguishing, poor low-load stable combustion ability, etc. Achieve strong self-stable combustion ability, improve low-load stable combustion ability, and enhance the effect of high-temperature smoke entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

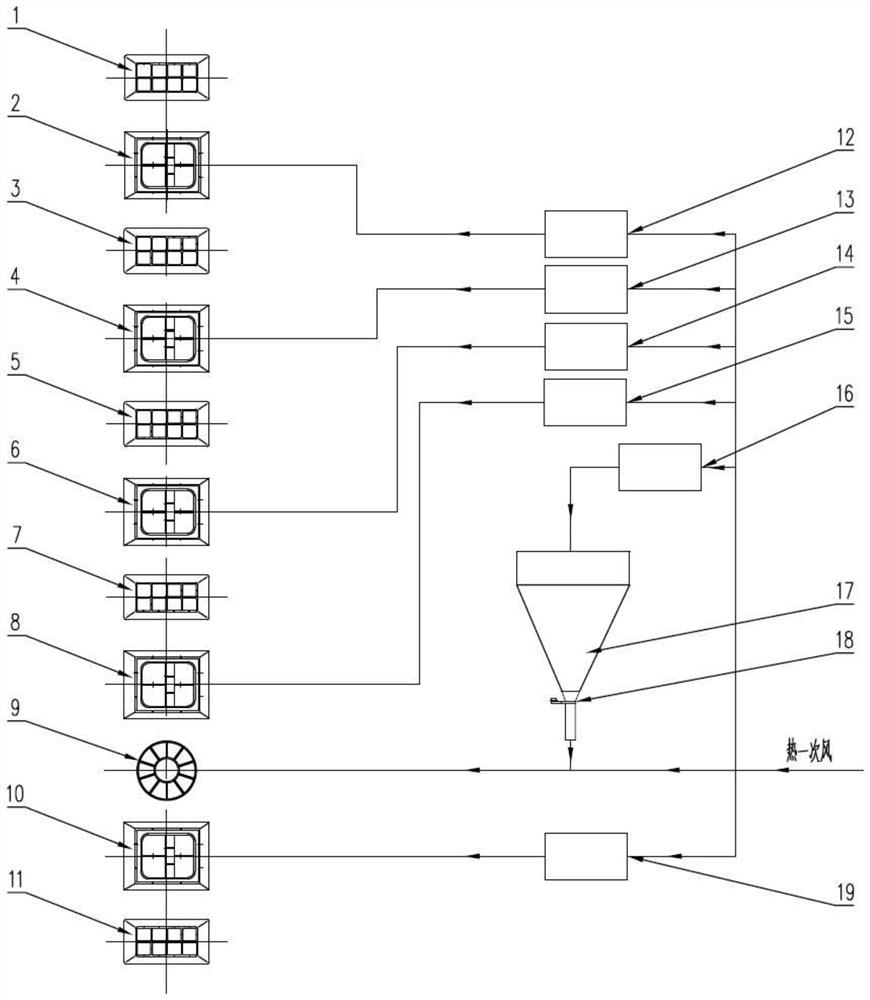

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

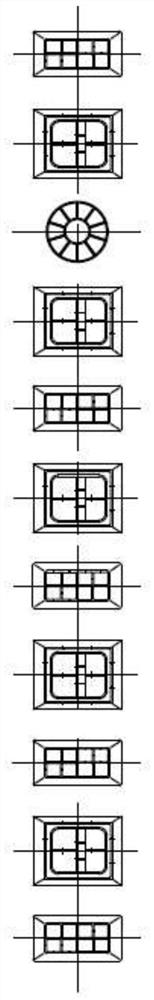

[0027] Such as figure 1 As shown, the present invention provides a combustion system suitable for flexible peak regulation of four-corner tangential boilers. In the main burner area of the four-corner water-cooled wall of the boiler furnace, the first direct-flow secondary air burner 1 is arranged sequentially from top to bottom. , The first DC pulverized coal burner 2, the second DC secondary air burner 3, the second DC pulverized coal burner 4, the third DC secondary air burner 5, the third DC pulverized coal burner 6, the second DC pulverized coal burner Four DC secondary air burners 7, fourth DC pulverized coal burner 8, swirl burner 9, fifth DC pulverized coal burner 10 and fifth DC secondary air burner 11, swirl burner 9 is arranged in Between the fourth direct-flow pulverized coal burner 8 of the second bottom layer and the fifth direct-flow pulveri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com