Low-load stable burning pulverized coal external heating smoke heating type turbulent burner and heating method

A swirl burner and external heating technology, applied in the burner, combustion method, burner and other directions of burning powder fuel, can solve the problems of inability to be absorbed by the power system, weak short-circuit current capability, and low reactive power supply performance, etc. Achieve compact structure, improve low-load stable combustion performance, and have a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

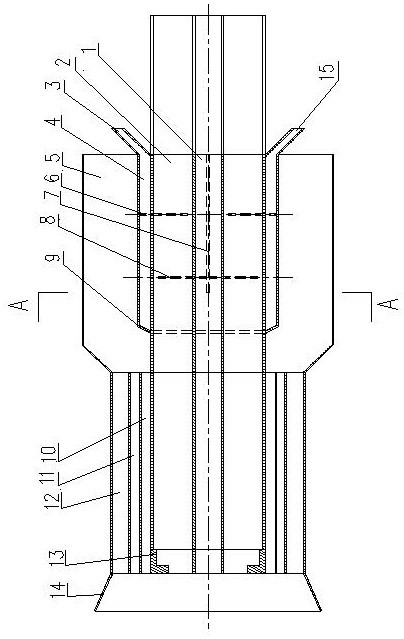

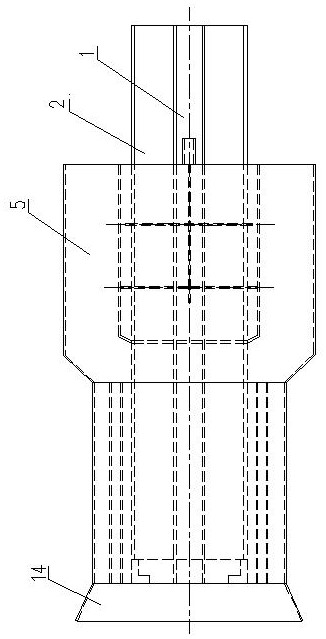

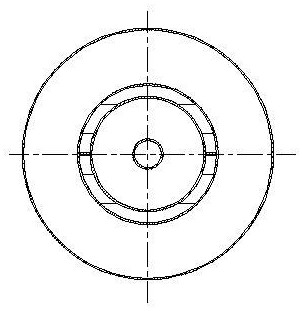

[0039] A smoke-heat type swirl burner for external heating of low-load and stable pulverized coal combustion. The composition includes a swirl burner. The swirl burner includes a central air channel 1 and an outer layer of the central air channel. A primary air channel 2 is provided. The left end of the primary air channel is close to the nozzle and a combustion stabilizing tooth 13 is arranged, and the right end is connected to the primary air supply pipe. The outer layer of the right half of the primary air channel is sequentially arranged with heating sleeves 4 and The wind box 5, the left end of the heating sleeve is blocked by the end baffle 9 of the heating sleeve, the upper right end is connected with the heating sleeve flue gas inlet 3, and the lower side is connected with the heating sleeve flue gas outlet 15. The inside of the sleeve is blocked by the heating sleeve flue gas baffle A6, the heating sleeve axial flue gas baffle 7, and the heating sleeve flue gas baffle B...

Embodiment 2

[0041] According to the external heating smoke-heated swirl burner for low-load stable combustion of pulverized coal according to embodiment 1, the left end of the wind box is provided with a secondary air channel 10, a tertiary air channel 11, and a right end of the fourth air channel 12 And open, the left side of the secondary air channel and the tertiary air channel are nozzles, the right side is connected with the wind box, the left side of the fourth air channel is provided with a cone-shaped nozzle 14, and the right side is connected to the air box. The described bellows are connected.

Embodiment 3

[0043] According to the external heating smoke-heated swirl burner for low-load stable combustion of pulverized coal according to embodiment 2, the central air channel, the primary air channel, and the combustion stabilizing tooth adopt wear-resistant and heat-resistant Alloy or ceramics, the secondary air duct, the tertiary air duct, the fourth air duct and the air box can be connected by welding, flange connection or integral casting. The cone-shaped nozzle is arranged on the outer edge of the fourth air nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com