Energy-saving type biomass fuel furnace

A biomass fuel, energy-saving technology, applied in the direction of fuel supply, combustion of solid fuel, combustion method, etc., can solve the problems of insufficient combustion, environmental pollution, restricting the application and development of biomass gasification technology, etc., to achieve good rotation Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0032] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

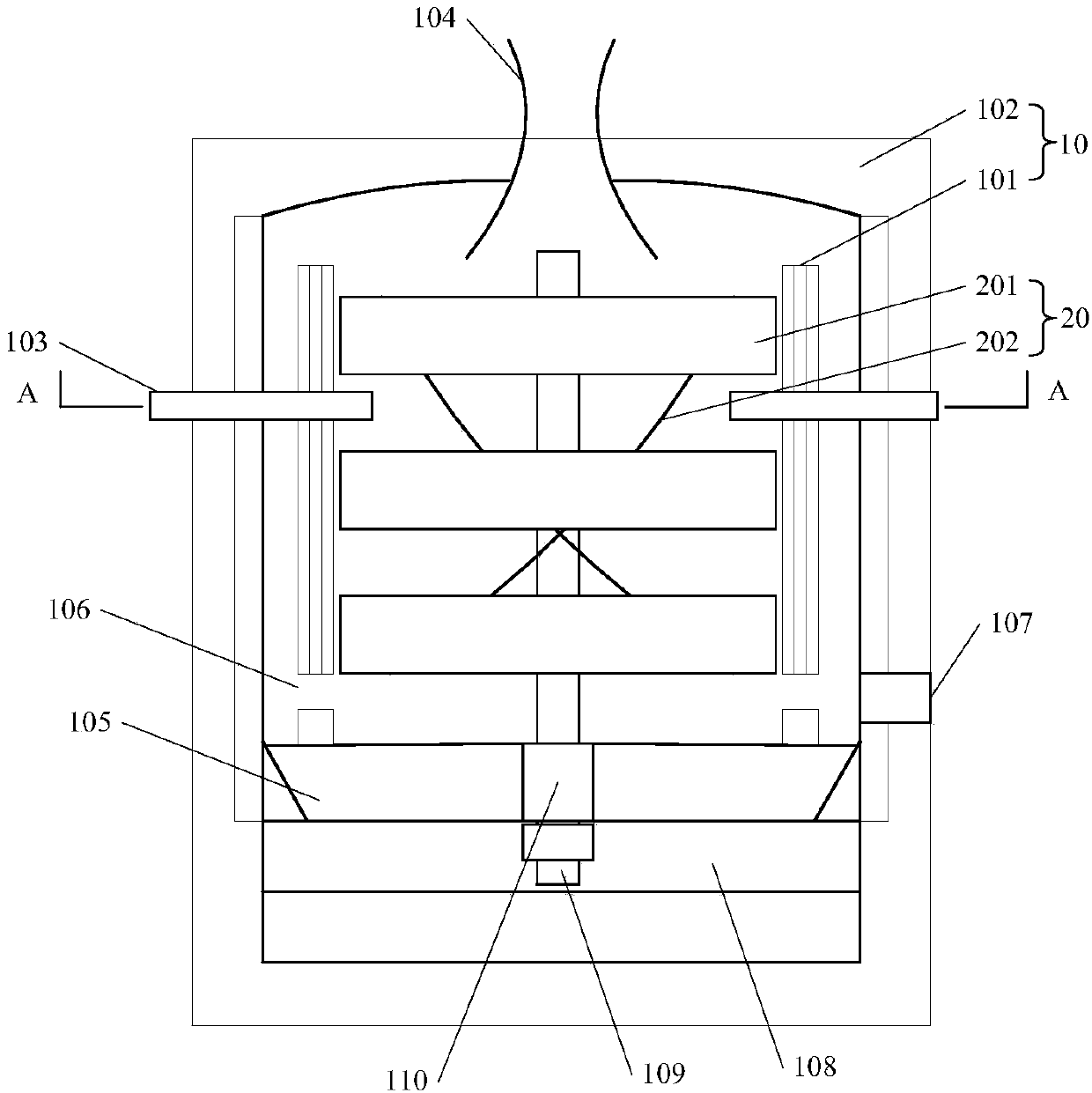

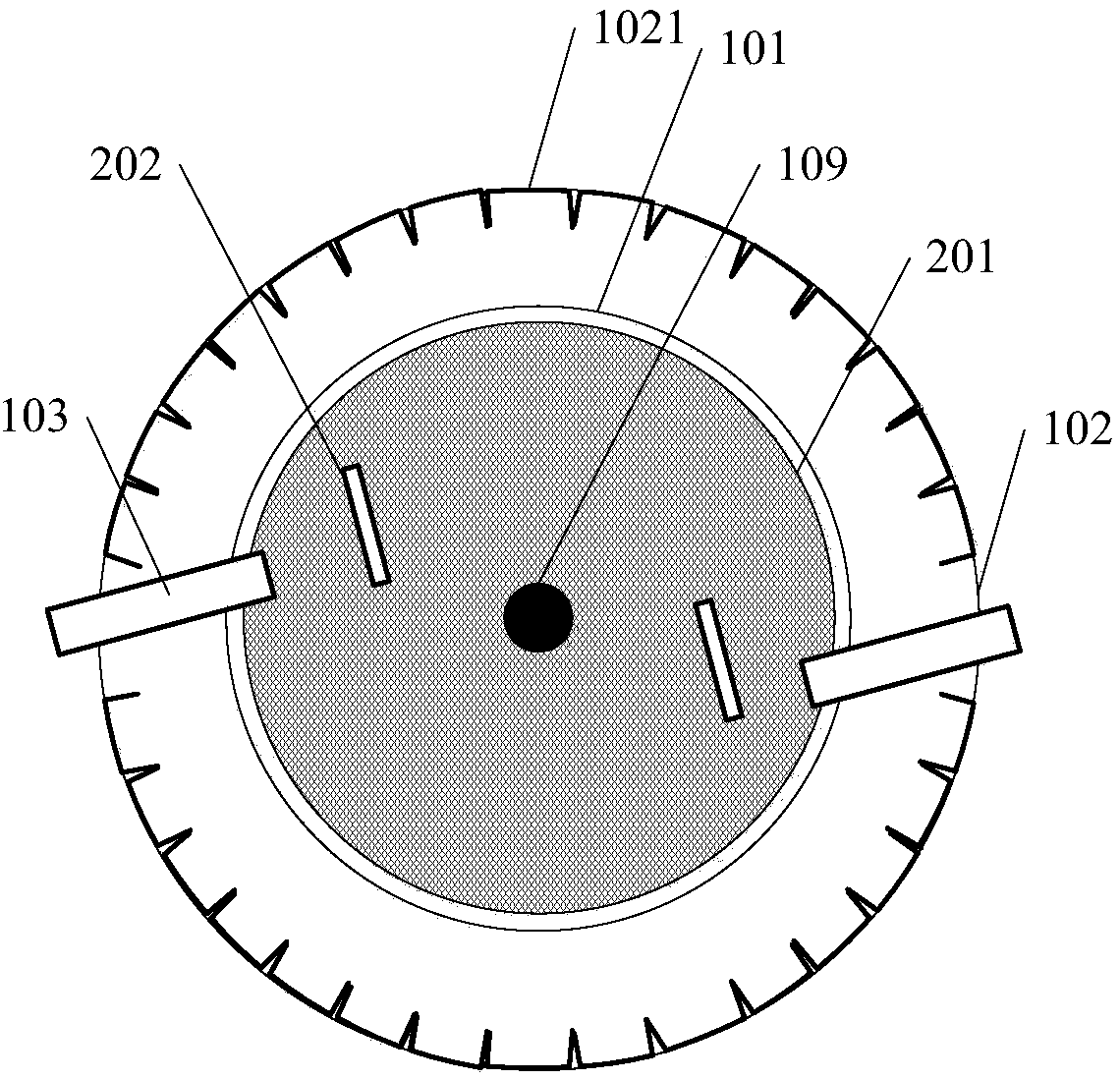

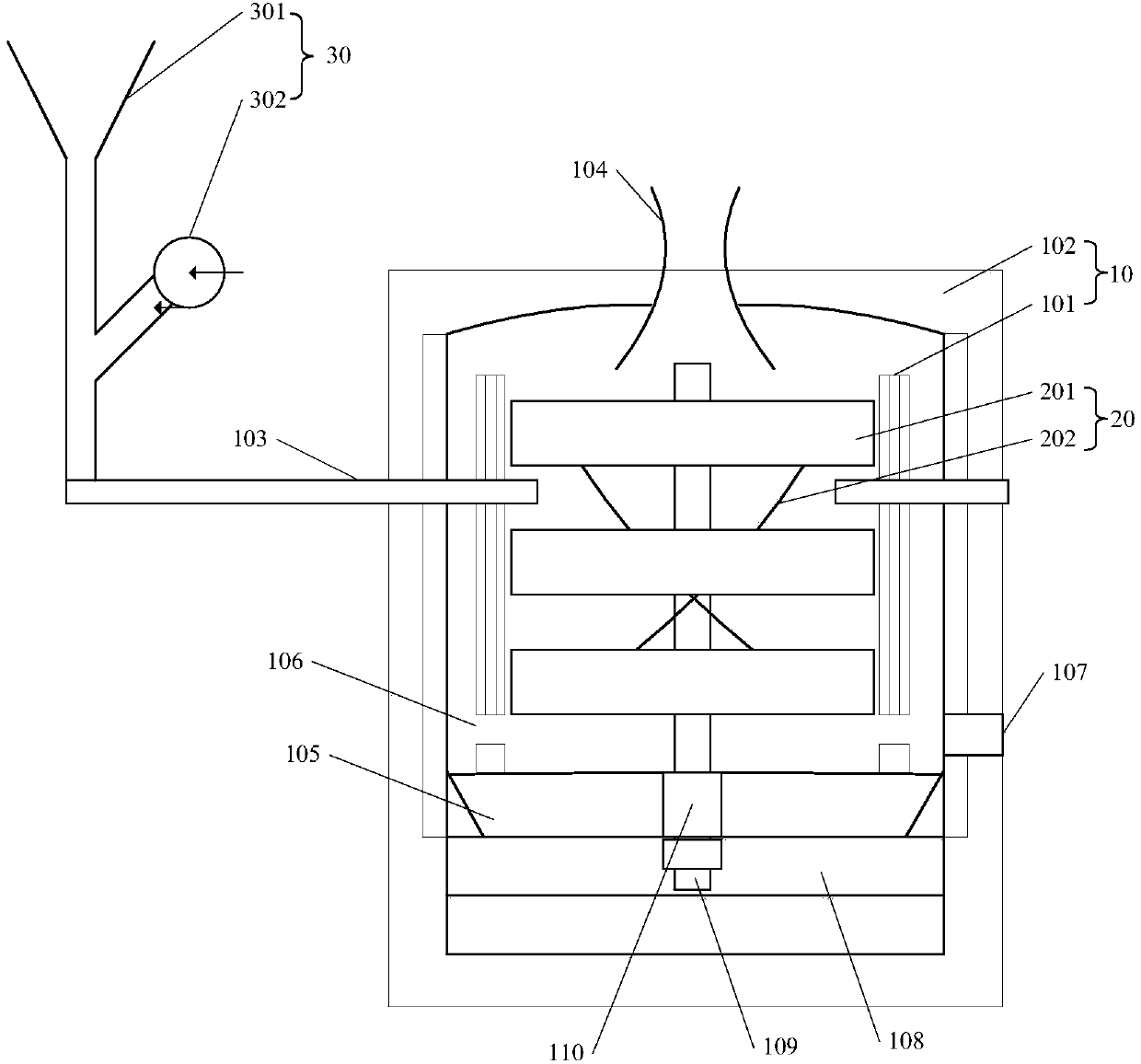

[0033] Such as figure 1 , 2 As shown, the present invention provides an energy-saving biomass fuel furnace, comprising:

[0034] A furnace body 1, which includes an inner furnace body 101 and an outer furnace body 102 nested in each other, and the distance between the inner furnace body and the outer furnace body is 16-25 cm, and the inner furnace body is an open upper end barrel structure; the outer furnace body is an airtight cylinder structure, and the inner top surface of the outer furnace body is arc-shaped, the upper end opening of the inner furnace body and the inner top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com