Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Less ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

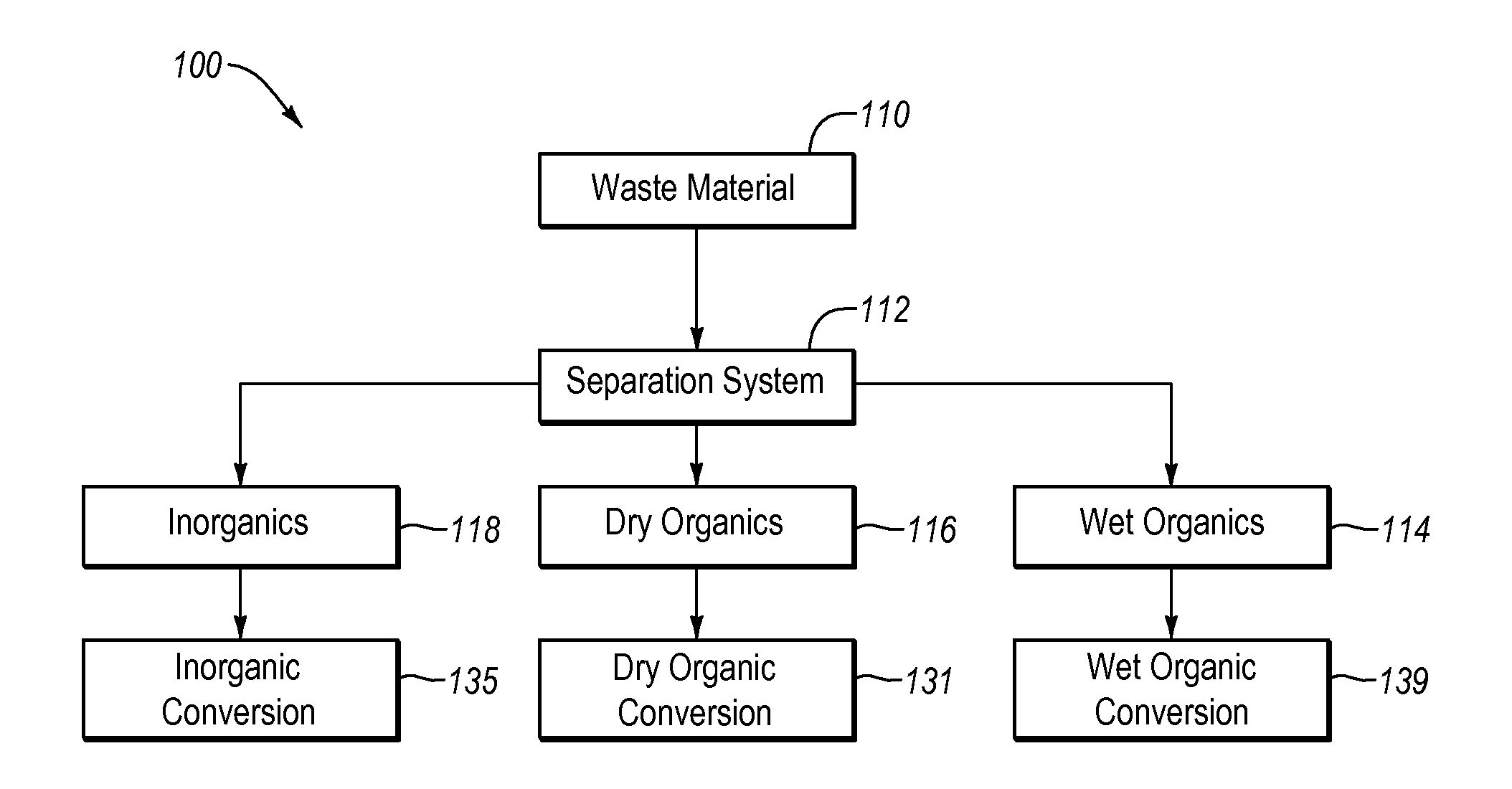

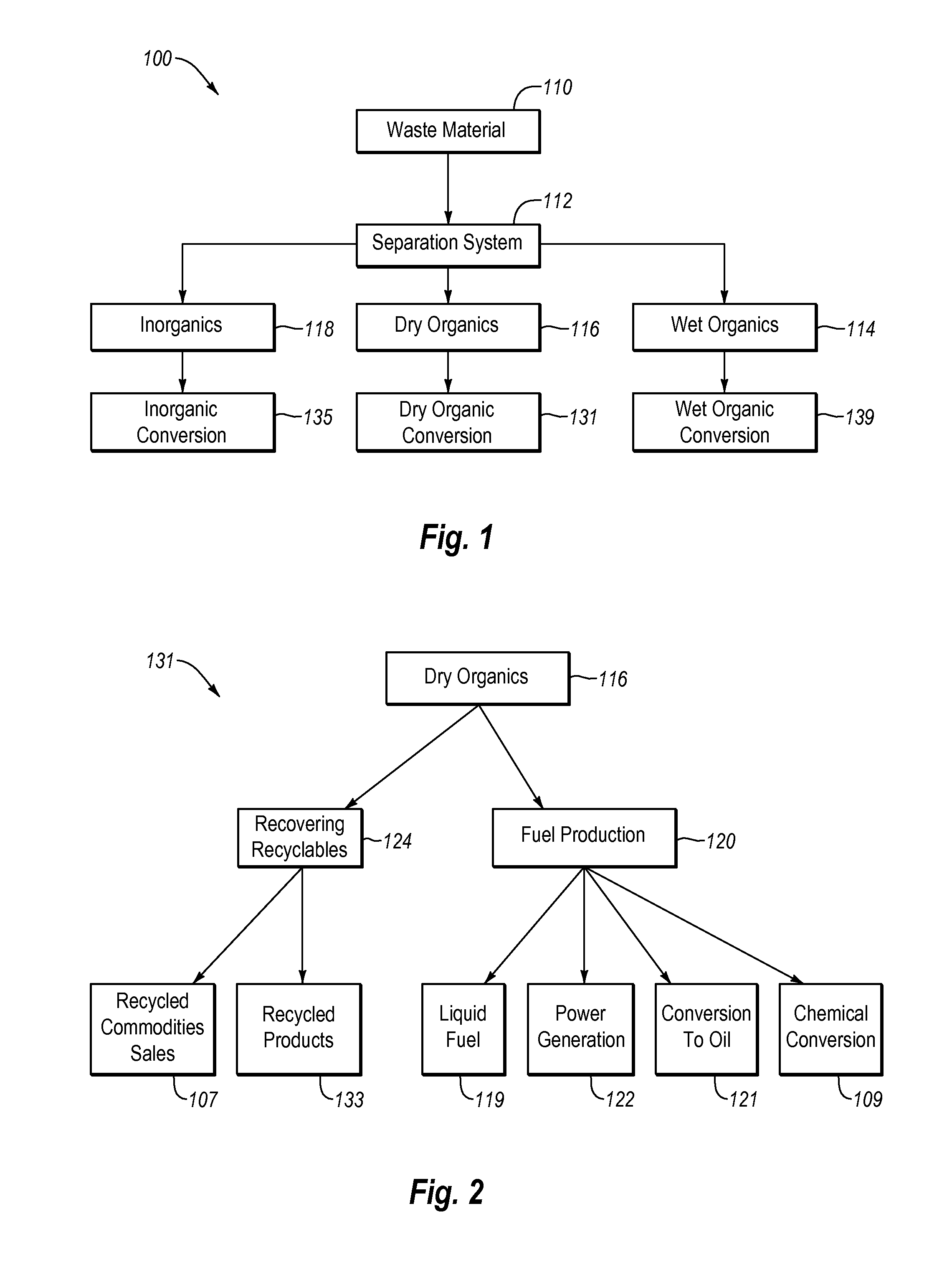

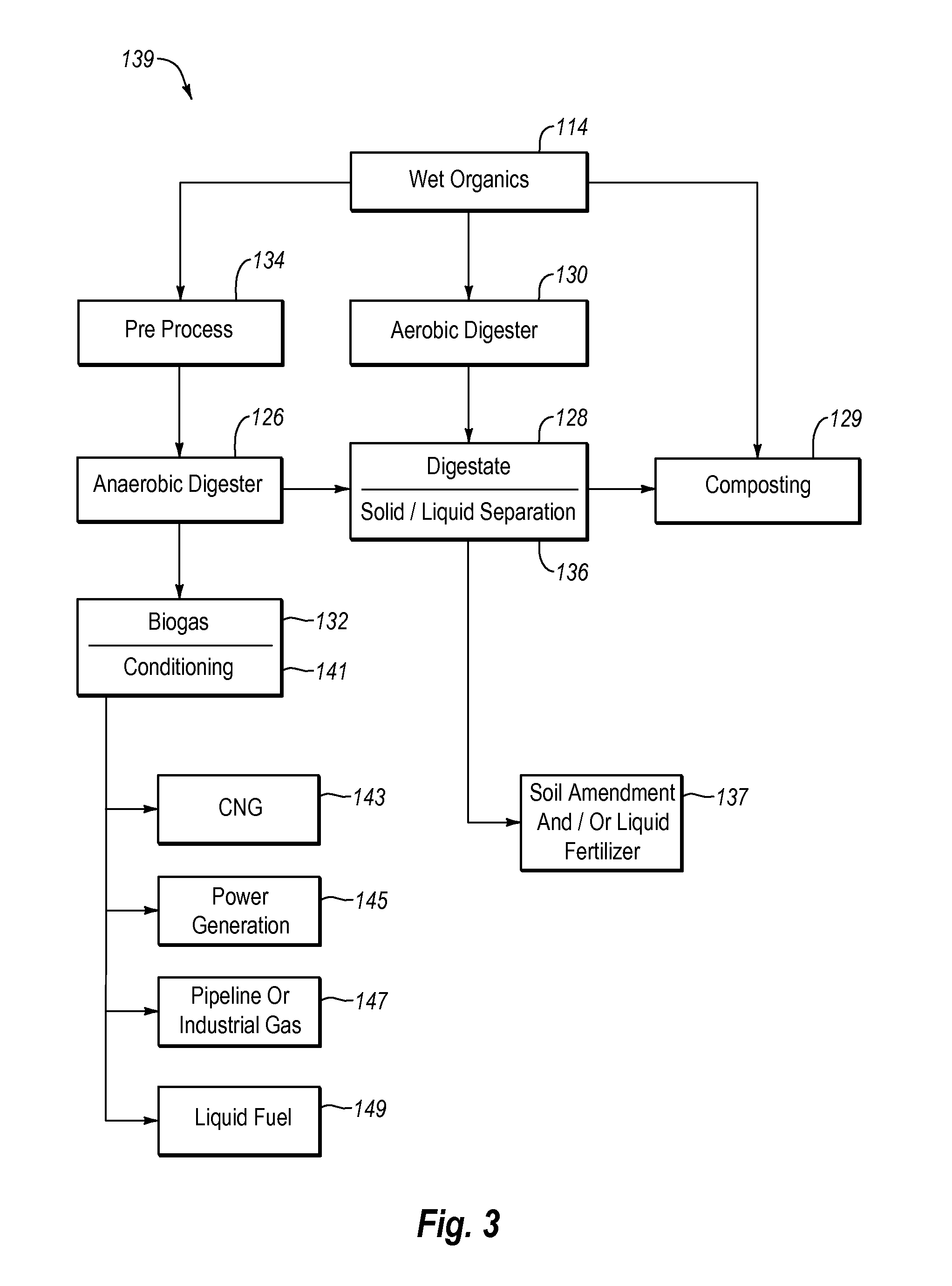

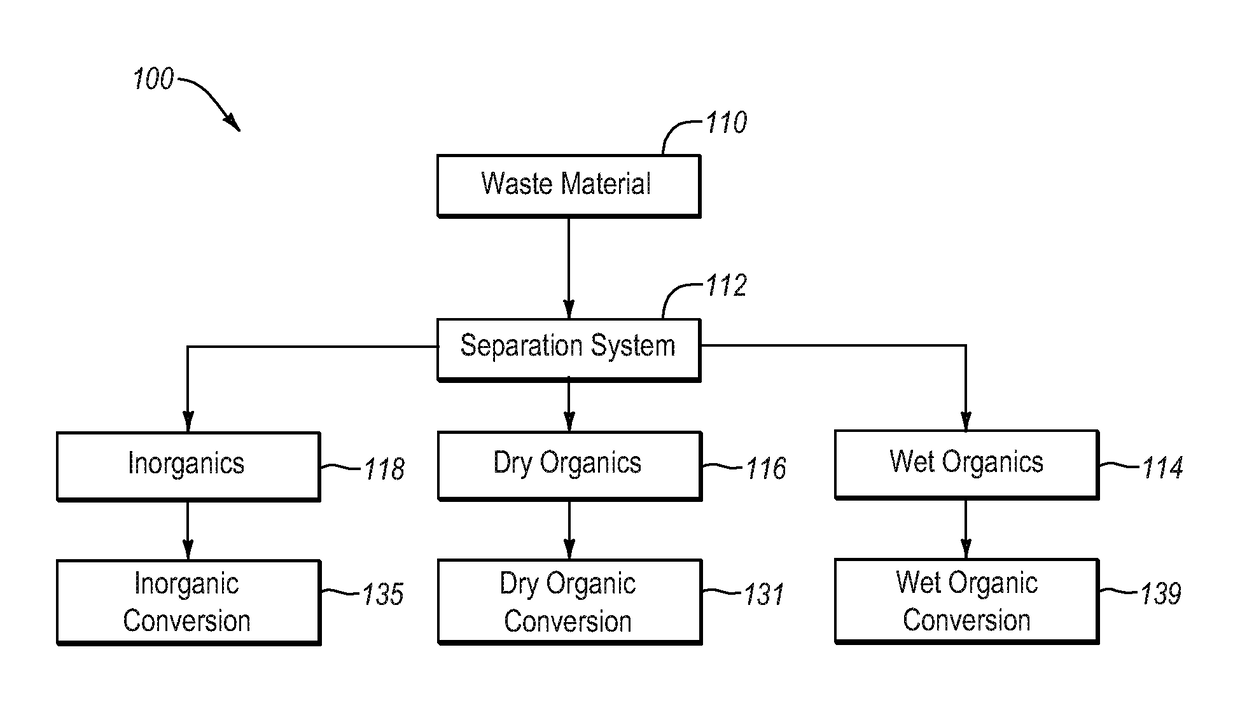

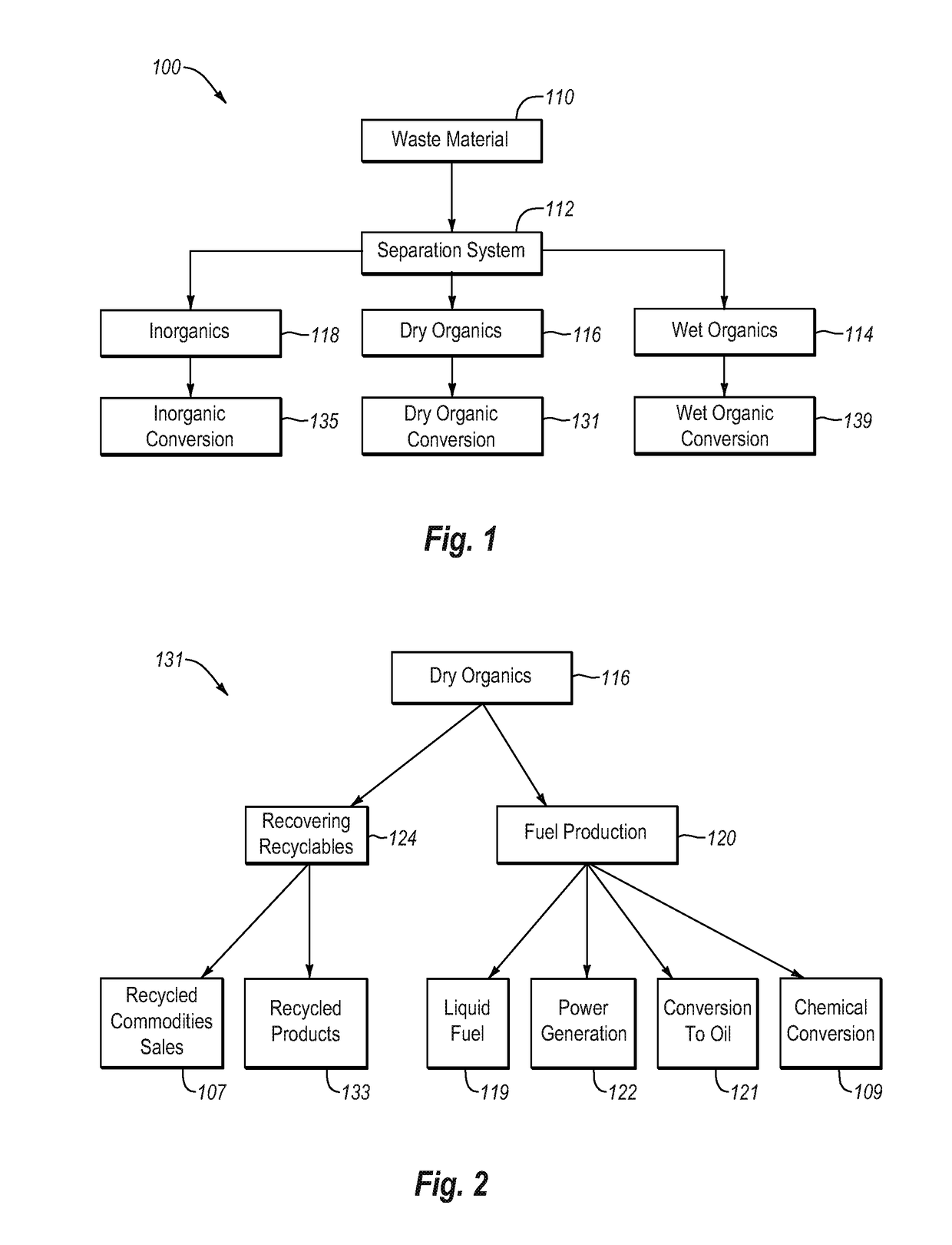

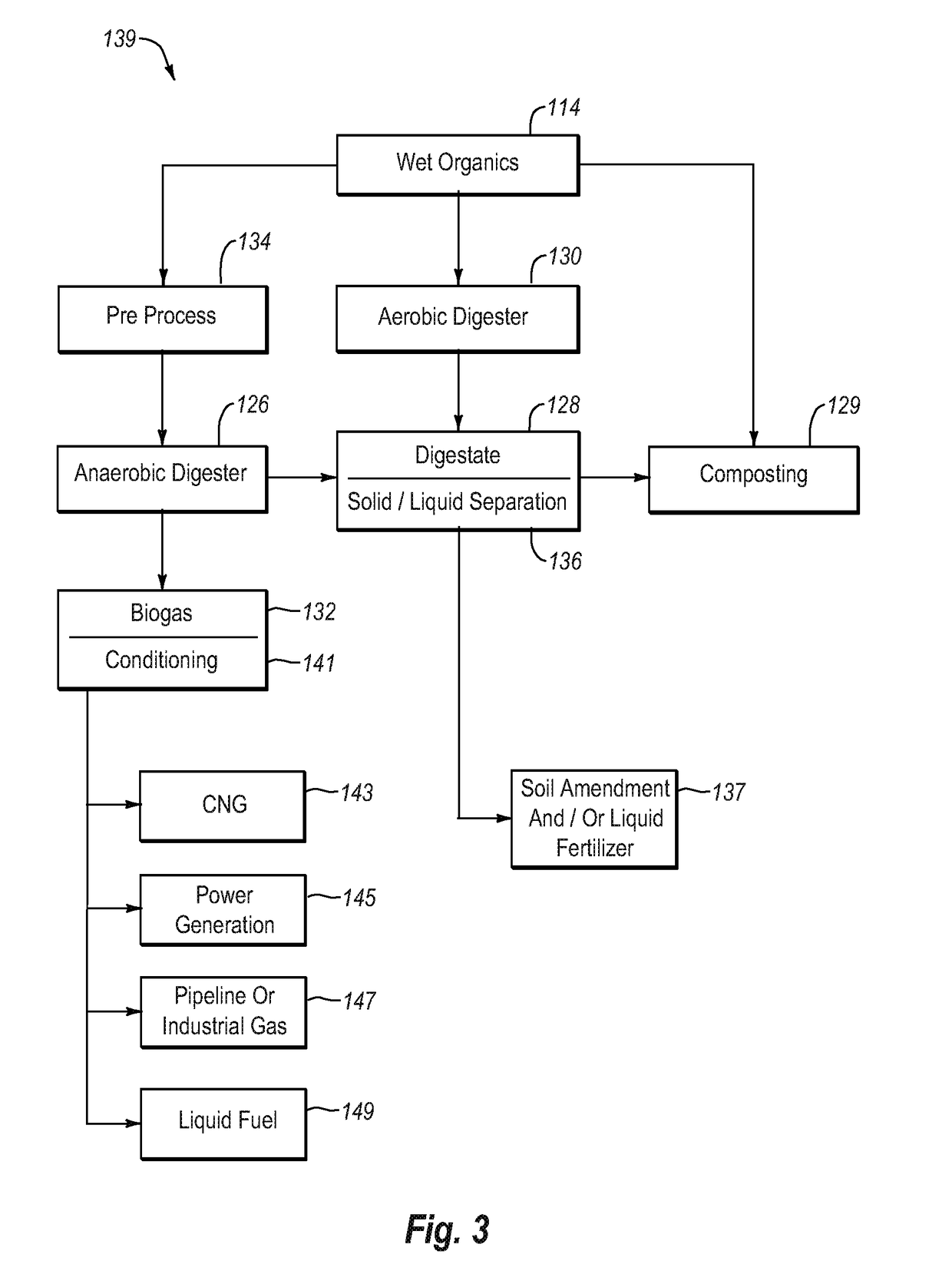

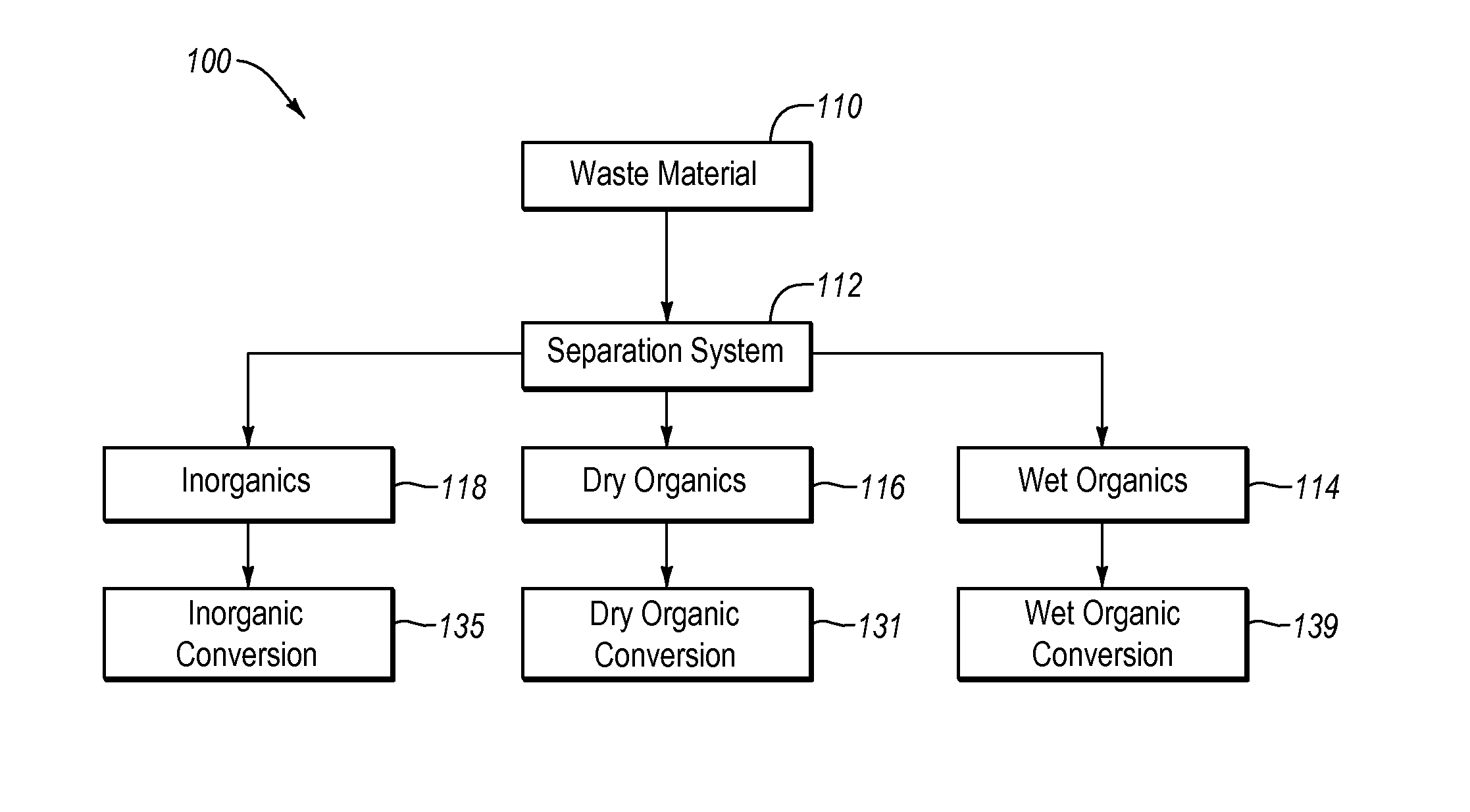

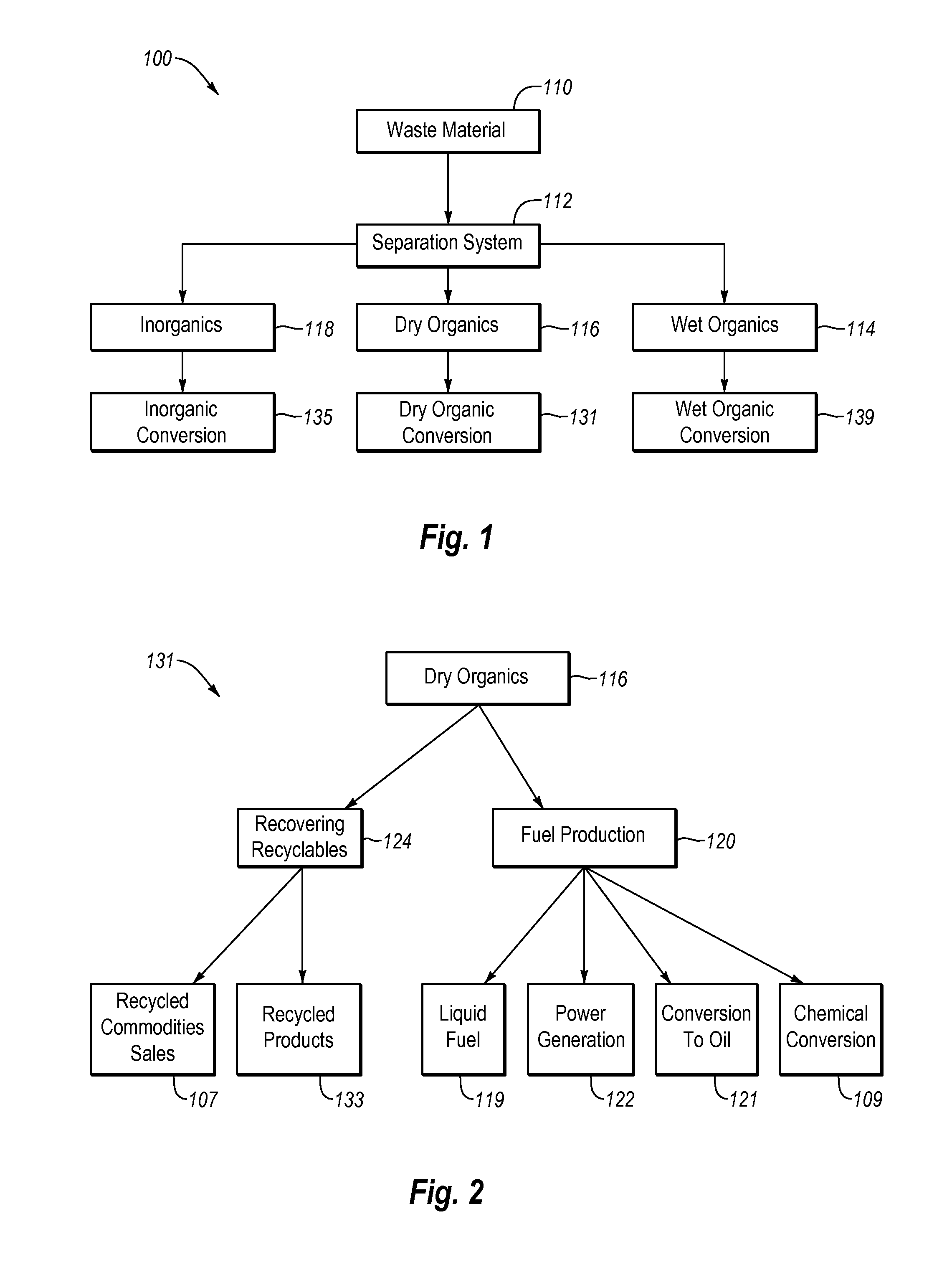

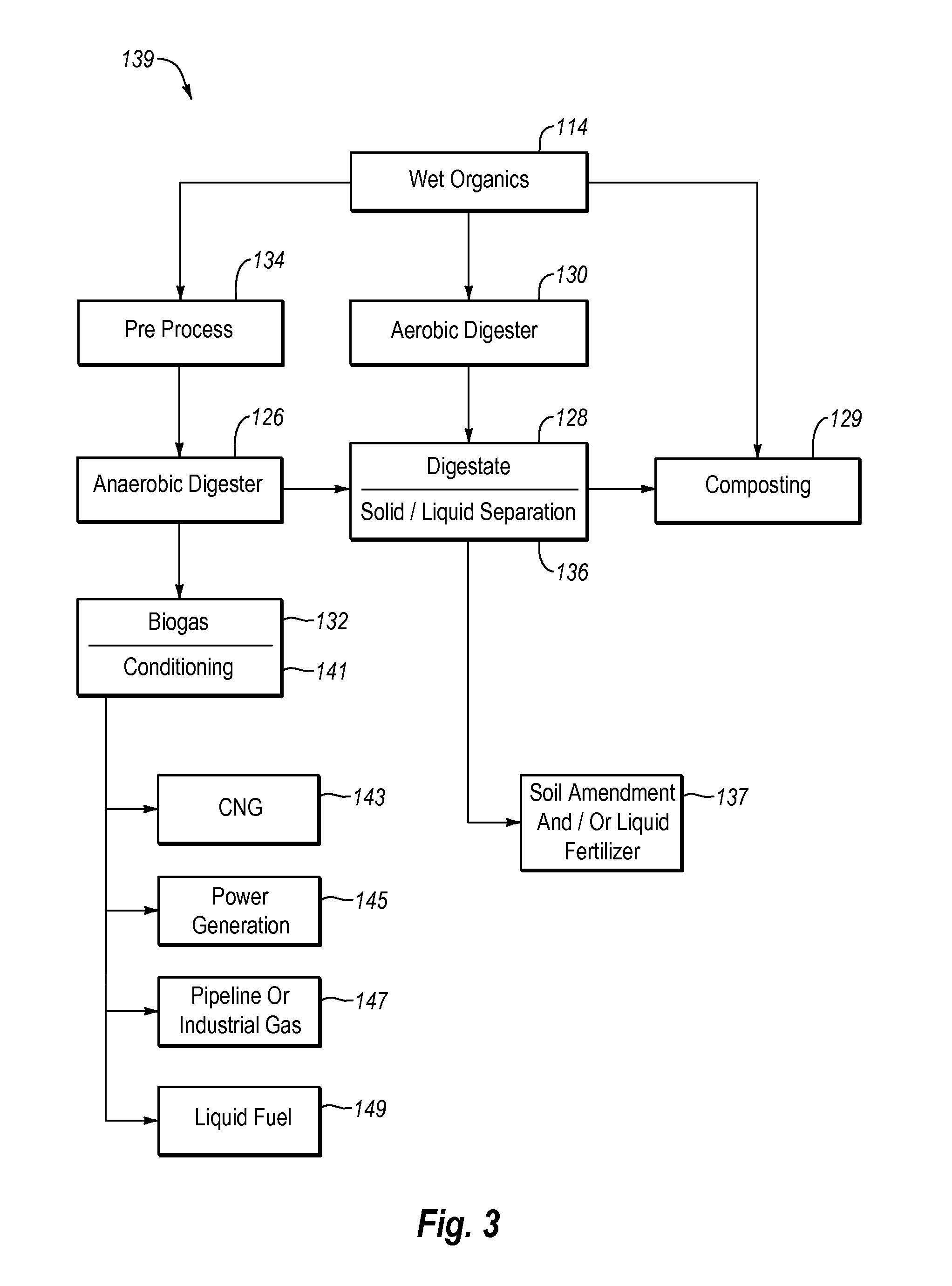

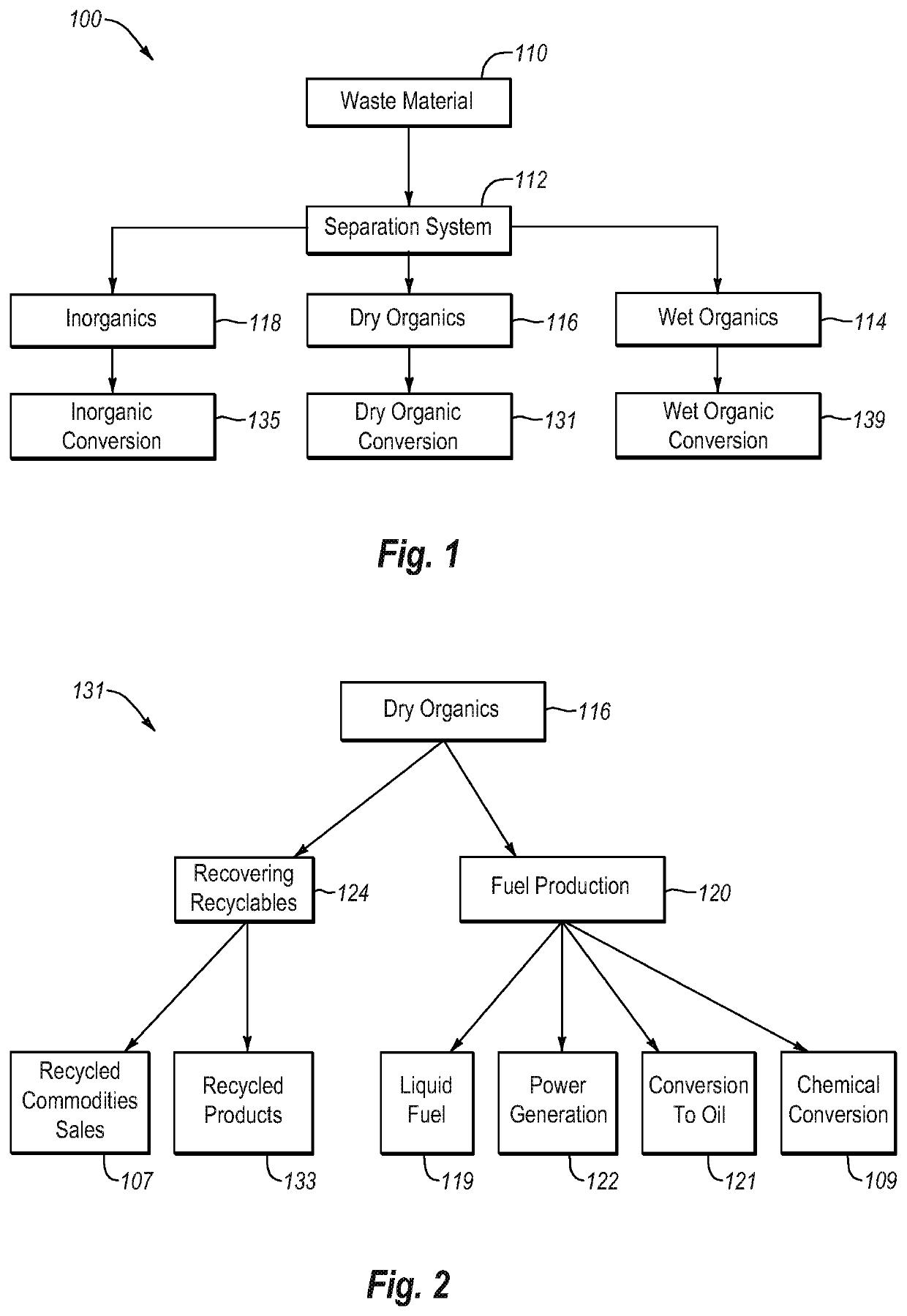

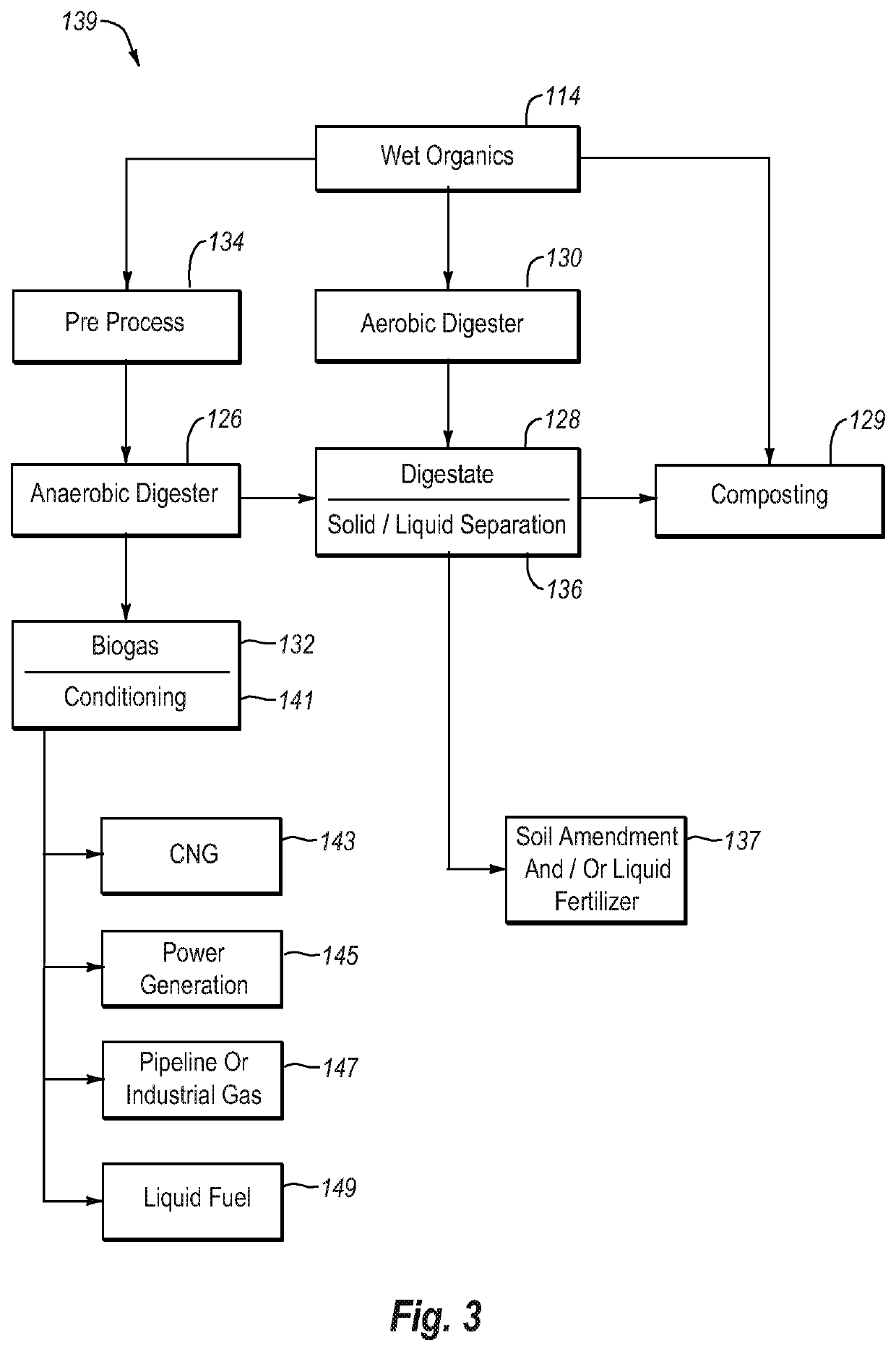

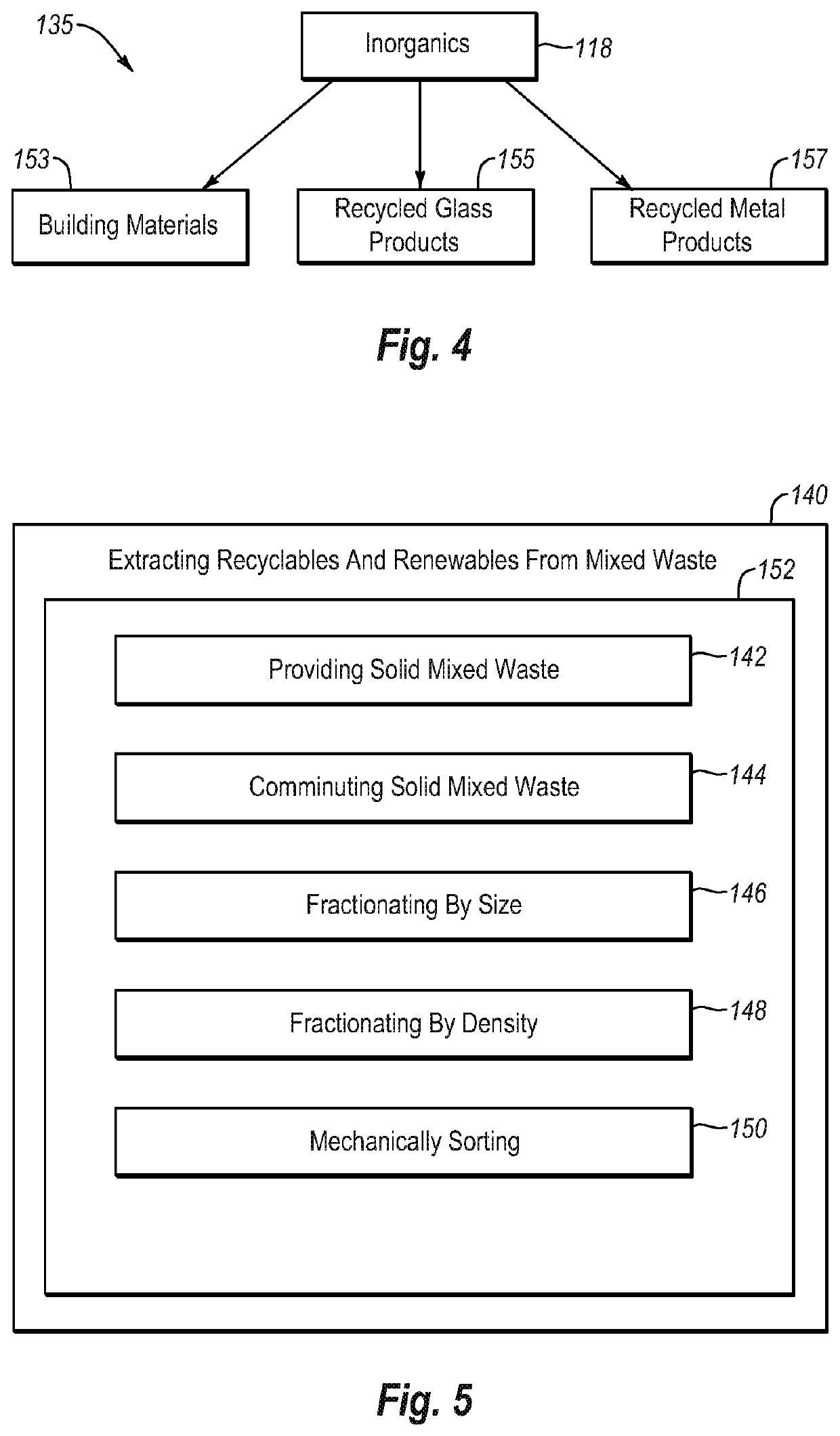

Systems and methods for processing mixed solid waste

ActiveUS20120190102A1Efficient extractionMaximize efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistry

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC +2

Machine-spraying-type plastering gypsum mortar and preparation technology thereof

ActiveCN104961423ASolve the problems that cannot meet the needs of mechanized constructionReduce dosageBond strengthMaterials science

The invention relates to machine-spraying-type plastering gypsum and a preparation technology thereof and belongs to the technical field of building materials. The machine-spraying-type plastering gypsum is characterized by being prepared from the following raw materials: 200-400 parts of gypsum, 10-60 parts of cement, 520-650 parts of fine aggregate, 80-160 parts of heavy calcium powder, 2-4 parts of redispersible emulsion powder, 2-4 parts of hydroxypropyl methyl cellulose ether, 0.15-0.25 part of an air entraining agent, 5-10 parts of expanded perlite, 0.3-0.8 part of a gypsum retarder and 200-300 parts of water. The machine-spraying-type plastering gypsum is applicable to being directly sprayed to a wall surface by adopting a mortar spraying machine, both time and labour are saved, construction efficiency can be improved, and cost is reduced; bonding performance with the wall surface is good, rebounce is not caused, anti-sagging performance is good, both bonding strength and compressive strength can meet requirements, and cracking of a wall body can be reduced; and usage amount of gypsum is low, and cost can be effectively reduced.

Owner:新疆荣高鸿骏新材料技术有限公司

Systems and methods for processing mixed solid waste

ActiveUS20170253891A1Efficient extractionMaximize efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistryMaterial flow

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC

Novel solid regenerated fuel and preparation method thereof

InactiveCN101928624ALess componentsRaise the ratioBiofuelsSolid fuelsEmission standardAir pollutants

The invention relates to the field of solid fuels, and discloses a novel solid regenerated fuel, which comprises solid wastes and additives, wherein the solid wastes have the heat value no more than 2,500Kcal / Kg and pollution factors less than 5. The raw materials are mainly the solid wastes with certain heat value and less pollution factors; according to the used solid wastes, the additives are selected; the prepared novel solid regenerated fuel has stable properties, is easy to store and transport, can be mixed with other fuels, generates a little ash after combustion, meets the combustion requirement of fuels, and ensures the heat value of more than 3,000Kcal / Kg; and waste gas generated after combustion can meet the integrated emission standard of air pollutants. The novel solid regenerated fuel has great environmental protection significance and energy conservation and emission reduction significance.

Owner:DALIAN DONGTAI INDAL WASTE TREATMENT

Systems and methods for processing mixed solid waste

ActiveUS8632024B2Maximize efficiencyImprove efficiencyInternal combustion piston enginesWaste processingEnvironmental chemistry

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC +2

Environmental-friendly solid fuel manufactured by municipal solid waste without manual classification and manufacturing method thereof

ActiveCN101831339AQuality improvementEfficient desulfurizationBiofuelsSolid fuelsBiotechnologySolid fuel

The invention discloses solid fuel manufactured by municipal solid wastes without manual classification. The solid fuel is manufactured by the following components in percentage by weight: 75%-85% of treated municipal solid wastes, 2%-7% of coal dust containing fixed carbon and 10%-20% of mixed additives. The invention aims at overcoming the defects in the prior art and increasing a novel treatment technology taking a biotechnology as a main technology to carry out advanced treatment on the municipal solid wastes, thereby providing the solid fuel which turns wastes into useful things by taking the municipal solid wastes as raw materials, has low production cost and little pollution, is beneficial to the environmental protection and has high combustion efficiency; and in addition, the invention has an other purpose of additionally providing a method which has simple process and environmental protection and is used for producing the solid fuel for changing a biochemical treatment methodof percolate generated in the wastes treatment process, wherein the biochemical treatment method has high production cost.

Owner:茹兆祥 +2

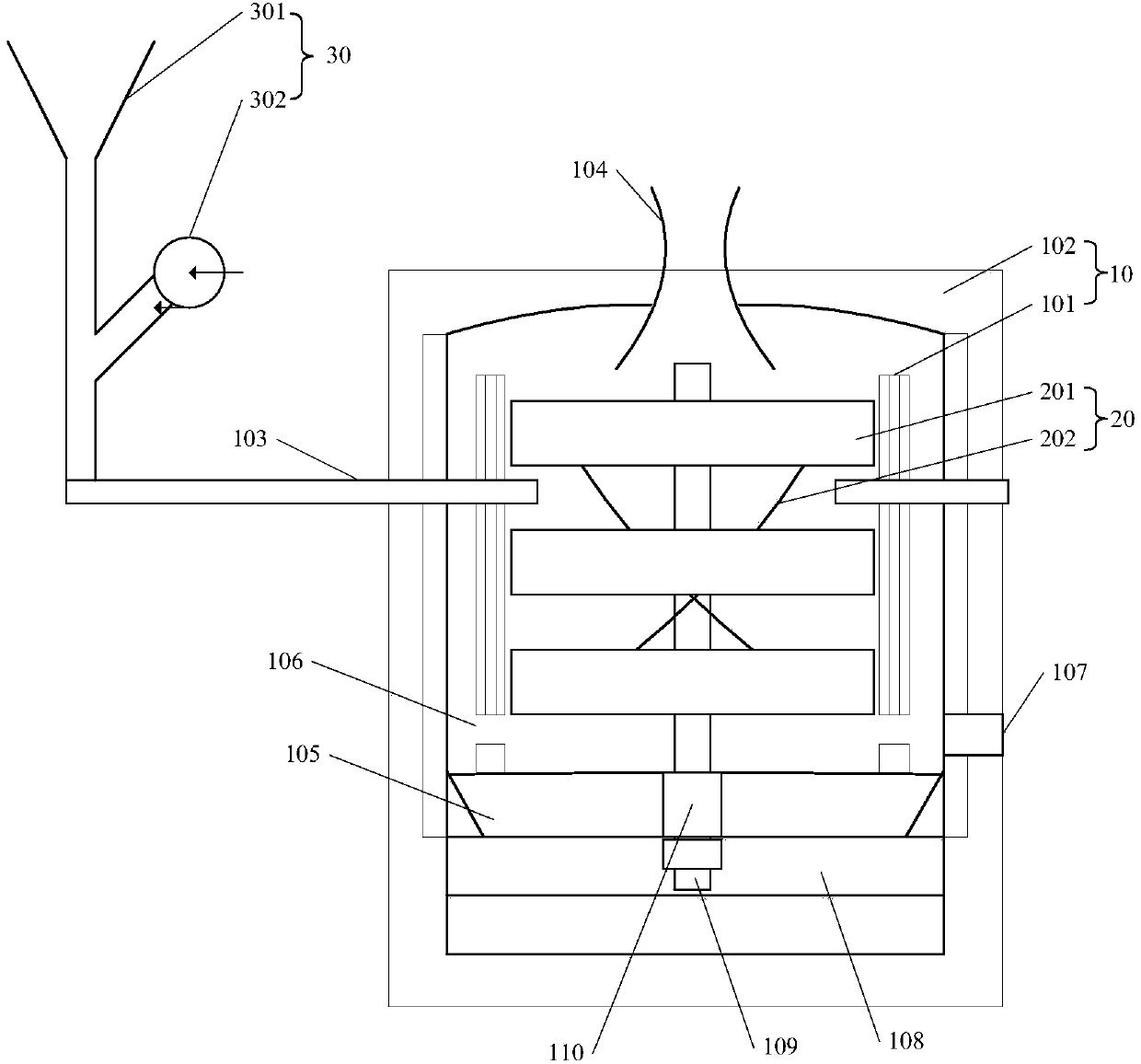

Bonfire oven

InactiveUS20140238282A1Easy to transportShort timeStoves/ranges with convection heatingCapillary burnersCombustorCombustion chamber

A bonfire oven has a body placeable on the ground. The body has a combustion cabinet and an auxiliary equipment cabinet. A burner contained in the combustion cabinet has a fire grate, a side plate extending upward from the fire grate, a top plate opposite to the fire grate, a blowing space beneath the fire grate, and a hearth defined by the fire grate and the side plate. A fuel supply mechanism, an electrical equipment and an air blower is contained in the auxiliary equipment cabinet. The bonfire oven further has a flame portion on the top which is a flame roaring space formed by at least one piece of high temperature resistant glass.

Owner:ZHU HONGFENG

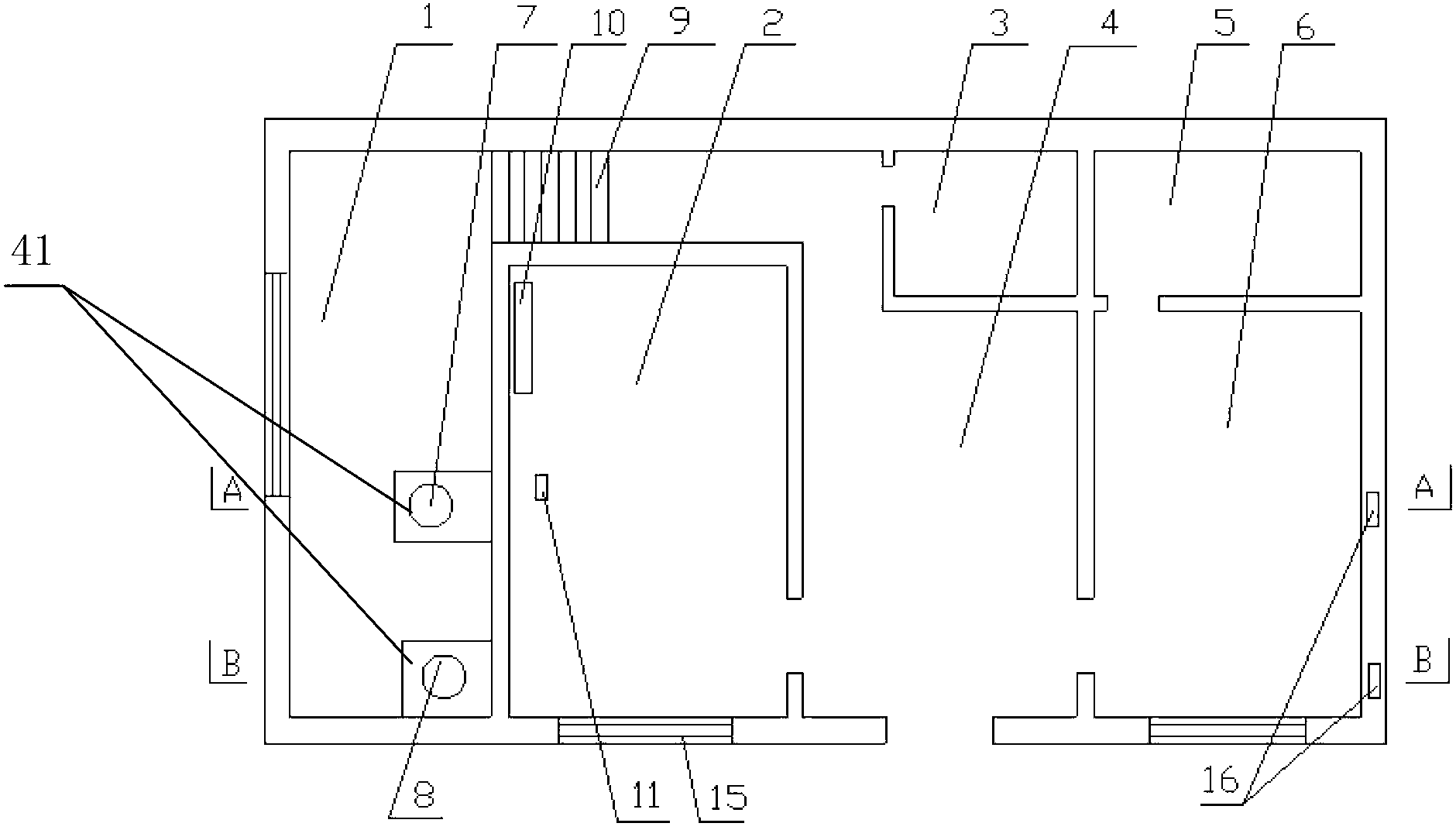

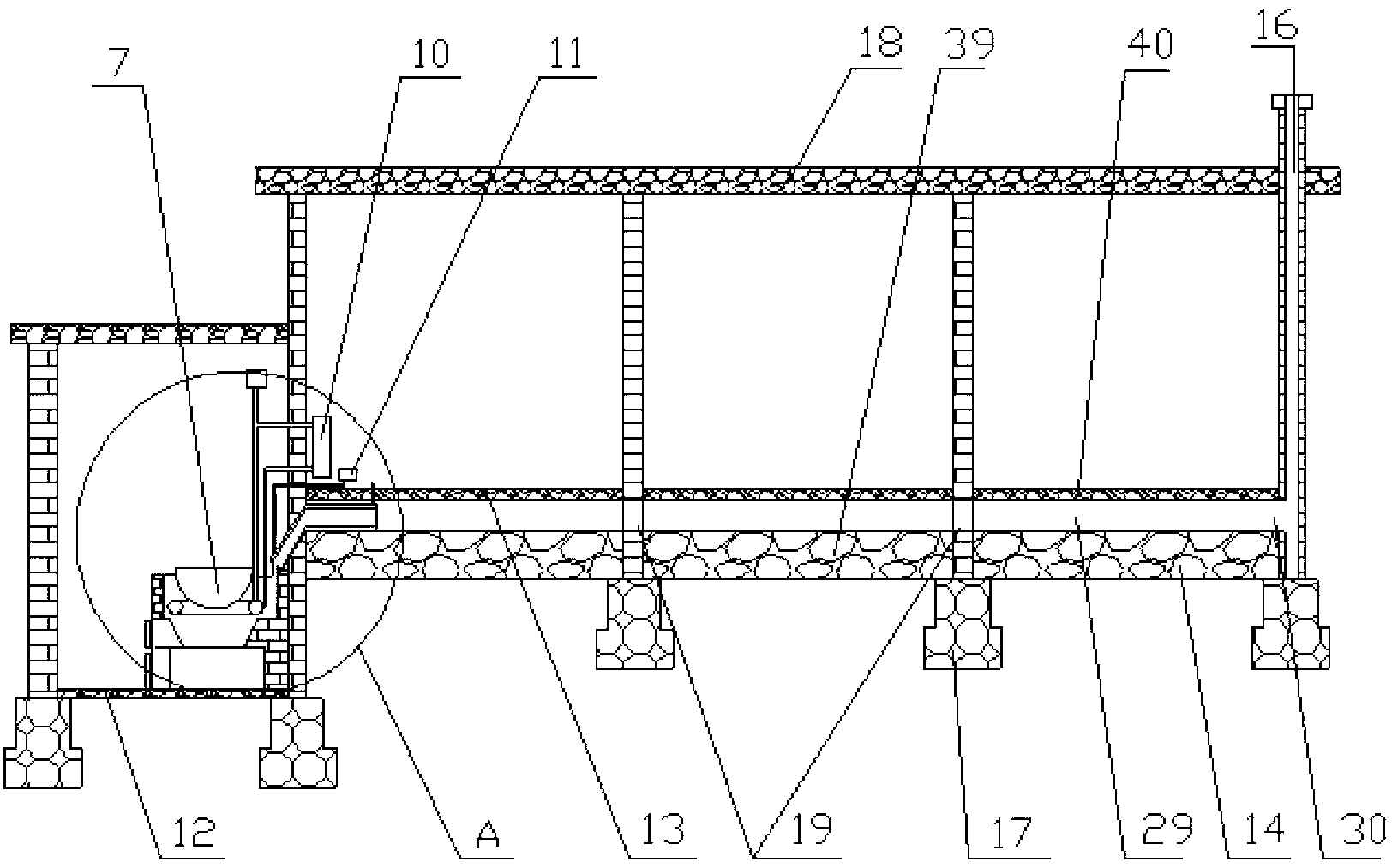

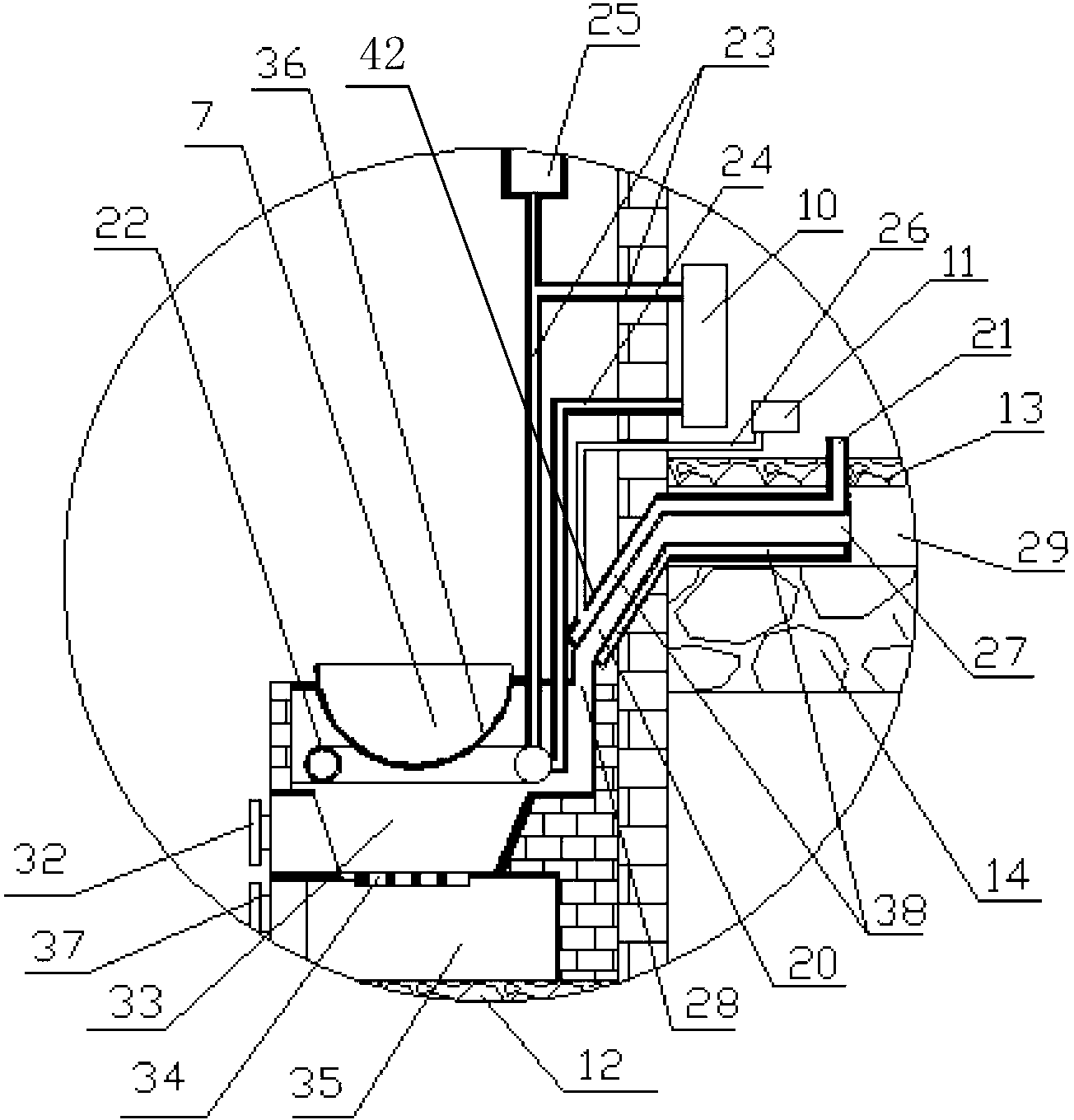

Heat storage pit warm in winter and cool in summer

InactiveCN103017246AUnobstructed smoke exhaustImprove efficiencyLighting and heating apparatusStove/ranges for heating waterPipingFlue

The invention relates to a heat storage pit warm in winter and cool in summer and belongs to the technical field of indoor worming facilities. The heat storage pit comprises a pit body, ranges and a chimney, wherein the pit body is positioned underground and comprises a pit plate and a grait heat storage bed; a flue is arranged between the pit plate and the grait heat storage bed; the chimney is vertical to the pit plate; the flue is communicated with the chimney; each range comprises a hearth and a dust falling chamber under the hearth, and a grate is arranged between the hearth and the dust falling chamber; the ranges are a winter range and a summer range; a hot water ring is arranged at the upper part in the hearth of the winter range; the two ends of the hot water ring are communicated with one end of a water supply pipe and one end of a water return pipe; the other ends of the water supply pipe and the water return pipe are communicated with a heating radiator; a smoke outlet of the hearth of the winter range is communicated with a smoke outlet cylinder; a smoke outlet of the smoke outlet cylinder is arranged in the chimney; a sleeve is arranged outside the smoke outlet cylinder in a sleeving manner; a hot air chamber is hermetically formed between the smoke outlet cylinder and the sleeve; one end of the hot air chamber is communicated with a blast pipe and a speed-regulating blast blower; and the other end of the hot air chamber is communicated with a hot air outlet pipe.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for plating double-layer zinc on surface of neodymium-iron-boron permanent magnet material

InactiveCN110791787AHigh porosityStrong dispersion abilityJewelleryCorrosion resistantNeodymium iron boron

The invention discloses a method for plating double-layer zinc on the surface of a neodymium-iron-boron permanent magnet material, and belongs to the field of surface treatment of sintered neodymium-iron-boron permanent magnet materials. The method is characterized in that the method comprises the following steps: (1) deoiling the neodymium-iron-boron permanent magnet material; (2) cleaning the deoiled neodymium-iron-boron permanent magnet material, and then pickling the neodymium-iron-boron permanent magnet material; (3) activating the acid-washed neodymium-iron-boron permanent magnet material; (4) performing sulfate zinc electroplating on the neodymium-iron-boron permanent magnet material to form a bottom zinc layer; (5) performing potassium salt zinc plating on the neodymium-iron-boronpermanent magnet material to form a surface zinc layer; and (6) passivating the surface of the galvanized neodymium-iron-boron permanent magnet material. The neodymium, iron and boron treated by the method for plating the double-layer zinc on the surface of the neodymium-iron-boron permanent magnet material are excellent in corrosion resistance, the salt spray resistance experiment after passivation can reach more than 120 hours, the bonding strength of a galvanized layer and the neodymium-iron-boron permanent magnet material is improved, and the corrosion resistance of the galvanized layer isalso improved.

Owner:ARCFL TECHNOLOGY LIMITED

Low-sulfur and environment-friendly coal and processing method thereof

InactiveCN105038891AImprove performanceEmission reductionSolid fuelsResource utilizationComponents of crude oil

The invention provides low-sulfur and environment-friendly coal which mainly comprises, by weight, 40-70 parts of semi coke powder, 20-50 parts of coal slime, 20-50 parts of pulverized coal, 1-5 parts of a binder and 2-6 parts of an additive. The semi coke is a novel carbon material which is obtained through carbonization and pyrolysis of cohesionless or weak-viscosity high volatile bituminous coal at the medium and low temperature, and the fixed carbon amount of the semi coke is larger than or equal to 82%. The coal slime is sticky waste produced in the coal washing and dressing process, and the fixed carbon content of the coal slime is 30-52%. The invention further provides a processing method of the low-sulfur and environment-friendly coal. In-place optimization of the semi coke powder is achieved, resource utilization is achieved for coal slime solid waste, and pollution caused by the waste to the environment is reduced. The total sulfur of briquette coal is smaller than or equal to 0.4, smoke and SO2 emission can be effectively reduced in the combustion process of briquette coal, and pollution to the atmosphere is reduced.

Owner:光大清洁技术股份有限公司

Method of cement kiln co-processing for calcium-added and passivated town sludge

ActiveCN102718378AEasy to transportEasy to handleSludge treatmentEnergy based wastewater treatmentCalcium in biologySludge

The invention discloses a method of cement kiln co-processing for calcium-added and passivated town sludge and solves the technical problems that the content of organic matters in the town sludge is lower while the content of heavy metals in the town sludge is higher, the nature of the sludge is not stable, the moisture content of the sludge is high and the sludge is difficult to transport. The implementation steps of the method are as follows: firstly, the constituents and the moisture content of the town sludge are tested, the pH value of the town sludge is usually between 6 and 8, and when the sludge meets leachate within the pH value range or in the landfilling state, the heavy metals are dissolved out easily, and the increasing of the pH value of the sludge is beneficial for passivation of the heavy metals and reduction of dissolution of the heavy metals; the town sludge is mixed with waste lime to ensure that the pH value of the mixture is between 9 and 10, and the mixture is kept stable at room temperature for 2-7 days; and the mixture enters a novel dry-process cement kiln from below a predecomposition furnace, silicon and calcium in the sludge and calcium in the lime can be used to produce silicate cement, and the organic matters in the sludge can be burnt so as to replace partial cement kiln fuel. The method of the cement kiln co-processing for the calcium-added and passivated town sludge is an economical, fuel-saving and low-pollution method for resource utilization of the town sludge.

Owner:南京希捷环保科技有限公司

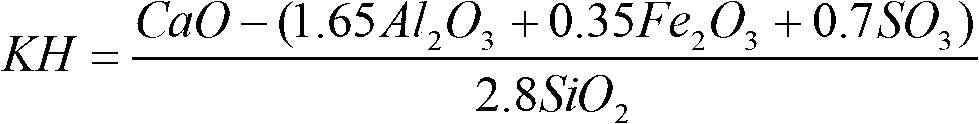

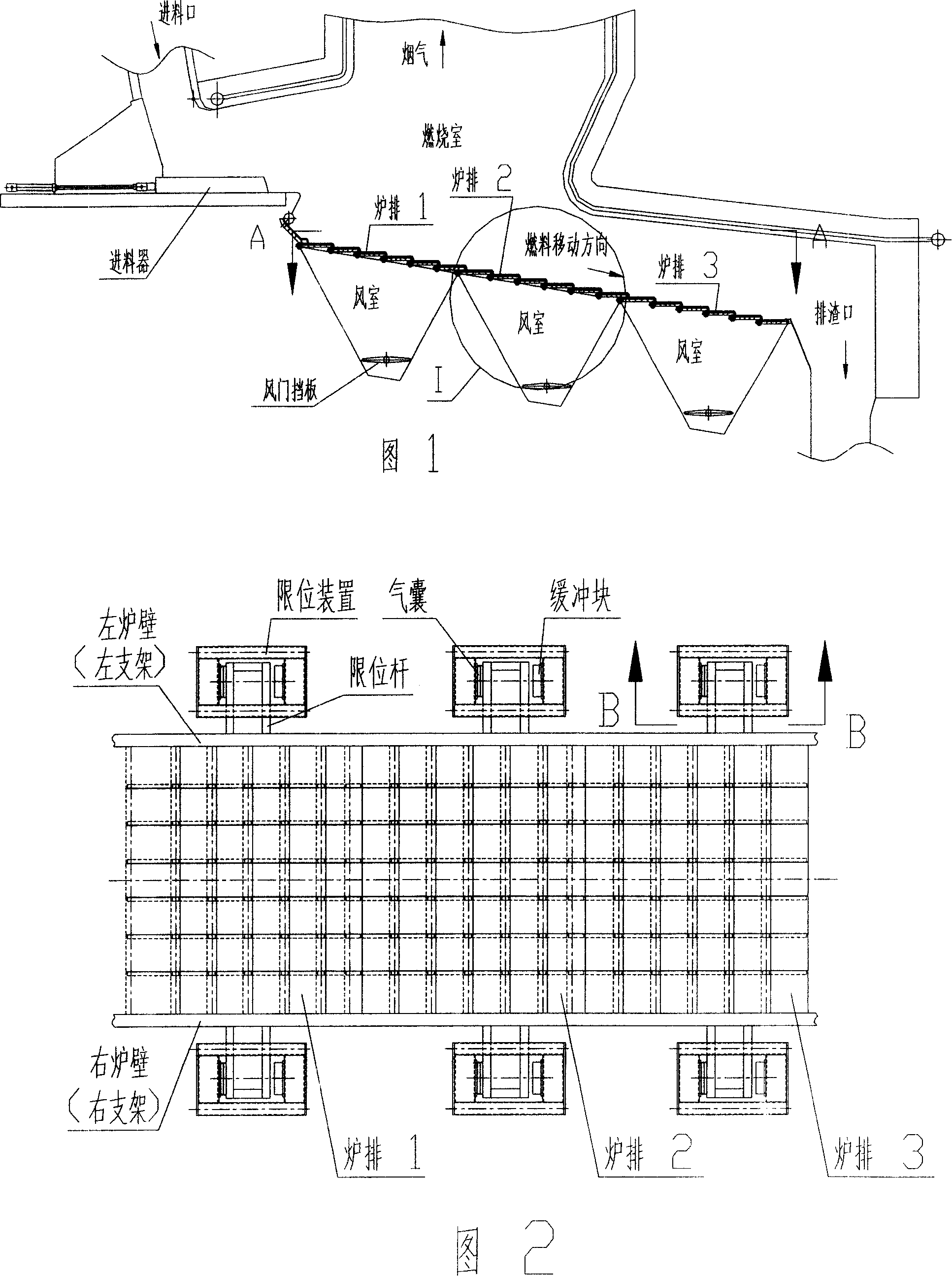

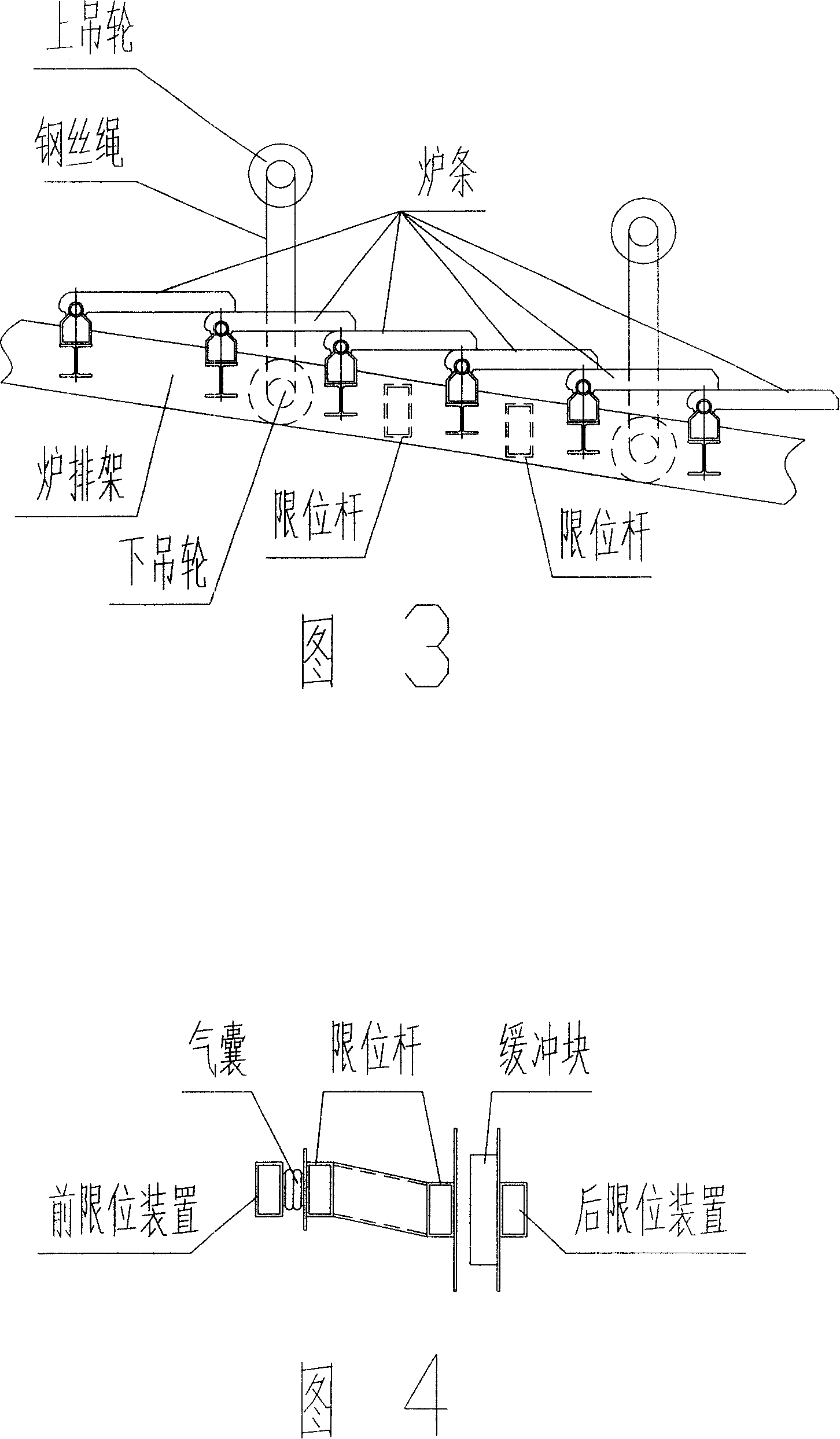

Vibrating high burn-out grate

InactiveCN101149152AReduce gapImprove combustion efficiencyRevolving grateTravelling grateCombustion chamberSlag

This invention is a vibrating high burnout grate. The fire bar is fixed at the grate surface. The grate is suspended on the furnace wall through steel wire and can move a little backwards. The air chamber in vibration device provides driving force for grate to move. The anterior end of grate is material feeding opening. The posterior end is slag-off opening. The superior end is combustion chamber. The inferior end is air chamber. This invention has high combustion efficiency and long life span.

Owner:刘沪滨

Bypass ventilation process and equipment

InactiveCN108534543AReduce lossReduce the difficulty of disposalRotary drum furnacesWaste heat treatmentCold airFlue gas

The invention belongs to the field of cement production process, and particularly relates to a bypass ventilation process and equipment. The bypass ventilation process comprises the following steps that step 1, high-temperature bypass flue gas with the temperature of 950-1250 DEG C extracted from a smoke chamber is subjected to dust collecting through a cyclone tube, the collected dust is returnedto a decomposing furnace or the smoke chamber, and enters a rotary kiln; step 2, after the high-temperature bypass flue gas after the treatment of the step 1 is mixed with cold air, the temperature of the high-temperature bypass flue gas is quenched and cooled down to 500 DEG C or below, and harmful components in the flue gas are agglomerated into solid particles; and step 3, the flue gas after quenching is subjected to dust collecting by a dust collector, and the dust which is not collected in the step 1 and the newly formed solid particles in the step 2 are collected, and the collected dustinside the dust collector is exhausted. The invention provides the bypass ventilation process and equipment which can effectively reduce the dust discharging amount of the bypass ventilation system and reduce the difficulty of disposal.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

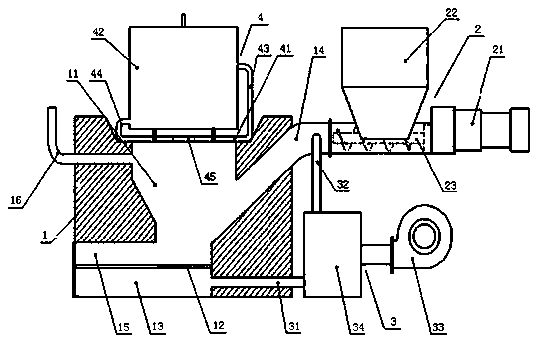

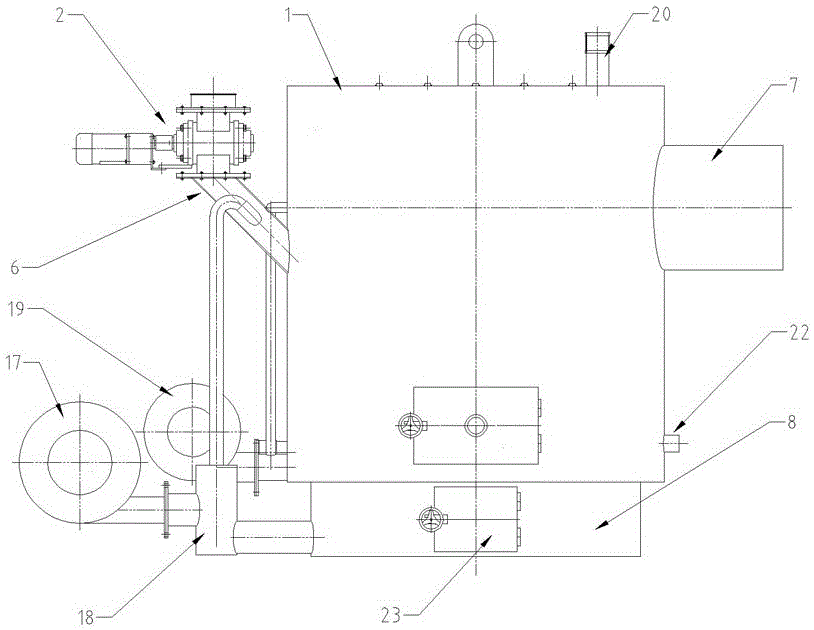

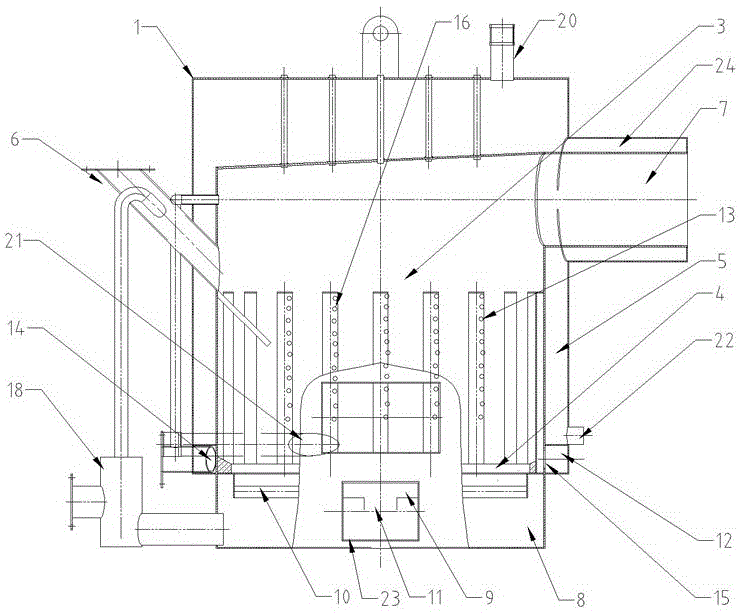

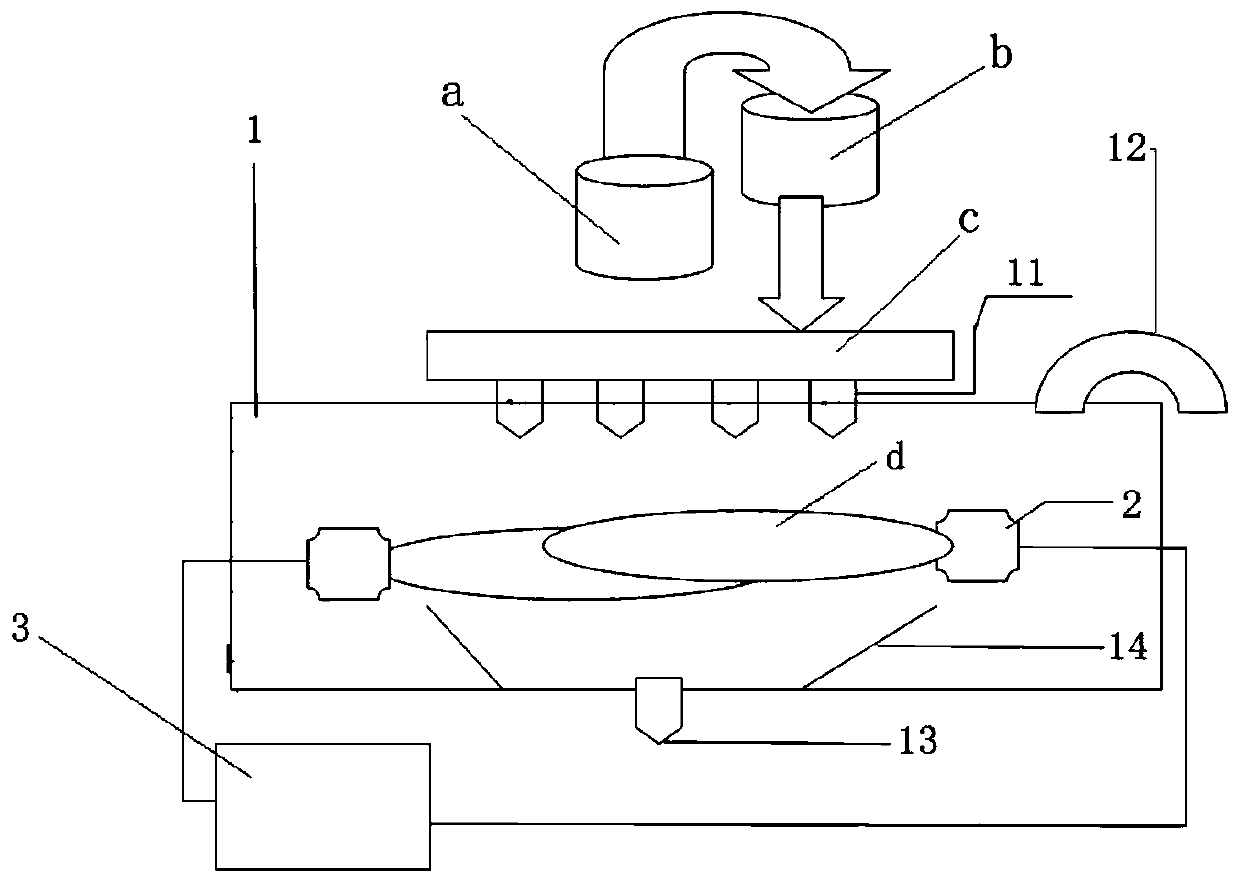

Combusting and heating boiler for biomass fuel

InactiveCN105509031ABurn fullyImprove combustion efficiencyFuel feeding arrangementsSolid fuel combustionThermal energyCombustion chamber

The invention discloses a combusting and heating boiler for biomass fuel. The combusting and heating boiler comprises a combustion boiler body, a feed mechanism, an air supply mechanism and a heating tank. A combustion chamber is formed in the middle of the combustion boiler body, the heating tank is arranged above the combustion chamber, the feed mechanism is communicated with a feed channel of the combustion boiler body, the air supply mechanism is communicated with a fire grate and the feed channel of the combustion boiler body, and the heating tank is provided with a cold water circulating pipe and a hot water circulating pipe both communicated with a tank body and a heating layer. The combusting and heating boiler has the advantages that the structure is simple, the biomass fuel can be combusted more fully, the combustion efficiency is high, flames are stable, the utilization rate of the thermal energy is high, the energy-saving effect is remarkable, the slagging and coking problems of a device in the combustion process of the biomass fuel are solved, and application is wide.

Owner:广西节得乐生物质能源科技有限公司

Coal-burning energy releasing powder and its prepn

The present invention discloses one kind of coal-burning energy releasing powder and its preparation process. The coal-burning energy releasing powder consists of saltpeter 0.5-1.5 weight portions, ferric dicyclopentadiene or allyl cyanurate 1-2 weight portions, potassium permanganate or potassium bromide 0.3-0.7 weight portions, sodium nitrate or calcium nitrate 0.3-0.7 weight portions, potassium permanganate or potassium persulfate 1.5 -2.5 weight portions, strontium nitrate or sodium bichromate 0.5-1.5 weight portions, calcium fluoride 1.5-2.5 weight portions, coal slag or char slag 1.5-2.5 weight portions, loess or lime 1.5-2.5 weight portions, potassium chlorate or potassium persulfate 0.5-1.5 weight portions, potassium nitrate 0.5-1.5 weight portions, and sodium chloride 80-90 weight portions. It can promote combustion of coal to convert the latent energy of coal into heat completely.

Owner:张学义

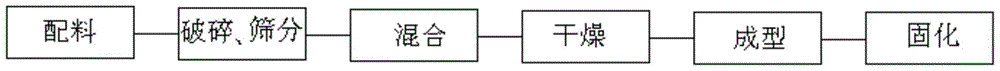

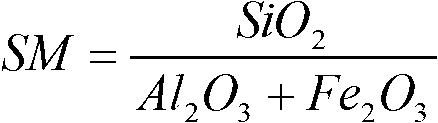

Composite carbonaceous reductant for industrial silicon and preparation method thereof

ActiveCN104003395AQuality improvementHigh fixed carbon content in cokeSilicon compoundsTrace elementNew energy

The invention relates to a composite carbonaceous reductant for industrial silicon and a preparation method thereof, and belongs to the industrial silicon smelting and new energy resource technical fields. The composite carbonaceous reductant is of a pellet shape, the fixed carbon content reaches above 75 wt.%, the volatile matter content is 15 wt.%-20 wt.%, the ash content is below 4 wt.%, and the contents of trace elements of Fe, Al and Ca in ash are controlled respectively below 0.15 wt.%, below 0.5 wt.% and below 0.6 wt.%. The preparation method comprises the steps: finely grinding petroleum coke and low-ash coal, mixed evenly, adding a binder and water, then pressing into pellets under the condition of the pressure of 5-10 MPa, drying the pellets, and thus obtaining the composite carbonaceous reductant. The composite carbonaceous reductant for industrial silicon is high in fixed carbon content and good in reaction activity; and the preparation method of the composite carbonaceous reductant for industrial silicon is simple in process and easy to industrialize.

Owner:KUNMING UNIV OF SCI & TECH

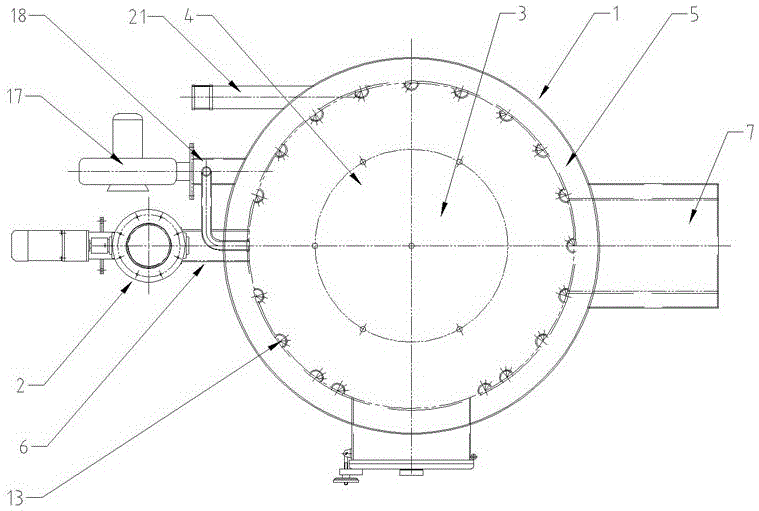

Biomass fuel boiler with rotatable fire grate

InactiveCN107741025APrevent fallingHeating up fastSolid fuel combustionWater heatersSlagMechanical engineering

The invention discloses a biomass fuel boiler with a rotatable fire grate. The biomass fuel boiler comprises a furnace body, wherein the furnace body comprises a first furnace body and a second furnace body which are arranged in a sleeved mode; the rotatable fire grate, wherein the rotatable fire grate is vertically arranged in the first furnace body in a rotating mode through a rotating shaft, the rotatable fire grate comprises multiple fuel trays, and the fuel trays are sequentially arranged in the axial direction of the rotating shaft at intervals; a pair of fins, wherein the pair of fins are spirally and symmetrically arranged on two sides of the rotating shaft, and sequentially penetrate through the multiple fuel trays; and pneumatic biomass powder feeding pipes, wherein one ends of the pneumatic biomass powder feeding pipes penetrate through the furnace body and extend to be opposite to the fins. A biomass particle feeding hole is formed in the top part of the furnace body; a mode water cooling wall is arranged on the side wall of the furnace body; a slag collecting tank is detachably arranged at the bottom part of the rotatable fire grate; multiple circulating ports are annularly and uniformly arranged on the side wall, close to the first furnace body, of the bottom of the second furnace body at intervals; and the biomass fuel boiler further comprises a smoke outlet anda base. According to the biomass fuel boiler, biomass powder and biomass particle fuel can be fully mixed and combusted, combustion is sufficient, the heat utilization rate is high, and energy-savingand environment-friendly effects are achieved.

Owner:江苏东方电力锅炉配件有限公司

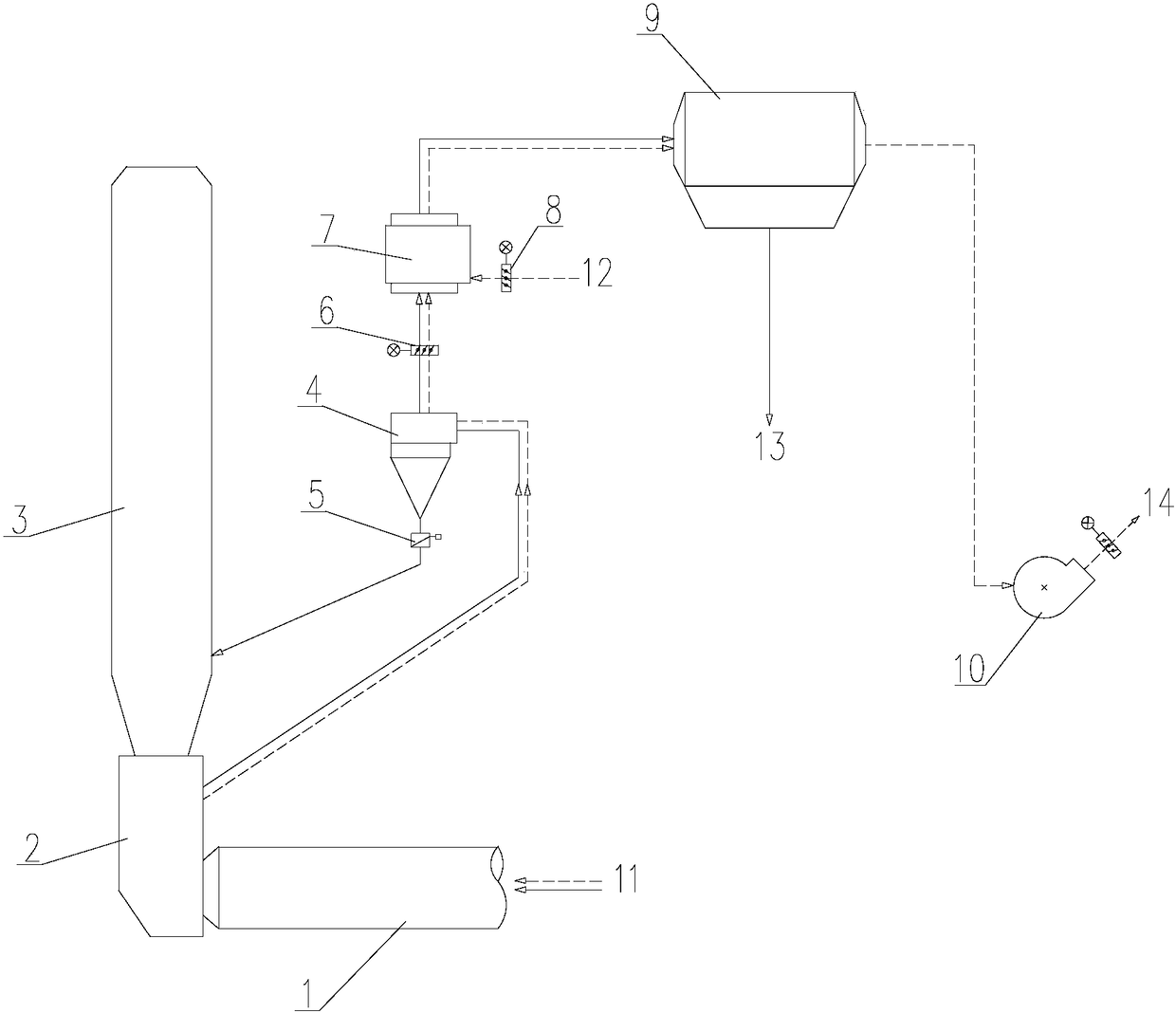

Biomass particle semi-gasification combustion handpiece

ActiveCN106196015ARapid fission decomposition gasificationBurn fullySolid fuel combustionCasings/liningsCycloneCombustion chamber

The invention relates to a biomass particle semi-gasification combustion handpiece. The biomass particle semi-gasification combustion handpiece comprise a furnace body, a feeding device, a primary cyclone oxygenating system and a secondary cyclone oxygenating system. A gasification combustion chamber is arranged on the upper portion of the furnace body. A flame bridge is arranged on the lower portion of the furnace body. An interlayer water jacket is arranged on the side face of the gasification combustion chamber. A water-cooled flame spray pipe communicating with the outside is arranged on the upper side portion or the top of the gasification combustion chamber. Through the biomass particle semi-gasification combustion handpiece, biomass particles can be sufficiently combusted, the defects that the biomass particles are not combusted evenly, blue smoke and black smoke are generated, the ash content is high, and ash is too much are effectively overcome, the biomass particle combustion efficiency is improved by about 5%, waste heat is absorbed and utilized, energy is saved, and emission is reduced.

Owner:郴州华峰能源科技有限公司

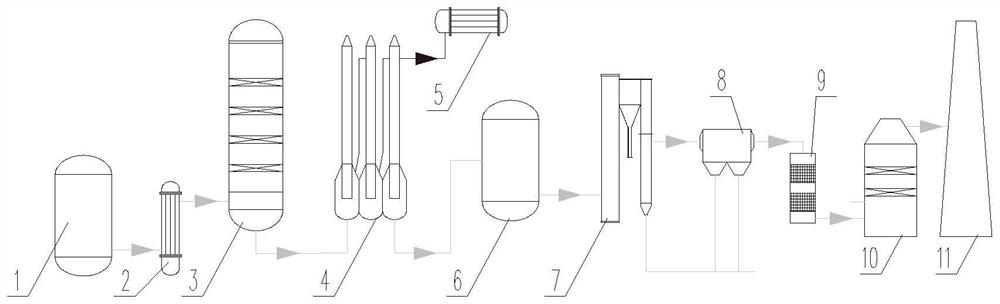

Biomass particle gasification process for kiln

ActiveCN102703123AHigh densityIncrease replacement rateCombustible gas productionWood shavingsHigh energy

The invention discloses a biomass particle gasification process for a kiln, which comprises the following steps of: smashing and pressing sawdust and wood shavings into biomass particles; adding the biomass particles into a biomass gas gasification furnace according to certain weight to carry out a thermalization cracking reaction to generate mixed gas by controlling the burning temperature in the furnace to be 900-1,200 DEG C; spraying the outlet mixed gas, and introducing the sprayed gas into a purifier for heat exchange; cooling, then introducing the gas into a cyclone chamber, and separating out ash content in the gas under the action of cyclone separation; and introducing gas after the cyclone separation into a separator, and under the condensation action of the separator, further separating out clean gas and liquid residues by controlling the clean gas output temperature to be 20-25 DEG C. Compared with the prior art, the biomass particle gasification process for the kiln has the advantages of high energy conversion ratio, high gas heat value, good purification effect, low tar content, large gas output and uniform gas outlet.

Owner:柳州东侯生物能源科技有限公司

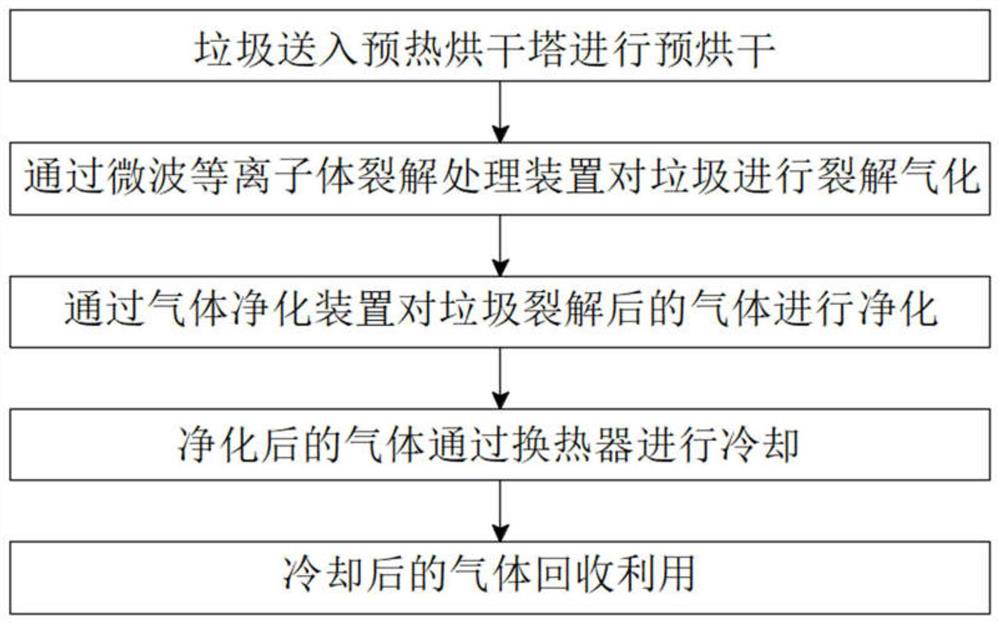

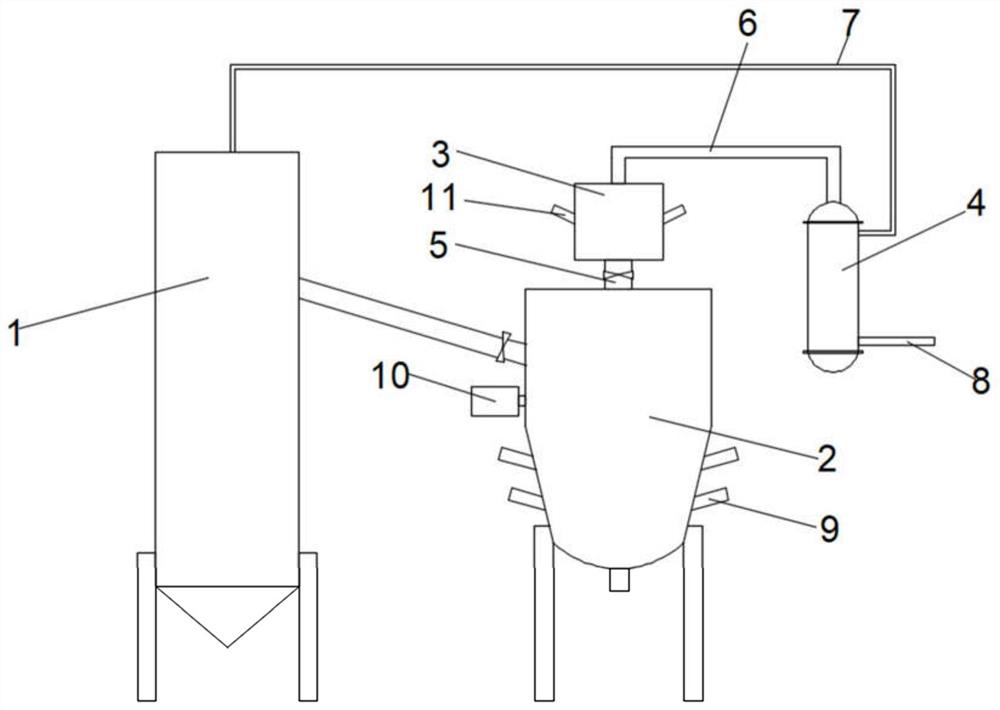

Microwave plasma cracking gasification technology

InactiveCN112410050AAchieving an almost complete decompositionNo pollution in the processProductsReagentsThermodynamicsHazardous substance

The invention provides a microwave plasma pyrolysis gasification technology, and relates to the technical field of garbage decomposition gasification. The microwave plasma pyrolysis gasification technology and application thereof comprise the following steps: S1, conveying to-be-treated garbage into a preheating drying tower for pre-drying treatment; s2, transporting the pre-dried garbage into a microwave plasma cracking treatment device through a propelling device; s3, cracking, by the microwave plasma cracking treatment device, the garbage in a vacuum environment for gasification; s4, introducing the generated gas into a gas purification device through a special channel for secondary cracking purification; and S5, extracting and recovering the gas after secondary cracking through an airextracting pump to obtain a product after garbage gasification. Through the microwave plasma pyrolysis gasification technology provided by the invention, the plastic garbage can be completely decomposed and gasified and converted into useful gas to be recycled; in addition, the recycled gas does not contain harmful substances, so that the technology is very environment-friendly.

Owner:广州市凯卫莎环保科技有限公司

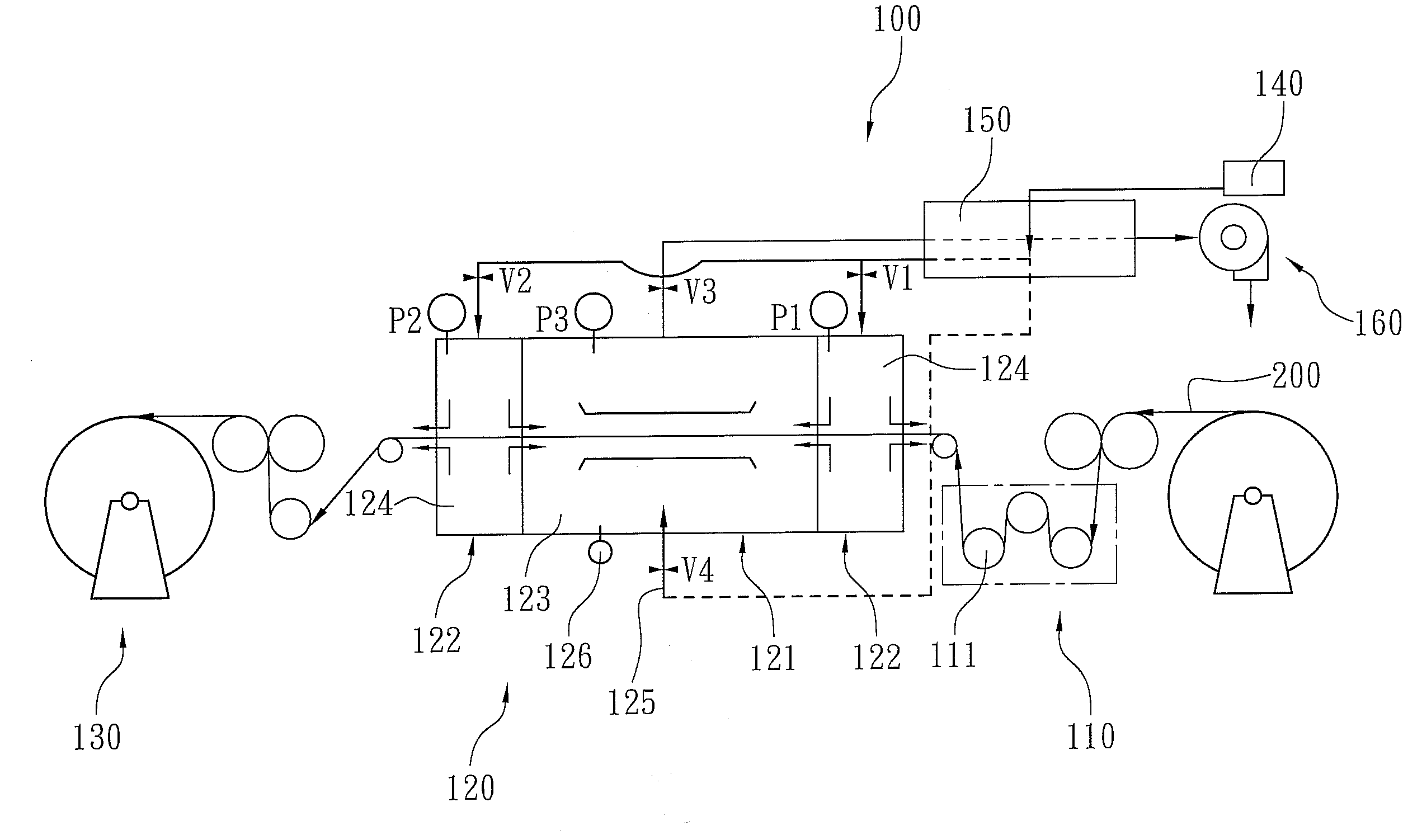

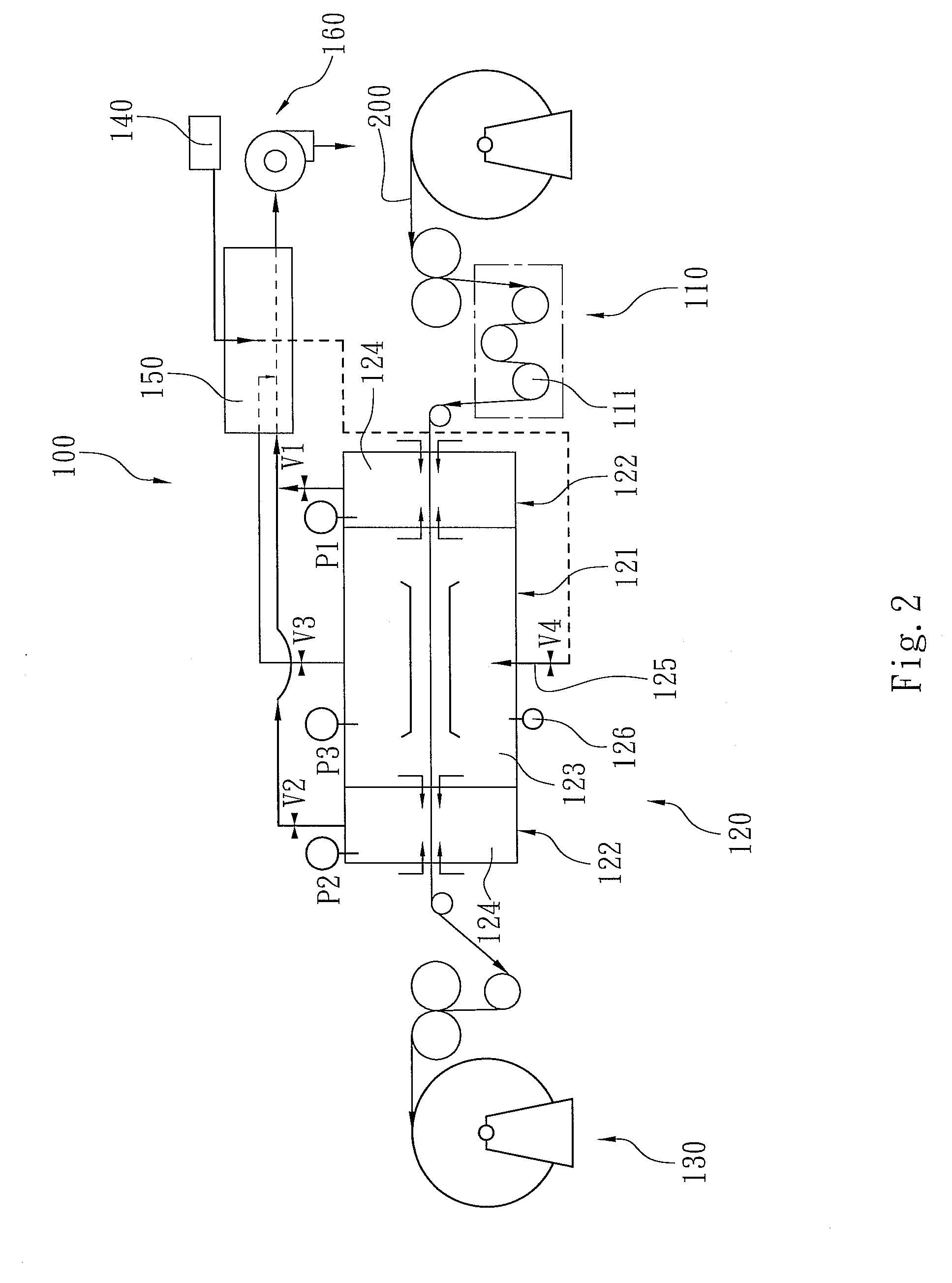

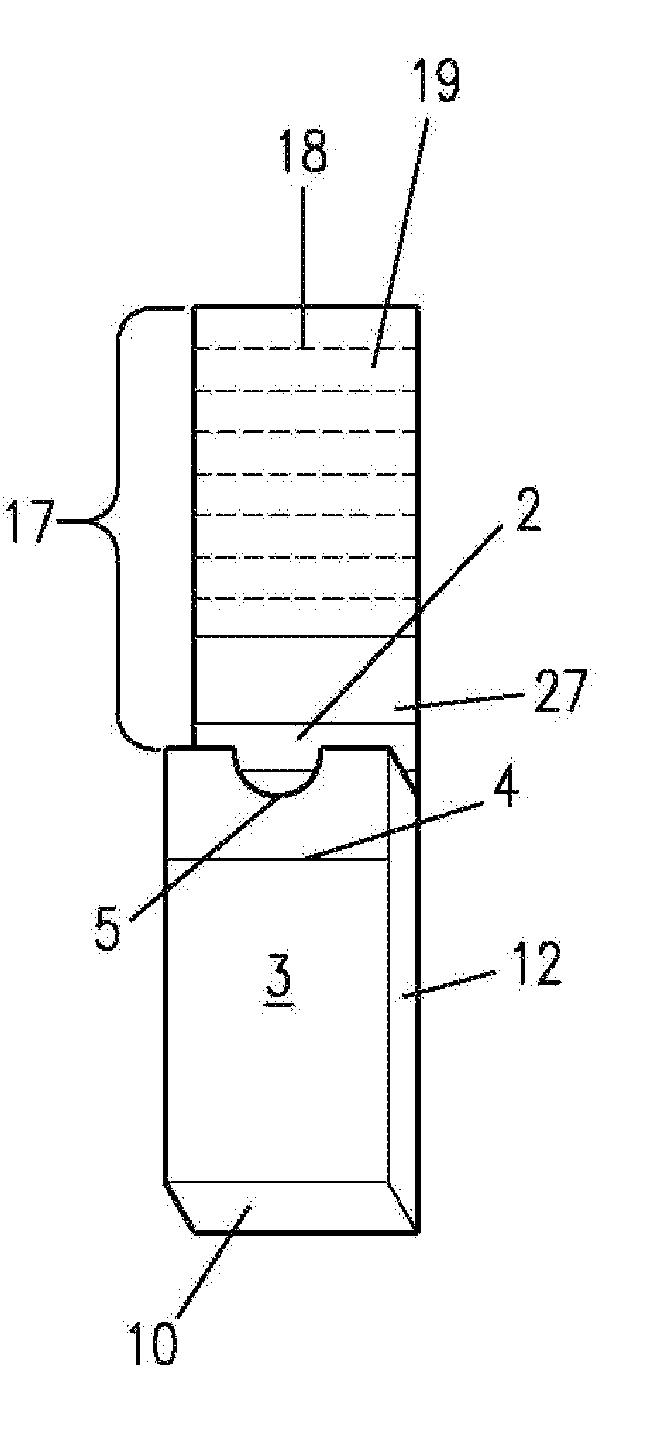

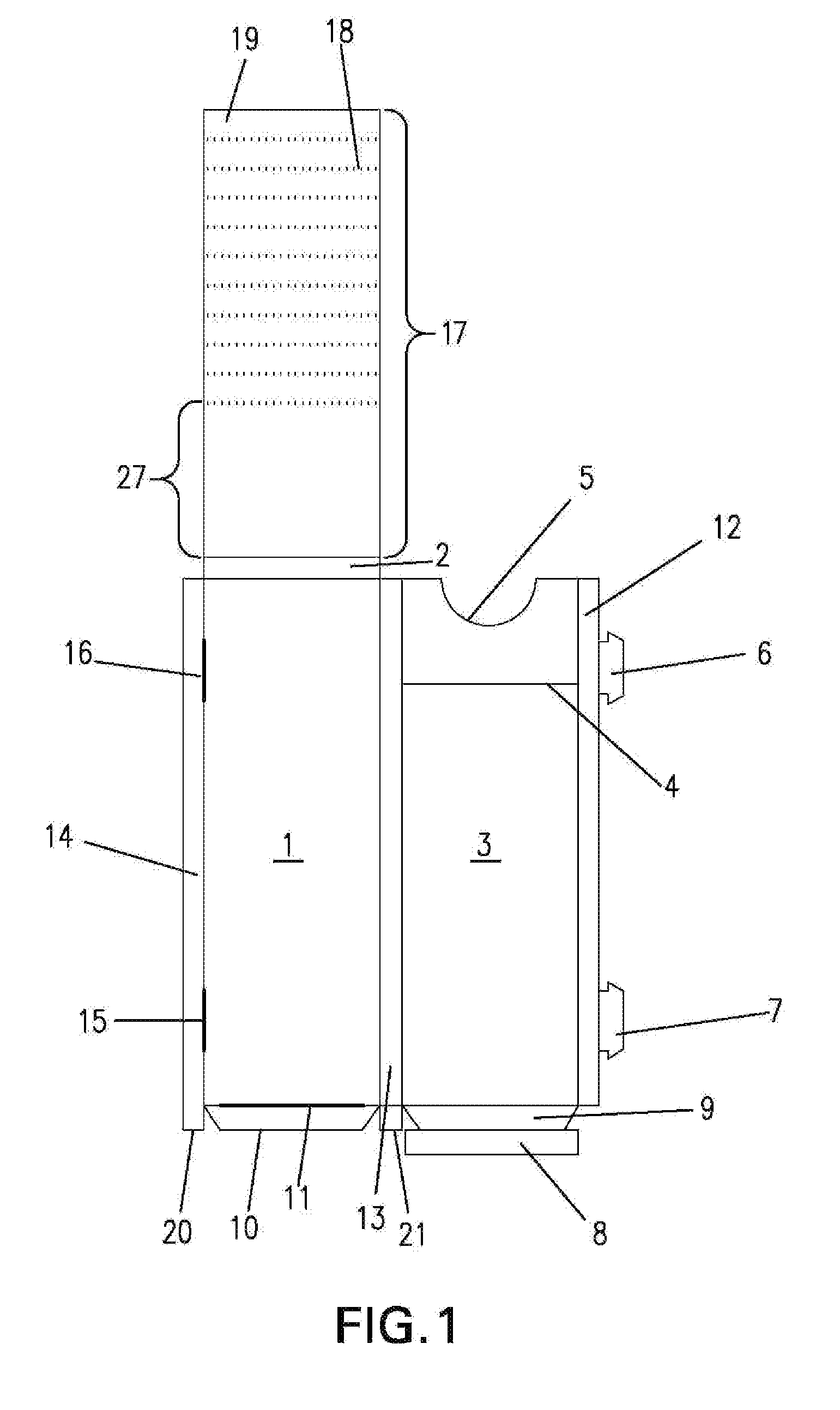

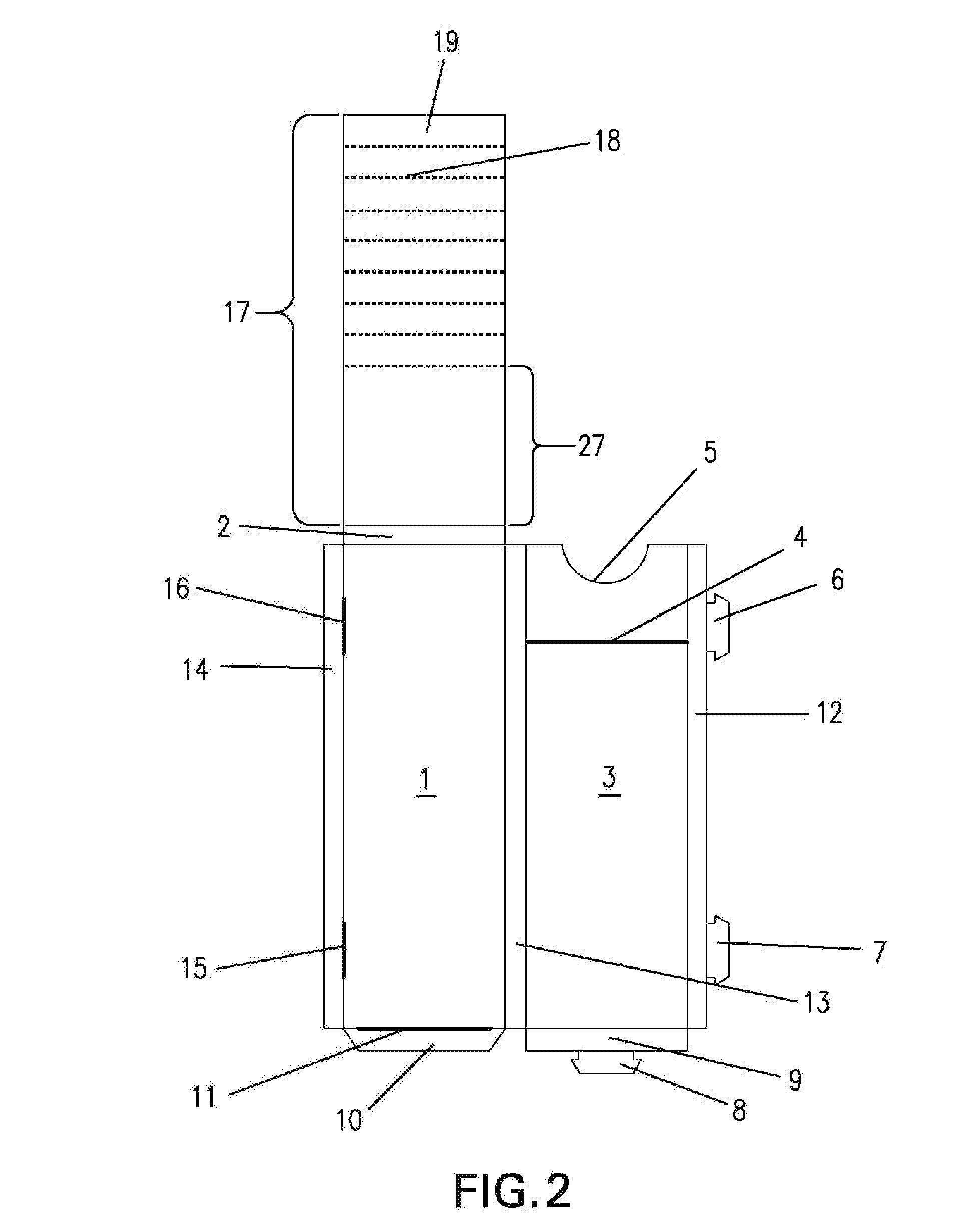

Carbonization apparatus and method of the same

InactiveUS20100189627A1High degreeEasy to disassemblePhysical/chemical process catalystsCarbon preparation/purificationCarbonizationAtmospheric pressure

A continuous negative pressure carbonization apparatus includes a material feeding device, a carbonizing chamber and a material collecting device. The material feeding device feeds the raw material. The carbonizing chamber receives and carbonizes the raw material and it includes a carbonization device and two buffering devices. The carbonization device has a carbonization chamber. The carbonization chamber has a material inlet and a material outlet. The buffering devices are respectively mounted and connected to the material inlet and the material outlet. The material collecting device collects the carbonized product from the carbonization chamber. When the raw material is carbonized in the carbonization chamber, the pressure of the carbonization chamber is kept at a negative pressure state smaller than the atmospheric pressure.

Owner:LINKWIN TECH

Systems and methods for processing mixed solid waste

ActiveUS20200316661A1Maximize efficiencyImprove efficiencyInternal combustion piston enginesWaste processingEnvironmental engineeringWaste management

Solid waste that includes a mixture of wet organic material and dry organic material can be are separated using mechanical separation to produce a wet organic stream enriched in wet organics and a dry organic stream enriched in dry organics. The separated wet organic stream and dry organic stream are separately converted to renewable or recyclable products using different conversion techniques particularly suited for the separated wet and dry organic streams.

Owner:UPLAND ROAD IP HOLDCO LLC

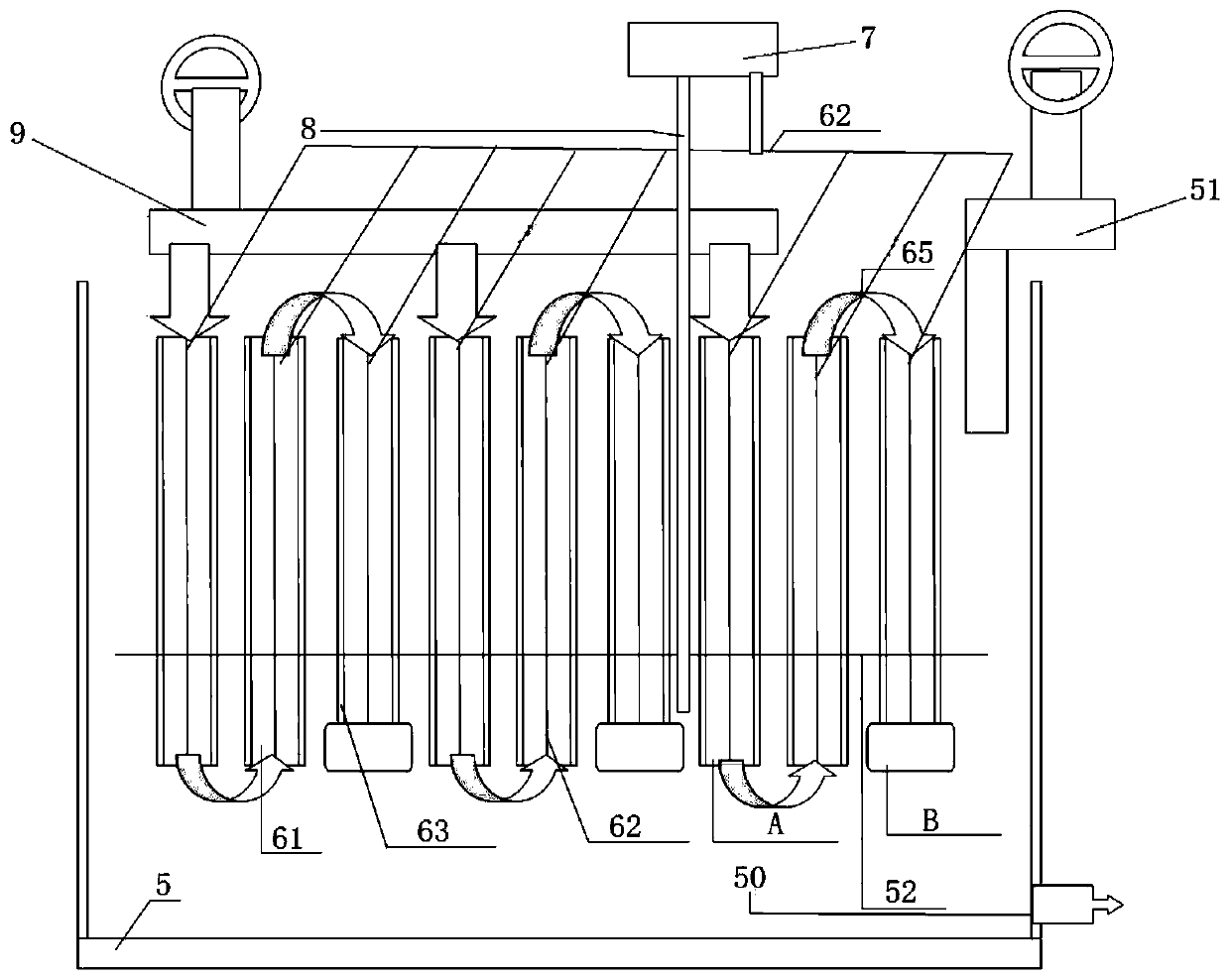

Advanced treatment method for PTA petrochemical wastewater

PendingCN112624237ASmall footprintSave land resourcesGas treatmentDispersed particle filtrationReboilerLiquid water

The invention discloses an advanced treatment method for PTA petrochemical wastewater, which comprises a reboiler, a steam stripping tower, a multi-effect evaporator and a condenser, and comprises the steps of pumping petrochemical wastewater into the reboiler, and indirectly exchanging heat with steam to enable the wastewater to form a steam-water mixture; enabling the steam-water mixture to enter the steam stripping tower, wherein the steam stripping tower operates under normal pressure, and after steam stripping separation, light components with the boiling point lower than that of water enter a light component collecting device to be recycled; enabling the wastewater at the bottom of the steam stripping tower to enter the multi-effect evaporator to evaporate the wastewater at the bottom of the steam stripping tower; enabling the evaporated water vapor to enters the condenser, and condensing the evaporated water vapor into liquid water for recycling; concentrating the remaining wastewater according to a proportion of 10-15 times, and storing in a buffer tank; and spraying the concentrated solution in the buffer tank into an incinerator to be incinerated, recycling heat generated by incineration, and carrying out treatment on smoke generated by incineration. Equipment adopted in the method is small in occupied area, and zero discharge of petrochemical wastewater and resource recycling of light components, industrial water and steam are completely achieved.

Owner:浙江百能科技有限公司 +1

Cigarette paper and dispensing package

InactiveUS20080302683A1Prevent escapeRegulate air flowNon-fibrous pulp additionNatural cellulose pulp/paperMouth pieceWater based

Cellulose-glycerol cigarette papers are described which has advantages such as milder taste, less chemicals, a slower burn with less ash and smoke, and also it is self-adhering when a water-based agent is applied. A cigarette paper dispensing package is also provided which enables easy access to a single cigarette paper. Tear-off mouthpiece filters are also integrally provided for within the package, while providing efficient dispensing of a single cigarette paper without spillage or grabbing too many inadvertently.

Owner:TANZER MICHAEL D

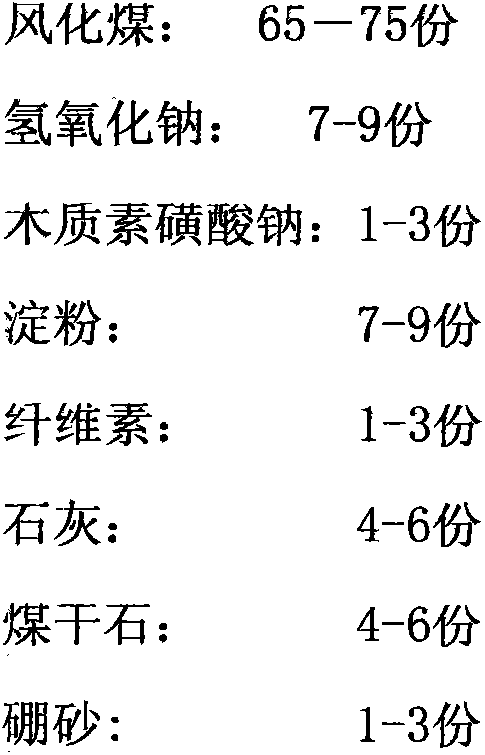

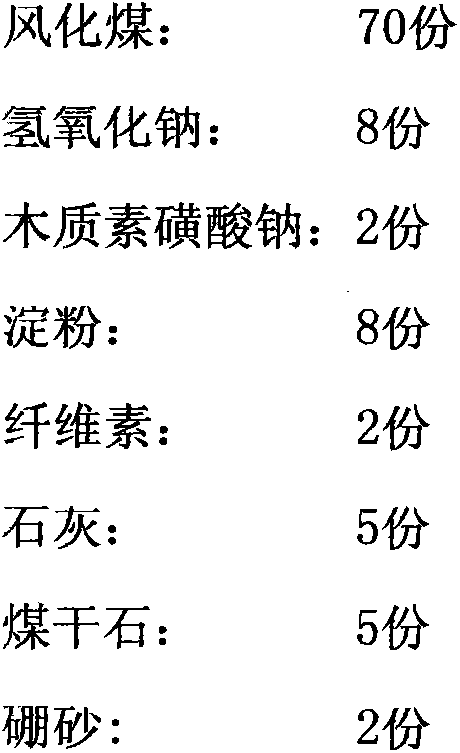

Efficient environment-friendly cheap adhesion agent of pellet and preparation method thereof

The invention relates to an efficient environment-friendly cheap adhesion agent of pellet, which is prepared from the following raw materials in parts by weight: 65-75 parts weathered coal, 7-9 parts of sodium hydroxide, 1-3 parts of sodium lignin sulfonate, 7-9 parts of starch, 1-3 parts of cellulose, 4-6 parts of lime, 4-6 parts of coal gangue and 1-3 parts of borax; the invention further relates to a preparation method of the efficient environment-friendly cheap adhesion agent of pellet, comprising the following steps of: 1) respectively taking out the weathered coal, the lime and the coal gangue according to the needed parts by weight, mixing and crushing for later use; 2) taking out the needed parts by weight of sodium hydroxide, adding water, heating up and stirring until dissolving the sodium hydroxide sufficiently for later use; 3) mixing the materials respectively prepared in the steps 1) and 2), stirring evenly, backing to dry, and crushing for later use; 4) taking out the needed parts by weight of sodium lignin sulfonate, starch, cellulose and borax, and mixing with the material prepared in the step 3), stirring and packaging, thereby obtaining the adhesion agent. The adhesion agent provided by the invention is suitable for preparation of pellet, and has the advantages of scientific and rational matching of ingredients, high pellet forming quality, good smelting result, low cost and easy preparation.

Owner:刘惠民 +1

Method for reducing porosity of surface coating of neodymium iron boron permanent magnet material

InactiveCN111020659AReduce porosityReduced magnetic flux lossPermanent magnet manufactureCapillary TubingPhysical chemistry

The invention discloses a method for reducing porosity of a surface coating of a neodymium iron boron permanent magnet material, belonging to the field of surface treatment of sintered neodymium ironboron permanent magnet materials. The method is characterized by comprising the steps of 1) deashing a neodymium iron boron permanent magnet material; 2) soaking the neodymium iron boron permanent magnet material in a sealant, and then carrying out water washing, wherein the sealant is an alcohol amine compound; 3) sequentially cleaning the wahsed neodymium iron boron permanent magnet material through an oil removal agent and an acid; and 4) activating the neodymium iron boron permanent magnet material, and then carrying out electroplating. According to the method for reducing the porosity ofthe surface coating of the neodymium iron boron permanent magnet material, hole sealing treatment is carried out before electroplating, water is sucked into gaps through capillary action, and oxide inthe gaps generates hydrated oxide through hydration, so that the volume of the oxide is increased, and the gaps are sealed; and furthermore, the porosity of the coating can be reduced, the coating isrelatively smooth and bright, and the magnetic flux loss of the magnet can be reduced.

Owner:ARCFL TECHNOLOGY LIMITED

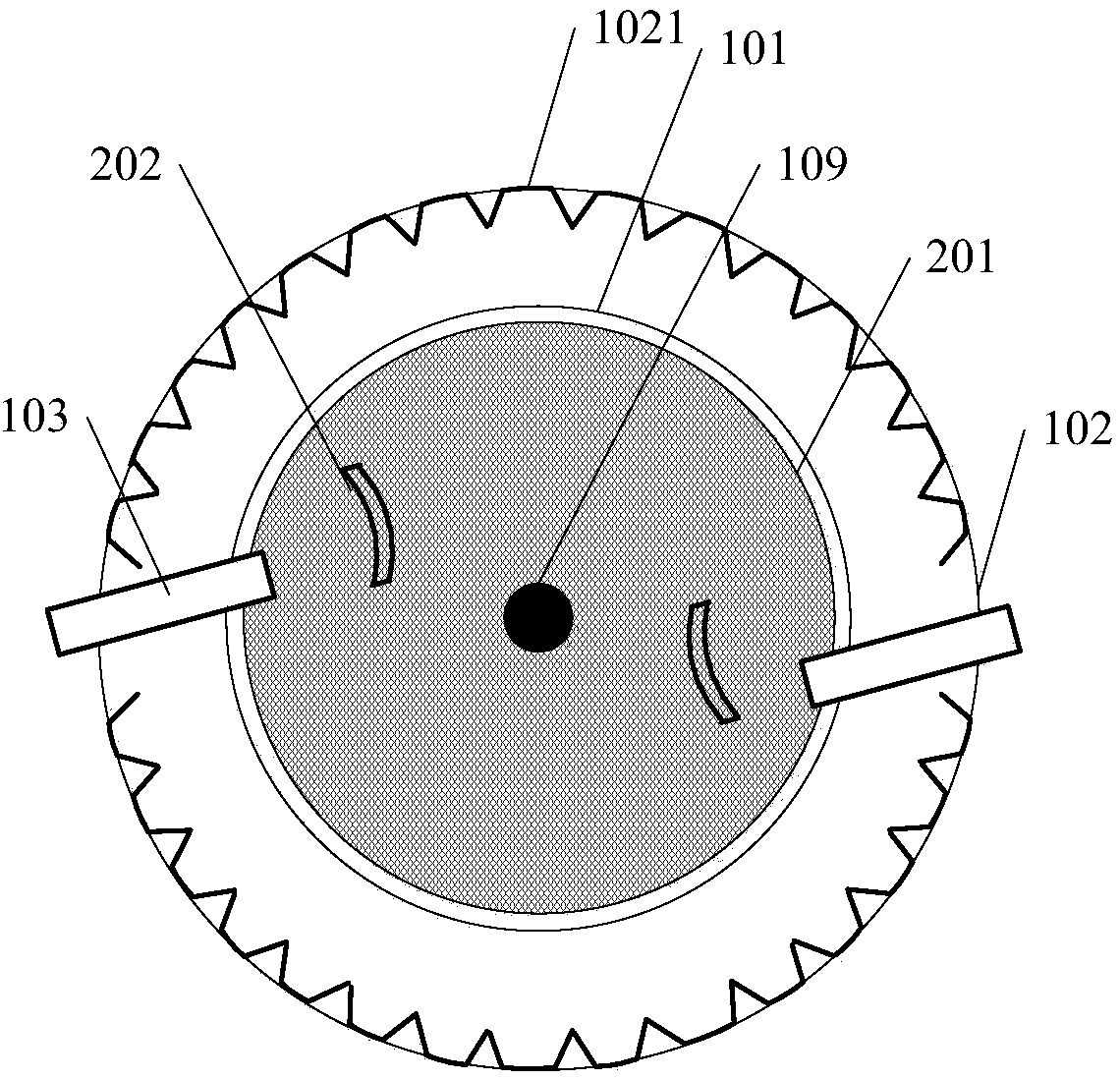

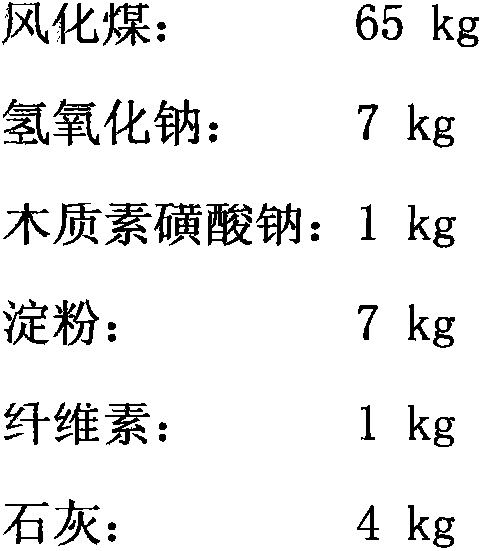

Preignition chamber with surrounding air suitable for rotational flow pulverized coal burner

InactiveCN107559820AAvoid powder accumulationPrevent slaggingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelRotational flowNozzle

A preignition chamber with surrounding air suitable for a rotational flow pulverized coal burner relates to the technical field of coal powder boilers. The invention aims to solve the problems of easiness in ash accumulation and easiness in slagging of the existing preignition chamber, so as to ensure long-term stable operation of the preignition chamber. The preignition chamber comprises a preignition chamber and a plurality of surrounding air nozzles, the rotational flow pulverized coal burner is arranged in the middle of the bottom end of the preignition chamber, a plurality of surroundingair nozzles are uniformly distributed in the bottom end of the preignition chamber along a circumferential direction, the surrounding air nozzles are inserted in the bottom surfaces of the preignitionchamber, the inside ends of the surrounding air nozzles are tightly attached to the inner drum wall of the preignition chamber, and gas is conveyed in the surrounding air nozzles. The invention is suitable for the rotational flow pulverized coal burner.

Owner:HARBIN INST OF TECH

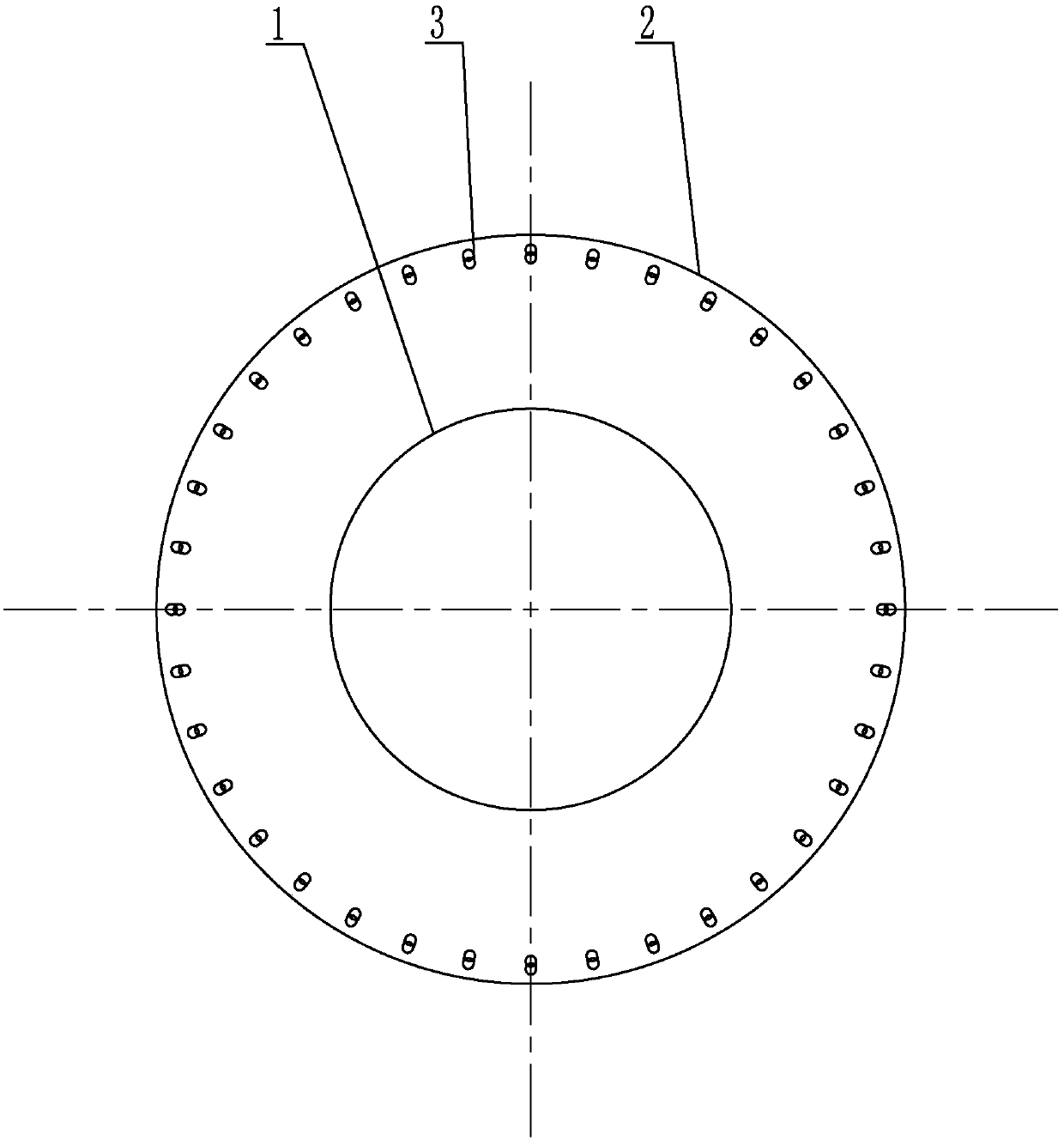

Distributed low-temperature plasma tubular accelerator straw fertilizer manufacturing machine

PendingCN111089302AEliminate the stubble effectAchieve capacity reductionIncinerator apparatusPotassium fertilisersAgricultural engineeringEnvironmental engineering

The invention relates to a distributed low-temperature plasma tubular accelerator straw fertilizer manufacturing machine, which comprises a high-temperature field sedimentation furnace, high-temperature plasma accelerators, a sealed water tank and a distributed low-temperature plasma tubular accelerator, wherein the high-temperature field sedimentation furnace is provided with a straw powder feeding hole, a tail gas discharging hole and an ash discharging hole; the flame nozzle of each high-temperature plasma accelerator communicates with the hearth of the high-temperature field sedimentationfurnace; the sealed water tank is provided with a liquid feeding and discharging valve and an air outlet and is filled with a preset water level of aqueous solution; the distributed low-temperature plasma tubular accelerator is used for manufacturing the tail gas of the high-temperature field sedimentation furnace into soluble fertilizers, and the soluble fertilizers are dissolved in the aqueous solution in the sealed water tank; and a condenser is arranged between the tail gas discharging hole and the sealed water tank. The hearth of the high-temperature field sedimentation furnace formed bythe high-temperature plasma accelerators generates a high-temperature even thermal force field; when straw powder particles fall to the high-temperature even thermal force field, the straw powder particles are instantaneously gasified, ashes sink to form soluble macroelement, medium element and trace element fertilizers, the tail gas is processed by the distributed low-temperature plasma tubular accelerator, nitrogen and sulfur gases condense and fall into water, and macroelement and medium element fertilizers are formed.

Owner:杭州三得农业科技有限公司

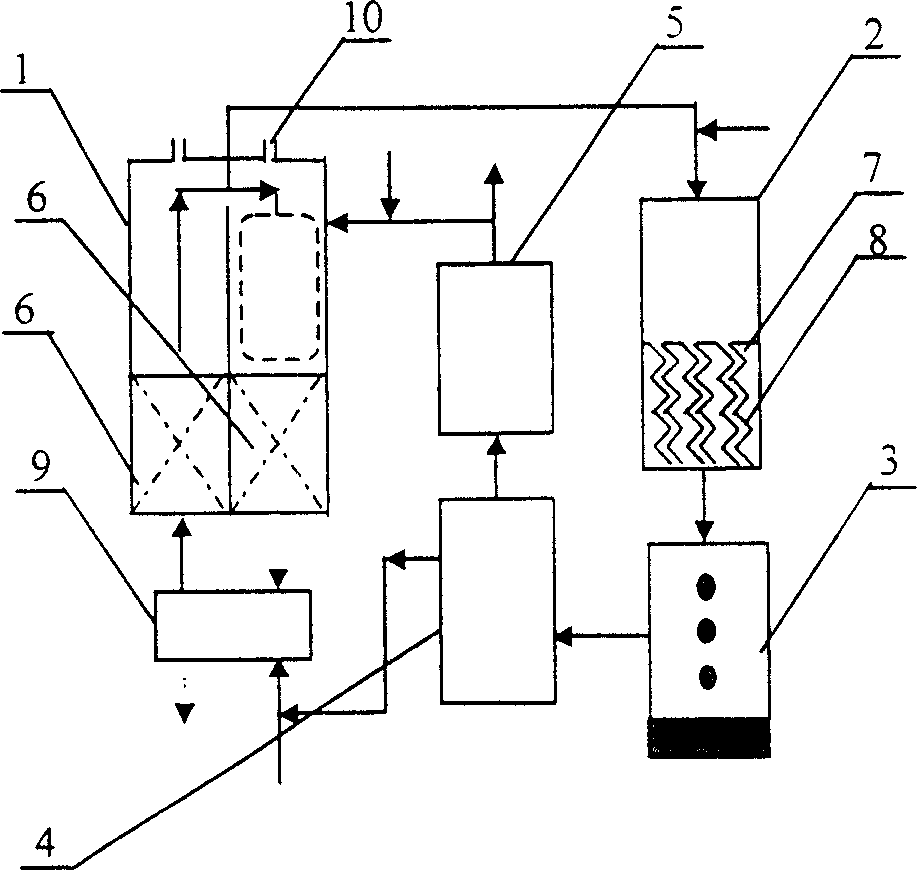

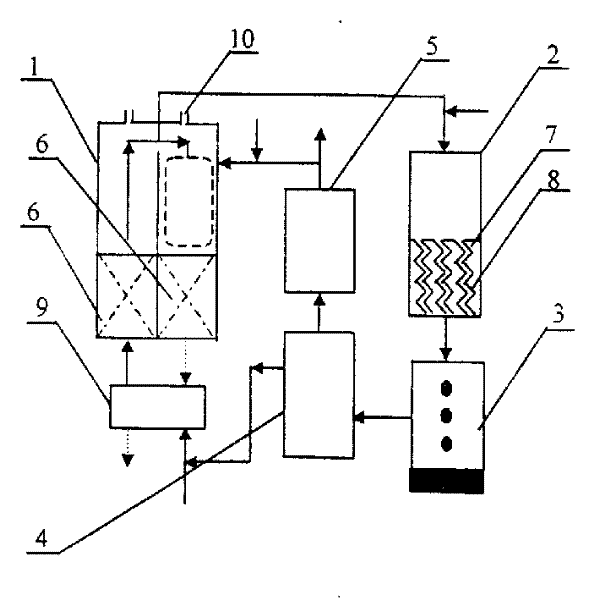

Gasifying method and device for treating low thermal value fuel

InactiveCN1502420AReduce the requirement of calorific value, so that the ash slag is melted into slag, the volume of ash slagSmall sizeWaste processingSolid waste disposalAir preheaterBiofuel

The present invention can be used for in-place treatment of low heating value coal, biofuel and domestic refuse, and it is characterized by that its air preheater is one-by-one communicated with gasifying device, gas-dregs separator, steam generator, gas purifying device and change-over valve by means of pipeline, and its change-over valve is communicated with heat recovering device placed in lower end of the air preheater, so that it is a closed circulating gasification system. In the course of gasification process for treating low heating valuve fuel, according to different material athe correspondent temperature can be controlled.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com