Microwave plasma cracking gasification technology

A microwave plasma, pyrolysis and gasification technology, applied in the direction of educts, special forms of dry distillation, petroleum industry, etc., can solve the problems of pollution, plastic waste cannot be effectively processed, etc., and achieve the effect of less ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

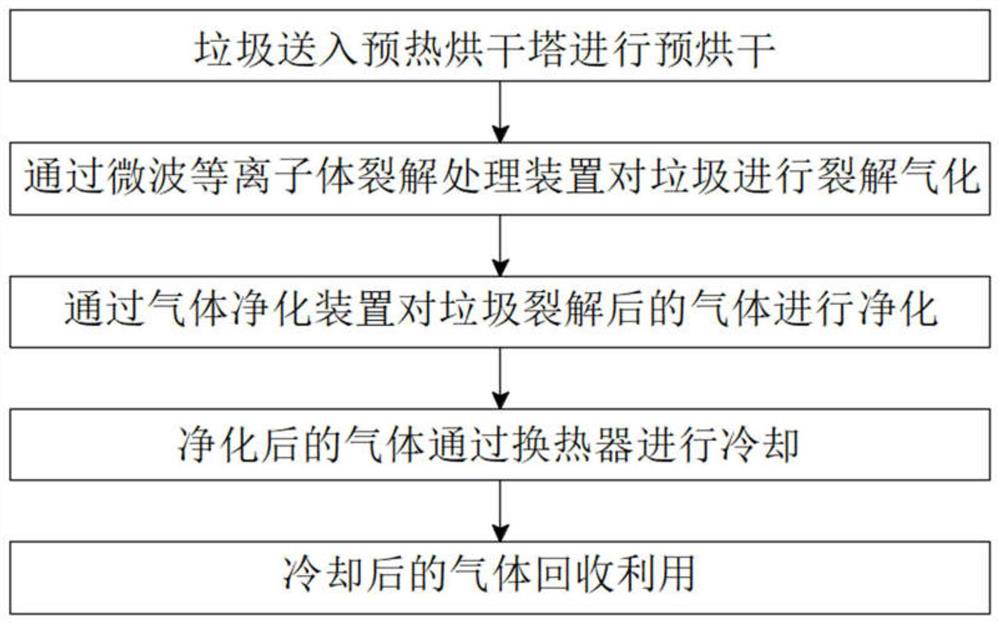

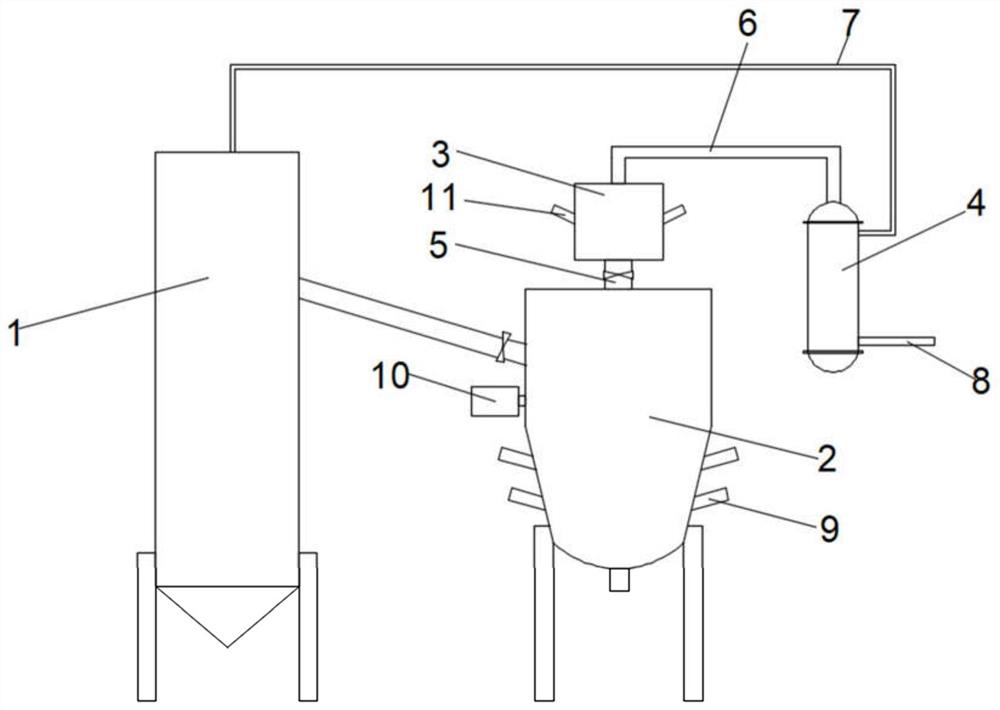

[0029] Such as Figure 1-2 As shown, the embodiment of the present invention provides a microwave plasma cracking gasification technology, comprising the following steps:

[0030] S1. First, transport the garbage to be processed to the preheating drying tower 1 for pre-drying treatment. After drying the garbage, it is convenient to speed up the subsequent cracking and gasification speed;

[0031] S2. Transport the pre-dried garbage to the microwave plasma cracking treatment device 2 through the propulsion device. The propulsion device is an auger feeding pipeline. The microwave plasma cracking treatment device 2 includes a reaction tower, and the lower end of the reaction tower A support frame is provided, a discharge port is provided at the bottom, a plurality of first microwave generators 9 are provided at the lower end of the reaction tower body, and a vacuum pump 10 is also provided on the side wall of the reaction tower at the same time for removing become a vacuum

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com