Fuel gas and fire coal power generating set dual-coupling power generation method and system

A technology for generating sets and power generation systems, which is applied to gas turbine devices, engine components, and engine cooling, etc., can solve the problem of reducing NOx emissions from coal-fired boilers, ignoring the strong reducibility of biomass gas, and not specifying the specific location where gas is fed into the boiler furnace. and operation mode, etc., to improve system reliability, improve heat exchange efficiency, and avoid complications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0025] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

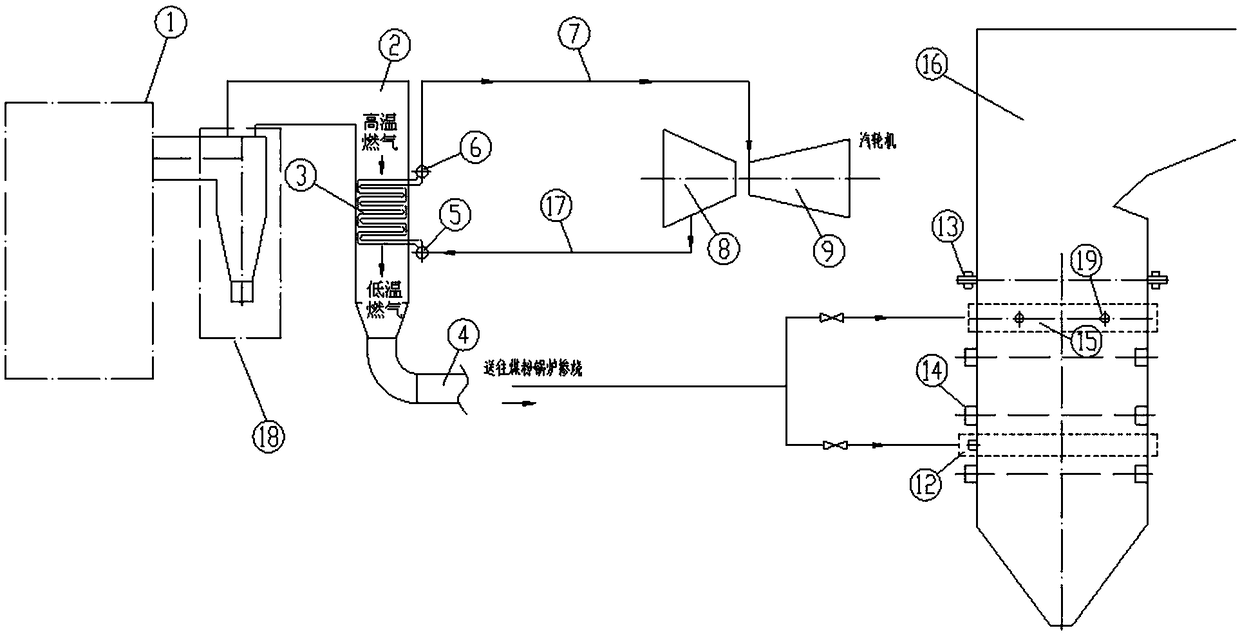

[0026] The present invention proposes a reasonable and efficient solution to the problems of inconvenient transportation of high-temperature gas when the gasification of biomass, garbage, sludge, etc. is coupled with coal-fired units, and the inability to make full use of the characteristics of flammability and reducibility of gas - —Double coupling method and system for gas and coal-fired generating sets (gas-steam coupling, gas-coal coupling).

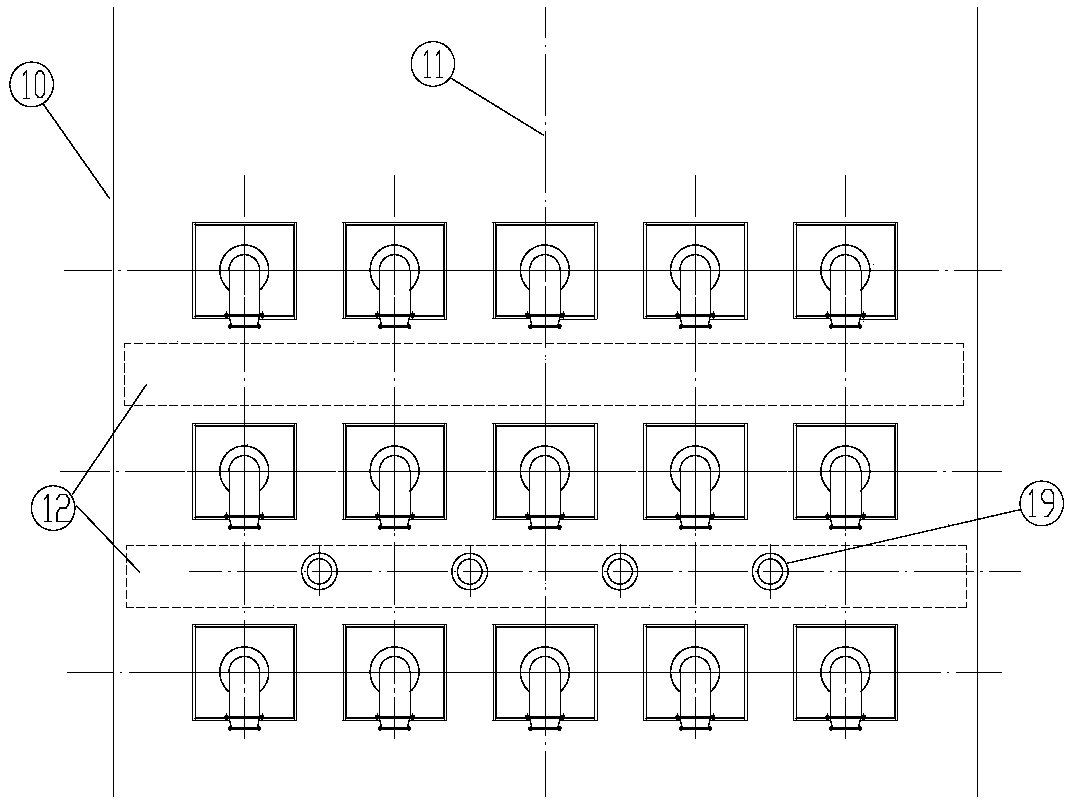

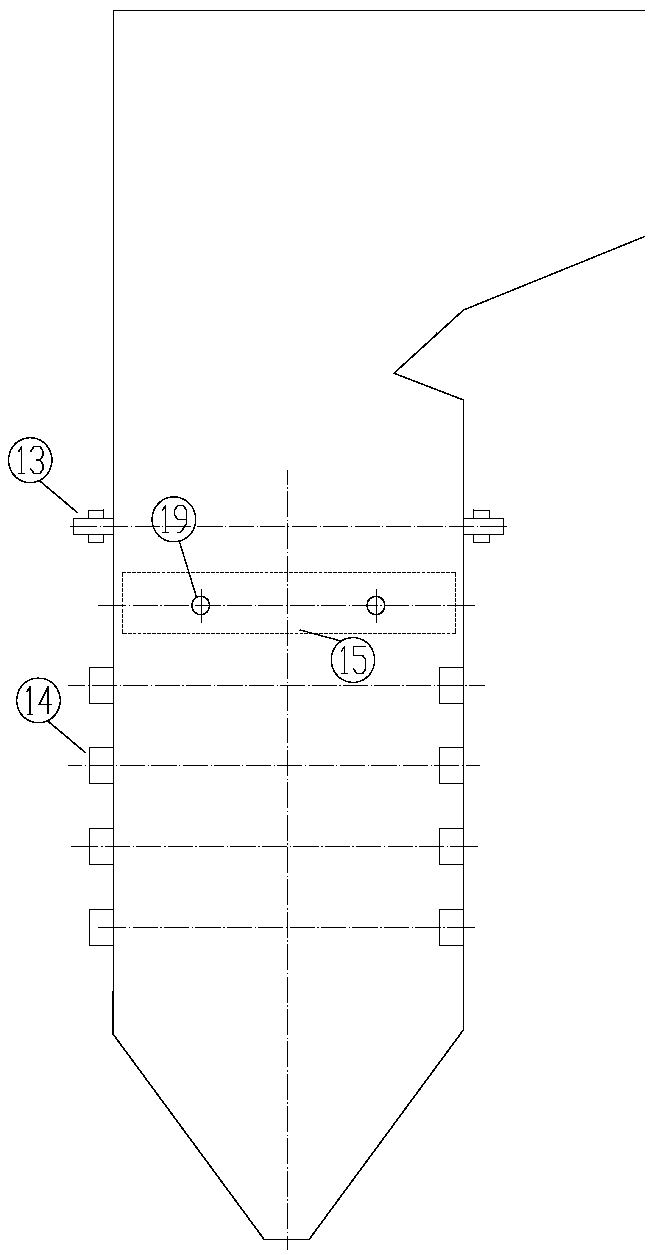

[0027] According to an exemplary embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com