An anti-overheating device and control method for a CFB boiler after burning peat

A technology to prevent overheating and peat, which is applied in the direction of combustion method, superheat temperature control, combustion type, etc., and can solve problems such as unit outage, affecting boiler safe operation, and boiler combustion conditions deviating from design standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

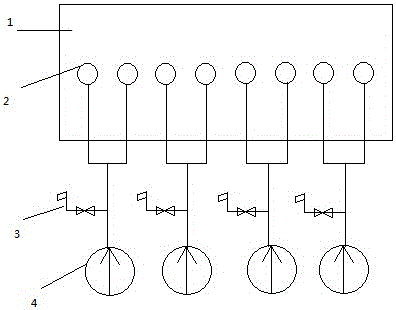

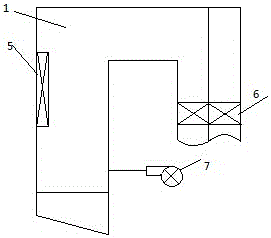

[0017] An anti-overheating device for a CFB boiler after burning peat, which includes a secondary fan 7, a low-temperature superheater and a low-temperature reheater 6, a paste pump 4 and a peat nozzle 2, and a paste pump 4 and a peat nozzle 2 They are connected by a peat delivery pipeline, and a peat pipeline emptying valve 3 is respectively installed on each peat delivery pipeline.

[0018] A zirconia measuring point is installed at the outlet of the low-temperature superheater and low-temperature reheater 6. The zirconia measuring points are located on the left and right sides of the outlet of the low-temperature superheater and the low-temperature reheater 6, and there are three on each side, and they are evenly distributed along the furnace width direction.

[0019] The control method of the anti-overtemperature device after the CFB boiler participates in burning peat, it comprises the following steps:

[0020] Step 1. Exhaust the peat pipeline emptying valve 3 every 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com