Construction technology for paving and prepressing solar power generation road surface photovoltaic module board

A technology of photovoltaic modules and construction technology, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., which can solve the problems of laying and preloading photovoltaic module boards without solar power generation surfaces, and reduce the void at the bottom of photovoltaic module boards Probability, effect of ensuring compactness, effective and durable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

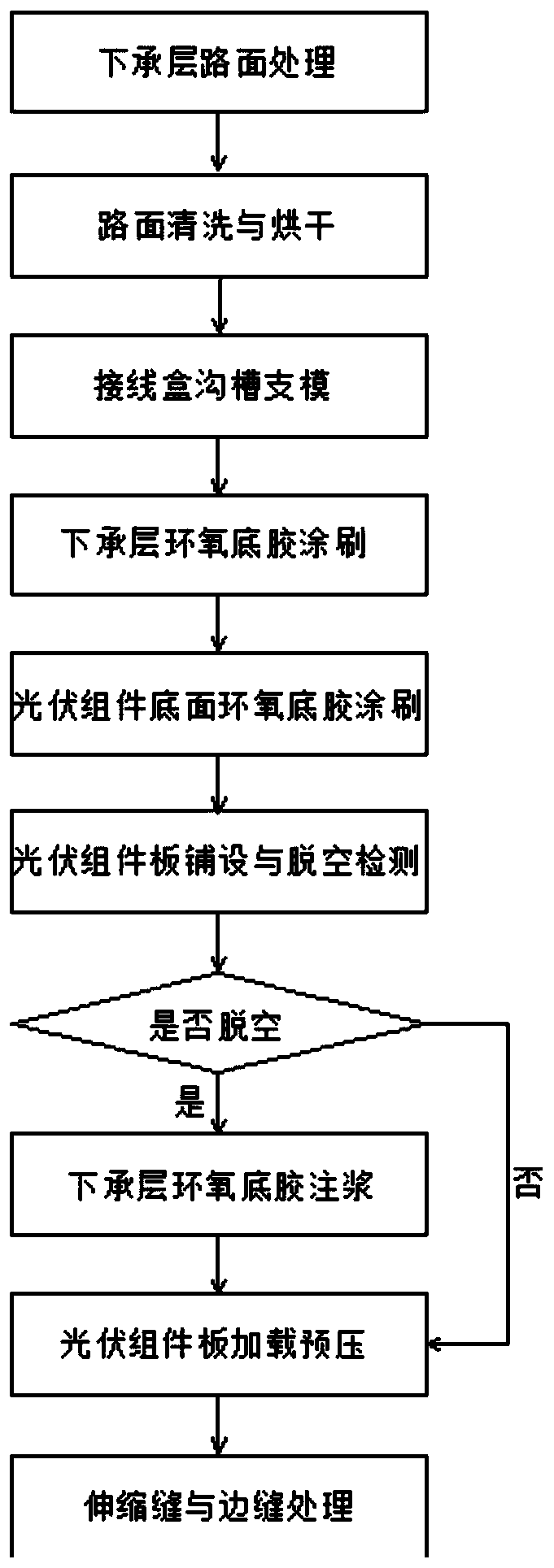

[0043] A construction process for laying and pre-pressing photovoltaic module boards on a solar power generation surface, the specific implementation steps are:

[0044] (1) The road surface treatment of the lower bearing layer. First, use the road surface roughening machine to perform roughening treatment on the road surface area paved with photovoltaic module panels, and then use the Bobcat sweeper to clean the loose aggregate particles and mineral powder on the road surface immediately behind the roughening machine. The mud was swept away.

[0045] (2) Pavement cleaning and drying. First, use a high-pressure sprinkler to clean the loose aggregate particles and mineral powder mud on the pavement surface and grooves. Then, use a blower to blow dry the road surface.

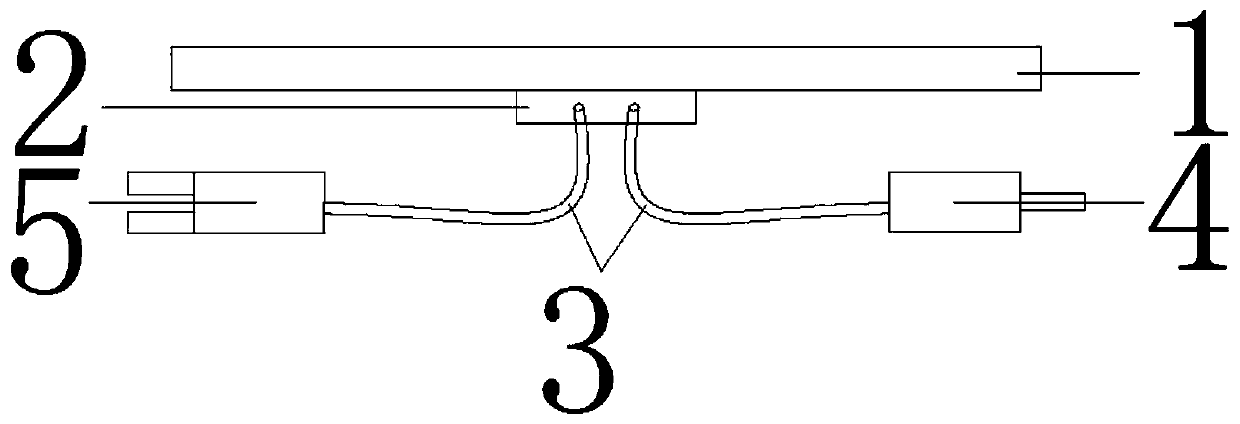

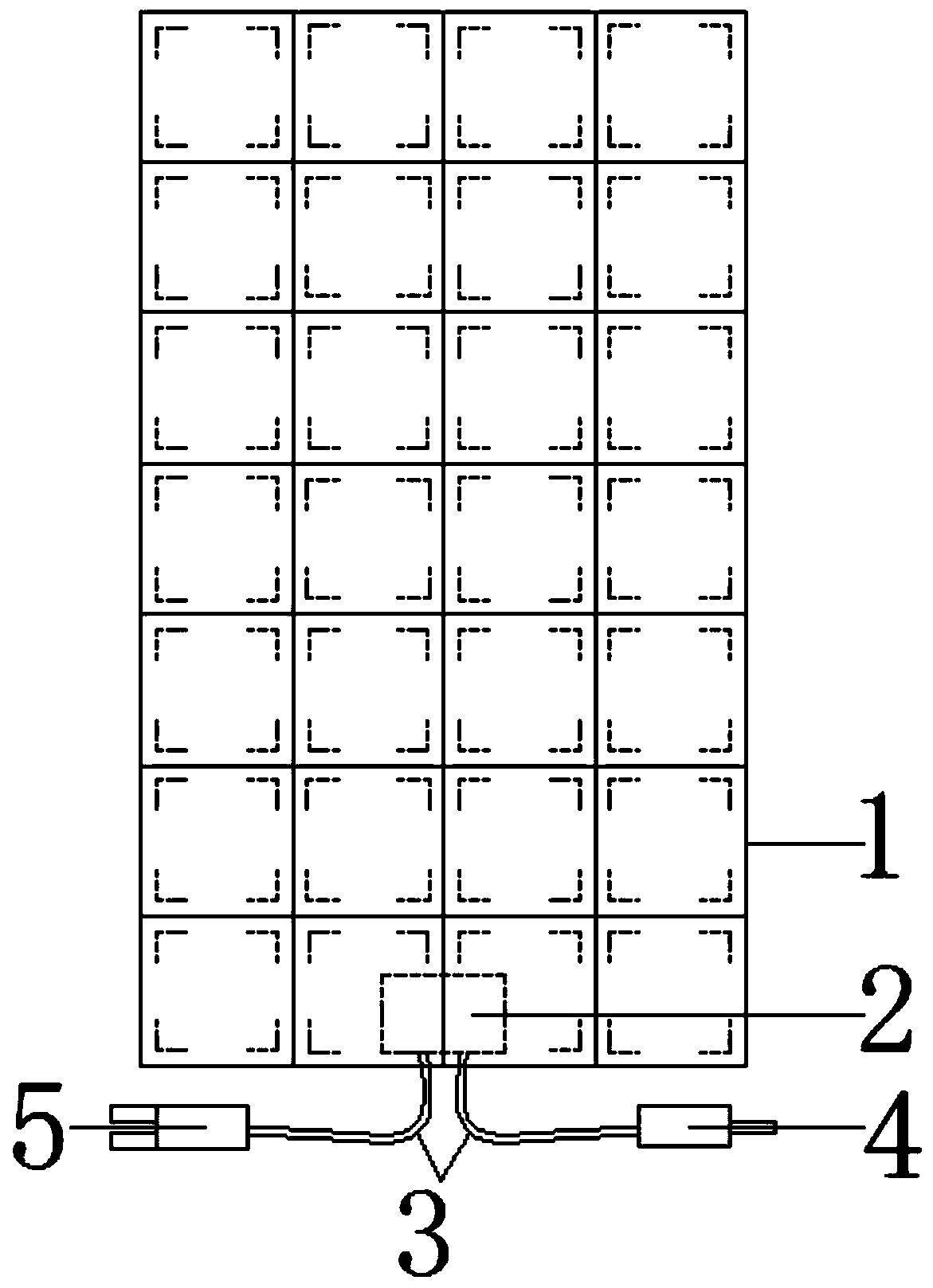

[0046] (3) Formwork support for the junction box groove. In the longitudinal power groove 6 , rough elastic-plastic materials such as cardboard are used to support the formwork for the junction box groove 8 .

...

Embodiment 2

[0053] A construction process for laying and pre-pressing photovoltaic module boards on a solar power generation surface, the specific implementation steps are:

[0054] (1) The road surface treatment of the lower bearing layer. First, use the road surface roughening machine to perform roughening treatment on the road surface area paved with photovoltaic module panels, and then use the Bobcat sweeper to clean the loose aggregate particles and mineral powder on the road surface immediately behind the roughening machine. The mud was swept away.

[0055] (2) Pavement cleaning and drying. First, use a high-pressure sprinkler to clean the loose aggregate particles and mineral powder mud on the pavement surface and grooves. Then, use a blower to blow dry the road surface.

[0056] (3) Formwork support for the junction box groove. In the longitudinal power groove 6 , rough elastic-plastic materials such as cardboard are used to support the formwork for the junction box groove 8 .

...

Embodiment 3

[0063] A construction process for laying and pre-pressing photovoltaic module boards on a solar power generation surface, the specific implementation steps are:

[0064] (1) The road surface treatment of the lower bearing layer. First, use the road surface roughening machine to perform roughening treatment on the road surface area paved with photovoltaic module panels, and then use the Bobcat sweeper to clean the loose aggregate particles and mineral powder on the road surface immediately behind the roughening machine. The mud was swept away.

[0065] (2) Pavement cleaning and drying. First, use a high-pressure sprinkler to clean the loose aggregate particles and mineral powder mud on the pavement surface and grooves. Then, use a blower to blow dry the road surface.

[0066] (3) Formwork support for the junction box groove. In the longitudinal power groove 6 , rough elastic-plastic materials such as cardboard are used to support the formwork for the junction box groove 8 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com