A construction technique for backfilling and compacting power trenches on solar power generation surfaces

A technology of trench backfilling and construction technology, which is applied in the field of solar power generation surfaces, can solve the problems that steel wheel rollers are not suitable for direct cross-slit rolling, and achieve the effects of improving stability and durability and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

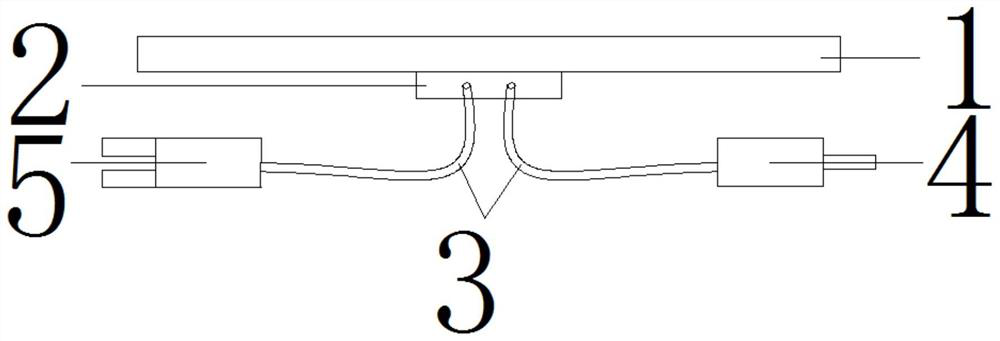

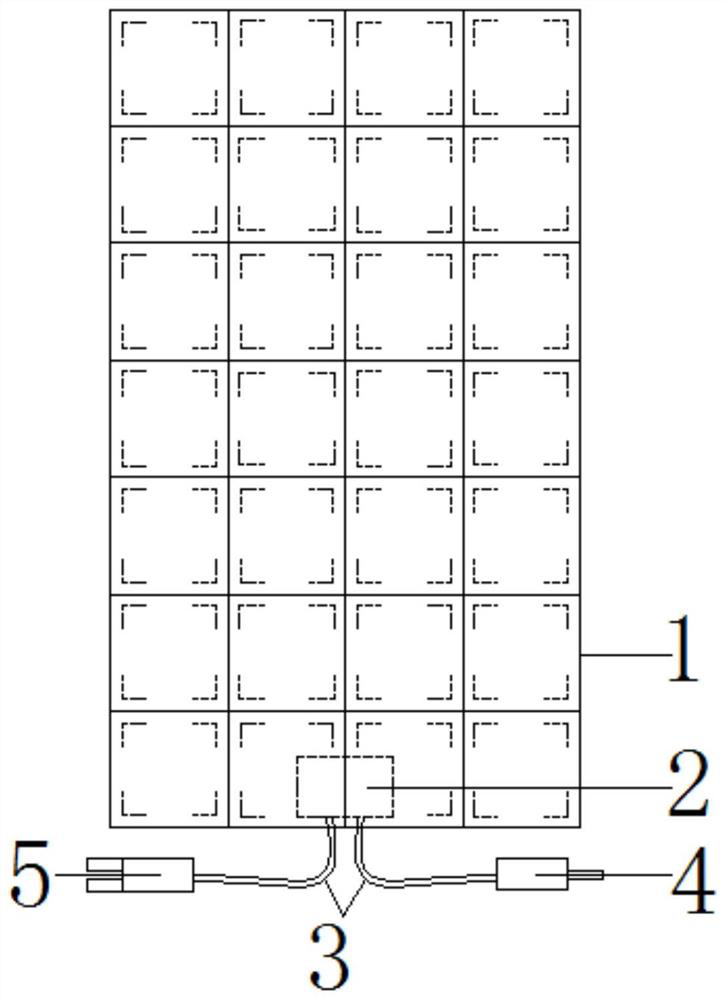

[0042] like Figure 1-2 As shown, the photovoltaic module board used in the construction process of backfilling and compacting the power groove of the solar power generation surface in the present invention includes a photovoltaic module 1, a junction box 2, a photovoltaic cable 3, a positive MC4 plug 4 and a negative MC4 plug 5, and a junction box 2 Located on the center line of the side of the short side below the photovoltaic module 1, and indented by a certain distance from the edge of the photovoltaic module 1 on the side of the short side, the side of the junction box 2 that is closer to the short side of the photovoltaic module 1 has a photovoltaic cable in the horizontal direction 3. The terminal of the photovoltaic cable 3 is connected with a positive MC4 plug 4 and a negative MC4 plug 5 .

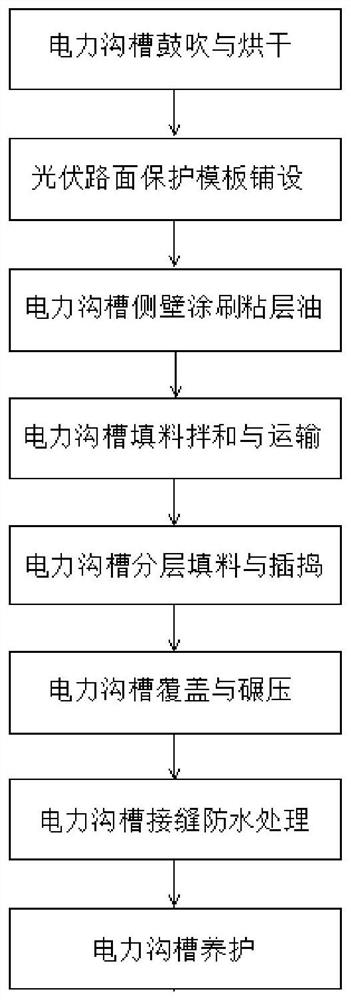

[0043] like image 3 As shown, the construction technology for backfilling and compacting the electric power trench on the solar power generation surface of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com