Sleeve grouting material for reinforcing steel bar connection in winter construction and preparation method thereof

A technology of sleeve grouting and steel bars, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of frost heave damage, impossibility of construction, high maintenance cost, etc., and achieves reduced corrosion and good reliability constructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

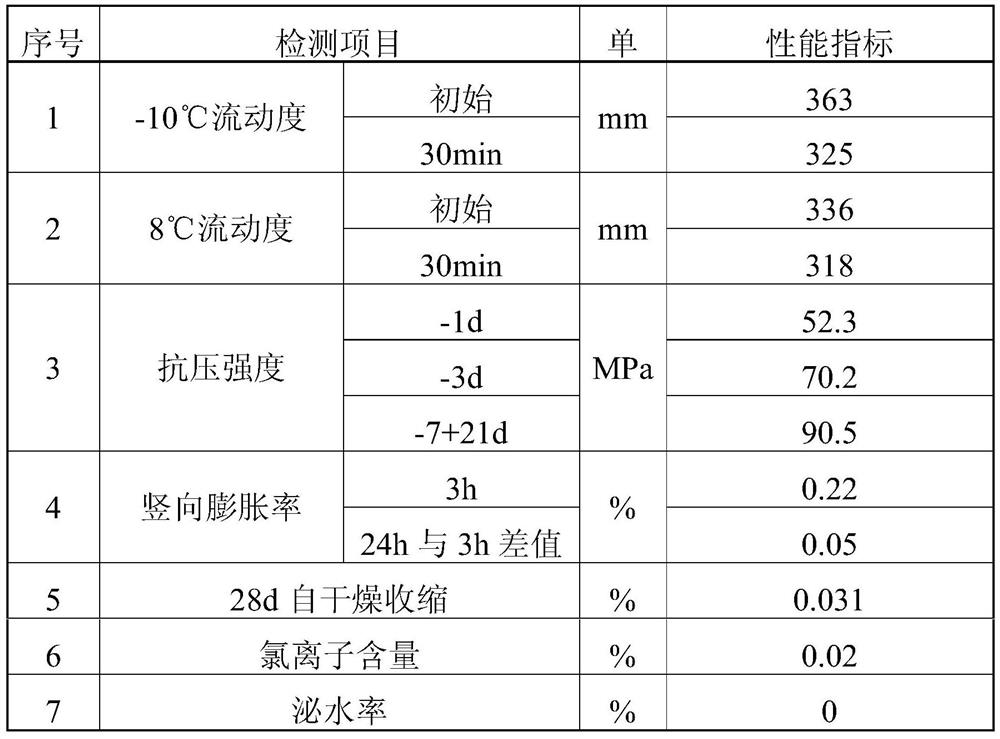

Embodiment 1

[0025] The sleeve grouting material for the connection of steel bars for winter construction in the present embodiment is composed of the following parts by weight:

[0026] P O52.5R 35 parts of ordinary Portland cement, 9 parts of high alumina cement, 5 parts of microbead fly ash, 34 parts of 20-40 mesh emery, 6 parts of 40-70 mesh emery, 3 parts of 70-140 mesh emery , 5 parts of anhydrite, 0.01 part of tartaric acid, 0.01 part of sodium gluconate, 0.1 part of lithium carbonate, 3 parts of ettringite expansion agent, 0.02 part of azodicarbonamide, 0.28 part of BASF F10 superplasticizer, Mingling Chemical 0.05 parts of P803 defoamer, 0.04 parts of nitrous acid rust inhibitor, 0.035 parts of hydroxypropyl methylcellulose ether, 0.2 parts of anti-saponification redispersible vinyl acetate / ethylene copolymer rubber powder, 0.1 parts of CSH nanoparticles, nitrous acid Sodium 0.4 parts.

[0027] After mixing the above materials evenly, place them in an environment of 8°C for 24 ho...

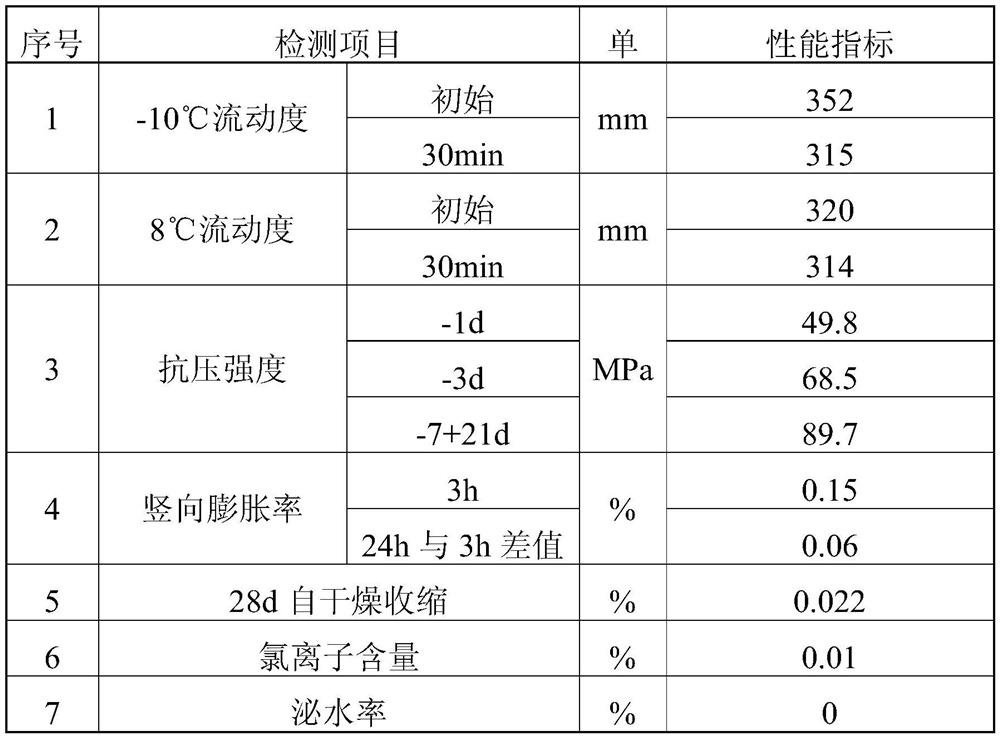

Embodiment 2

[0032] The sleeve grouting material for the connection of steel bars for winter construction in the present embodiment is composed of the following parts by weight:

[0033] 20 parts of P O52.5R ordinary portland cement, 15 parts of fast-hardening sulphoaluminate cement, 10 parts of high alumina cement, 5 parts of heavy calcium superfine powder, 20-40 mesh, washing, drying and screening of river sand 35 parts, 40-70 mesh washed, dried and screened river sand 5 parts, 70-140 mesh river sand 2 parts, anhydrous gypsum 4 parts, tartaric acid 0.025 parts, lithium carbonate 0.15 parts, quicklime expansion agent 4 parts, azo Diformamide 0.025 parts, Sika 325C water reducer 0.31 parts, Mingling Chemical P803 defoamer 0.05 parts, amino alcohol rust inhibitor 0.05 parts, hydroxypropyl methyl cellulose ether 0.03 parts, anti-saponification redispersible 0.15 parts of vinyl acetate / ethylene copolymer rubber powder, 0.1 parts of CSH nanoparticles, and 0.35 parts of sodium nitrate.

[0034...

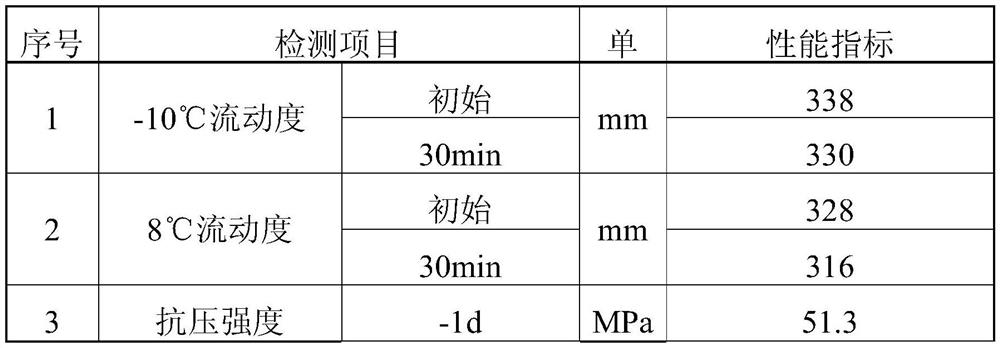

Embodiment 3

[0039]The sleeve grouting material for the connection of steel bars for winter construction in the present embodiment is composed of the following parts by weight:

[0040] 35 parts of P O52.5R ordinary portland cement, 15 parts of rapid hardening sulphoaluminate cement, 5 parts of silica fume, 35 parts of 20-40 mesh machine-made sand, 7 parts of 40-70 mesh machine-made sand, 0.02 part of tartaric acid , 0.15 parts of lithium carbonate, 3 parts of ettringite expansion agent, 0.025 parts of azodicarbonamide, 0.27 parts of BASF melamine water reducing agent, 0.05 parts of Mingling Chemical P803 defoamer, 0.05 parts of amino alcohol rust inhibitor , 0.035 parts of hydroxypropyl methylcellulose ether, 0.1 parts of anti-saponification redispersible vinyl acetate / ethylene copolymer rubber powder, 0.1 parts of CSH nanoparticles, and 0.45 parts of sodium nitrate.

[0041] After mixing the above materials evenly, place them in an environment of 8°C for 24 hours, and measure the fluidit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com