Head design of combustion chamber of twin-stage premixing ground-based gas turbine

A combustor and head technology, which is applied in the field of dual-stage premixed ground gas turbine combustor head design, can solve the problems of increased NOx emissions and increased fuel non-uniformity, and achieve reduction of NOx emissions, improvement of combustion efficiency, Avoid the effect of localized high temperature zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

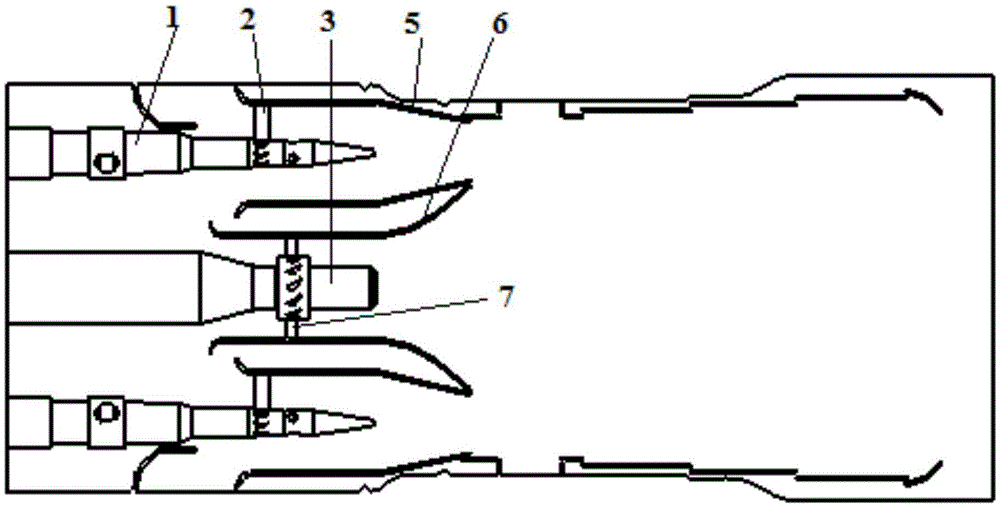

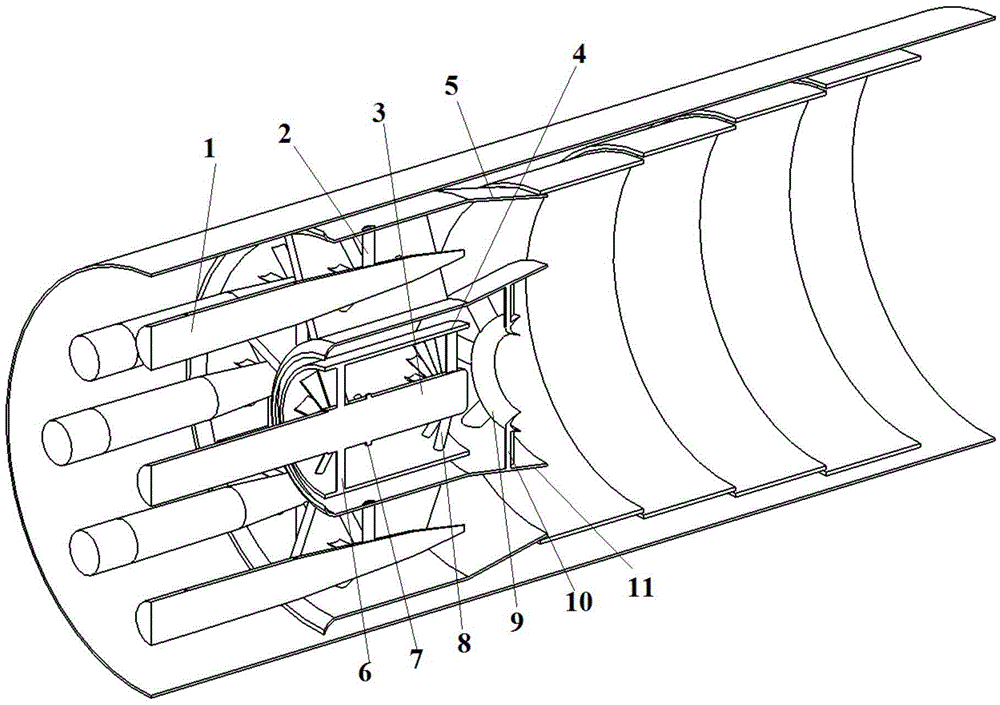

[0013] Such as figure 2 As shown, the combustor head design of a two-stage premixed surface gas turbine in this embodiment includes a swirl tube 4 at the center duty level and a swirl tube 5 at the outer main combustion level. In this embodiment, in the on-duty swirl barrel, the first swirler and the second swirler 8 are fixed on the duty-grade fuel spray rod 3 .

[0014] The total length of the straight cylindrical swirl tube 4 in the center of the combustion chamber head is 120 mm to 140 mm, and the diameter is 100 to 110 mm. Two swirlers are installed at the front and back of the swirl cylinder 4: the first swirler 6 is axially 8-12 mm away from the inlet end, and the blade height of the first swirler 6 is 32-33 mm. The angle is 30-40°, the number of blades is 12-14; the axial distance of the second swirler is 105-115mm from the inlet end, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com