Ball-shape top-burning type hot-air furnace with annular-arranged vertical up-spray burner

A technology of annular arrangement and burners, applied in combustion methods, combustion equipment, furnaces, etc., can solve problems such as unreasonable structure, uneven distribution of combustion airflow temperature and velocity, poor overall heat transfer effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

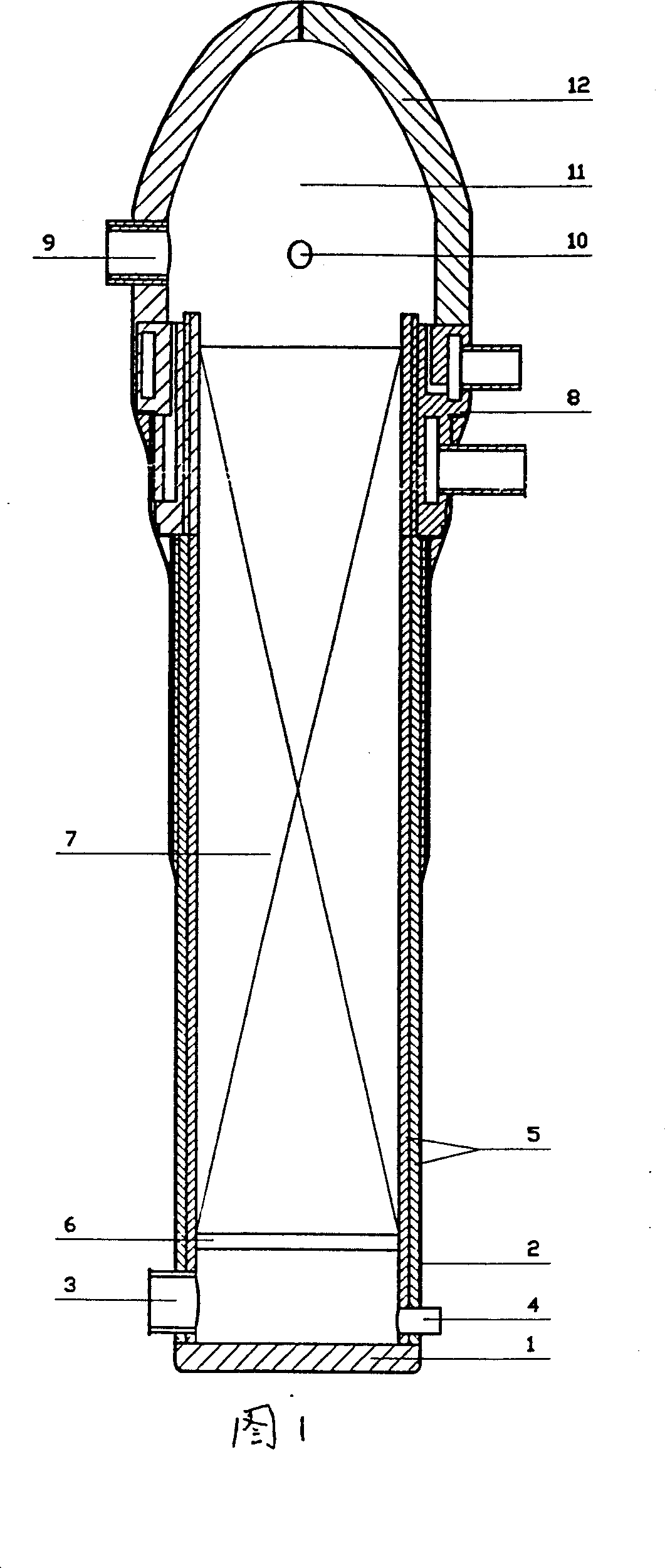

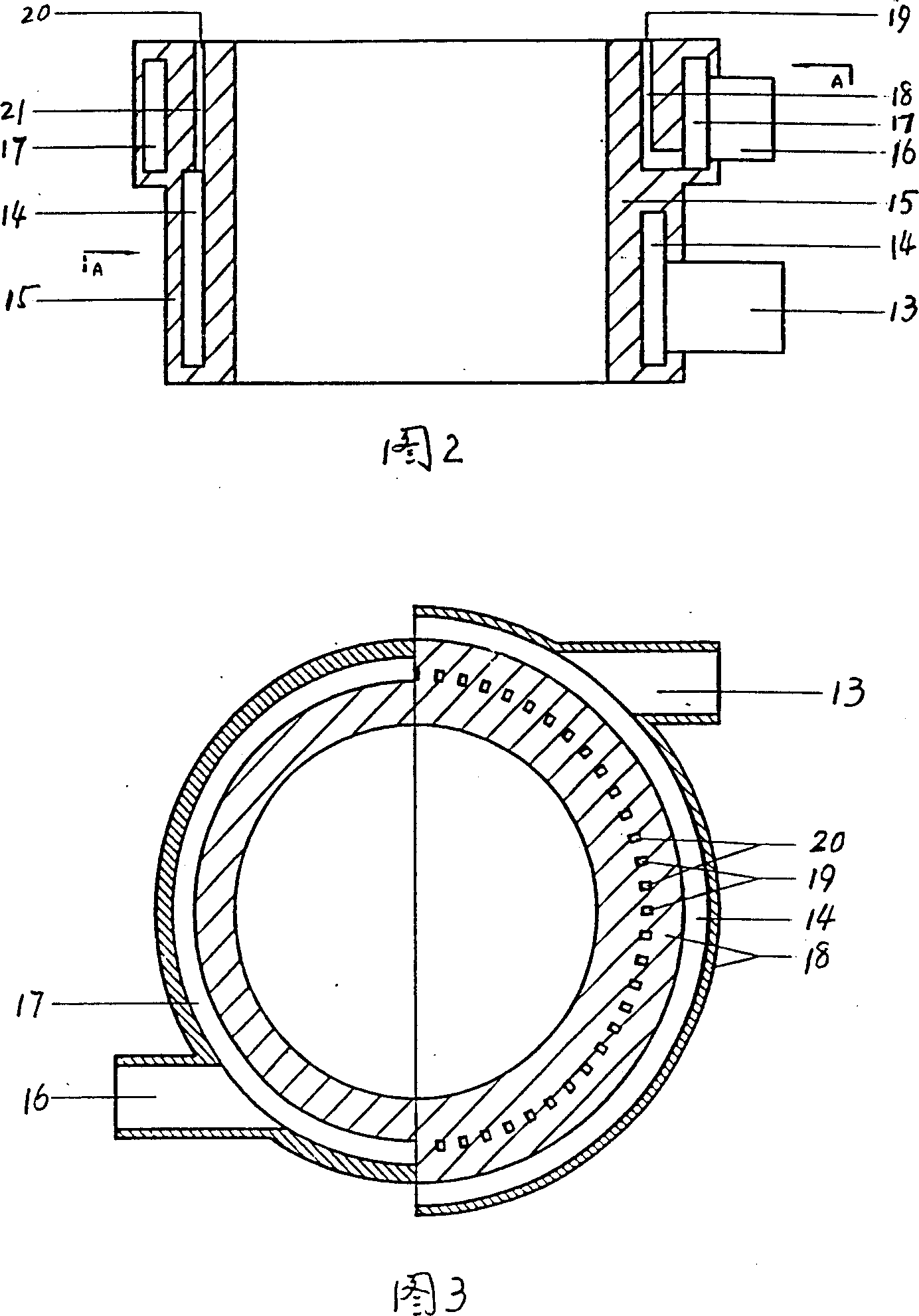

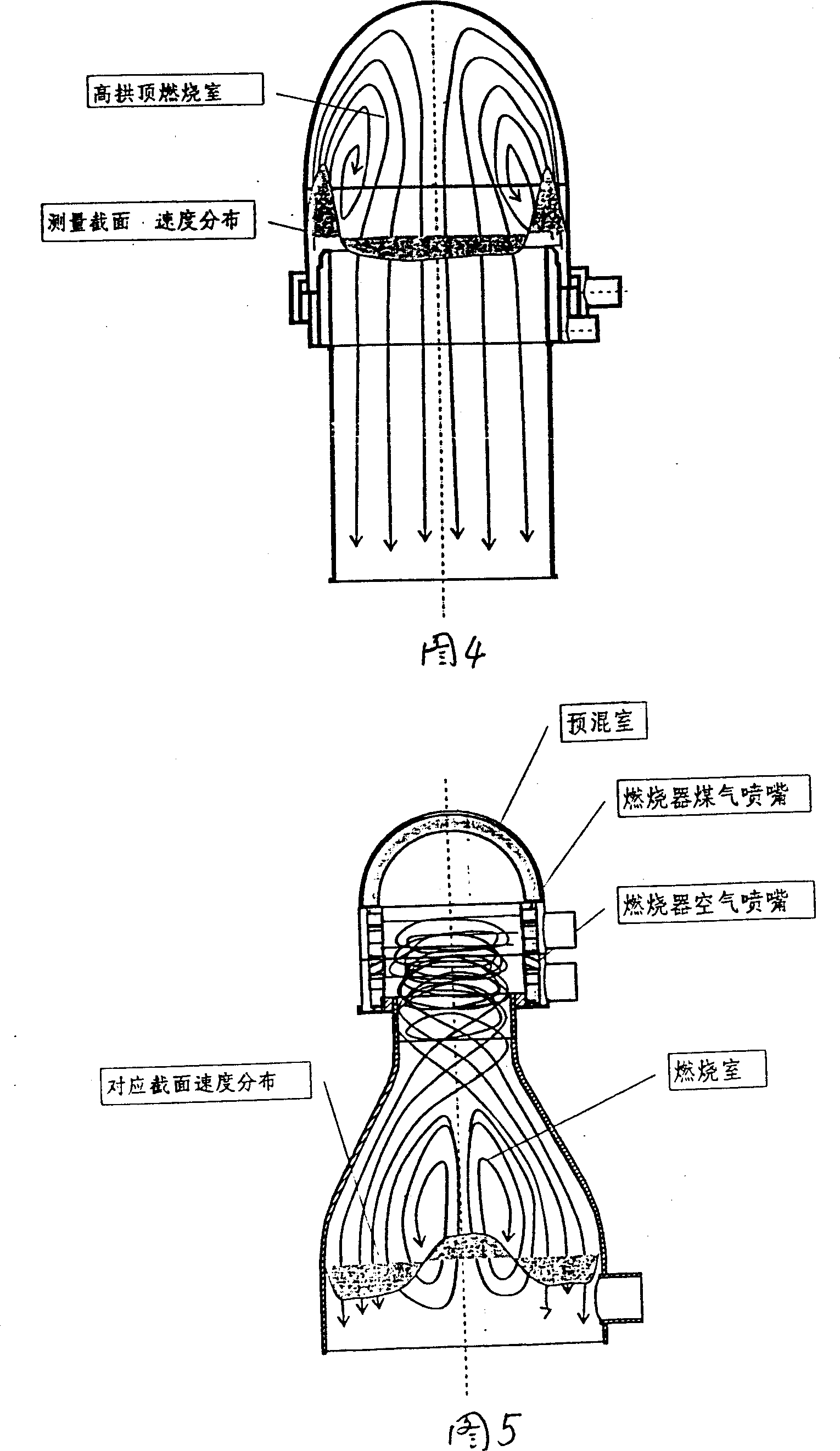

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Shown in Fig. 1 and Fig. 2, the present invention includes a furnace top 12, a combustion chamber 11, a ceramic burner 8 and a body of furnace 2, the bottom of the body of furnace 2 has a flue opening 3 and a furnace bottom 1, and the body of the furnace on the top of the flue opening Furnace grate 6 is installed, and the furnace body is a regenerator 7. There is a ceramic burner 8 between the upper part of the furnace body and the furnace roof, and is placed at the lower part of the combustion chamber 11. There is a hot air outlet 9 on the furnace roof 12, and ceramic burners 8 There is a vertical gas preheating loop 14 inside the burner wall 15, a vertical combustion air preheating loop 17 in the upper expansion body, and a vertical gas outlet 21 and a nozzle on the top of the vertical gas preheating loop 20. There is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com