Ellipsoidal high-power microwave plasma diamond film deposition device

A high-power microwave and plasma technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of difficult adjustment of the device, difficult to increase the microwave power, etc., to avoid pollution, water cooling and vacuum sealing Good performance and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

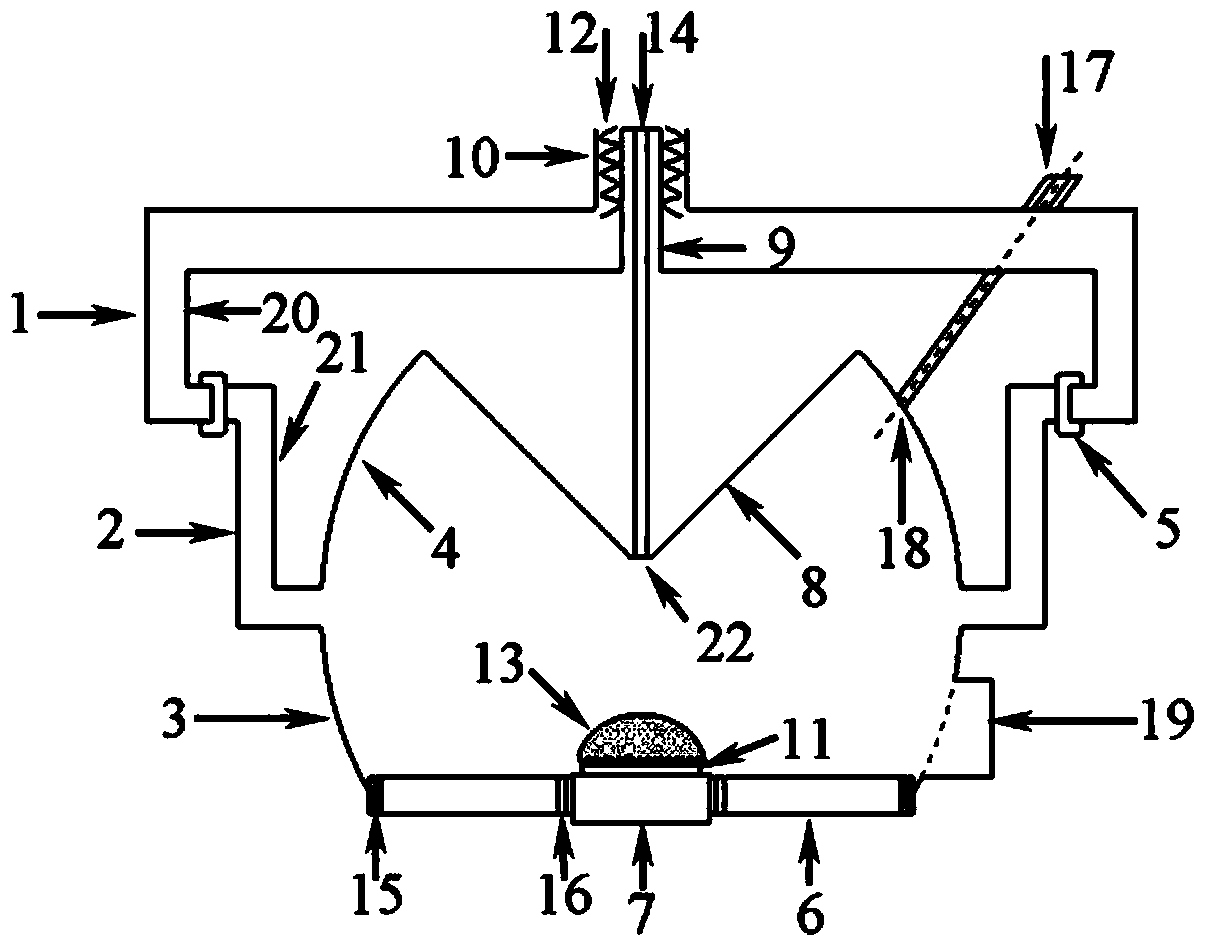

[0035] Such as figure 1 As shown, the present invention is an ellipsoidal high-power microwave plasma diamond film deposition device, which consists of a stepped ring microwave coupling system, a ring-shaped quartz microwave window arranged at the step of the ring antenna, an ellipsoidal microwave resonant cavity, and an adjustable deposition Table, conical upper reflector and adjustable cylindrical lower reflector, air inlet and outlet, temperature measuring hole and observation window;

[0036] The stepped annular microwave coupling system is composed of a coaxial microwave feeding port 12, a stepped annular outer cavity wall, and an internal stepped annular microwave coupling antenna; wherein the microwave feeding port 12 is composed of a coaxial outer conductor 10 and a coaxial inner conductor 9 Composition; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com