Dense medium ore sorting equipment

A heavy medium and separation technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low separation accuracy, difficult operation, and complicated heavy medium beneficiation process, so as to improve the separation accuracy, cost avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

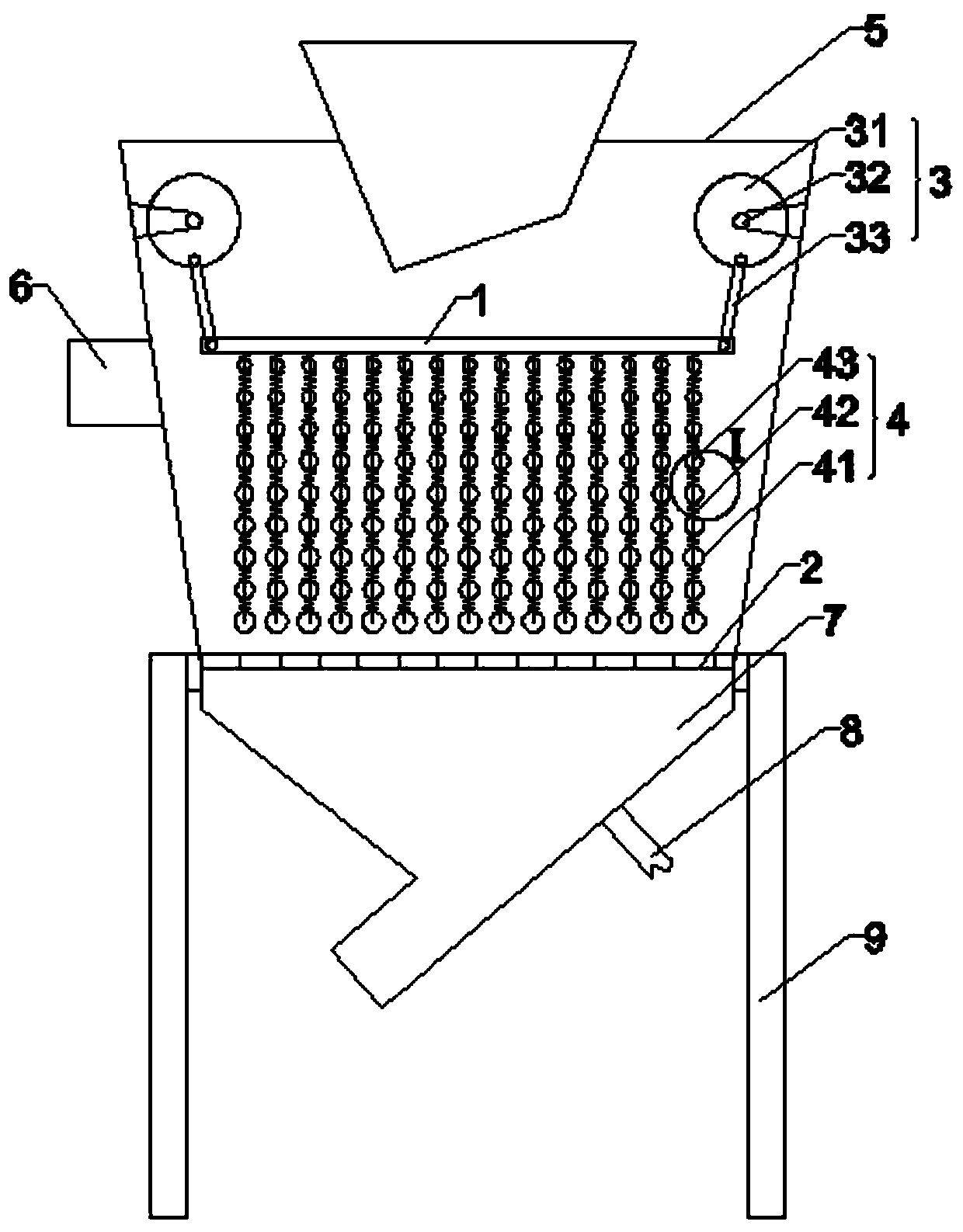

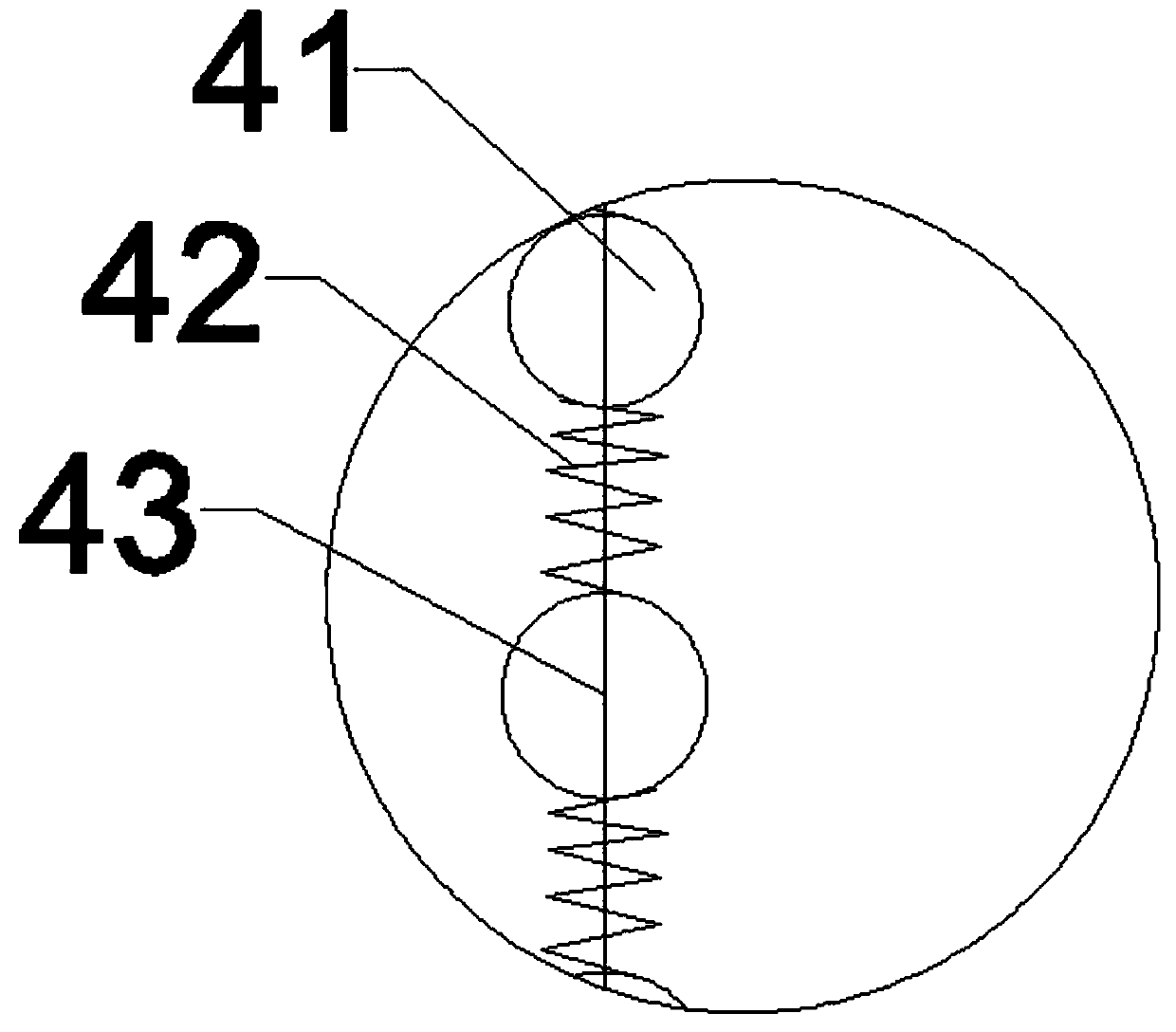

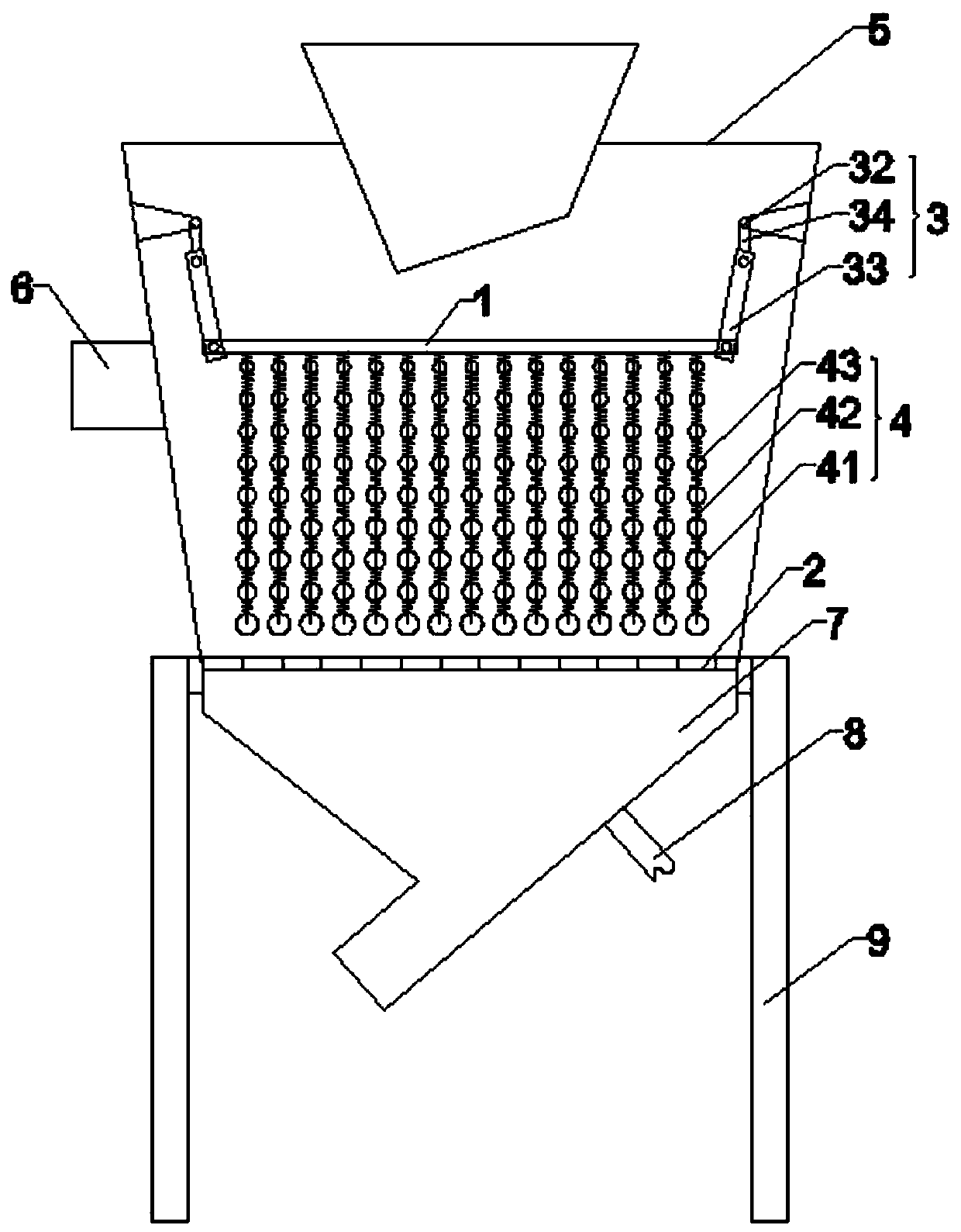

[0028] like Figure 1 to Figure 5 As shown, a kind of dense medium ore separation equipment of the present invention includes a separation cylinder 5, a moving sieve plate 1, a fixed sieve plate 2 and a lifting device 3, and the fixed sieve plate 2 is arranged at the lower end of the separation cylinder 5 At the discharge port, the movable sieve plate 1 is set in the sorting cylinder 5 through the lifting device 3, and the lifting device 3 can drive the movable sieve plate 1 to move up and down, and the upper part of the side wall of the sorting cylinder 5 is provided with tailings discharge Port 6, dense medium chains 4 are arranged at intervals on the lower end surface of the movable sieve plate 1, the heavy medium chains 4 include a fixed strip 43 and a dense medium sphere 41, one end of the fixed strip 43 is connected to the end surface of the movable sieve plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com