Material conveying apparatus with functions of uniformly distributing material and performing self-excitation vibration

A technology for conveying devices and materials, applied in the field of agricultural machinery research, can solve the problems of vibration and noise of the whole machine, materials cannot be effectively distributed, and the transmission mechanism is complicated, so as to reduce the vibration and noise of the whole machine, protect physical and mental health, and reduce complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

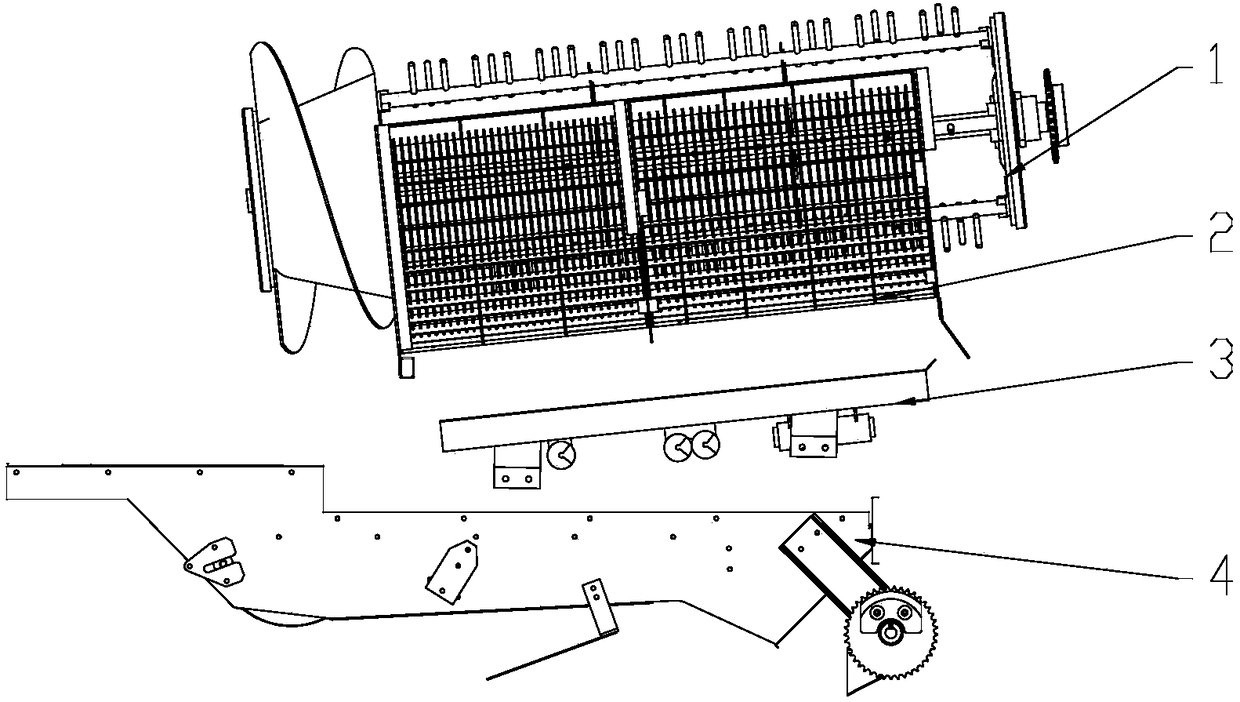

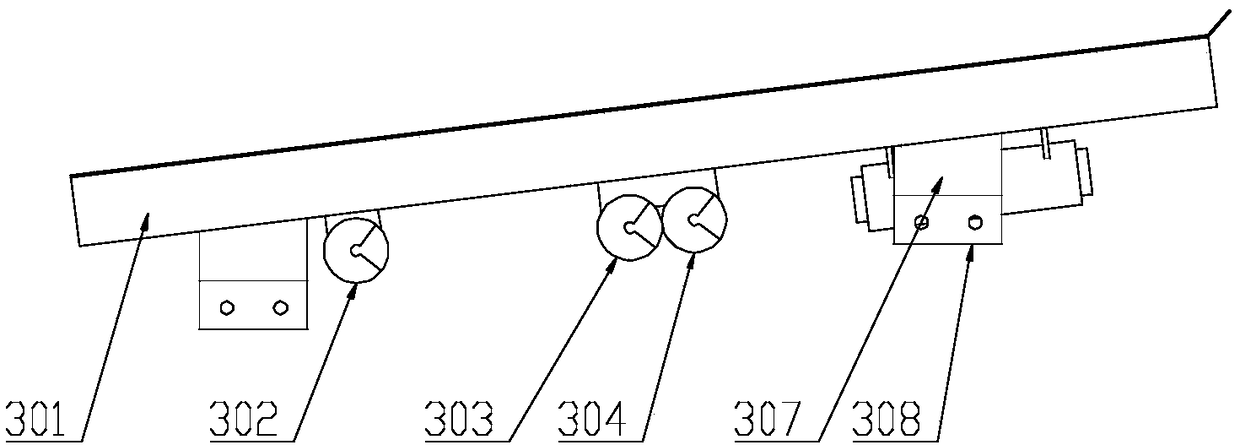

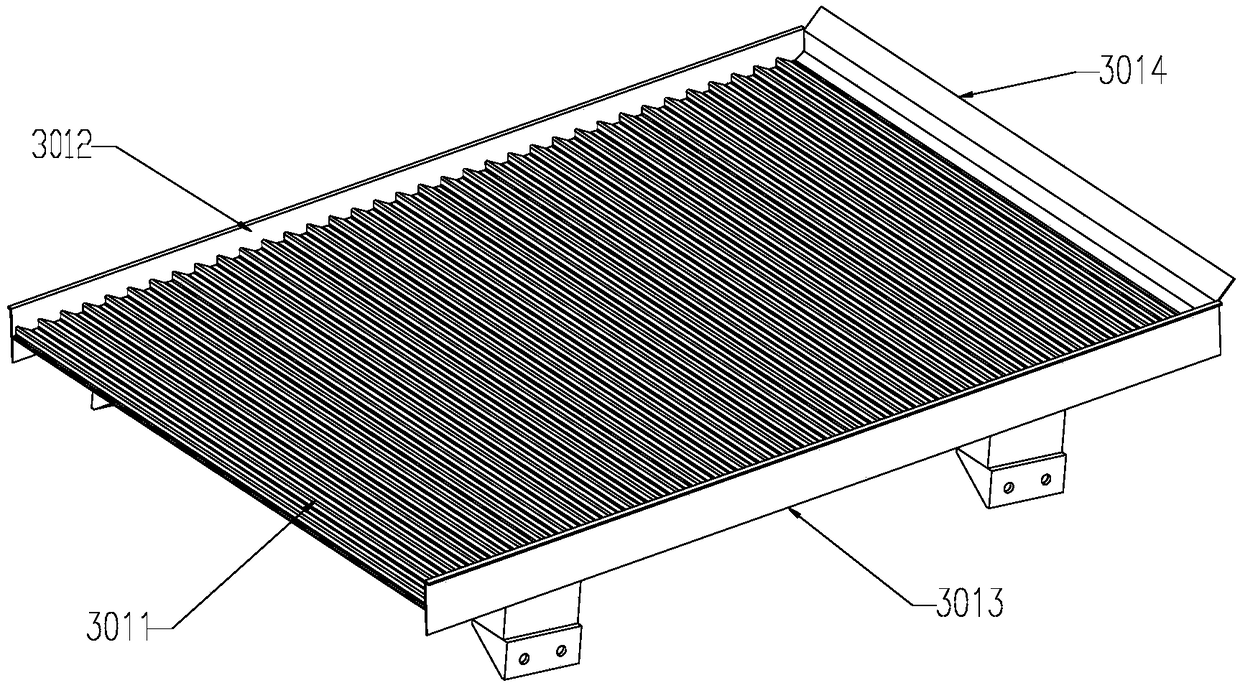

[0030] figure 1 , 2 Shown is an embodiment of the material conveying device with uniform material distribution and self-exciting vibration function of the present invention, the material conveying device with uniform material distribution and self-exciting vibration function includes a flexible shaking conveying device 3, the The flexible shaking conveying device 3 includes a material shaking plate 301, a longitudinal vibration motor I302, a longitudinal vibration motor II 303, a longitudinal vibration motor III 304, a horizontal vibration motor I305, a lateral vibration motor II 306, a flexible shock absorbing pad 307 and an installation base 308 , The flexible shaking conveying device 3 is installed below the threshing cylinder 1 and the concave plate 2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com