High-efficiency spodumene beneficiation method

A technology of spodumene ore and beneficiation method, which is applied in the field of mineral processing engineering, can solve problems such as waste, poor separation index, and unreasonable utilization of lithium resources, and achieve good separation effect and reduce grinding cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

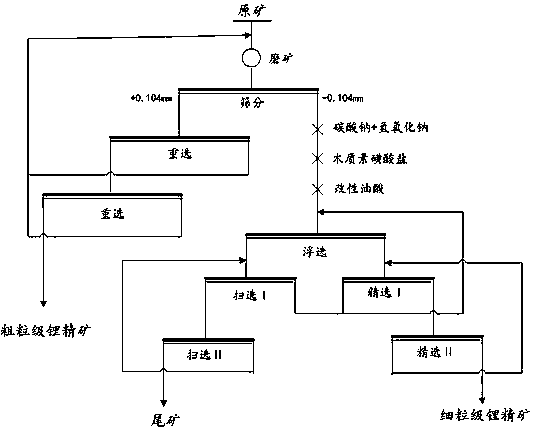

Method used

Image

Examples

Embodiment 1

[0019] Li contained in a spodumene mine in Sichuan 2 The O grade is 1.38%, and the -0.074mm particle size after grinding accounts for 50%. Screen the spodumene slurry and classify it into two grades of +0.104mm and -0.104mm. The +0.104mm particle size spodumene ore is subjected to gravity separation and separation twice through a centrifugal concentrator to obtain a coarse-grained spodumene concentrate product, and the tailings and medium ore products obtained by gravity separation are returned to the mill. Add 2000g / t sodium carbonate and 800g / t sodium hydroxide to the -0.104mm particle size spodumene slurry, stir for 40 minutes, then add 40g / t calcium lignosulfonate and 200g / t modified oleic acid for pulping, Fine-grained spodumene concentrate products are obtained after one rough, two fine, and two sweep flotation operations. The coarse spodumene concentrate, the fine spodumene concentrate and the final tailings are respectively filtered, dried, weighed, and tested to obt...

Embodiment 2

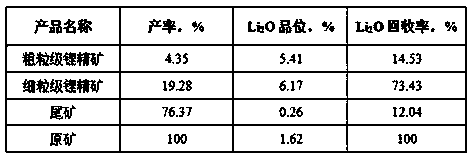

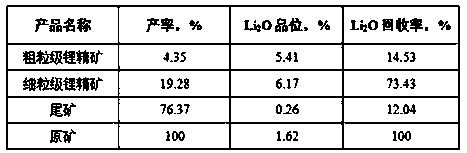

[0022] Li contained in a spodumene mine in Australia 2 The O grade is 1.62%, and the -0.074mm particle size after grinding accounts for 60%. Screen the spodumene slurry and classify it into two grades of +0.104mm and -0.104mm. The +0.104mm particle size spodumene ore is subjected to gravity separation and separation twice through a centrifugal concentrator to obtain a coarse-grained spodumene concentrate product, and the tailings and medium ore products obtained by gravity separation are returned to the mill. Add 3000g / t sodium carbonate and 1500g / t sodium hydroxide to the spodumene pulp of -0.104mm particle size, stir for 40 minutes, then add 100g / t sodium lignosulfonate and 600g / t modified oleic acid for pulping, Fine-grained spodumene concentrate products are obtained after one rough, two fine, and two sweep flotation operations. The coarse spodumene concentrate, the fine spodumene concentrate and the final tailings are respectively filtered, dried, weighed, and tested to...

Embodiment 3

[0025] Li Contained in a Spodumene Mine in Xinjiang 2 The O grade is 1.45%, and the -0.074mm particle size after grinding accounts for 30%. Screen the spodumene slurry and classify it into two grades of +0.104mm and -0.104mm. The +0.104mm particle size spodumene ore is subjected to gravity separation and separation twice through a centrifugal concentrator to obtain a coarse-grained spodumene concentrate product, and the tailings and medium ore products obtained by gravity separation are returned to the mill. Add 1000g / t sodium carbonate and 400g / t sodium hydroxide to the spodumene pulp of -0.104mm particle size, stir for 40 minutes, then add 20g / t ammonium lignosulfonate and 400g / t modified oleic acid for pulping, Fine-grained spodumene concentrate products are obtained after one rough, two fine, and two sweep flotation operations. The coarse spodumene concentrate, the fine spodumene concentrate and the final tailings are respectively filtered, dried, weighed, and tested to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com