Waste ore sorting method and device based on laser induced breakdown spectroscopy (LIBS)

A laser-induced breakdown and sorting device technology, applied in the field of laser spectrum detection, can solve the problems of not having the function of real-time monitoring and adjustment of sample height, irregular shape, and not having the function of area array scanning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

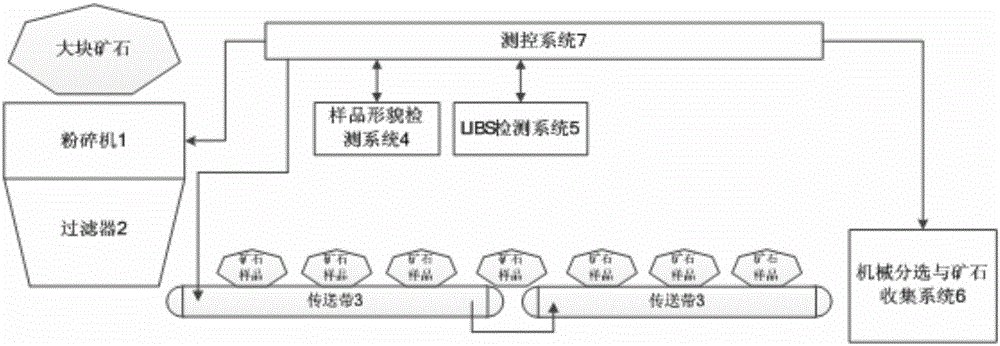

[0030] This embodiment is used to measure the nickel element content of Hongqiling Nickel Mine in Panshi, Jilin, and sort ores of different grades according to the measurement results. The structure diagram is as follows figure 1 As shown, the specific sorting process is divided into the following eight steps:

[0031] Step 1: Send the large pieces of ore into the crusher 1 for crushing, and then use the filter 2 to screen the shape and volume of the crushed ore, and the ore with a moderate volume directly enters the conveyor belt 3 for testing.

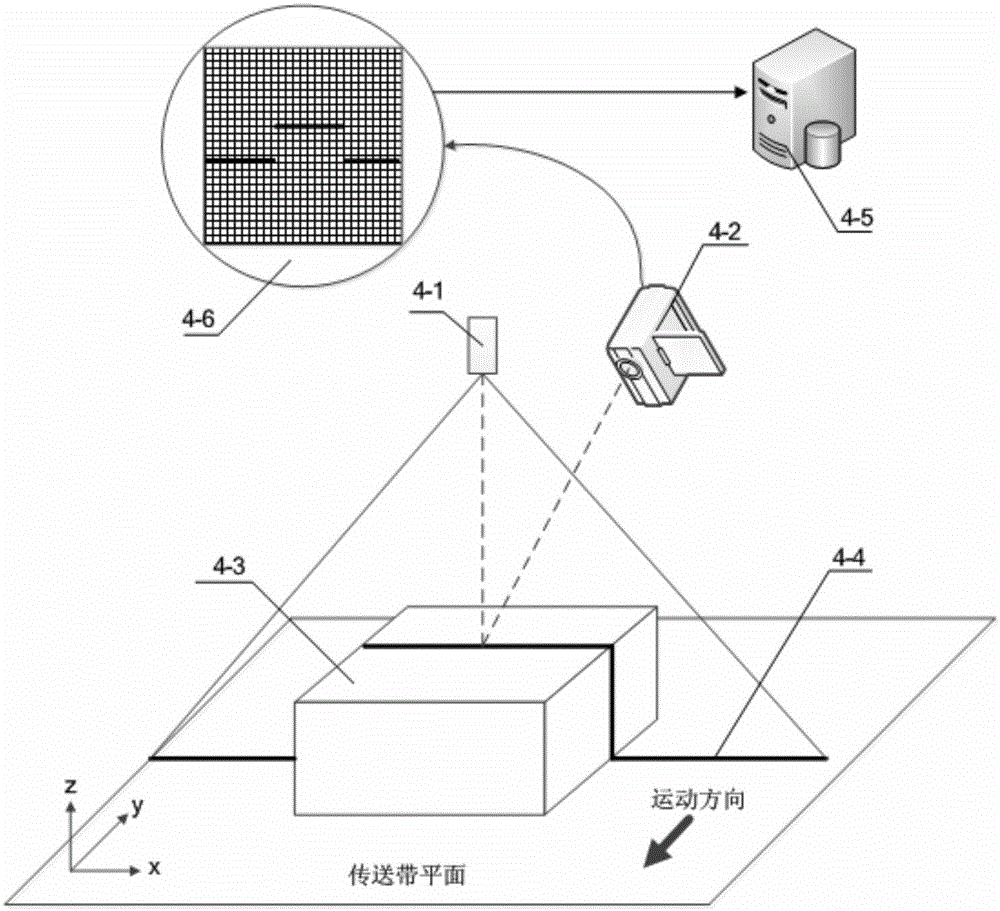

[0032] The second step: the conveyor belt 3 transports the ore sample to the detection area of the sample shape detection system 4, such as figure 2 As shown, the linear laser projector 4-1 projects a narrow light band 4-4 onto the ore sample 4-3, which presents a distorted curve on the surface, and the ore is collected by the camera 4-2 at a non-projector viewing angle The sample image 4-6 is transmitted to the data processing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com