X-ray radiation pre-selecting enrichment method for copper sulfide ore with low grade

A copper sulfide, low-grade technology, used in chemical instruments and methods, solid separation, classification, etc., can solve problems such as waste of resources, achieve stable operation, improve economic and technical indicators and comprehensive benefits, and improve equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The low-grade copper sulfide ore raw ore that adopts contains Cu 0.21% by weight percentage;

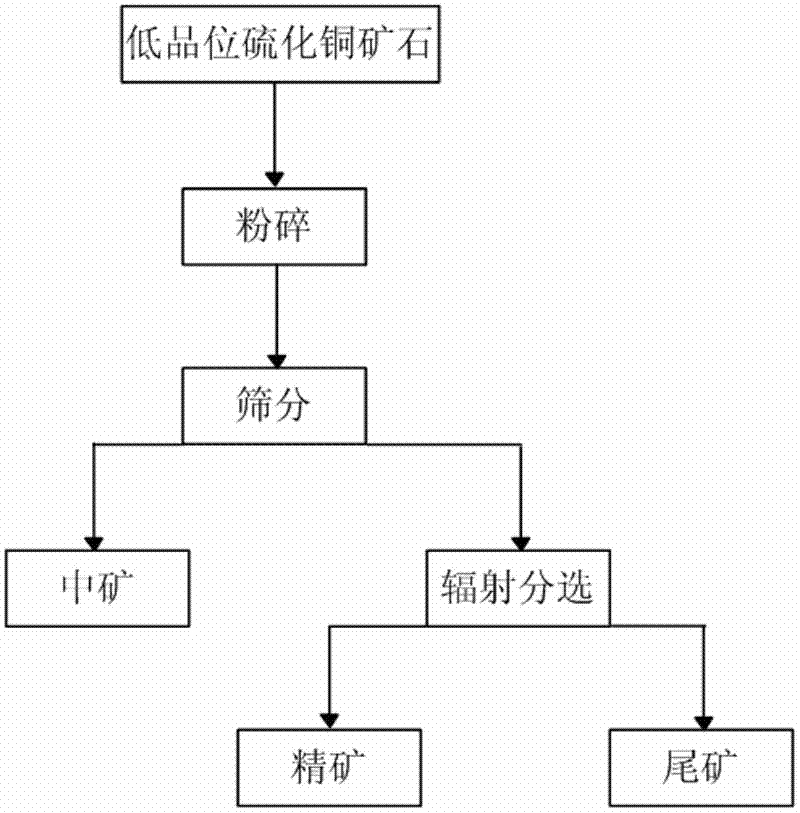

[0025] Use a crusher to crush the raw ore of low-grade copper sulfide ore to ≤200mm;

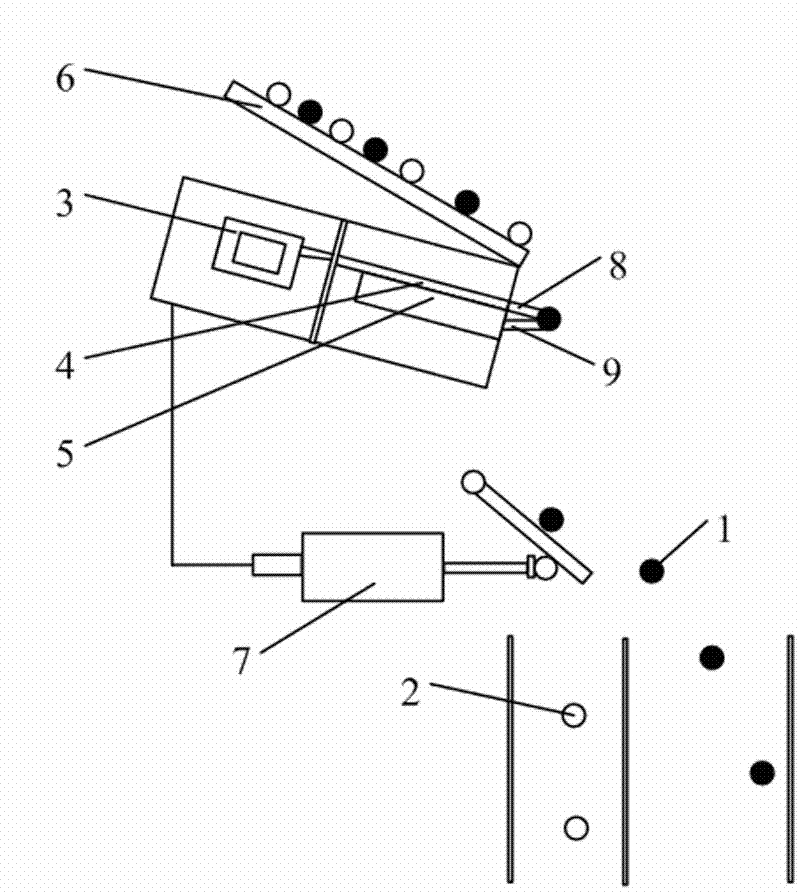

[0026] Sieve the crushed material with a sieving machine with a sieve size of 20mm. The material with a particle size of 20-200mm on the sieve is used as the copper sulfide ore feed; the material under the sieve is treated as a middle ore; The conveyor belt is transported to the mine bin of the X-ray radiation sorter;

[0027] Turn on the X-ray radiation sorter and the ore bin feeder, set the spectral ratio threshold for the separation of concentrate and tailings in the control system of the X-ray radiation sorter, the threshold is 0.15, and the ore bin feeder The copper sulfide ore in the feed is fed into the X-ray radiation sorting machine through the ore bin feeder, and after being sorted by the X-ray radiation sorting machine, the copper ore concentrate with a copper ore spectral ratio ...

Embodiment 2

[0031] The low-grade copper sulfide ore raw ore that adopts contains Cu 0.34% by weight percentage;

[0032] Use a crusher to crush the raw ore of low-grade copper sulfide ore to ≤200mm;

[0033] Sieve the crushed material with a sieving machine with a sieve size of 35mm. The material with a particle size of 35-200mm on the sieve is used as the copper sulfide ore feed; the material under the sieve is treated as a middling ore; The conveyor belt is transported to the mine bin of the X-ray radiation sorter;

[0034] Turn on the X-ray radiation sorter and the ore bin feeder, set the spectral ratio threshold for the separation of concentrate and tailings in the control system of the X-ray radiation sorter, the threshold is 0.25, and the ore bin feeder The copper sulfide ore in the feed is fed into the X-ray radiation sorting machine through the ore feeder, and after being sorted by the X-ray radiation sorting machine, the copper sulfide ore spectral ratio is greater than 0.25. F...

Embodiment 3

[0038] The raw ore of low-grade copper sulfide ore contains Cu0.28% by weight percentage;

[0039] Use a crusher to crush the raw ore of low-grade copper sulfide ore to ≤200mm;

[0040] Sieve the crushed material with a sieving machine with a sieve size of 30mm. The material with a particle size of 30-200mm on the sieve is used as the copper sulfide ore feed; the material under the sieve is treated as a middling ore; The conveyor belt is transported to the mine bin of the X-ray radiation sorter;

[0041] Turn on the X-ray radiation sorter and the ore bin feeder, set the spectral ratio threshold for the separation of concentrate and tailings in the control system of the X-ray radiation sorter, the threshold is 0.20, and the ore bin feeder The copper sulfide ore in the feed is fed into the X-ray radiation sorting machine through the ore bin feeder, and after being sorted by the X-ray radiation sorting machine, the copper sulfide ore concentrate and ore with ore spectral ratio g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com