Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Selective inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

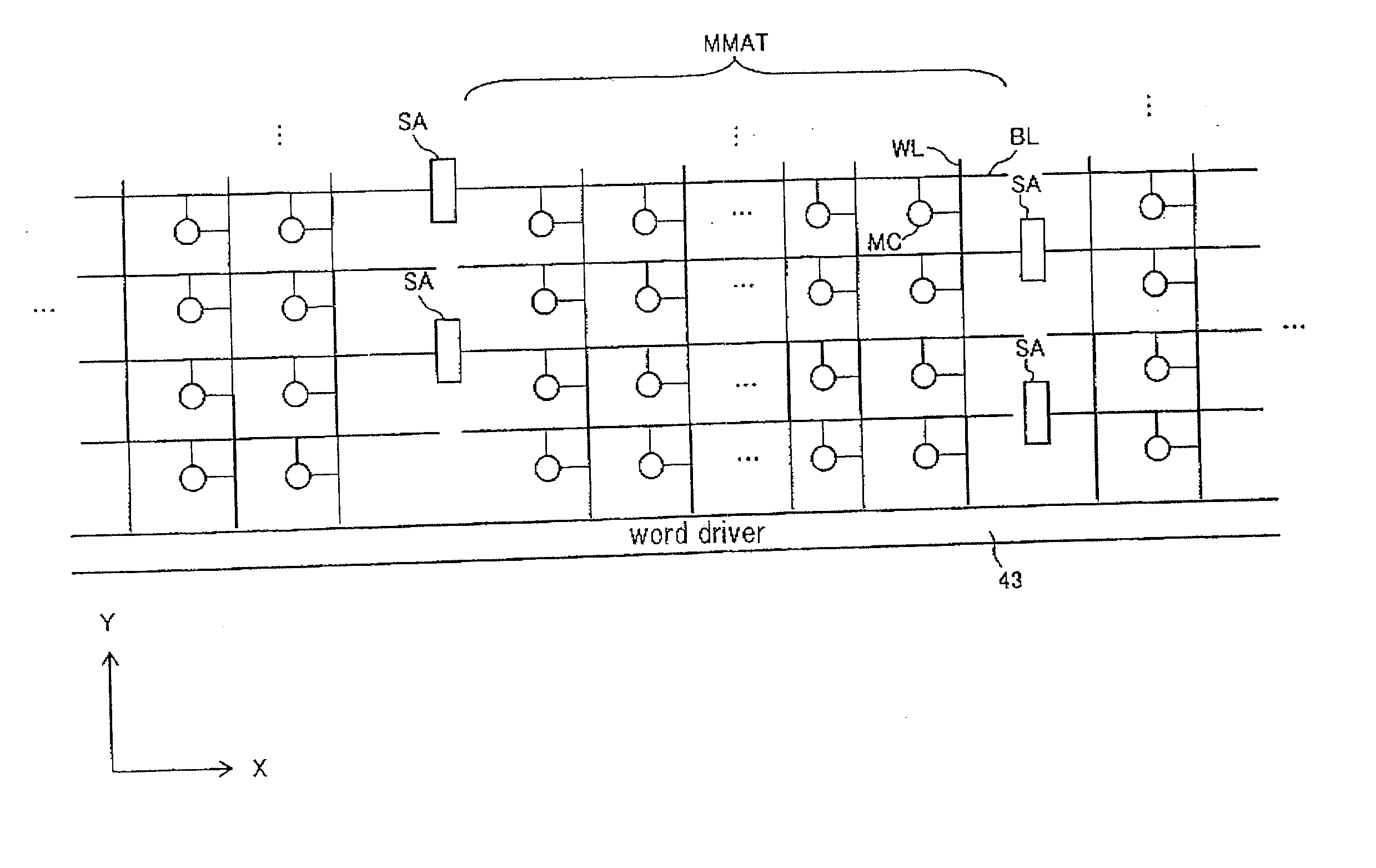

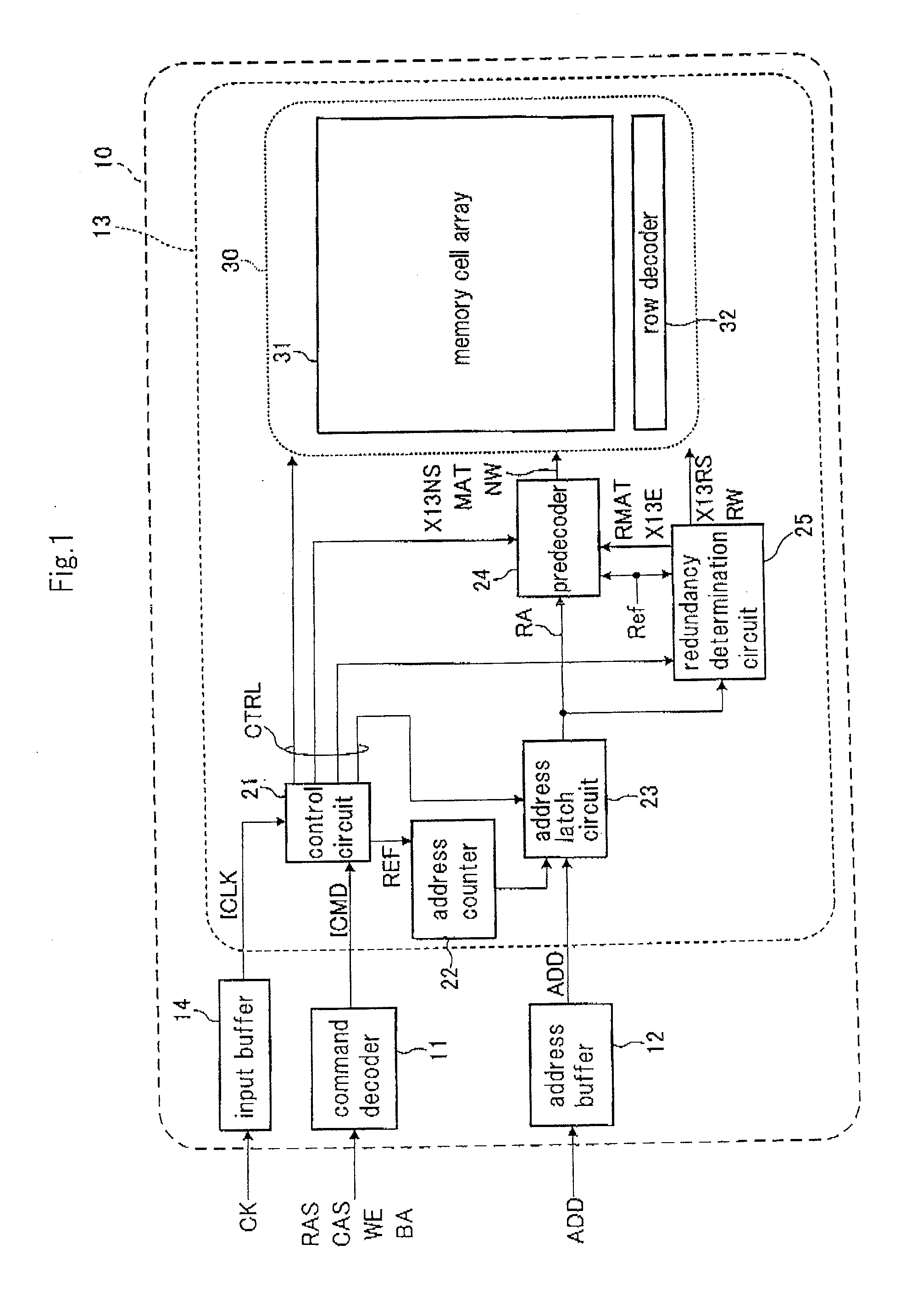

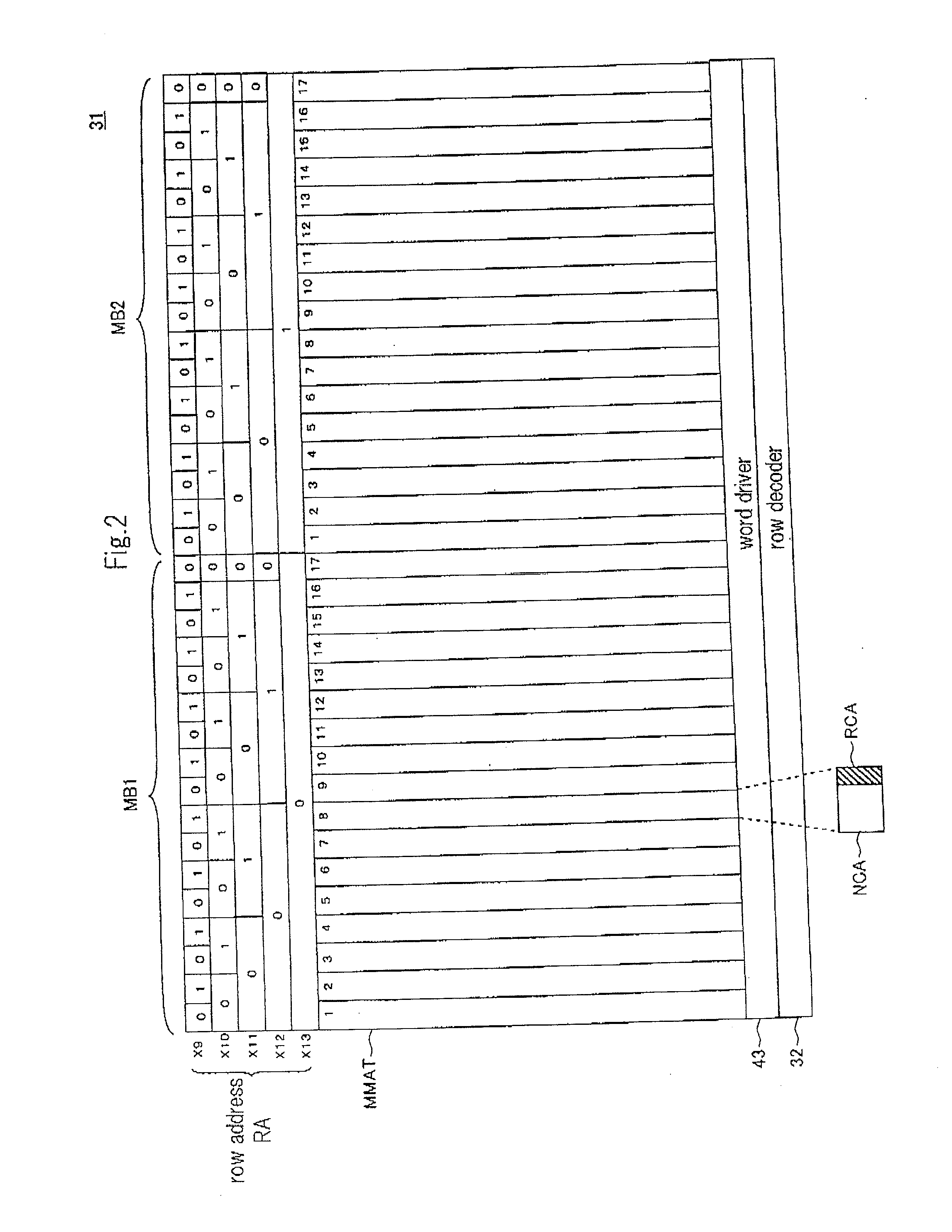

Semiconductor device enabling refreshing of redundant memory cell instead of defective memory cell

A semiconductor device includes memory blocks MB1 and MB2 and redundancy determination circuit 25 that can enter a normal operation mode that accesses either memory block MB1 or memory block MB2 and a refresh mode that simultaneously accesses both memory block MB1 and memory block MB2. In response to normal memory cell NMC that belongs to at least one of memory blocks MB1 and MB2 being replaced by redundant memory cell RMC in the refresh mode, redundancy determination circuit 25 deactivates normal cell area NCA to which normal memory cell NMC that is a source of replacement belongs, and activates redundant cell area RCA to which redundant memory cell RMC that is to be replaced belongs and normal cell area NCA to which normal memory cell NMC that is not being replaced belongs.

Owner:LONGITUDE LICENSING LTD

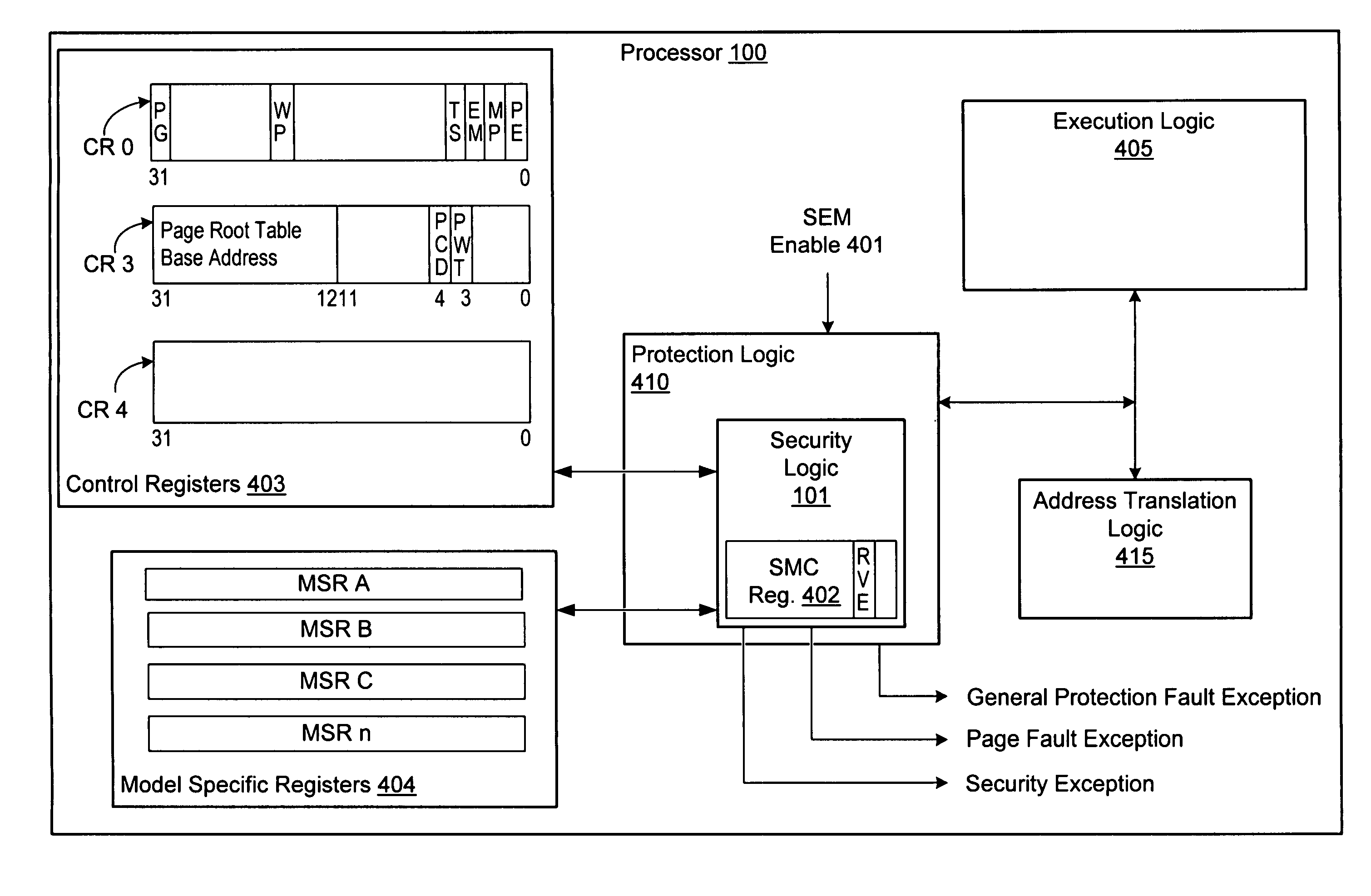

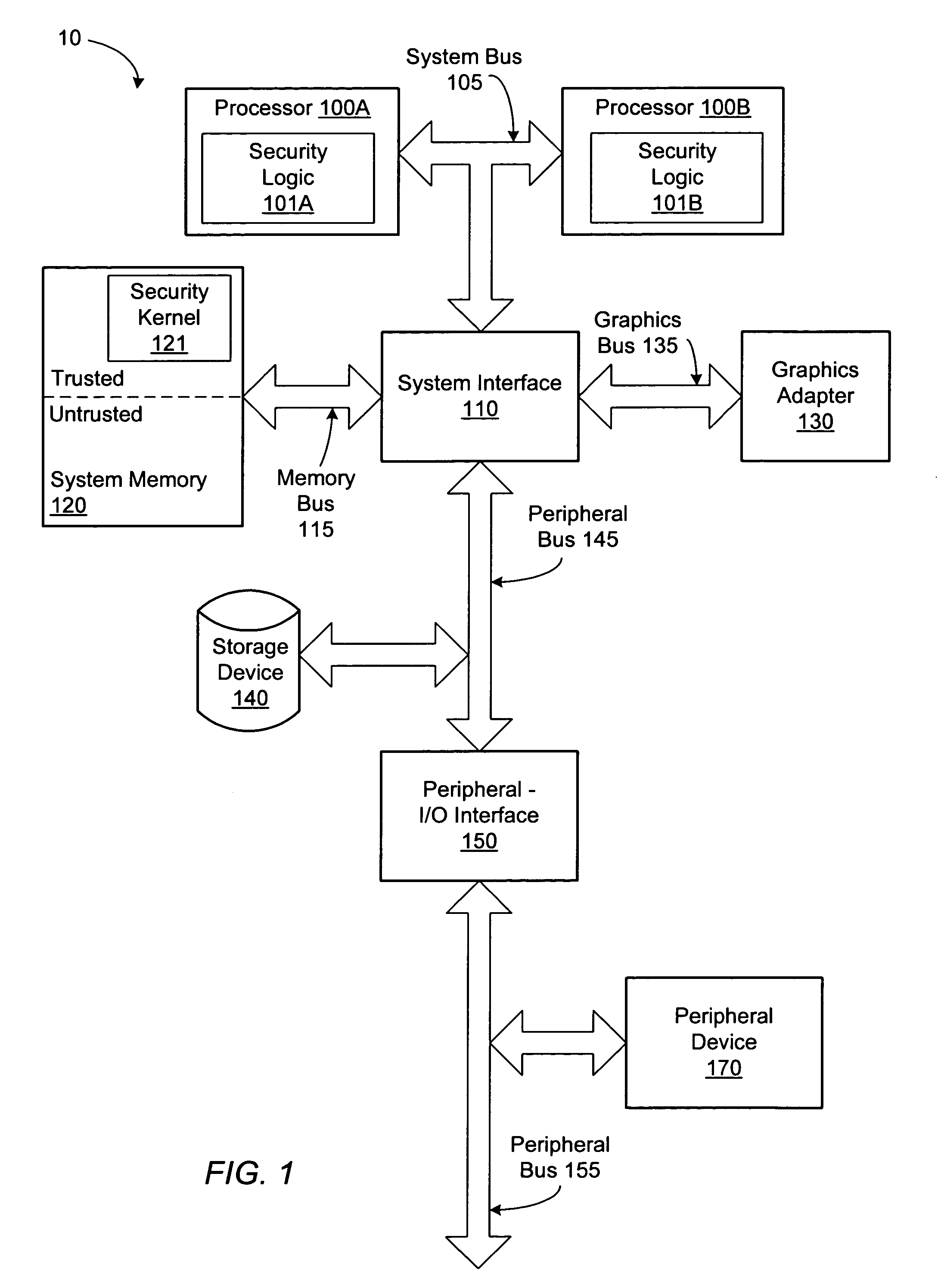

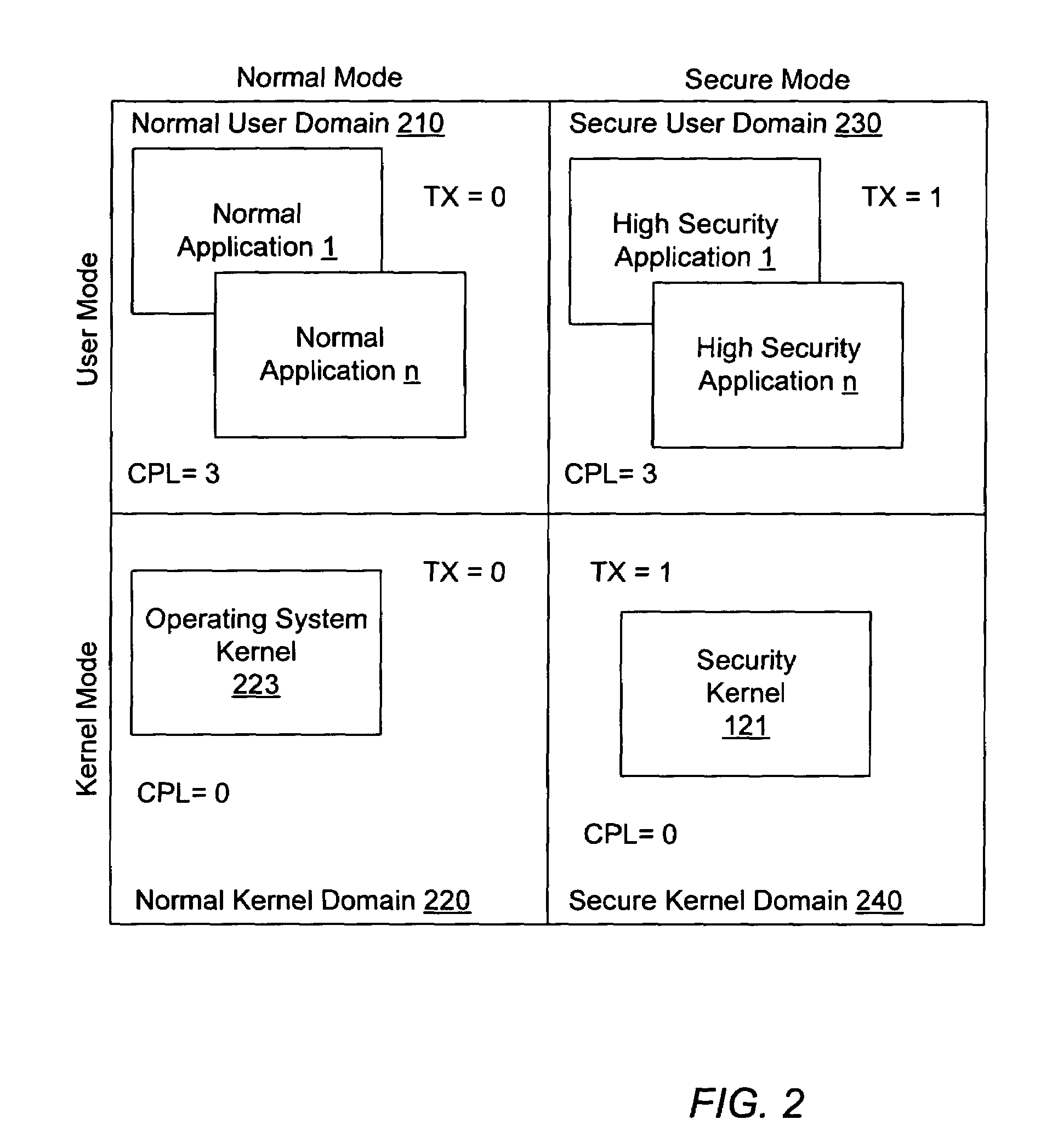

Controlling access to a control register of a microprocessor

Controlling access to a control register of a microprocessor. A method of controlling access to a control register such as CR3, for example, of a processor having a normal execution mode and a secure execution mode may include storing address translation table information in the control register, allowing a software invoked write access to modify the address translation table information during the normal execution mode and selectively inhibiting the software invoked write during the secure execution mode.

Owner:ADVANCED SILICON TECH

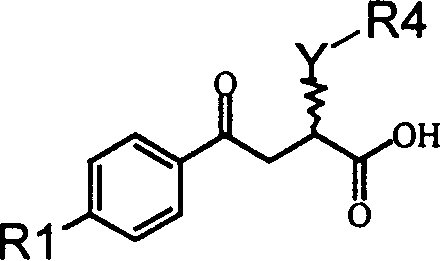

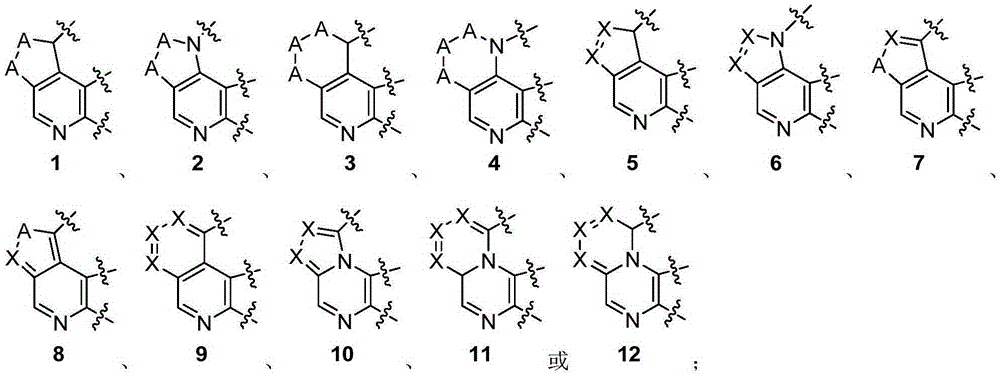

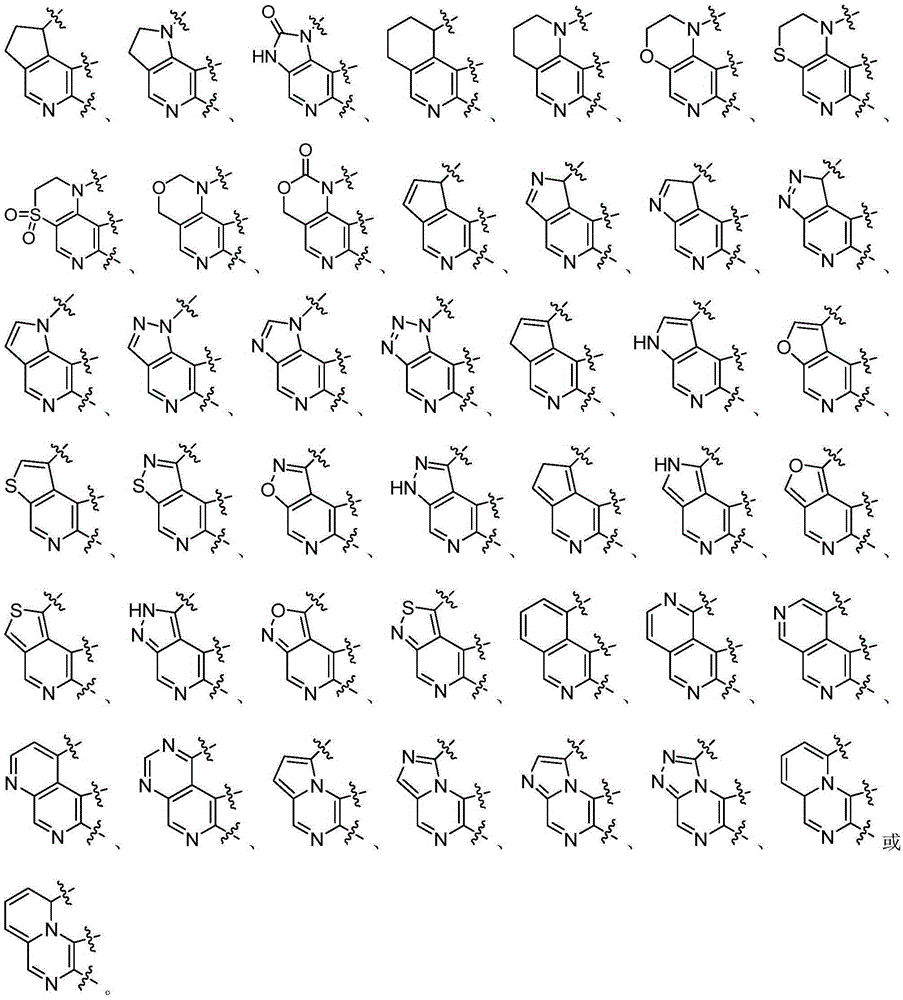

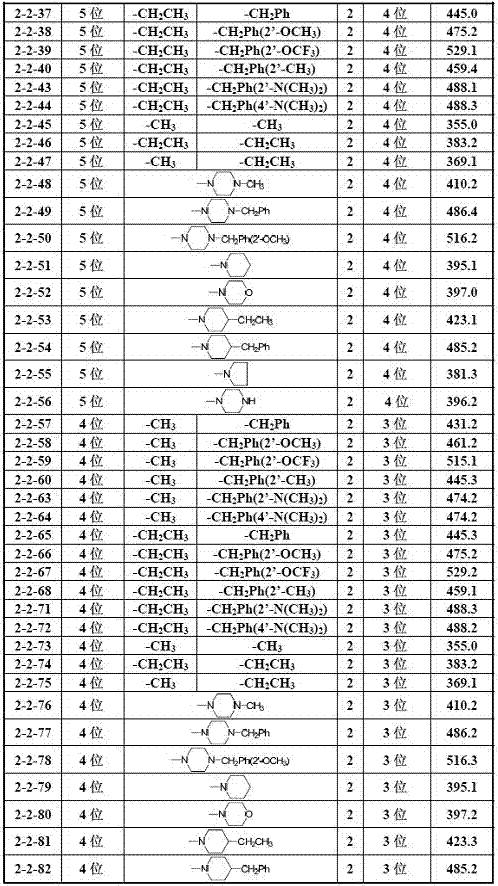

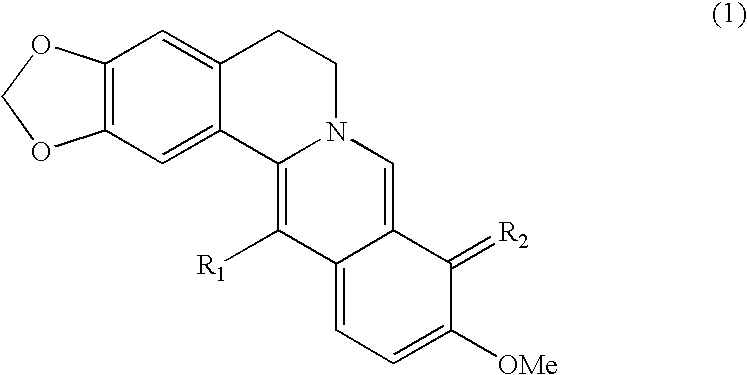

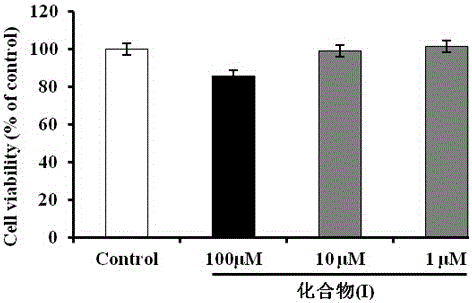

Nitrogen-containing fused heterocycle compound as well as preparation method, composition and application thereof

ActiveCN105481858AGood medicineSignificant inhibition of proliferationOrganic active ingredientsOrganic chemistryEnantiomerNitrogen

The invention discloses a nitrogen-containing fused heterocycle compound shown by a formula I, a pharmaceutically acceptable salt thereof, or enantiomers, diastereoisomers, tautomers, solvates, metabolic precursors or prodrugs of the nitrogen-containing fused heterocycle compound and the pharmaceutically acceptable salt thereof, or a pharmaceutical composition containing the nitrogen-containing fused heterocycle compound and an application of the nitrogen-containing fused heterocycle compound. The nitrogen-containing fused heterocycle compound disclosed by the invention has relatively good antitumor activity.

Owner:上海医药集团(本溪)北方药业有限公司

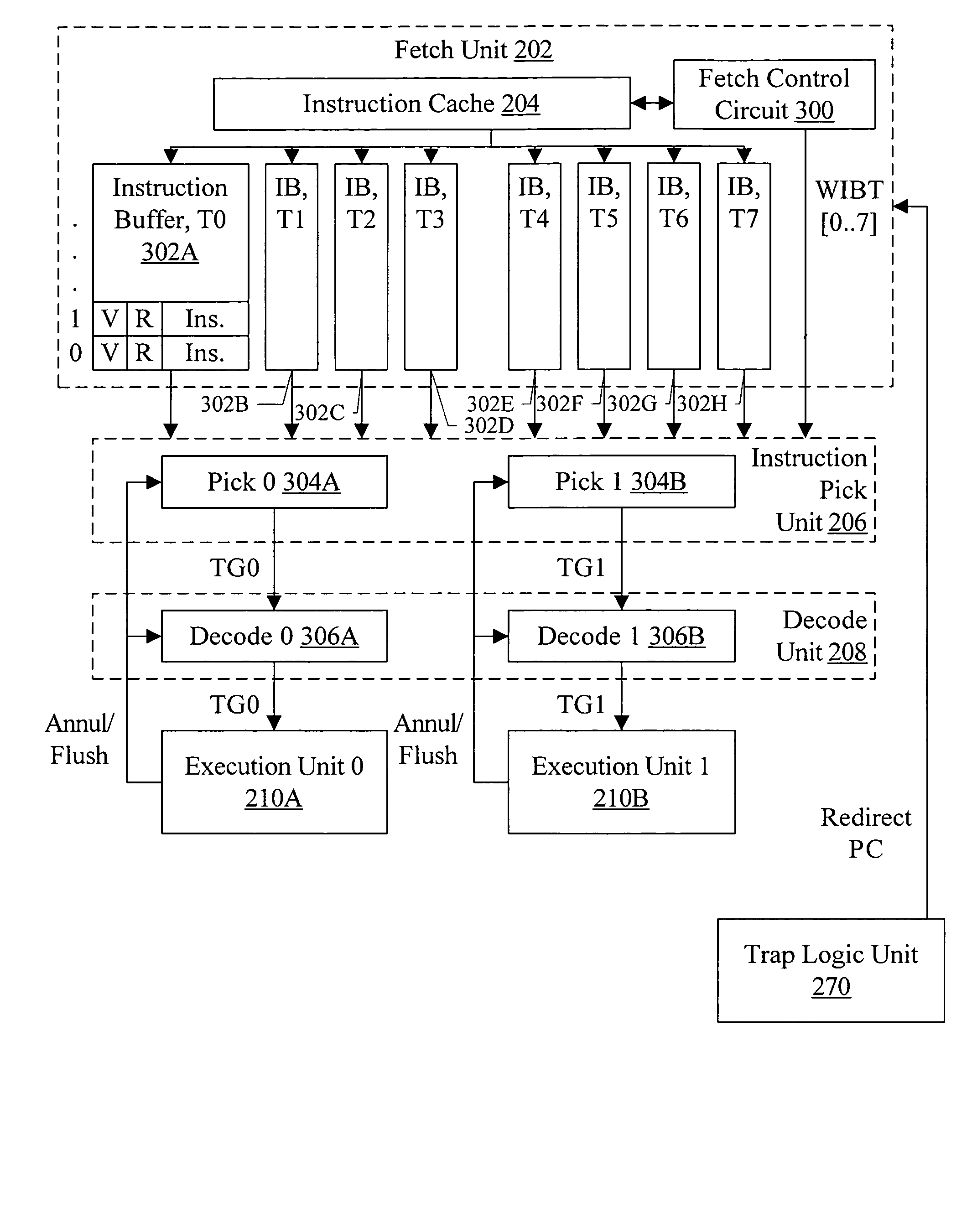

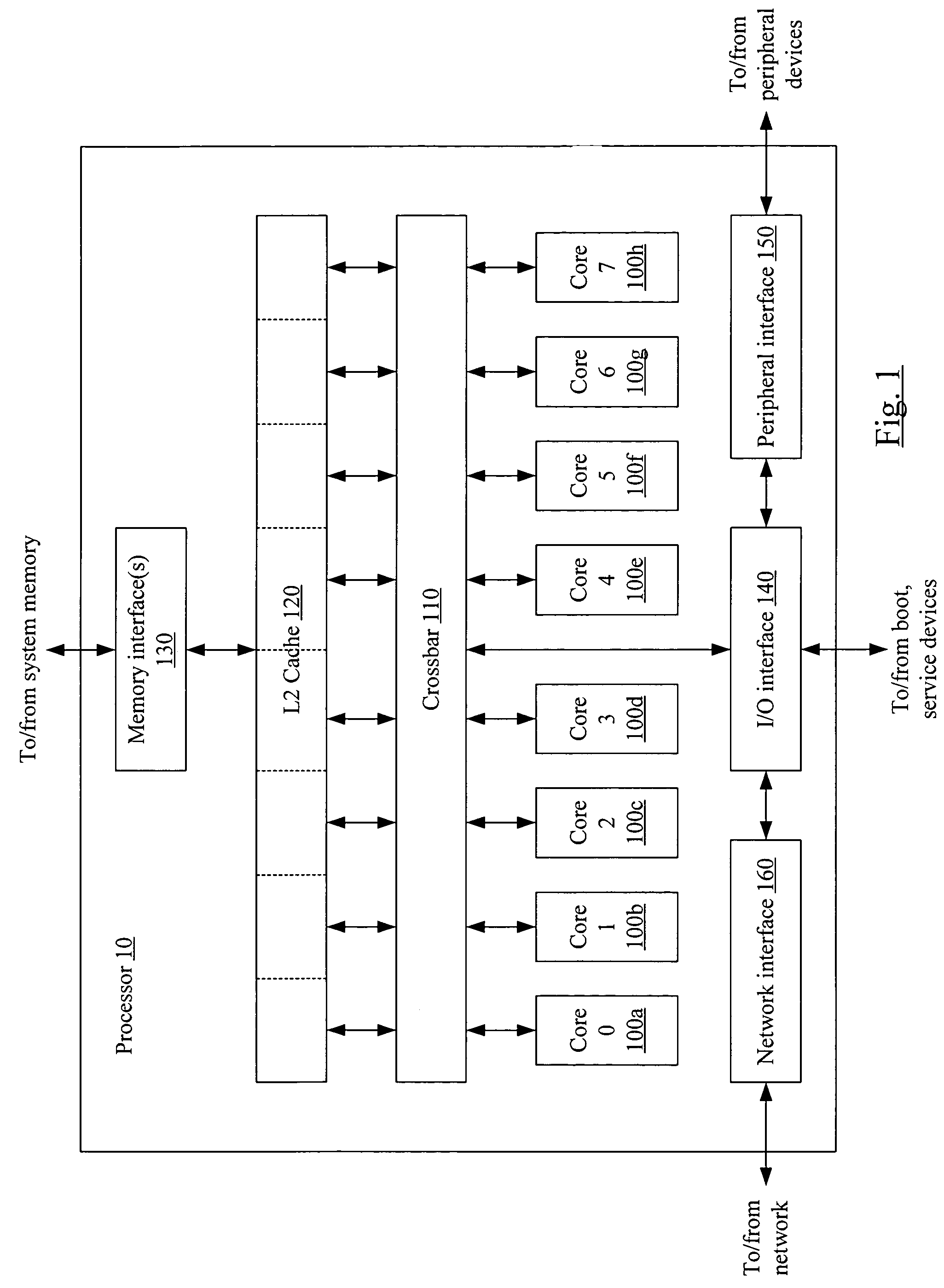

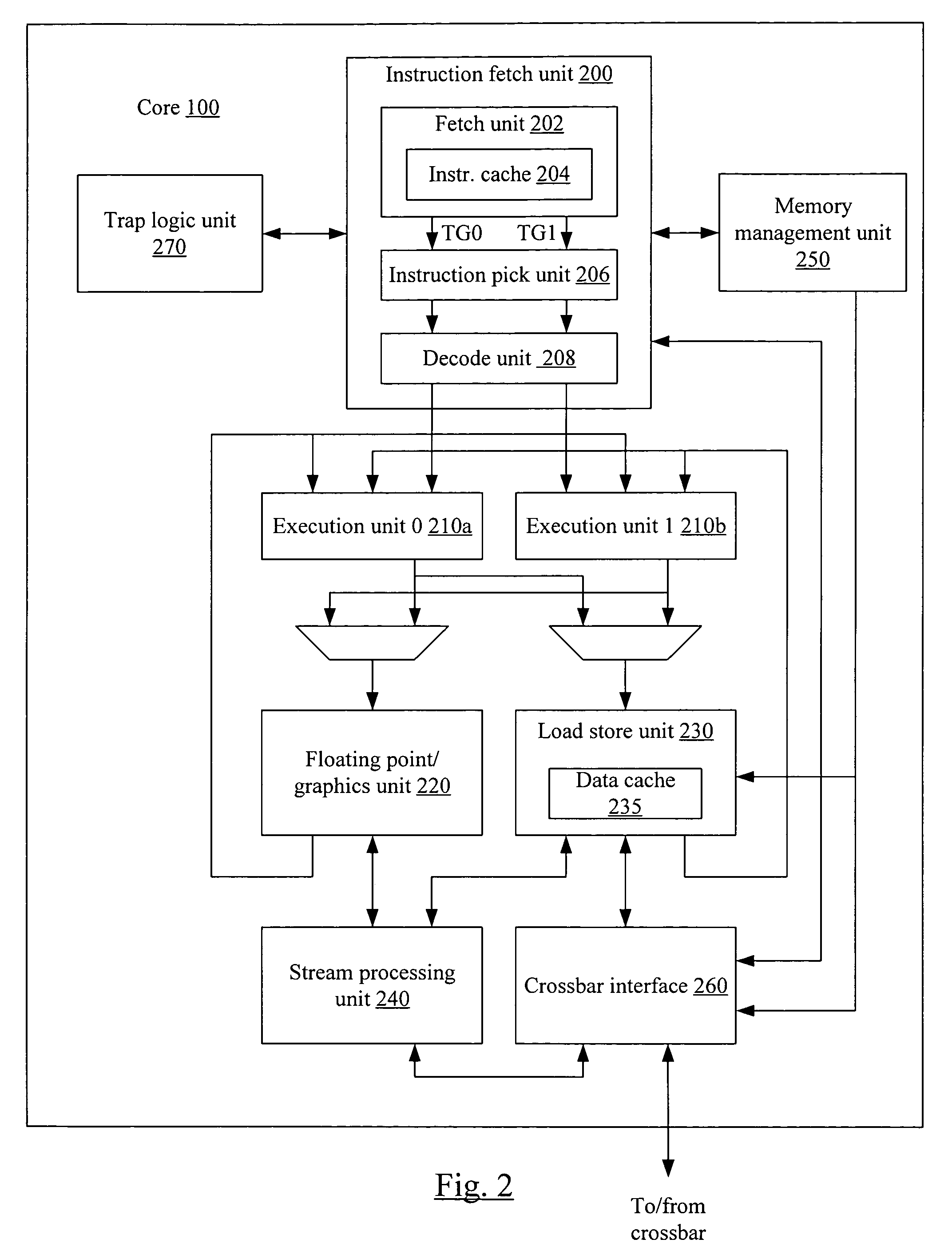

Delay slot handling in a processor

ActiveUS7861063B1Selective inhibitionDigital computer detailsMemory systemsControl transferInstruction prefetch

In one embodiment, a processor comprises a fetch unit and a pick unit. The fetch unit is configured to fetch instructions for execution by the processor. The pick unit is configured to schedule instructions fetched by the fetch unit for execution in the processor. The pick unit is configured to inhibit scheduling a delayed control transfer instruction (DCTI) until a delay slot instruction of the DCTI is available for scheduling. For example, in some embodiments, the pick unit may inhibit scheduling until the delay slot instruction is written to an instruction buffer, until the delay slot instruction is fetched, etc.

Owner:ORACLE INT CORP

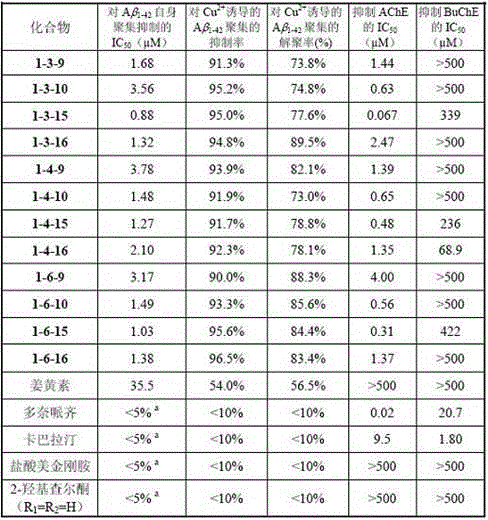

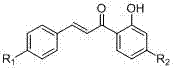

2-hydroxyl chalcone compound as well as preparation method and purpose thereof

ActiveCN105481706AEnhanced inhibitory effectStrong inhibitory activitySenses disorderNervous disorderHuntingtons choreaNeuro-degenerative disease

The invention discloses a novel 2-hydroxyl chalcone compound (I), as well as pharmacy acceptable salt, preparation method, medical composition, and purpose thereof in preparing medicines for treating and / or preventing neurodegenerative diseases including but not limited to vascular dementia, Alzheimer's diseases, Parkinson's diseases, Huntington's diseases, dementia relevant to HIV, multiple sclerosis, amyotrophic lateral sclerosis, neuropathic pain, glaucoma and the like (As shown in the description.).

Owner:SICHUAN UNIV

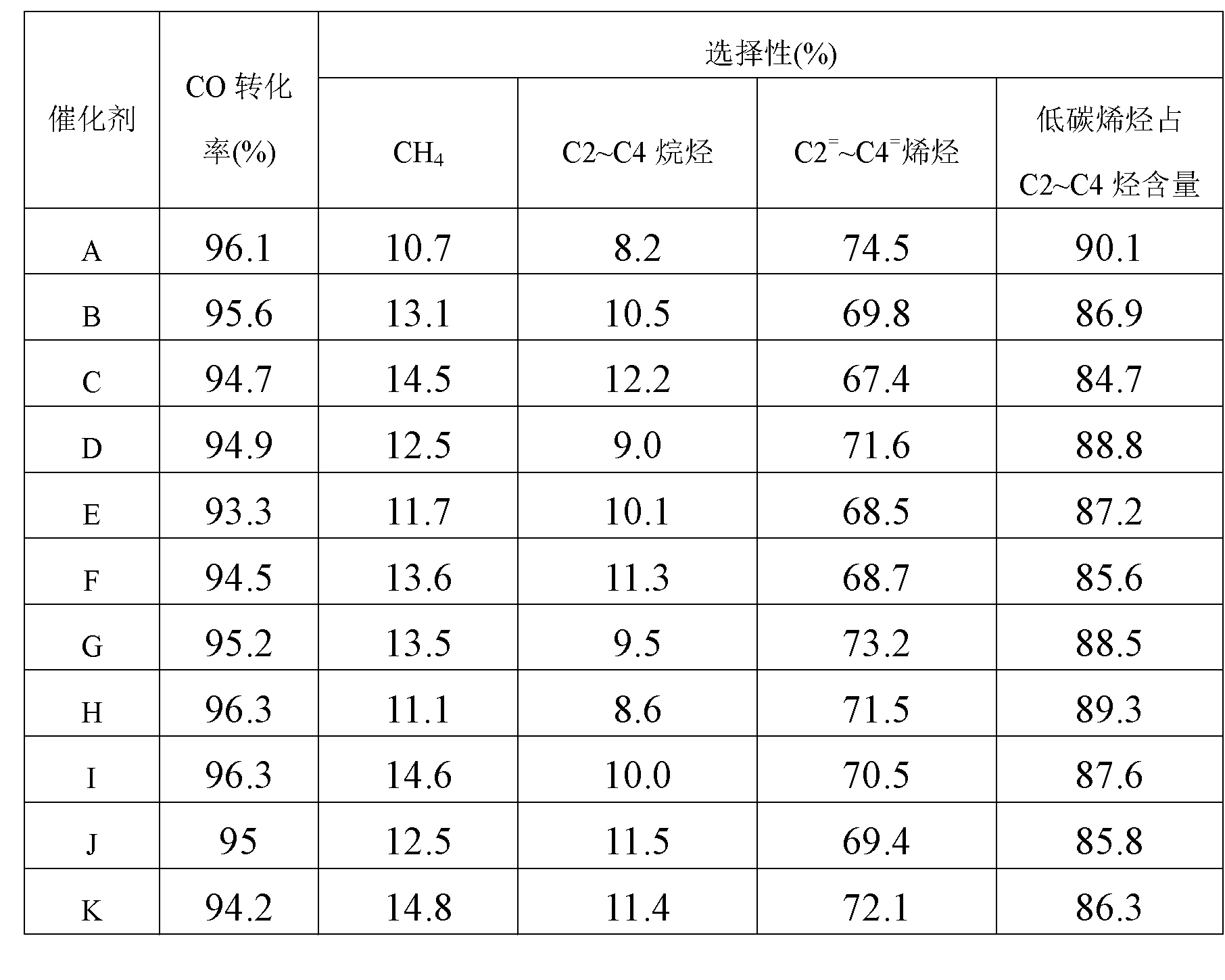

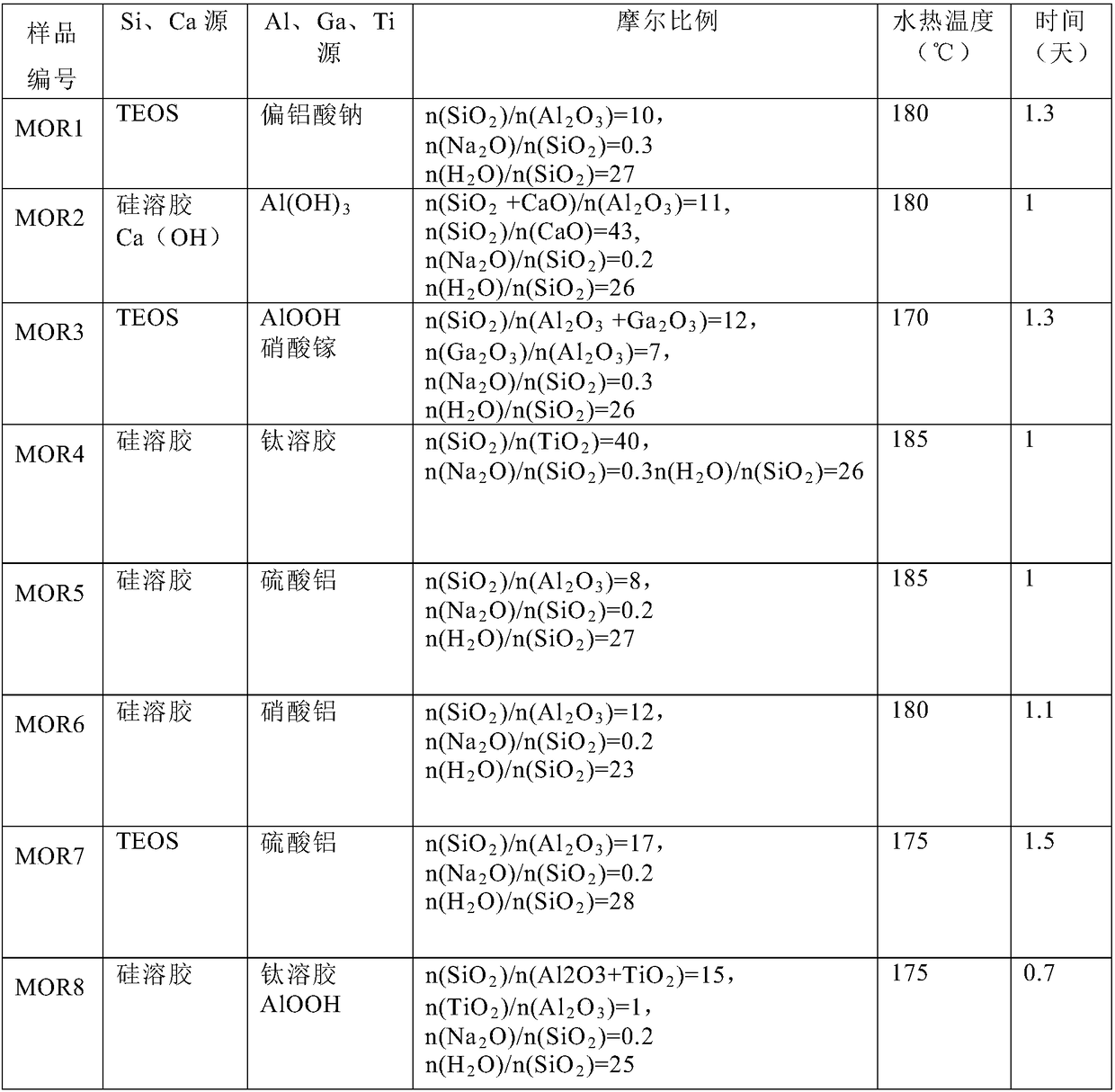

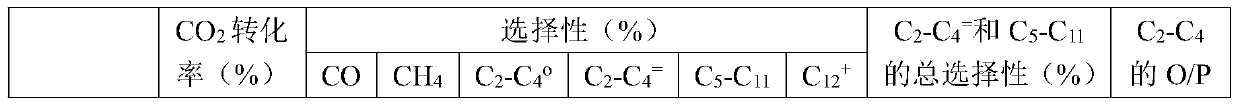

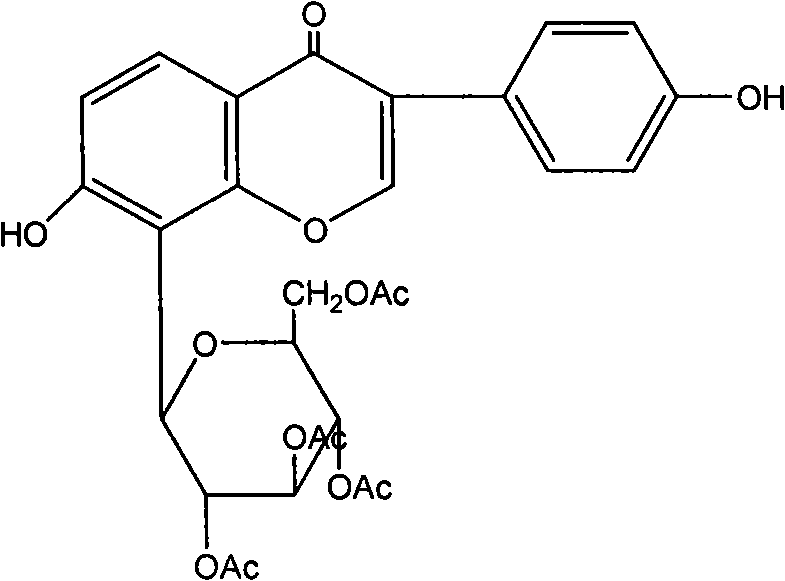

Fischer-Tropsch synthetic catalyst for preparing low-carbon olefin by utilizing synthetic gas, modified molecular sieve carrier and preparation method

ActiveCN103230810AModification method is simple and convenientLow costHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveHydrogen

The invention provides a Fischer-Tropsch synthetic catalyst for preparing low-carbon olefin by utilizing synthetic gas, a modified molecular sieve carrier and a preparation method. The Fischer-Tropsch synthetic catalyst comprises the components, namely a molecular sieve carrier and an active component, wherein the molecular sieve is a silicon-aluminium molecular sieve and / or high-silicon molecular sieve carrier modified by cerate and / or praseodymium salt, the active component takes Fe as a main component and also comprises active components, namely Mn and Cu, and an alkaline auxiliary, and the modified molecular sieve accounts for 40-80wt%; mass percent of the cerate and / or praseodymium salt on the modified molecular sieve is 1-20% of the molecular sieve; the cerate and / or praseodymium salt modified molecular sieve carrier is a cerium and / or praseodymium modified molecular sieve formed by treating a silicon-aluminium molecular sieve and / or high-silicon molecular sieve with an acid solution to obtain a hydrogen type molecular sieve, steeping the hydrogen type molecular sieve in a cerate and / or praseodymium salt solution and then drying and roasting; the cerate and / or praseodymium salt modified molecular sieve is steeped in a saline solution of the active component; and then drying and roasting are carried out, so that the Fischer-Tropsch synthetic catalyst for preparing the low carbon olefin by utilizing the synthetic gas is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

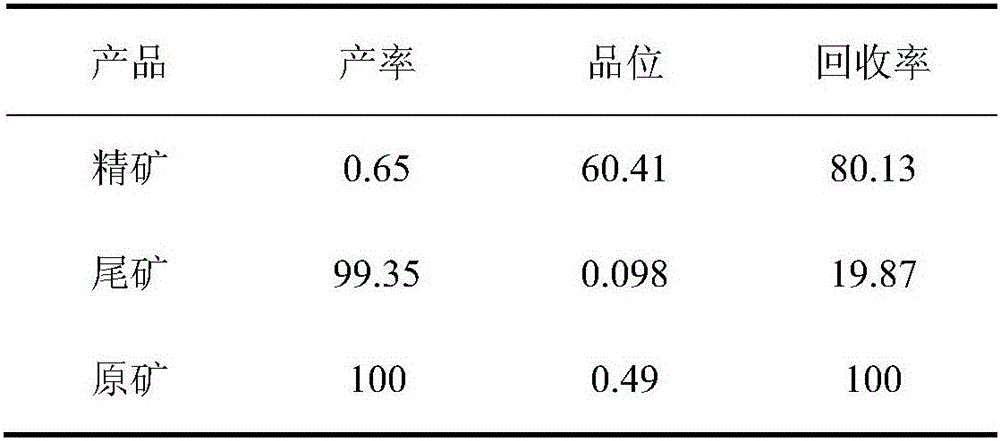

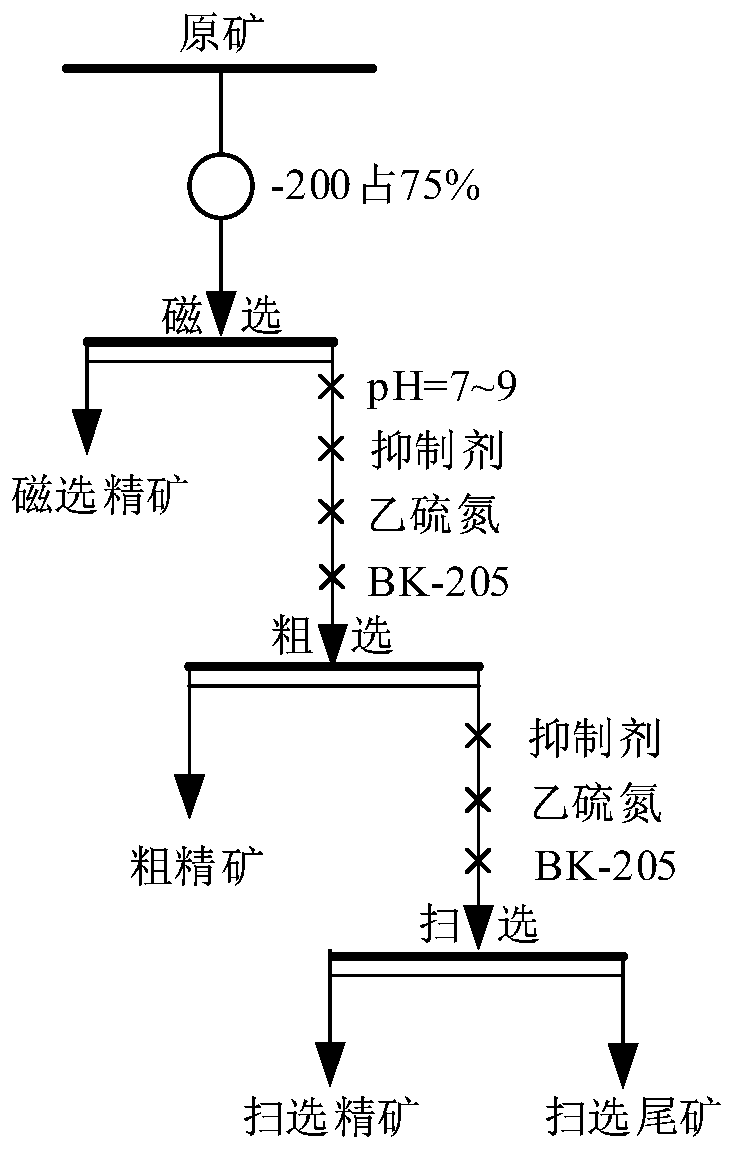

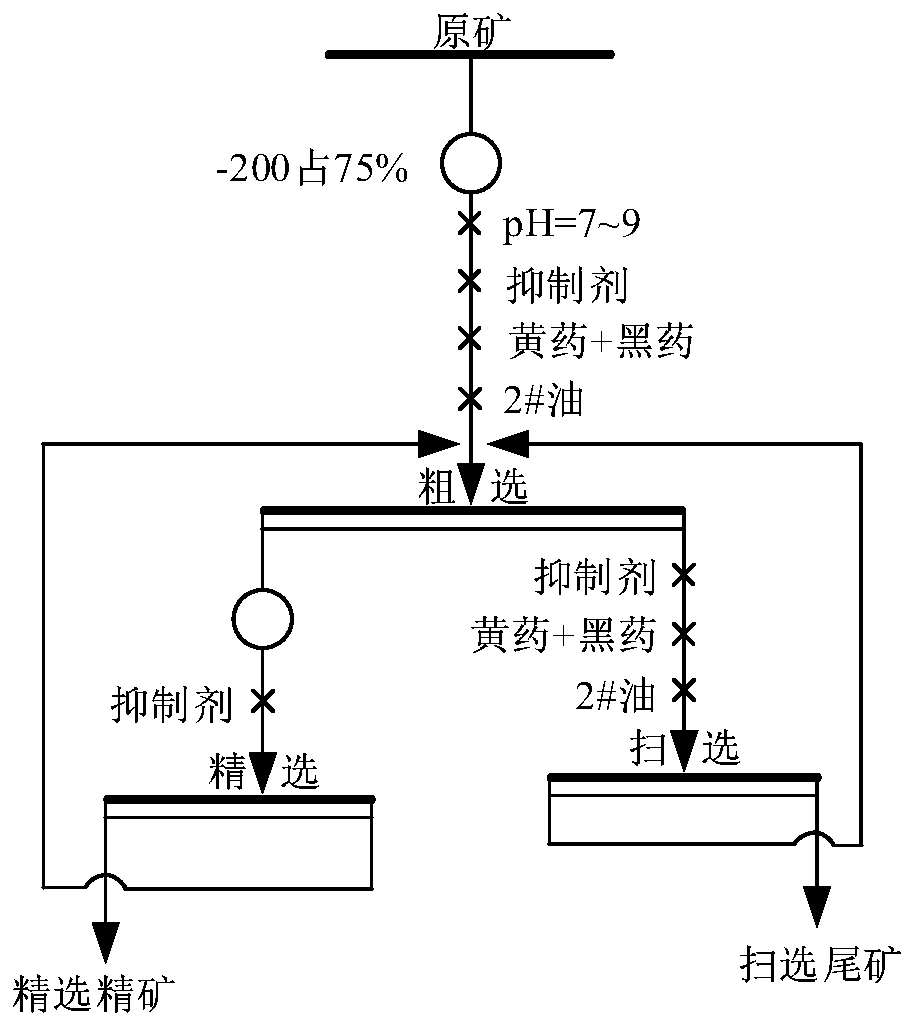

Method for selecting scheelite at normal temperature

ActiveCN106000655AEnhanced ChelationEnergy saving and emission reduction clean productionFlotationOre concentrateScheelite

The invention discloses a method for selecting scheelite at normal temperature. The method comprises the following steps: (1) pulping: a raw ore is milled and classified to prepare pulp with a concentration of 30-35%; the pulp is injected in a flotation machine; and the pH of the pulp is adjusted within 7-9; (2) roughing: a water glass and sodium humate combined inhibiting agent is adopted to inhibit a calcium-contained gangue mineral; and a sodium oleate and benzohydroxamic acid combined capturing agent is added for roughing and scavenging to obtain a scheelite concentrate; (3) the concentration of the scheelite concentrate is condensed to 60%; and the water glass and sodium humate combined inhibiting agent is added for strongly stirring by above 30 m under the effect of a normal-temperature magnetic field to dilute to the mass concentration of 30%; and (4) six times of blank selection are performed for the scheelite concentrate treated in the step (3) to obtain the scheelite concentrate.

Owner:JIANGXI UNIV OF SCI & TECH

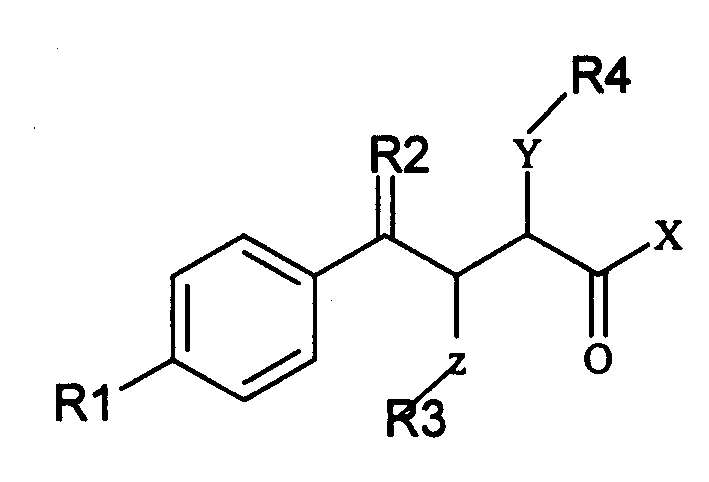

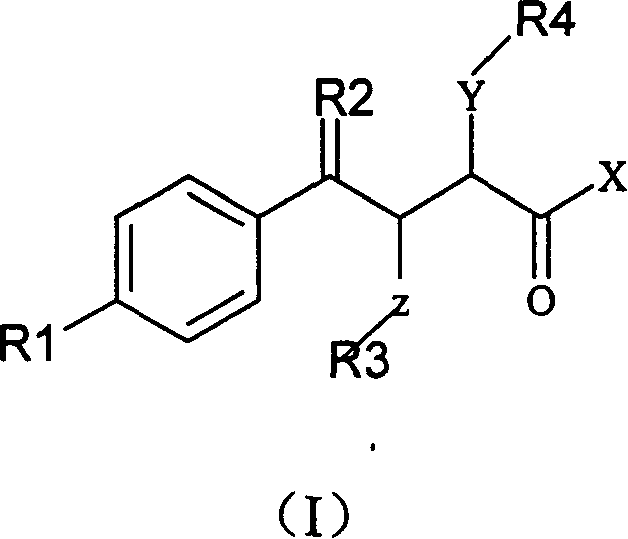

Alpha position heteroatom substituted gamma aryl ketobutyric acid derivative, process, pharmaceutical combination and uses thereof

InactiveCN1566065AActivity hasSelective inhibitionOrganic chemistrySkeletal disorderKetoneAcid derivative

The invention relates to a gamma methyl ethyl ketone acid derivative represented by general formula (I), and contains gamma-aryl-alpha-amido-beta, its preparing process, pharmaceutical compositions containing them and use as medicament, in particular as medicament for treating osteoarthritis and tumor.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

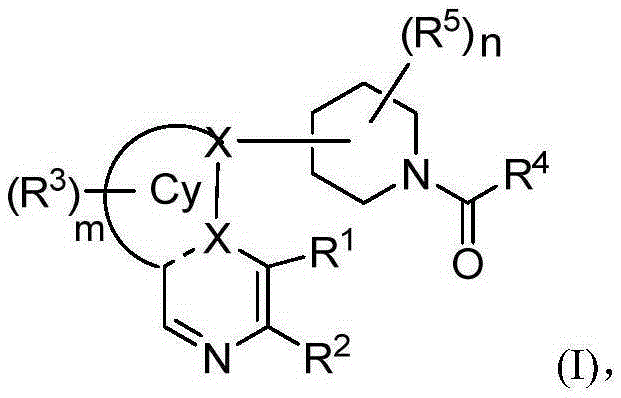

Heterarylation compound and application thereof to drugs

ActiveCN105566321AHas inhibitory effectSelective inhibitionOrganic active ingredientsNervous disorderMetaboliteGeometric isomer

The invention discloses a heterarylation compound and application thereof to drugs, and particularly discloses a heterarylation compound or stereoisomers, geometric isomers, tautomers, nitrogen oxide, hydrate, solvates, metabolites, pharmaceutically acceptable salt or pro-drugs of the heterarylation compound and a drug composition with the heterarylation compound. The invention further discloses application of the compound or the drug composition to drug preparation. The drugs can be used for treating autoimmune diseases or proliferative diseases.

Owner:SUNSHINE LAKE PHARM CO LTD

Base-modified catalyst and method for preparing ethylene through hydrogenating reaction of carbon monoxide

ActiveCN108940355AEasy to separateHigh selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsMixed gasMethane

The invention belongs to ethylene preparation through direct hydrogenation conversion of carbon monoxide, and particularly relates to a base-modified catalyst and a method for preparing ethylene through a hydrogenating reaction of carbon monoxide. According to the method, mixed gas of carbon monoxide and hydrogen is adopted as a reaction raw material, a conversion reaction is performed on a fixedbed or a mobile bed, and a catalyst which is a composite catalyst is obtained by compounding a component A and a component B together through mechanical mixing; and active components of the componentA are metal oxide, and the component B is an organic alkali-modified molecular sieve with an MOR structure; the weight ratio of the active components of the component A to the component B is 0.1-20, preferably 0.3-8, and the reaction process has a high product yield and selectivity; and the selectivity to C2-C3 olefin is as high as 86-92%, hydrocarbon products containing four carbon atoms or aboveare less than 7%, and the selectivity to a by-product methane is extremely low and lower than 5%; and the selectivity and space-time yield of ethylene are obviously improved, and the selectivity reaches 75-85%, and the method has a good application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

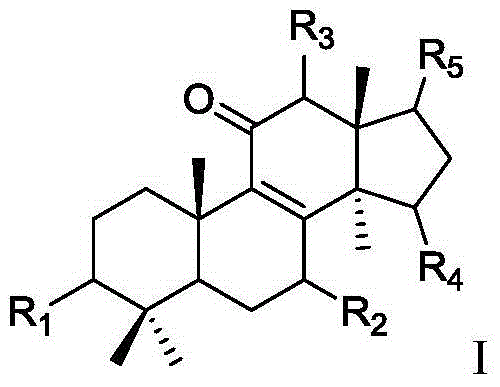

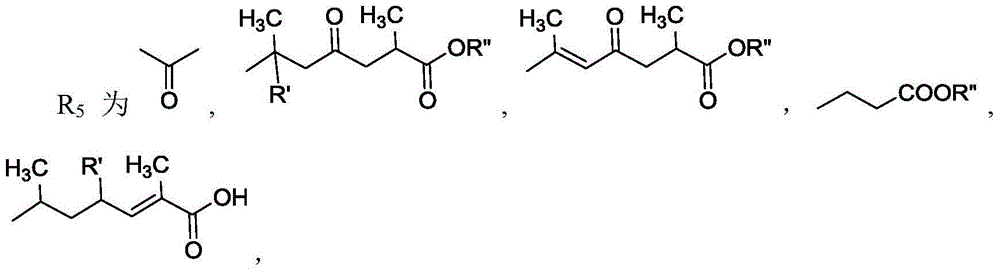

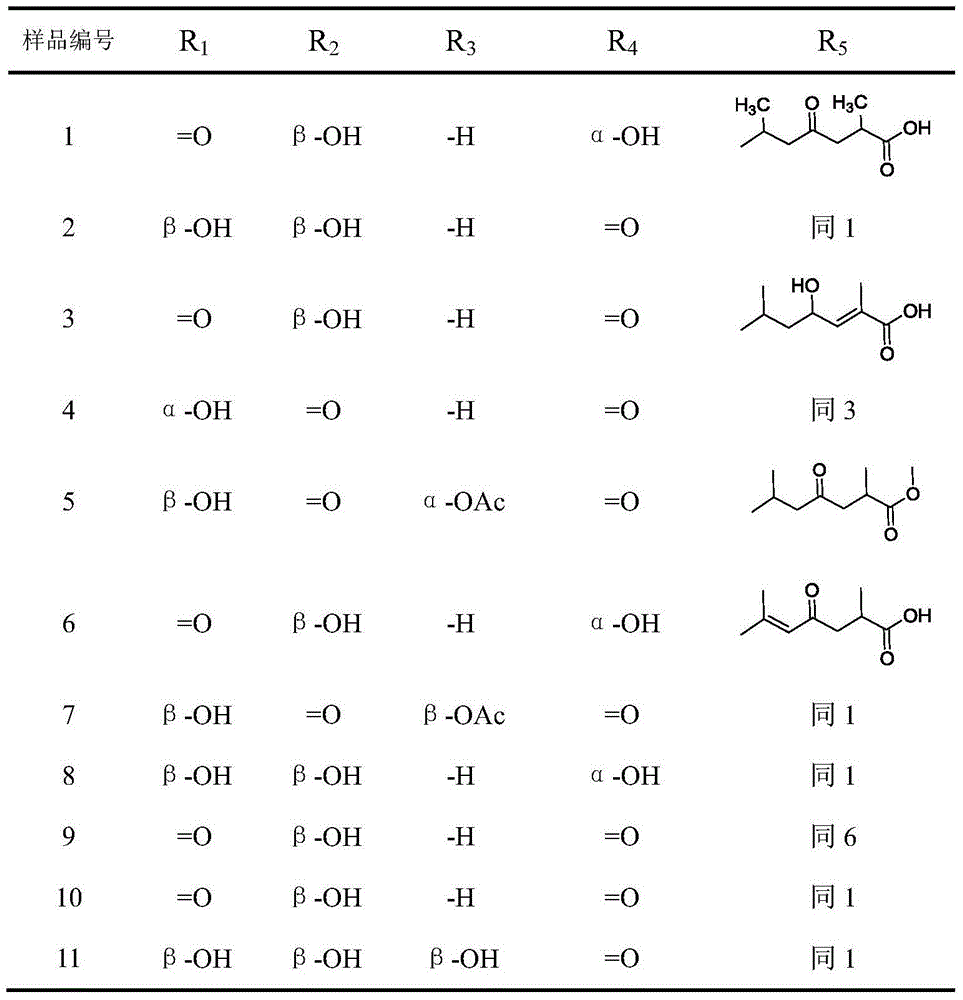

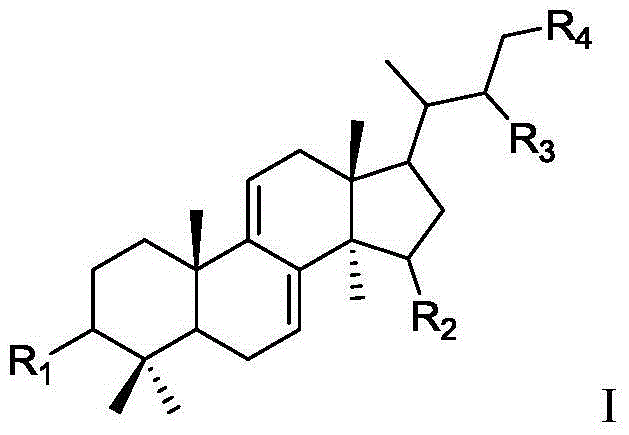

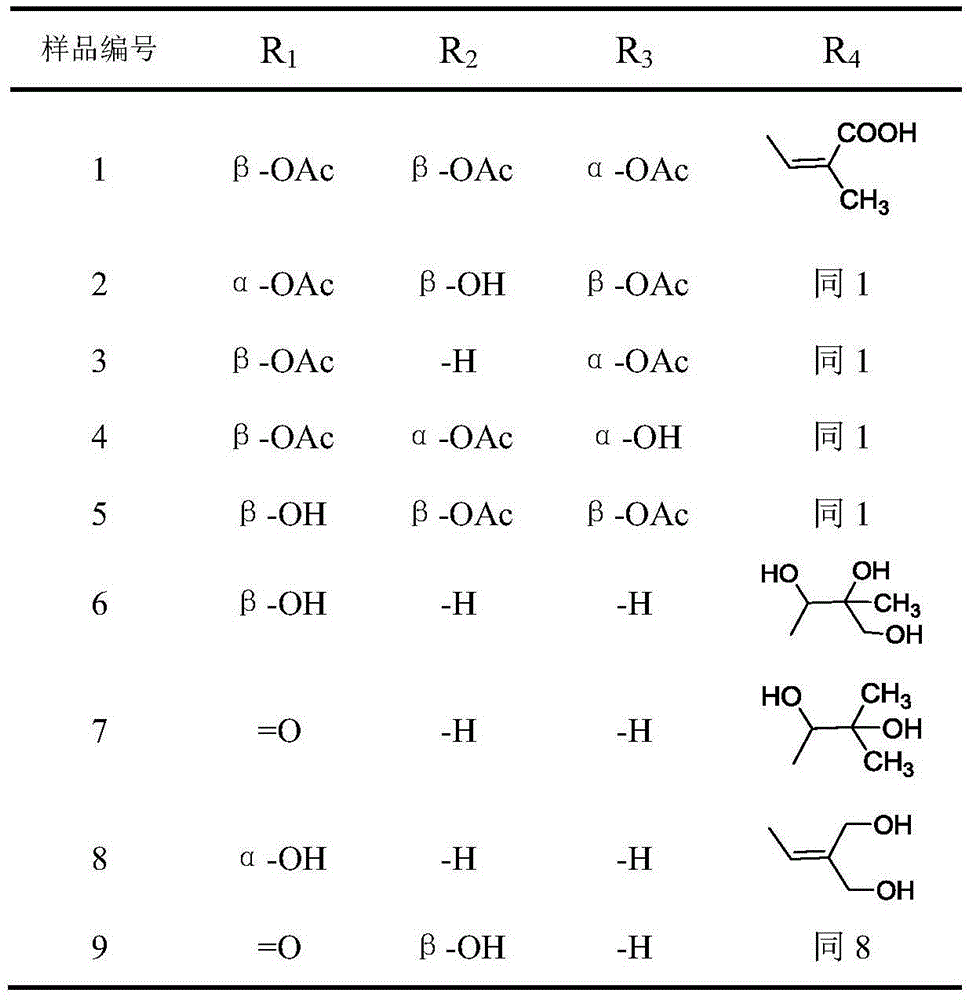

11 beta-hydroxysteroid dehydrogenase inhibitor and its pharmaceutical composition and use

InactiveCN104873520ASelective inhibitionOrganic active ingredientsNervous disorder11-beta-Hydroxysteroid DehydrogenasesGanoderic acid

The invention provides a novel use of a ganoderic acid component with a structure shown in the general formula I as a 11 beta-HSD inhibitor. The ganoderic acid component as a 11 beta-hydroxysteroid dehydrogenase inhibitor with a novel structure has a certain selective inhibition effect on 11 beta-HSD1 and can be used for preparation of drugs for adjusting lipid metabolism and treating diabetes, adiposis and cardiovascular diseases.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

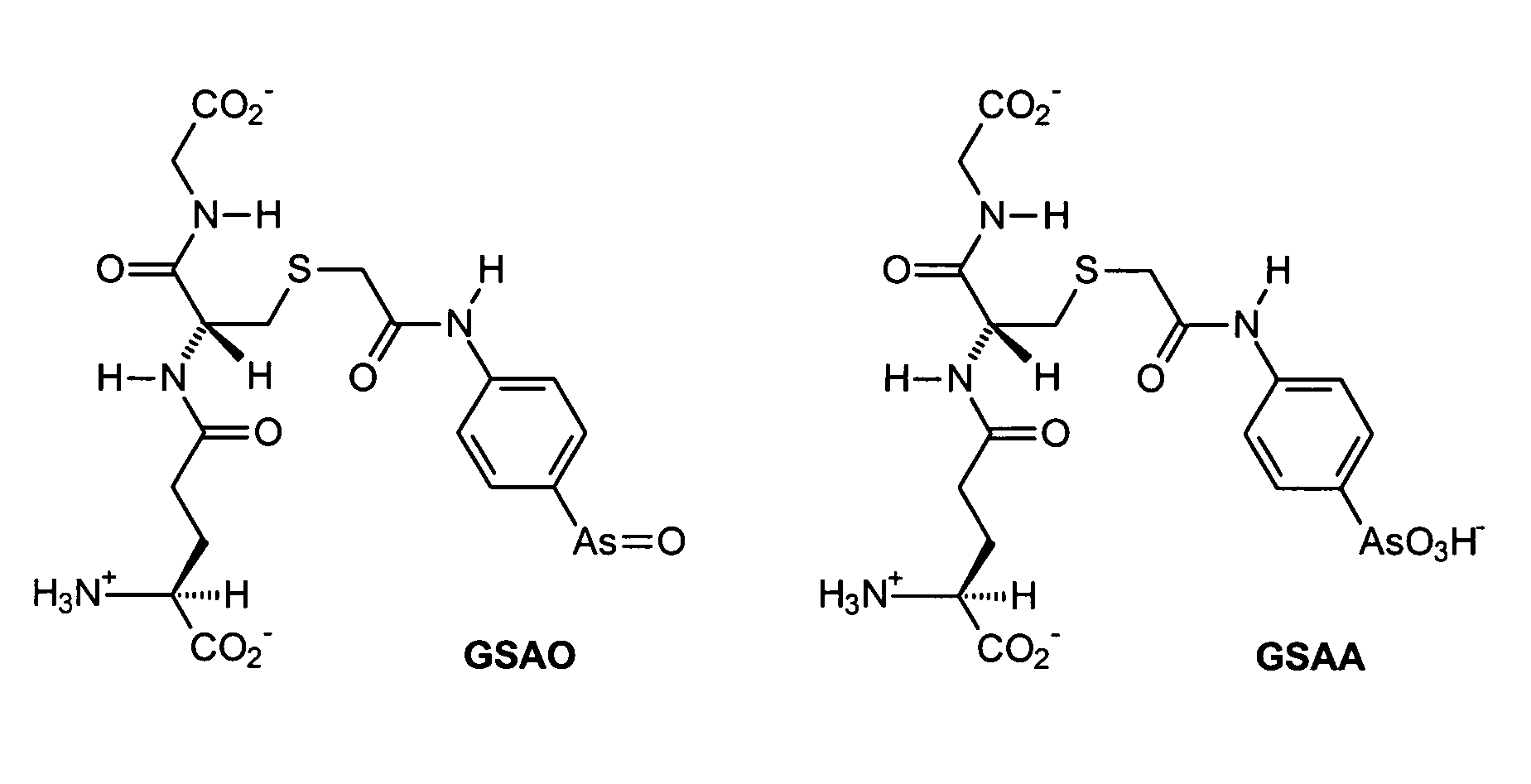

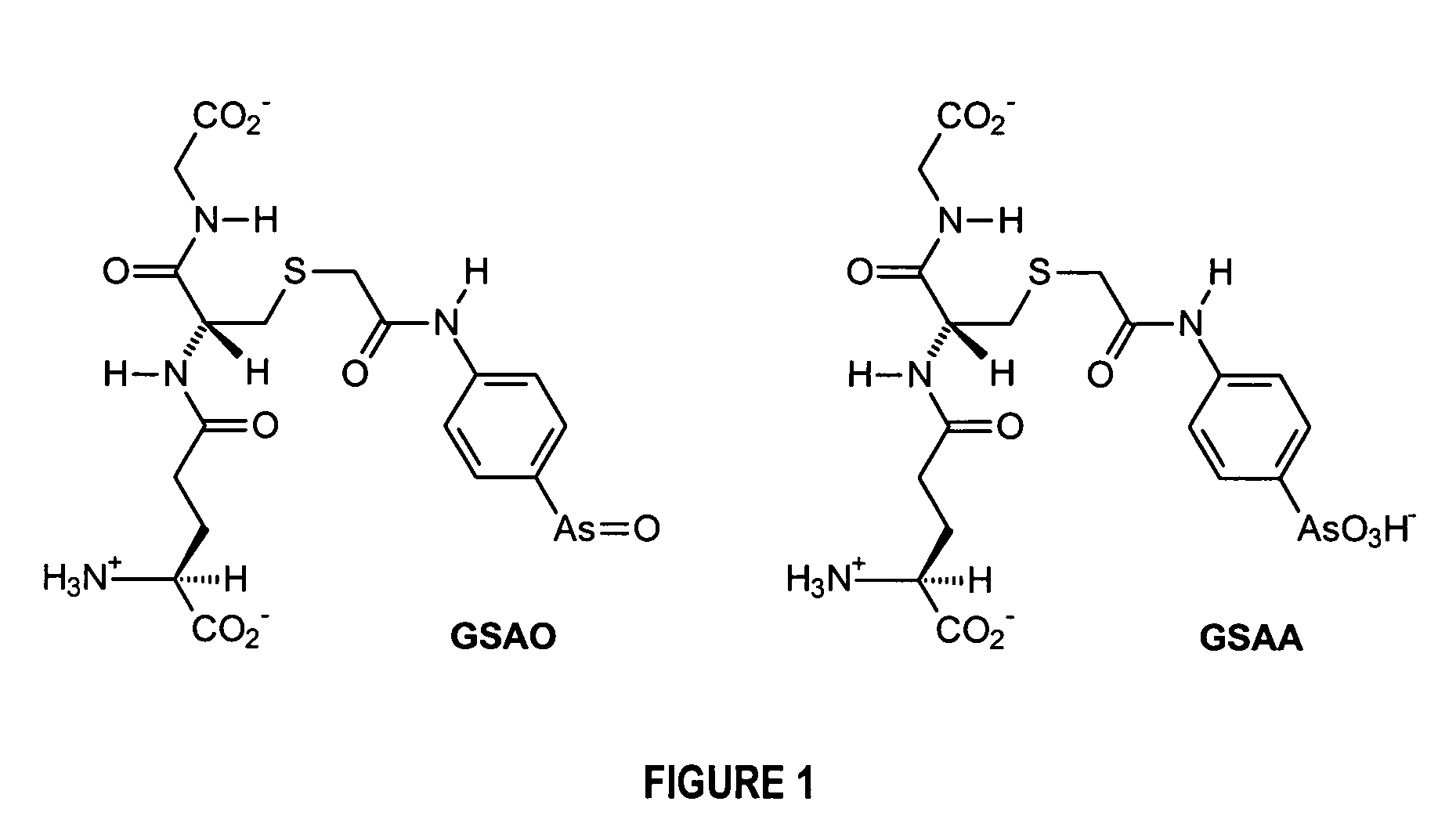

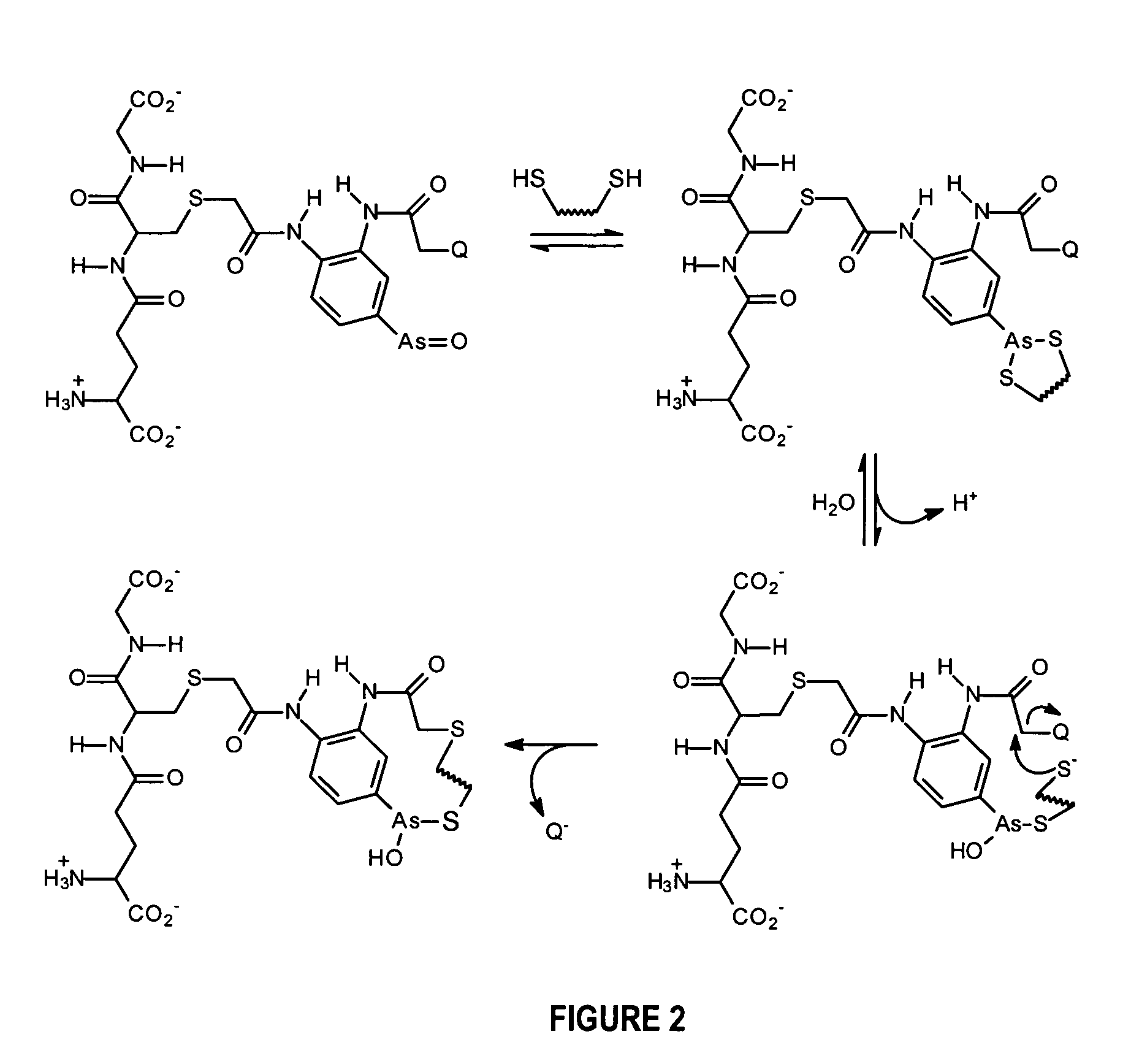

Substantially cell membrane impermeable compound and use thereof

InactiveUS7074766B1Selective inhibitionSenses disorderPeptide/protein ingredientsCell membraneCombinatorial chemistry

The present invention relates to a compound according to Formula (I): A-(L-Y)p, wherein A comprises at least one substantially cell-membrane impermeable pendant group; L comprises any suitable linker and / or spacer group; Y comprises at least one arsenoxide or arsenoxide equivalent; p is an integer from 1 to 10; and the sum total of carbon atoms in A and L together, is greater than 6.

Owner:UNISEARCH LTD

Feed additive capable of improving anti-stress and immunity of ruminants and preparation method thereof

InactiveCN106509415AMeet needsEnhance non-specific immunityFood processingAnimal feeding stuffEcological environmentPhosphate

The invention discloses a feed additive capable of improving anti-stress and immunity of ruminants and a preparation method thereof. The feed additive capable of improving the anti-stress capability and immunity of ruminants is prepared from the following raw materials: bacillus subtilis powder, lactobacillus plantarum powder, saccharomycete powder, catechuic acid, xylooligosaccharide, calcium fatty acids, chromium nicotinate, medical stone, vitamin C, vitamin B1, nicotinic acid, pine pollen, tricalcium phosphate, manganese sulfate, soy isoflavone, berberine, soya bean meal, versioolor swallowwort root, herba ephedra, futokadsura stem, herba potentillae chinensis, ford manglietia fruit, ciliate desert-grass, ajuga decumbens, tangerine leaves, cow soapwortseed and table salt. The feed additive capable of improving the anti-stress capability and immunity of ruminants contains multiplex vitamins, trace elements and Chinese medicinal herb ingredients, and all the ingredients achieve a synergistic effect, so that the intestinal micro-ecological environments of ruminants can be effectively improved, the quantity of pathogens is reduced, stress reaction is reduced to a great extent, the immunity is improved and thus the disease incidence of ruminants.

Owner:SHANDONG JIANYUAN BIOTECHNOLOGY CO LTD

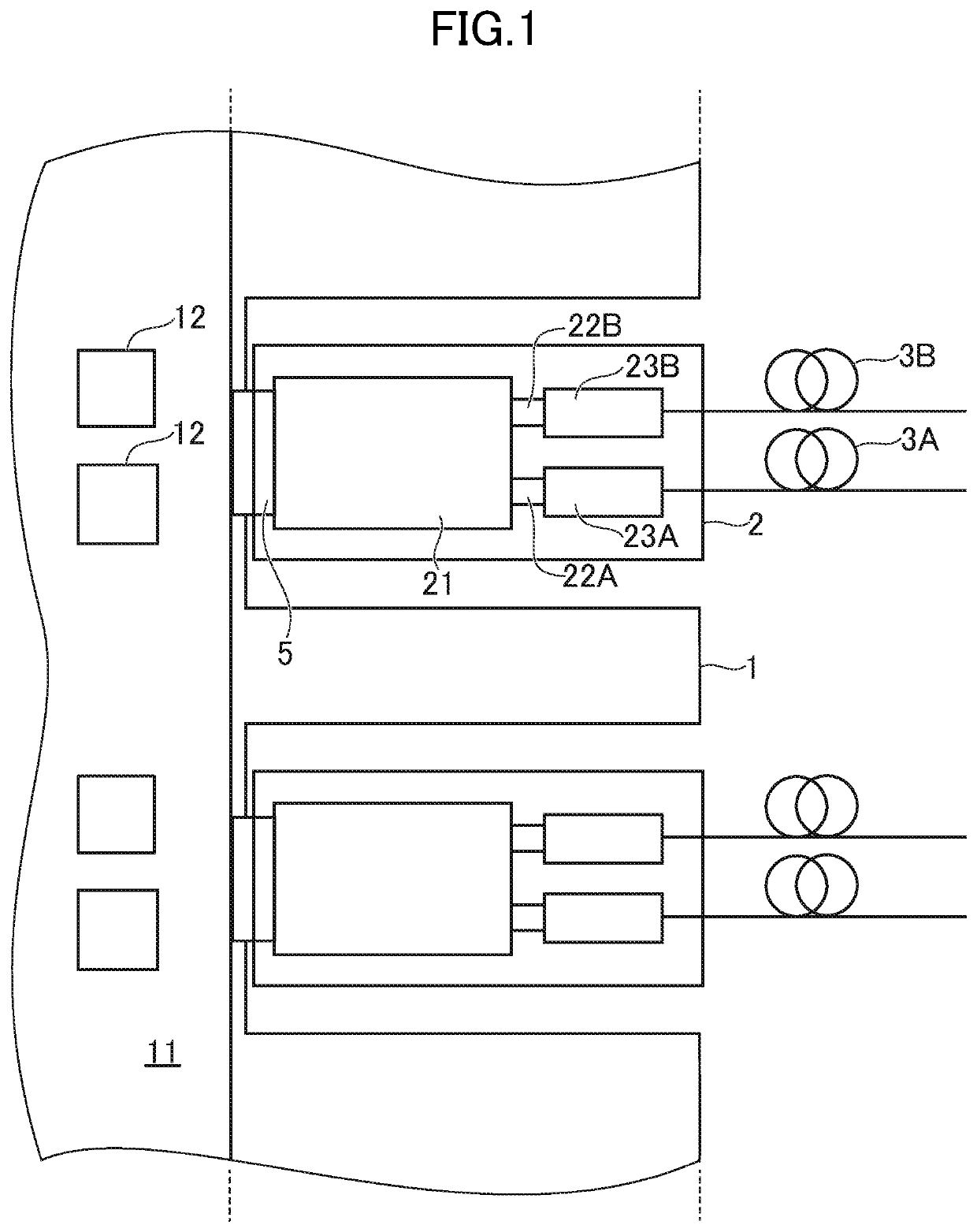

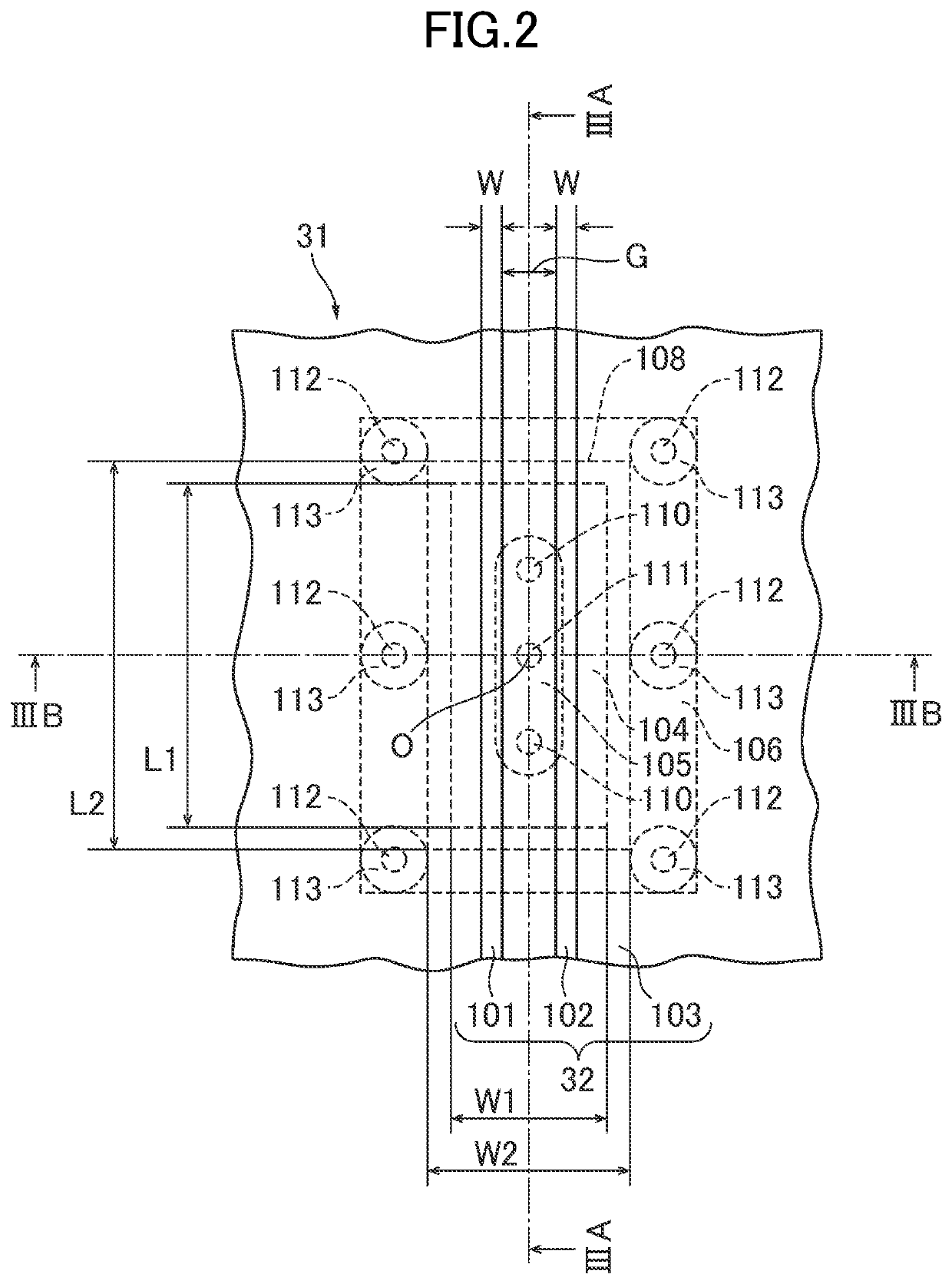

Printed circuit board, optical module, and optical transmission equipment

ActiveUS20200045808A1Selective inhibitionIncrease costMagnetic/electric field screeningCross-talk/noise/interference reductionElectrical conductorOptical Module

Provided is a printed circuit board realizing selective inhibition of electromagnetic noise and enabling high-density arrangement of differential transmission lines without increasing cost. The printed circuit board includes a pair of strip conductors (first layer), a first resonance conductor plate, a ground conductive layer (together with a second layer) including an opening portion, a second resonance conductor plate (third layer), a third resonance conductor plate (fourth layer), first via holes connecting the first and second resonance conductor plates, a second via hole connecting the second and third resonance conductor plates, and third via holes connecting the third resonance conductor plate and the ground conductive layer, wherein a polygon obtained by sequentially connecting centers of the adjacent third via holes overlaps so as to include the first resonance conductor plate, and center-to-center distance between the adjacent third via holes is 0.5 wavelength or less at frequency corresponding to the bit rate.

Owner:LUMENTUM JAPAN INC

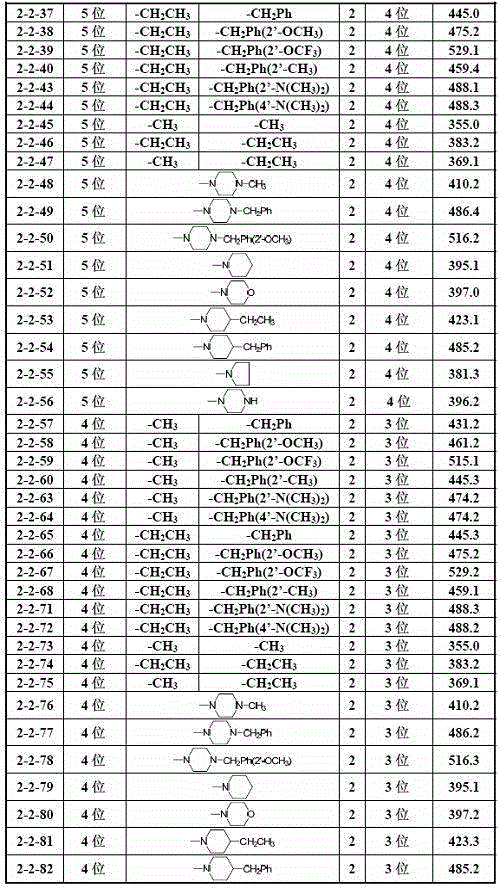

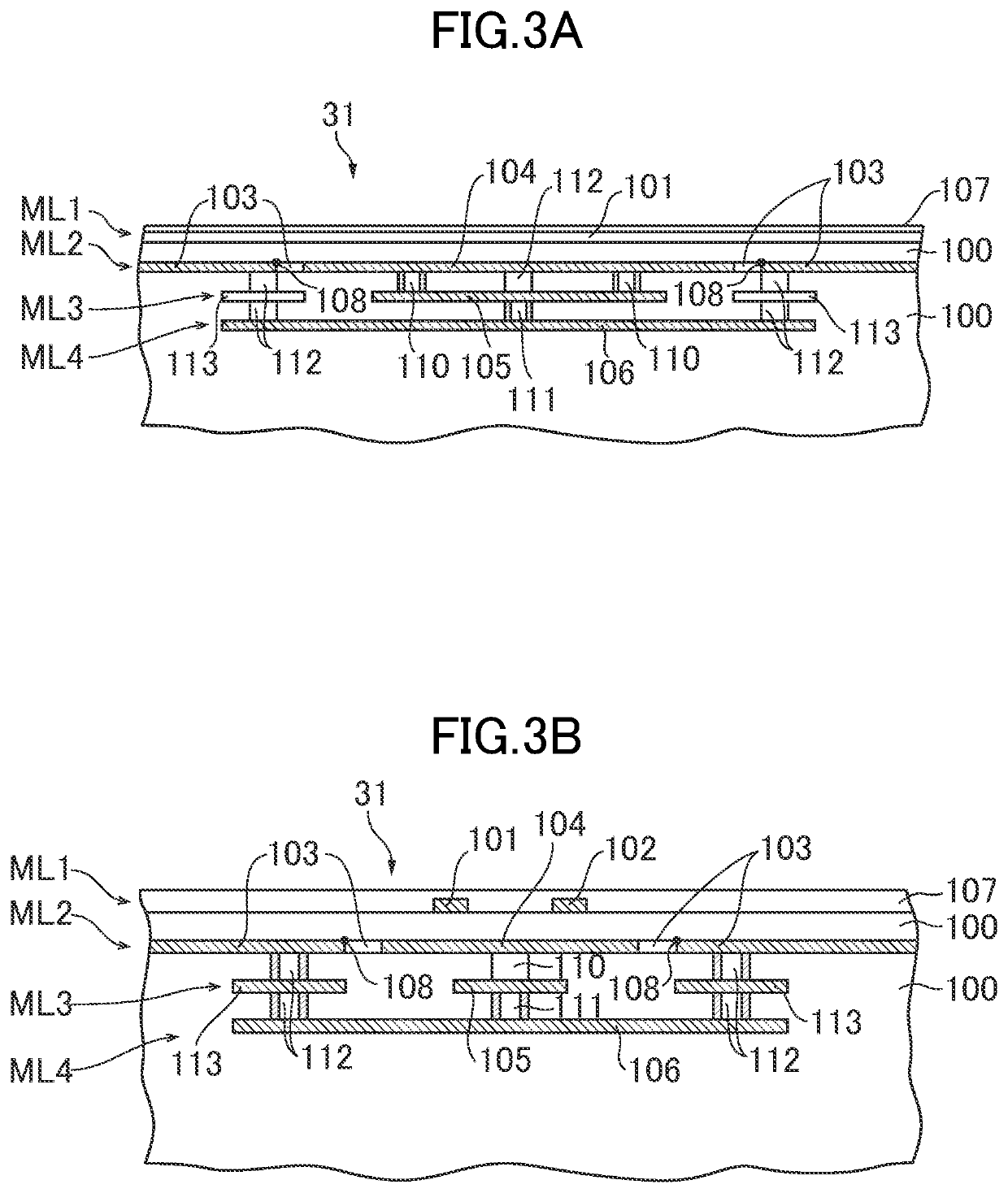

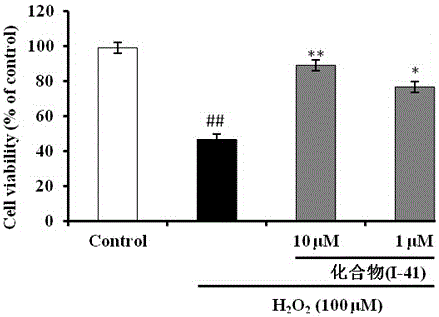

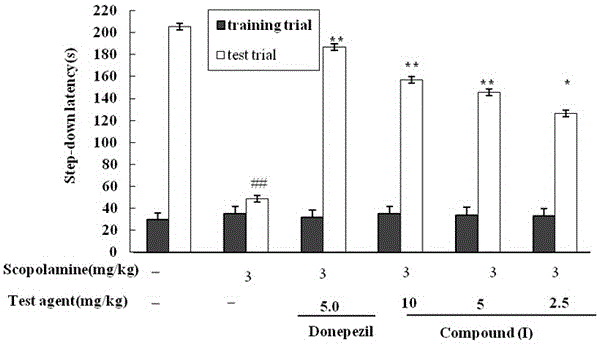

N-(1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine-O-alkylamine compound and application

InactiveCN106831574AImproves antioxidant activitySignificant neuroprotective effectOrganic active ingredientsNervous disorderDiseaseOxidation Activity

The invention belongs to the technical field of medicinal chemistry and discloses a N-(1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine-O-alkylamine compound (I) and pharmaceutically acceptable salt, and a preparation method and application thereof. The structure is as shown in a formula I. The compound (I) provided by the invention has high butyrylcholine esterase inhibiting activity, anti-oxidation activity and Abeta1-42 aggregation inhibiting activity, and has remarkable neuroprotective function on PC12 cell injury induced by hydrogen peroxide, which indicates that the compound is a multi-target-point inhibitor. The compound further shows a good effect of treating alzheimer disease in in-vivo experiments, and has low toxicity and a good clinical application prospect.

Owner:NANYANG NORMAL UNIV

Catalyst for co-production of low carbon alkenes from carbon dioxide hydrogenation to gasoline and preparation method of catalyst

InactiveCN110586108ALow selectivityHigh selectivityHydrocarbon from carbon oxidesCatalyst activation/preparationCobaltCleaning product

The invention discloses a catalyst for co-production of low carbon alkenes from carbon dioxide hydrogenation to gasoline and a preparation method of the catalyst. The catalyst takes gamma-Al2O3 as a carrier, the carrier is doped with three elements of Fe, Co and Na, and according to the weight of the carrier, the contents of the Fe, the Co and the Na are respectively 8.3wt.%, 1.7wt.% and 1.8-7.4 wt.%. The catalyst for the co-production of the low carbon alkenes from the carbon dioxide hydrogenation to the gasoline and the preparation method of the catalyst have the advantages that (1) selectivity of a by-product which is carbon monoxide can be greatly reduced by doping cobalt in an iron-base catalyst, the iron cobalt bimetallic metal has high selectivity of low-carbon olefin and gasoline distillate hydrocarbon under promotion of sodium, so while the FeCoNa / gamma-Al2O3 catalyst catalyzes the carbon dioxide hydrogenation to produce a gasoline cleaning product, the enane ratio of low-carbon hydrocarbons is greatly increased, and selectivity of methane and the carbon monoxide which are not ideal products is successfully inhibited; (2) the FeCoNa / gamma-Al2O3 catalyst has a high conversion rate of CO2; and (3) the space velocity of the reaction CO2 of the carbon dioxide hydrogenation catalyzed by the FeCoNa / gamma-Al2O3 catalyst is high.

Owner:NORTHWEST UNIV(CN)

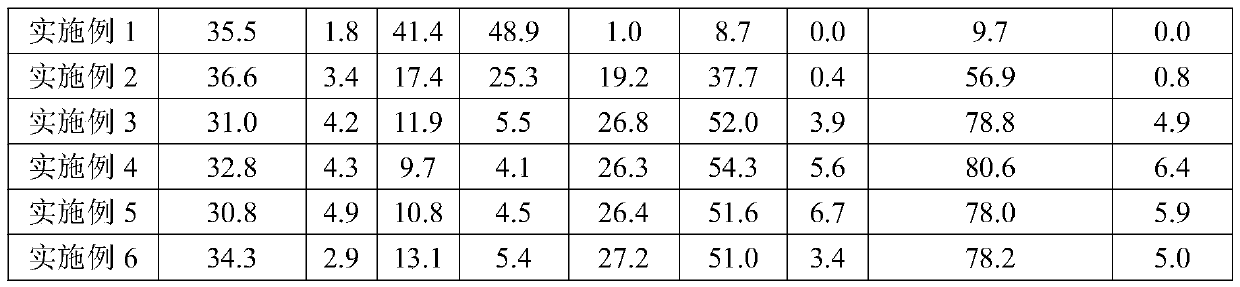

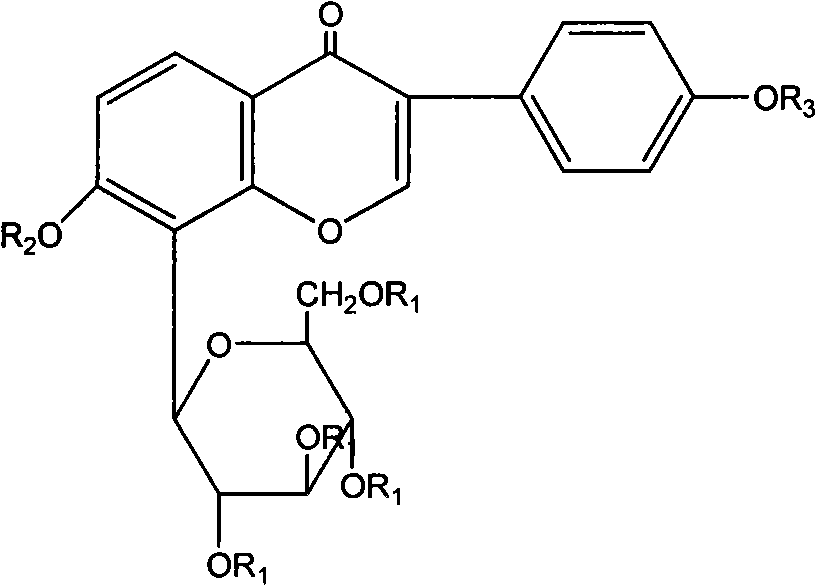

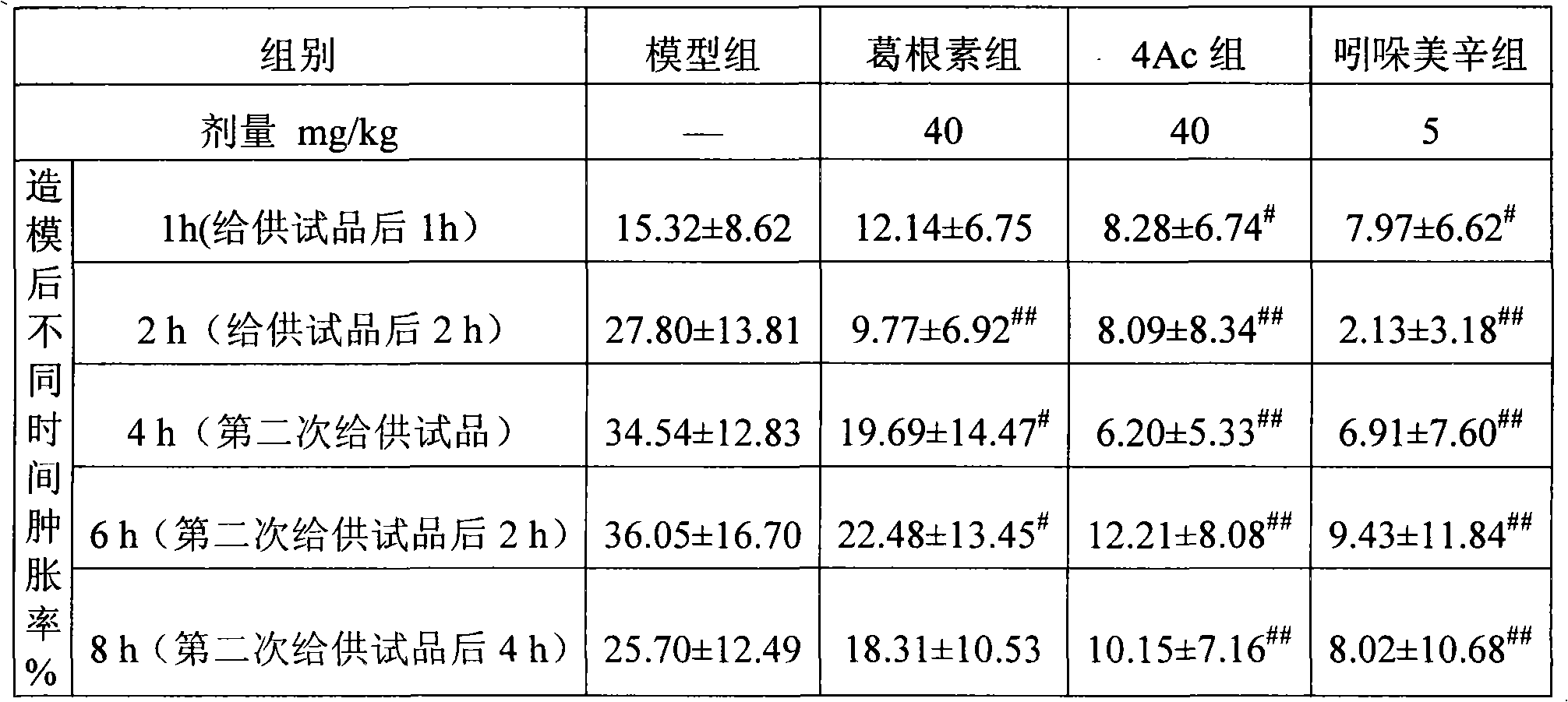

Uses of puerarin and derivatives thereof in preparing medicament

ActiveCN101301303ARaw materials are easy to getEasy to useOrganic active ingredientsAntipyreticSide effectMyocarditis

The invention relates to a novel application of puerarin and derivates thereof in the pharmaceutical field. The puerarin and the derivates thereof have a COX-2-selective inhibition effect, are safe in use without toxic side effect, and have notable effectiveness. The puerarin and the derivates thereof can be used to prevent and cure osteoarthritis, rheumatic arthritis, rheumatoid arthritis, urarthritis, hepatitis, conjunctivis, myocarditis, secondary inflammations caused by tumor and diabetes, itai itai diseases caused by cold or trauma, and other difficult and baffling diseases.

Owner:CHONGQING ACAD OF CHINESE MATERIA MEDICA

A class of 2-hydroxychalcone compounds, their preparation methods and uses

ActiveCN105481706BEnhanced inhibitory effectStrong inhibitory activitySenses disorderNervous disorderHuntingtons choreaChalcone

The invention discloses a novel 2-hydroxyl chalcone compound (I), as well as pharmacy acceptable salt, preparation method, medical composition, and purpose thereof in preparing medicines for treating and / or preventing neurodegenerative diseases including but not limited to vascular dementia, Alzheimer's diseases, Parkinson's diseases, Huntington's diseases, dementia relevant to HIV, multiple sclerosis, amyotrophic lateral sclerosis, neuropathic pain, glaucoma and the like (As shown in the description.).

Owner:SICHUAN UNIV

11 beta-hydroxysteroid dehydrogenase inhibitor and its pharmaceutical composition and use

InactiveCN104873521ASelective inhibitionOrganic active ingredientsNervous disorder11-beta-Hydroxysteroid DehydrogenasesGanoderic acid

The invention provides a novel use of a ganoderic acid component with a structure shown in the general formula I as a 11 beta-hydroxysteroid dehydrogenase inhibitor. The ganoderic acid component as a 11 beta-hydroxysteroid dehydrogenase inhibitor with a novel structure has a certain selective inhibition effect on 11 beta-HSD1 and can be used for preparation of drugs for adjusting lipid metabolism and treating diabetes, adiposis and cardiovascular diseases.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

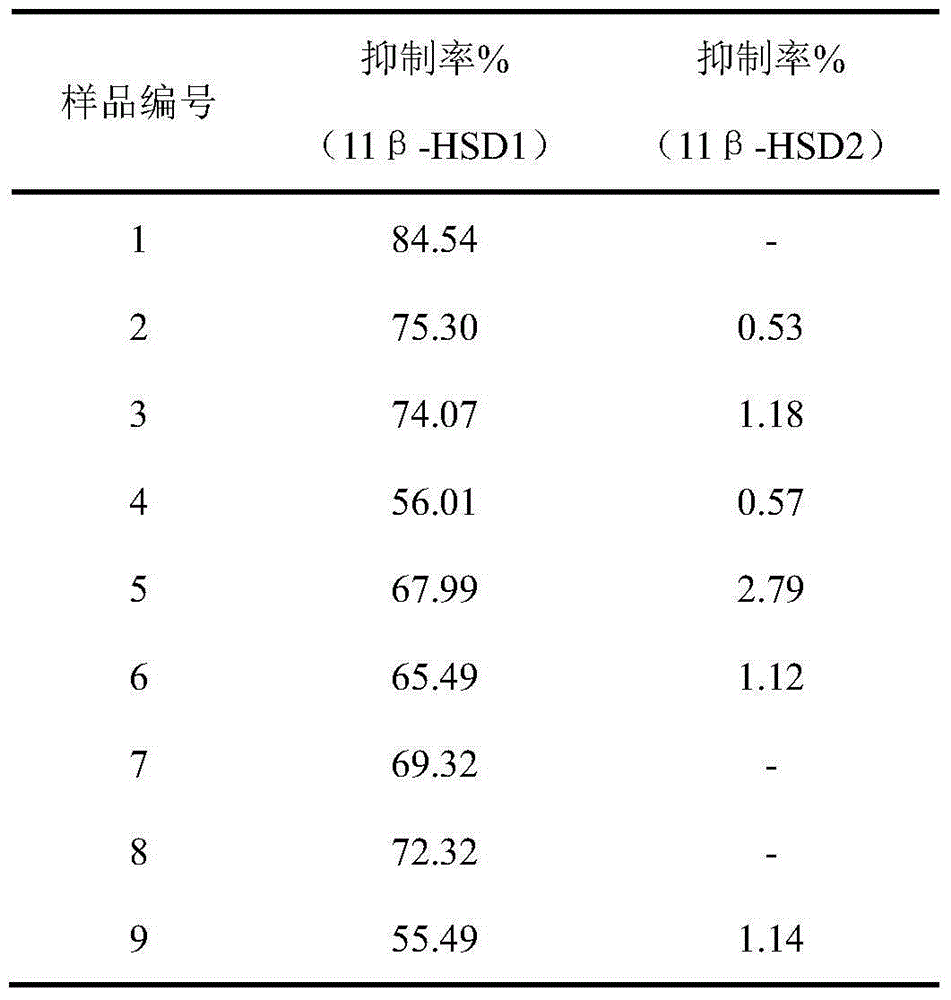

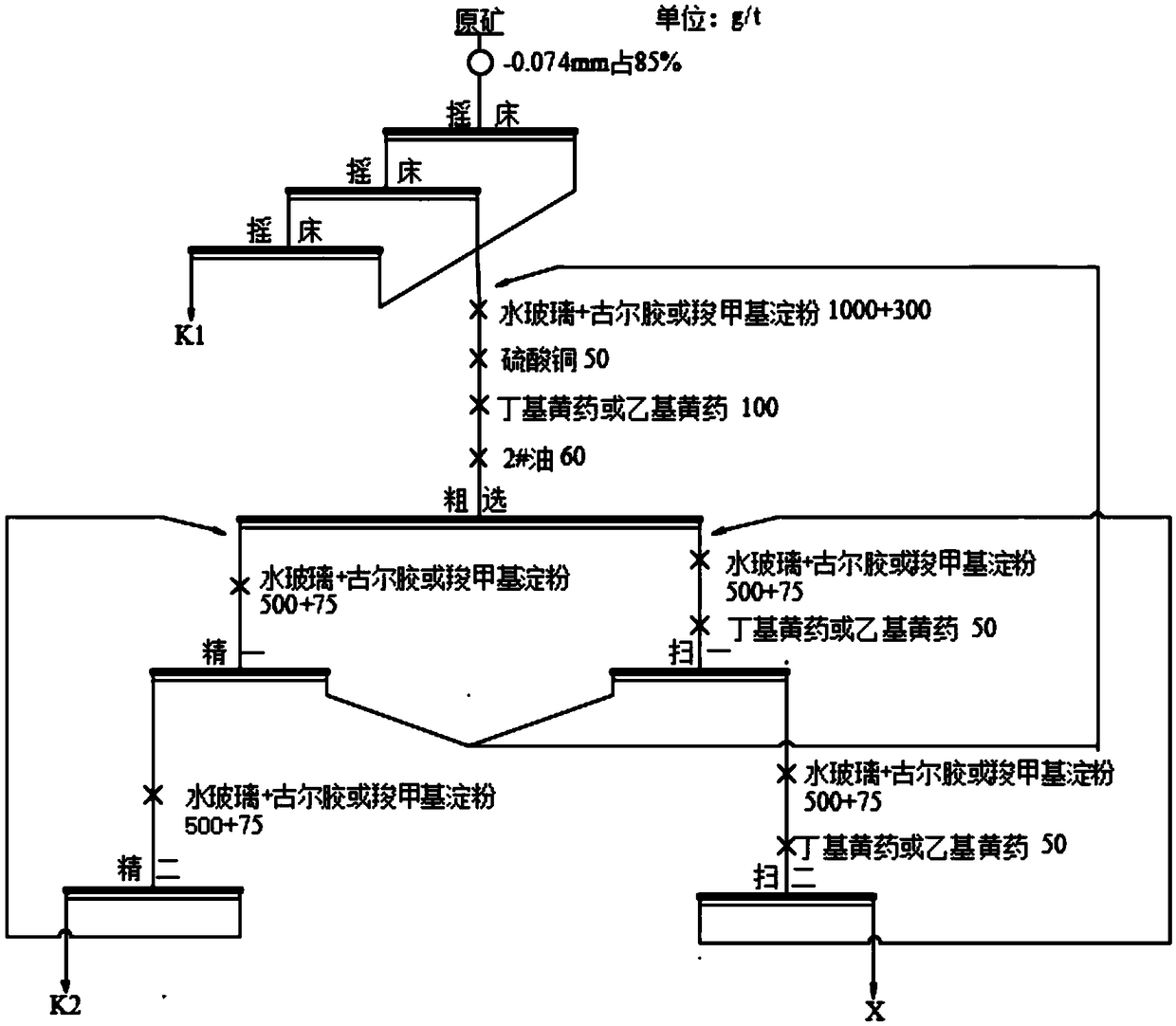

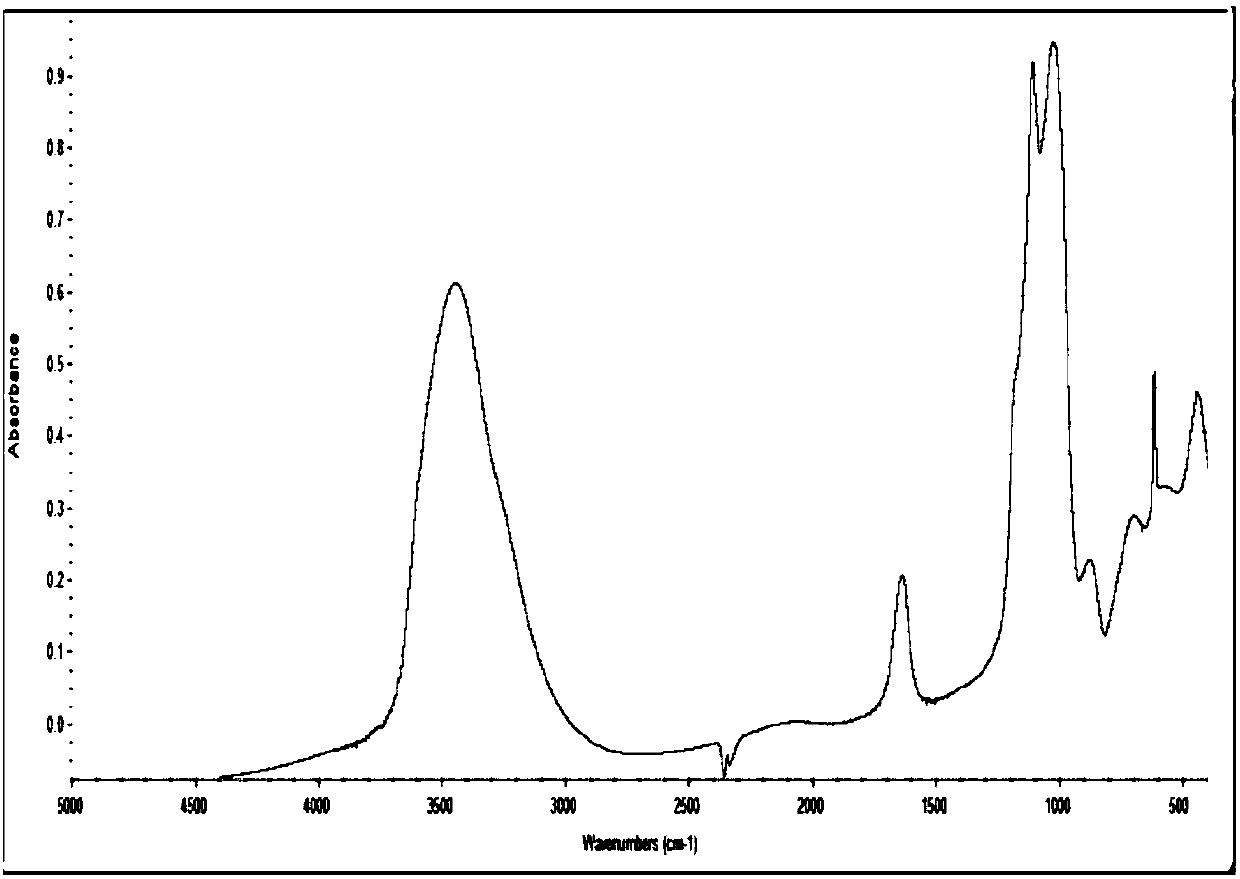

Flotation separation method of high-sulfur and high-arsenic gold ore

ActiveCN108745624AImprove hydrophilicityEnhanced inhibitory effectFlotationWet separationMaterials scienceSeparation method

The invention discloses a flotation separation method of high-sulfur and high-arsenic gold ore, and belongs to the technical field of mineral processing. The flotation separation method comprises thesteps of (1) grinding raw ore to the preset fineness; (2) performing shaking table sorting treatment on ground products so as to recycle natural and native gold dissociated from the raw ore; and (3) merging shaking table tailings, then performing flotation operation, adding water glass and macromolecular agents containing -OH and -O- groups as a combined inhibitor, adding copper sulfate as an activating agent, fully mixing, then adding a collecting agent and a foaming agent, and performing flotation separation so as to obtain gold concentrates. According to the flotation separation method of the high-sulfur and high-arsenic gold ore, gold is recycled by adopting a reselection-flotation combined technological process, so that the recycling of gold is strengthened; the macromolecular agentscontaining the -OH and -O- groups are added, so that the inhibiting effects on chlorite, steatite and other laminar silicate mineral gangue minerals are enhanced, efficient separation of gold carryingminerals and gangue minerals is realized, and the grade of the gold concentrates is guaranteed. The process has the advantages of operation simplicity and high adaptability to ore and can satisfy the requirements of industrial production.

Owner:CENT SOUTH UNIV +1

T cell immune response inhibitor

InactiveUS20070184037A1Avoid immune responseSelective inhibitionBiocideNervous disorderCell immune responsePathogen

The present invention discloses a T-cell immune response inhibitor. The T-cell immune response inhibitor supplied in the present invention comprises a targeted pathogen nucleic acid vaccine and said nucleic acid vaccine's expression protein antigen; or it comprises a targeted pathogen nucleic acid vaccine and said nucleic acid vaccine expression protein antigen's active polypeptide; or it comprises the inactivated pathogen and targeted pathogen nucleic acid vaccine. The T-cell immune response inhibitor in the present invention is able to stimulate the organism to produce the normal specific antibody immune response and to suppress a specific cell's immune response, in particular the Th1 immune response, thus it may be effectively applied to treatment of autoimmune diseases, organ transplants, allergies and control of T-cell levels.

Owner:CHINA AGRI UNIV

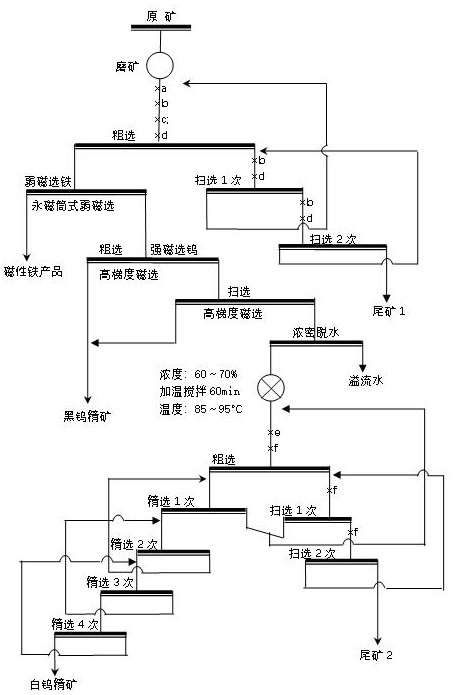

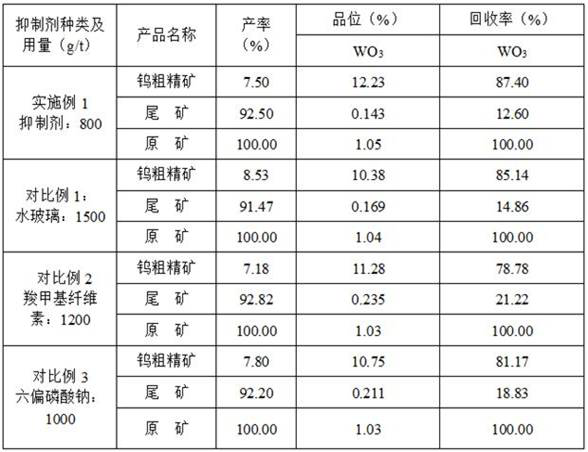

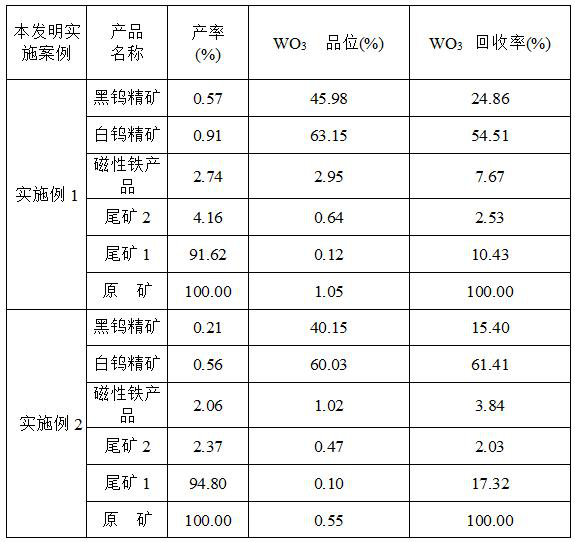

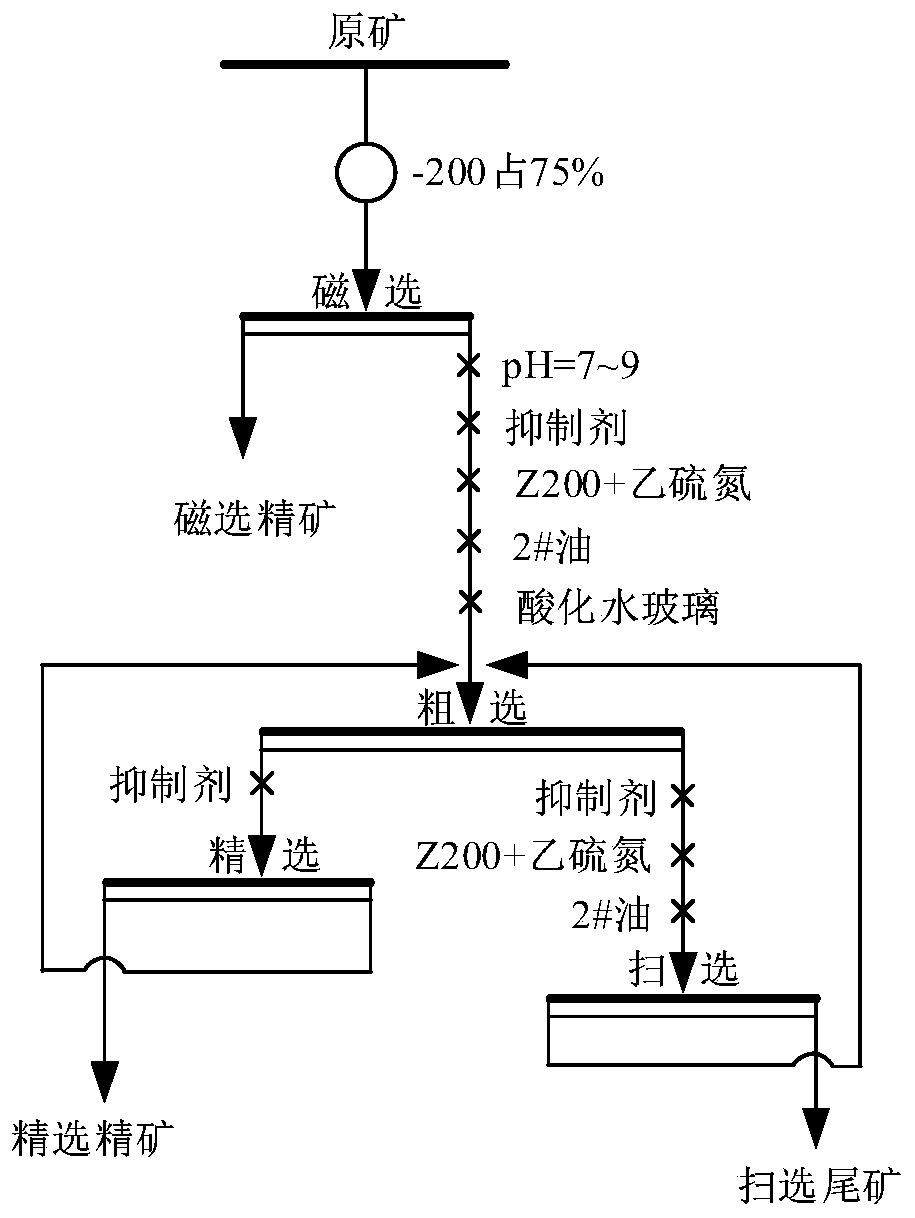

Beneficiation method for mixed refractory tungsten ore

PendingCN113369005AEfficient separationEfficient enrichmentFlotationWet separationOre concentrateMining engineering

The invention relates to a beneficiation method for mixed refractory tungsten ore. The beneficiation method comprises the following steps: (1) grinding crushed raw ore of scheelite and wolframite paragenic ore to obtain ore pulp; (2) when the pH value of the ore pulp is 7.0-9.0, an inhibitor, adding an activating agent lead nitrate and a collecting agent for mixed tungsten roughing, and respectively obtaining tungsten rough concentrate ore pulp and roughing tailing ore pulp; (3) performing mixed tungsten scavenging operation on the roughing tailing ore pulp twice to obtain tungsten scavenging tailings I; (4) carrying out weak magnetic iron removal operation on the tungsten rough concentrate ore pulp to respectively obtain a magnetic iron product and magnetic separation tailing ore pulp; (5) carrying out strong magnetic roughing and scavenging on the magnetic separation tailing ore pulp to respectively obtain a wolframite concentrate product and scavenging operation tailings; (6) performing dense dehydration on the scavenging operation tailings, and obtaining ore pulp with the concentration being 60%-70%; and (7) carrying out concentrated scheelite flotation operation on 60%-70% of ore pulp to respectively obtain scheelite concentrate and tungsten scavenging tailings II. The method provided by the invention effectively realizes effective separation and enrichment of wolframite and scheelite.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

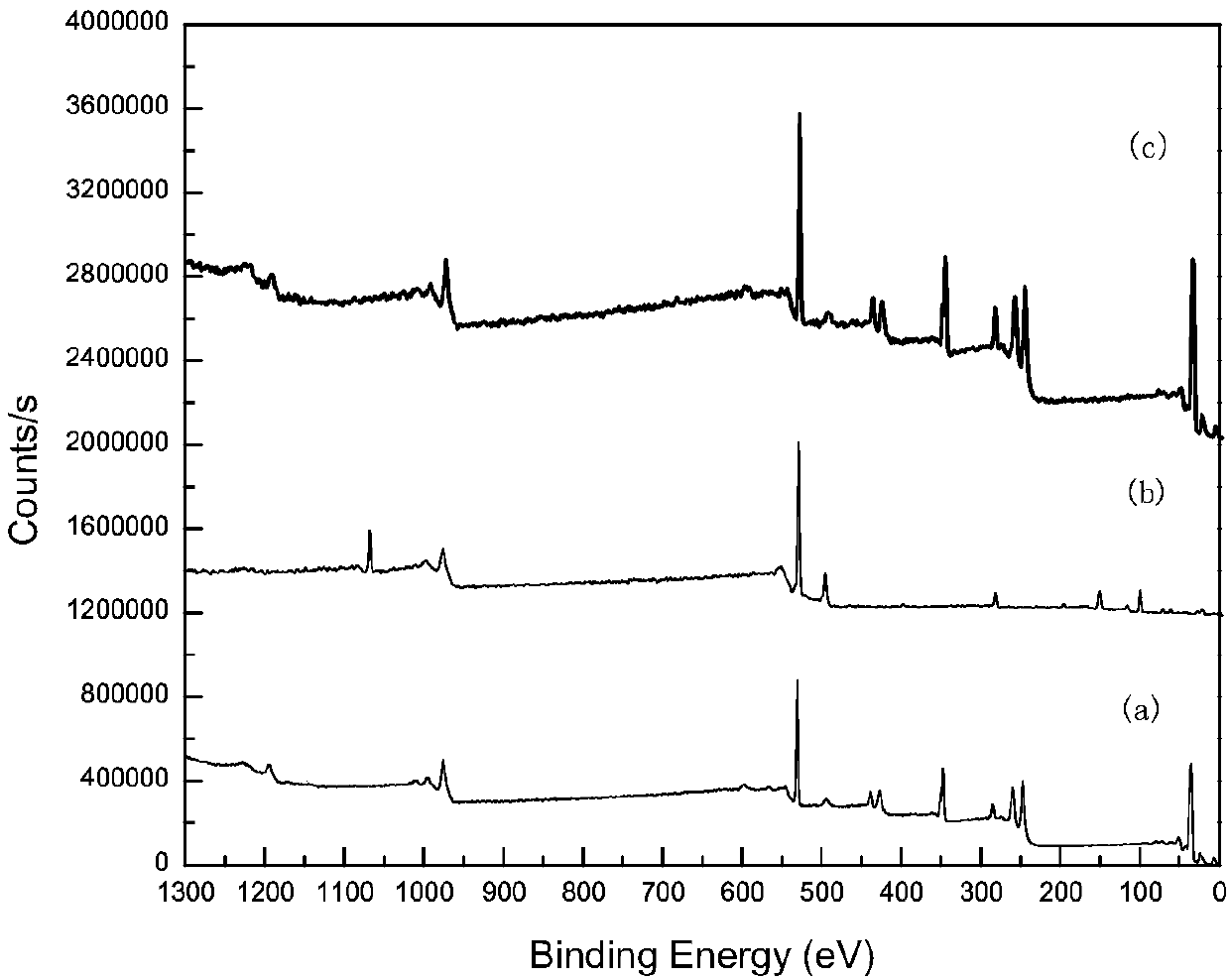

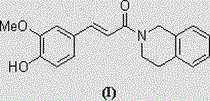

High-magnesium sulfide ore flotation inhibitor with slow-release conversion function and application thereof

ActiveCN109985731ALow costThe synthesis method is simpleCalcium/strontium/barium fluoridesFlotationAlkaline earth metalMineral flotation

The invention discloses a high-magnesium sulfide ore flotation inhibitor with slow-release conversion function and an application thereof. The inhibitor is CaF2, BaF2 and other nano alkaline earth metal fluoride colloidal particles or high-activity natural alkaline earth metal mineral powder, and is used for flotation separation of high-magnesium sulfide ore, which can slowly release F- ion in theore pulp and the MgF2 thin film is preferentially formed on the surface of the magnesium-containing mineral, so that the surface of oxide gangue minerals such as magnesium oxide has a structure similar to that of MgF2, the surface electrical properties of magnesium-containing minerals is changed, magnesium-containing mineral is prevented from heterogeneously coagulating with sulfide minerals dueto electrostatic attraction, and the entrainment, encapsulation and agglomeration of gangue minerals are reduced, the high-efficiency inhibition of the oxide gangue mineral such as magnesium oxide canbe realized, the flotation separation efficiency of such as copper-cobalt-nickel sulfide minerals and magnesium-containing gangue minerals can be greatly improved.

Owner:CENT SOUTH UNIV

Calcium-containing or silicate-containing gangue mineral flotation depressant and preparation method and application thereof

ActiveCN107837967AEfficient flotation separationSelective inhibitionFlotationMineral flotationHigh pressure

The invention discloses a calcium-containing or silicate-containing gangue mineral flotation depressant and a preparation method and application thereof. The flotation depressant is formed by polymerizing an inorganic polymer and metal ions. The preparation method of the flotation depressant comprises the steps that diatomaceous earth and a sodium hydroxide solution react under a high-temperatureand high-pressure condition to obtain the inorganic polymer, and then polymerization reaction is carried out on the inorganic polymer and metal salt to obtain the flotation depressant. The method is simple and low in cost, the prepared flotation depressant has extremely strong selective depressing effect on the calcium-containing and silicate-containing gangue mineral so that high-efficiency flotation separation of a tungsten-containing mineral from the gangue mineral can be realized; and the use amount of a chemical agent is small, the cost is low, and the flotation index is stable so that the depressant and the method can be widely applied to the great improvement of the concentrate grade and the recovery rate in the tungsten ore flotation process.

Owner:CENT SOUTH UNIV +1

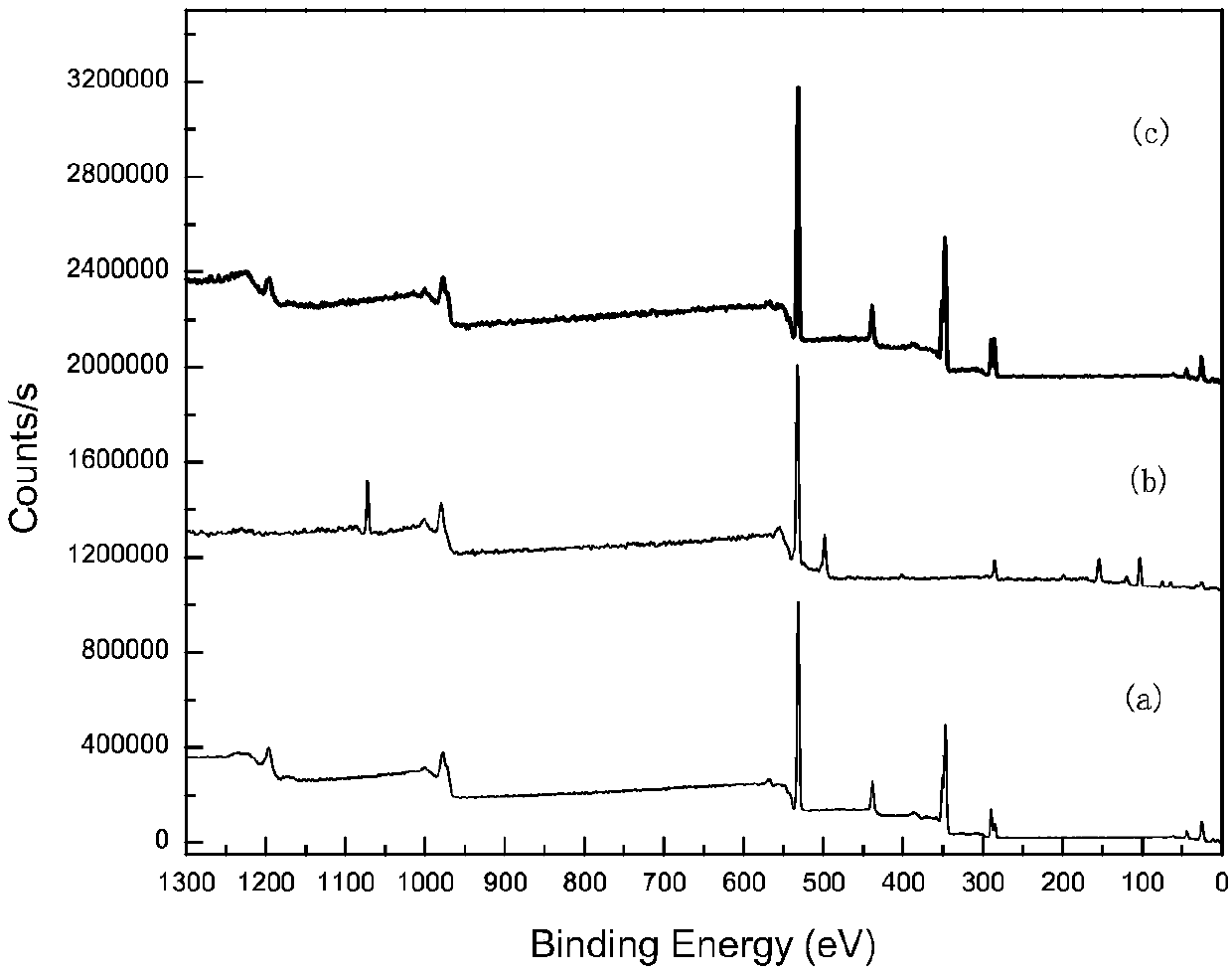

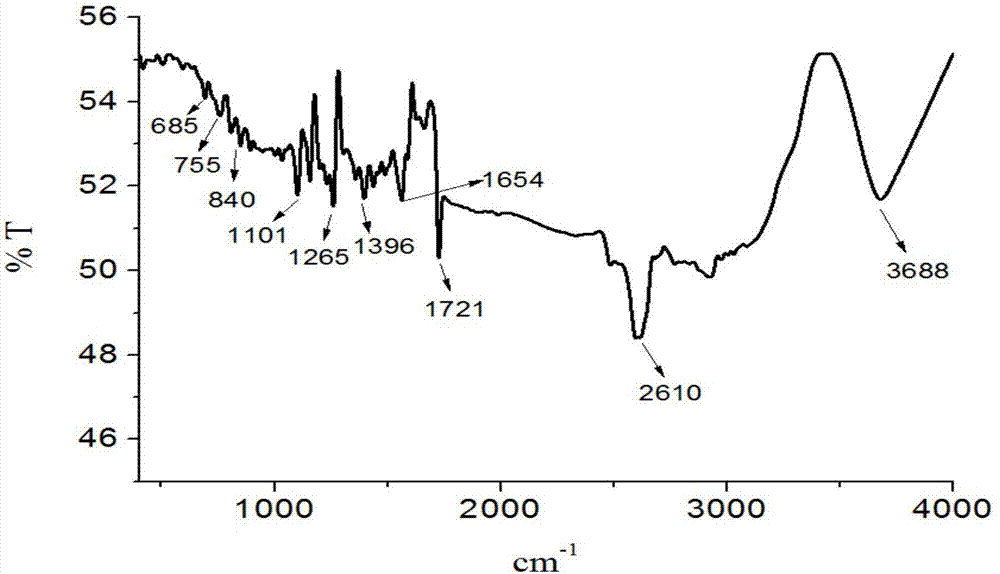

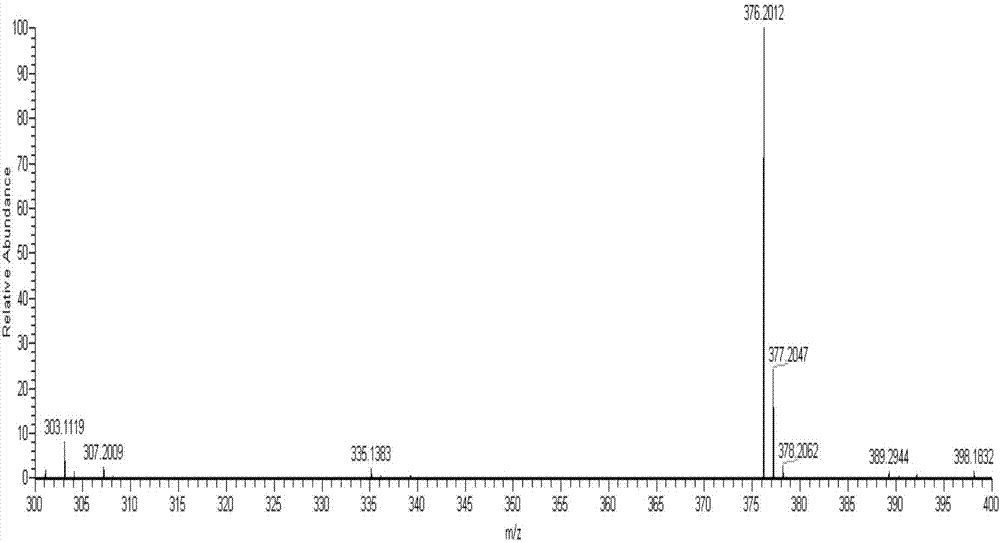

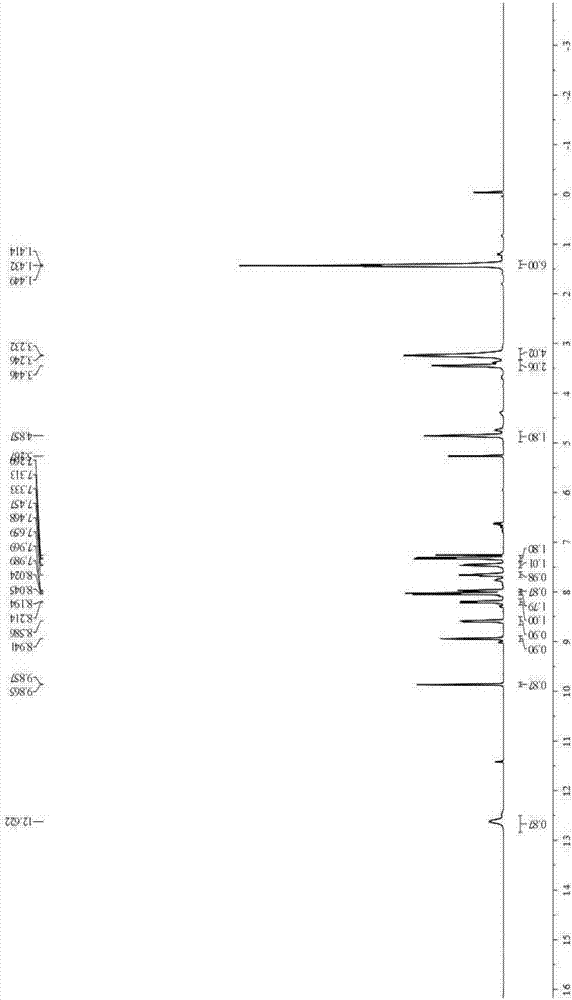

Water-soluble copper (II) complex as well as synthesis method and application thereof

InactiveCN107417708AGood water solubilityLiver cytotoxicity is lowOrganic active ingredientsGroup 1/11 organic compounds without C-metal linkagesSelective inhibitionSolvent

The invention discloses a water-soluble copper (II) complex as well as a synthesis method and an application thereof. The water-soluble copper (II) complex has the chemical formula being [Cu(L)(SO4)(HCl)], wherein L denotes N-(4-benzoic acid-2-diethylaminoethyl)-8-quinoline aldimine hydrochloride ligand; the complex belongs to the P-1 space group of the triclinic system, the cell parameters are shown as follows: alpha is equal to 95.262(5) angstrom, beta is equal to 98.450(5) angstrom and gamma is equal to 99.530(5) angstrom. The synthesis method of the complex comprises steps as follows: the ligand and copper sulfate pentahydrate are taken and subjected to a complexing reaction in a first polar solvent, and the complex is obtained. The applicant finds that the complex has a selective inhibition function on MGC80-3 and HeLa tumor cell beads and has lower toxicity to liver cells.

Owner:GUANGXI NORMAL UNIV

Collophanite reverse flotation depressing agent and application thereof

The invention discloses a collophanite reverse flotation depressing agent and an application thereof. The collophanite reverse flotation depressing agent is prepared by use of a method which comprises the steps of heating phosphoric acid to the range from 90 to 110 DEG C, continuously adding phosphorus pentoxide and stirring for dispersing, and after finishing adding, preserving heat and continuing stirring for 0.5-1.0 hour to obtain the collophanite reverse flotation depressing agent, wherein a mass ratio of the phosphoric acid to the phosphorus pentoxide is 1: 1 to 1: 4, the concentration of the phosphoric acid is that the mass percent content of P2O5 is 20-85wt%, the phosphorus pentoxide powder is the oxides of yellow phosphorus, and the mass percent content of P2O5 of the phosphorus pentoxide powder is more than 95wt%. The depressing agent has strong selective depression effect relative to single phosphoric acid or sulfuric acid, and thus is low in dosage in flotation, and meanwhile, the dosage of the phosphoric acid or the sulfuric acid also can be reduced. The collophanite reverse flotation depressing agent overcomes the shortcomings of calcium scaling and pipe blockage due to high dosage of the phosphoric acid or the sulfuric acid, and high flotation cost of a traditional process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

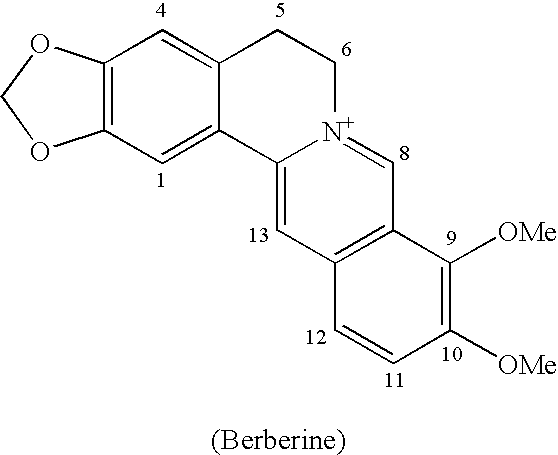

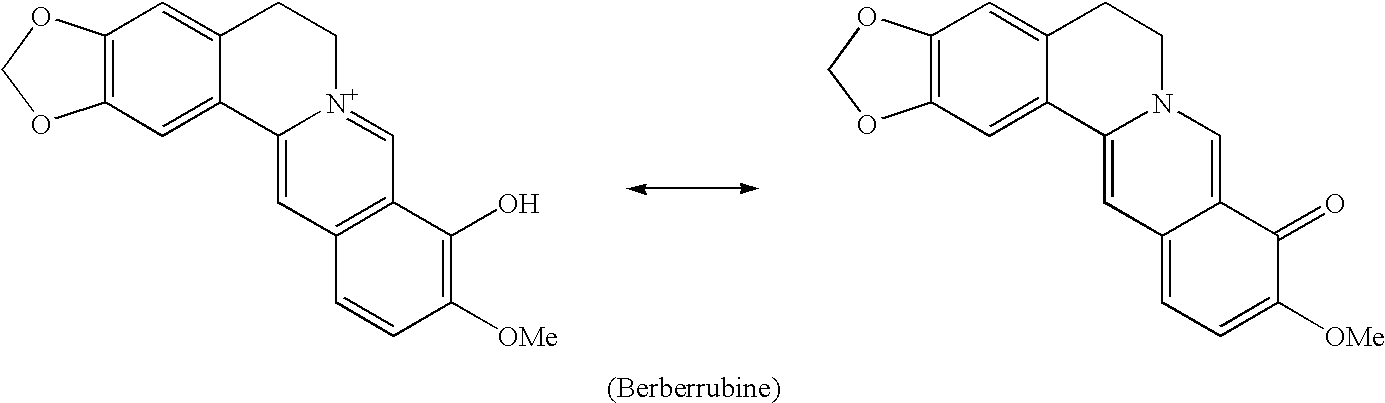

Berberrubine Derivatives Having Antifungal Activities

InactiveUS20100292476A1Selective inhibitionGood antifungal activityBiocideOperating means/releasing devices for valvesBerberineAntifungal antibiotic

The present invention relates to a berberrubine derivative having superior antifungal activity, more particularly to a berberrubine derivative having inhibitory activity against chitin synthase, which participates in the synthesis of chitin and is essential in the growth of fungi, and having a potent antifungal activity against human pathogenic fungi.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

(N-1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine compound, and preparation method and application thereof

InactiveCN106831573AImproves antioxidant activitySignificant neuroprotective effectOrganic active ingredientsNervous disorderDiseaseCell injury

The invention belongs to the technical field of medicine, and relates to a (N-1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine compound, and a preparation method and application thereof. The structure is as shown in a formula I (the formula I is as shown in the description). The (N-1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine compound provided by the invention has excellent butyrylcholine esterase inhibiting activity, remarkable Abeta1-42 aggregation inhibiting activity, anti-oxidation activity and high neuroprotective activity on PC12 cell injury induced by hydrogen peroxide in in-vitro experiments; and the (N-1,2,3,4-tetrahydroisoquinolinyl)-feruloylagmatine (I) compound is a multi-target-point inhibitor, further shows a good effect of treating alzheimer disease in in-vivo experiments, and has low toxicity and a good clinical application prospect.

Owner:NANYANG NORMAL UNIV

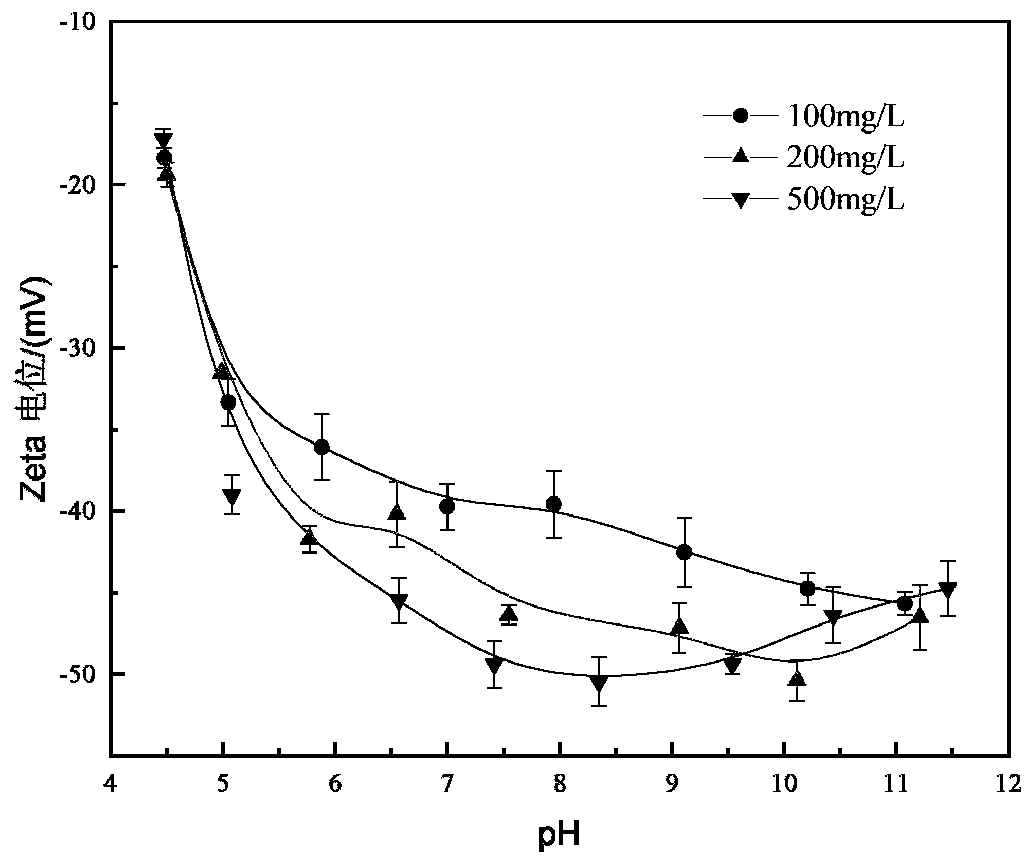

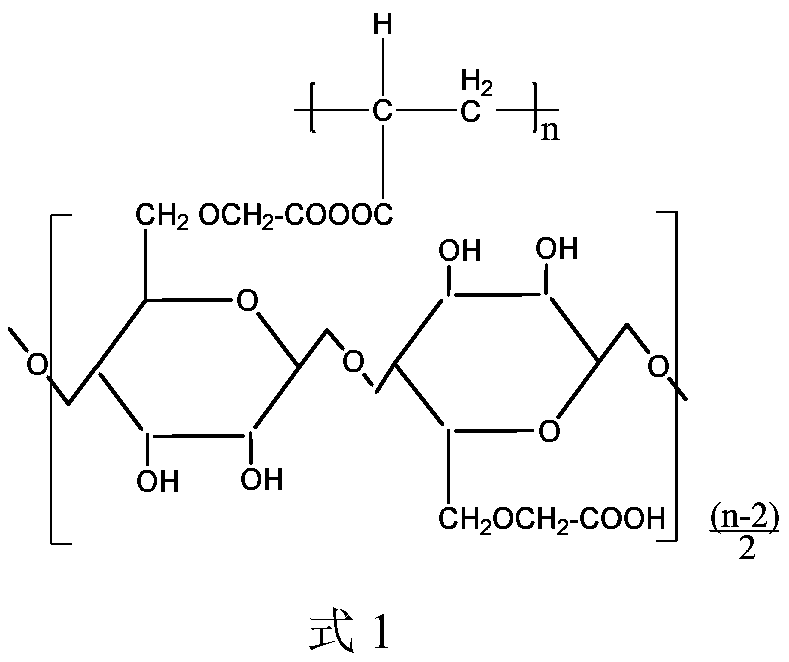

Copper-based coordination polymer, preparation method thereof and application of polymer serving as gangue mineral inhibitor to copper-nickel sulfide ore flotation

ActiveCN110052332AEfficient flotation separationSelective inhibitionFlotationNickel sulfideColloidal particle

The invention discloses a copper-based coordination polymer, a preparation method thereof and an application of the polymer serving as a gangue mineral inhibitor to copper-nickel sulfide ore flotation. Polyacrylic acid-carboxymethyl cellulose mixed anhydride and bivalent copper ions are coordinated and polymerized to obtain the copper-based coordination polymer. The copper-based coordination polymer can be effectively dispersed in solution and self-assembled to form colloidal particles loaded with strong negative charge on surfaces, so that the copper-based coordination polymer can be attachedto the surfaces of gangue minerals loaded with positive charged on the surfaces, and the gangue mineral is strongly hydrophilic. The copper-based coordination polymer is applied to copper-nickel sulfide ore flotation and has high selective inhibitory effects on the gangue minerals such as serpentines and quartz loaded with the positive charged on the surfaces, so that copper-nickel sulfide ores and the gangue minerals can be efficiently separated by flotation.

Owner:CENT SOUTH UNIV

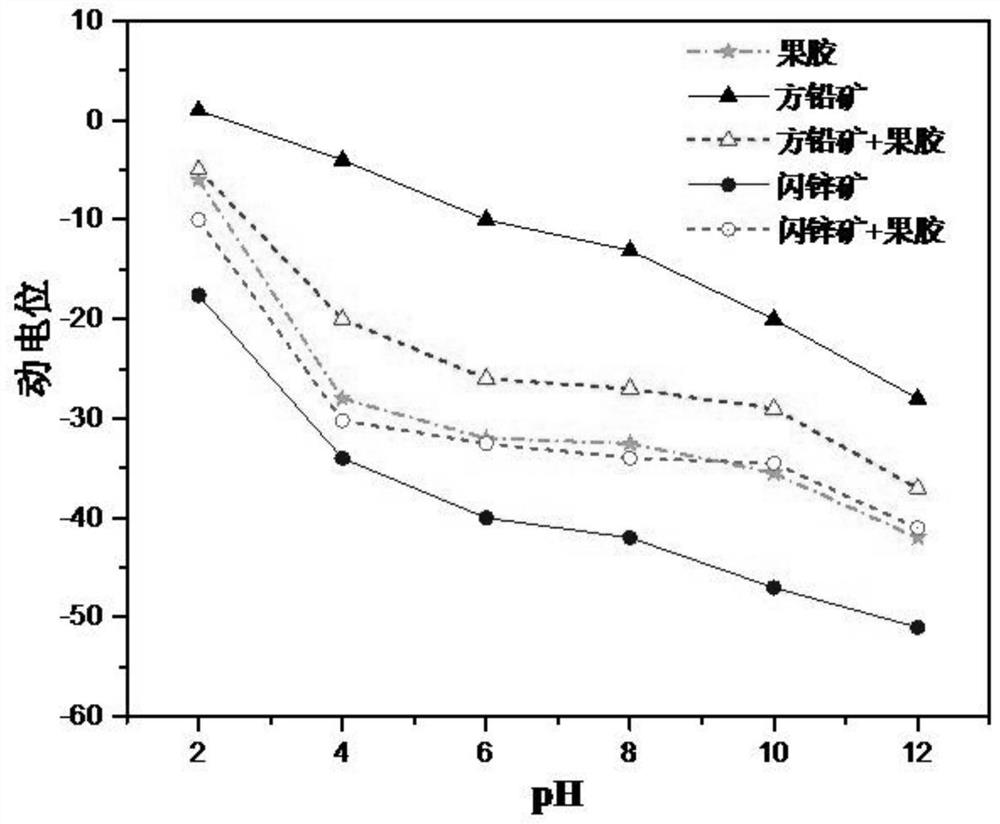

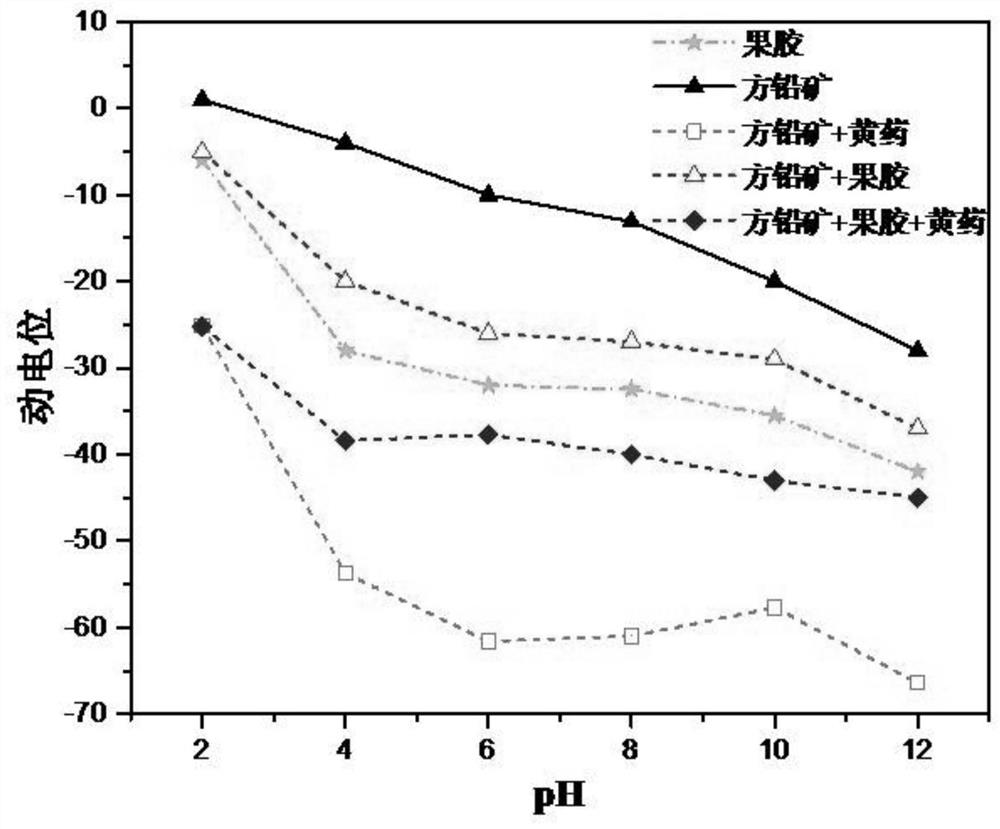

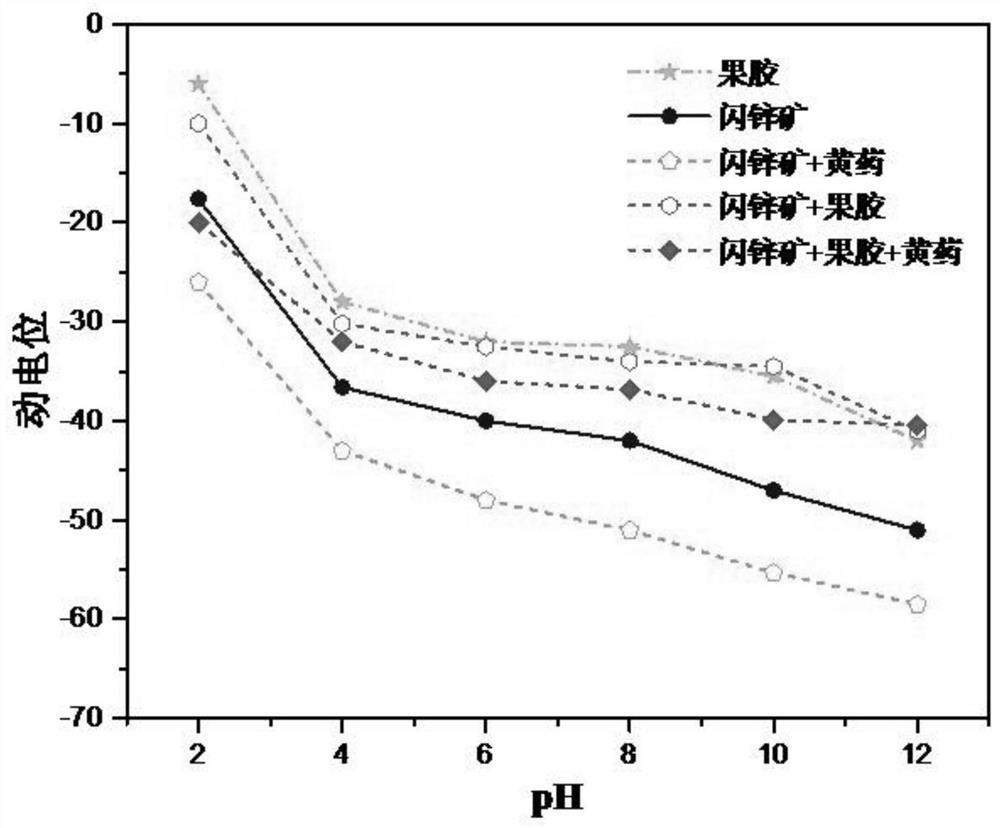

Flotation method of lead-zinc sulfide ore and sphalerite combined inhibitor

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com