High-magnesium sulfide ore flotation inhibitor with slow-release conversion function and application thereof

A mineral flotation and inhibitor technology, applied in the field of high magnesium sulfide mineral flotation inhibitor and magnesium-containing mineral inhibitor, can solve the problems of entrainment, wrapping, agglomeration, agglomeration, difficulty in flotation separation, fine particle size, etc. The effect of reducing the cost of chemicals, efficient flotation separation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

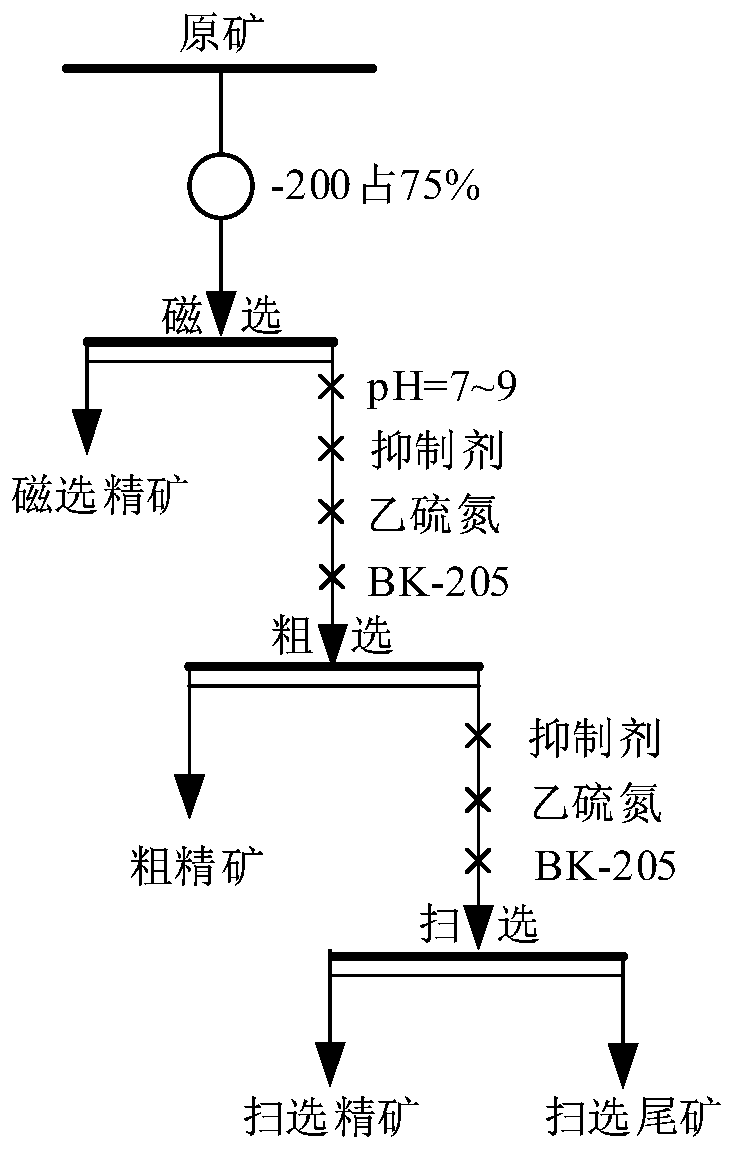

[0032] The fluorite natural pure mineral that is ground to amorphous (-2μm) is used for the flotation of a nickel-copper sulfide ore. The multi-element analysis results of a sulfide ore raw ore are shown in Table 1. It can be seen that the ore gangue minerals are mainly oxides, mainly including MgO, SiO 2 、Al 2 o 3 . Such as figure 1 As shown, in view of the characteristics of the ore, a beneficiation process of one-stage grinding + magnetic separation + one rough and one sweep is adopted. The collector is ethyl disulfide nitrogen, the inhibitor is natural fluorite particles with amorphous surface, and the foaming agent is BK205. The mixing time after adding the inhibitor is controlled at 10min, and the stirring intensity is 1500rpm. After flotation separation, the grade of nickel in the concentrate reached 4.24%, the recovery rate reached 73.21%, the grade and recovery rate of copper in the concentrate were 0.82% and 69.13%, and the grade of magnesium oxide in the conce...

Embodiment 2

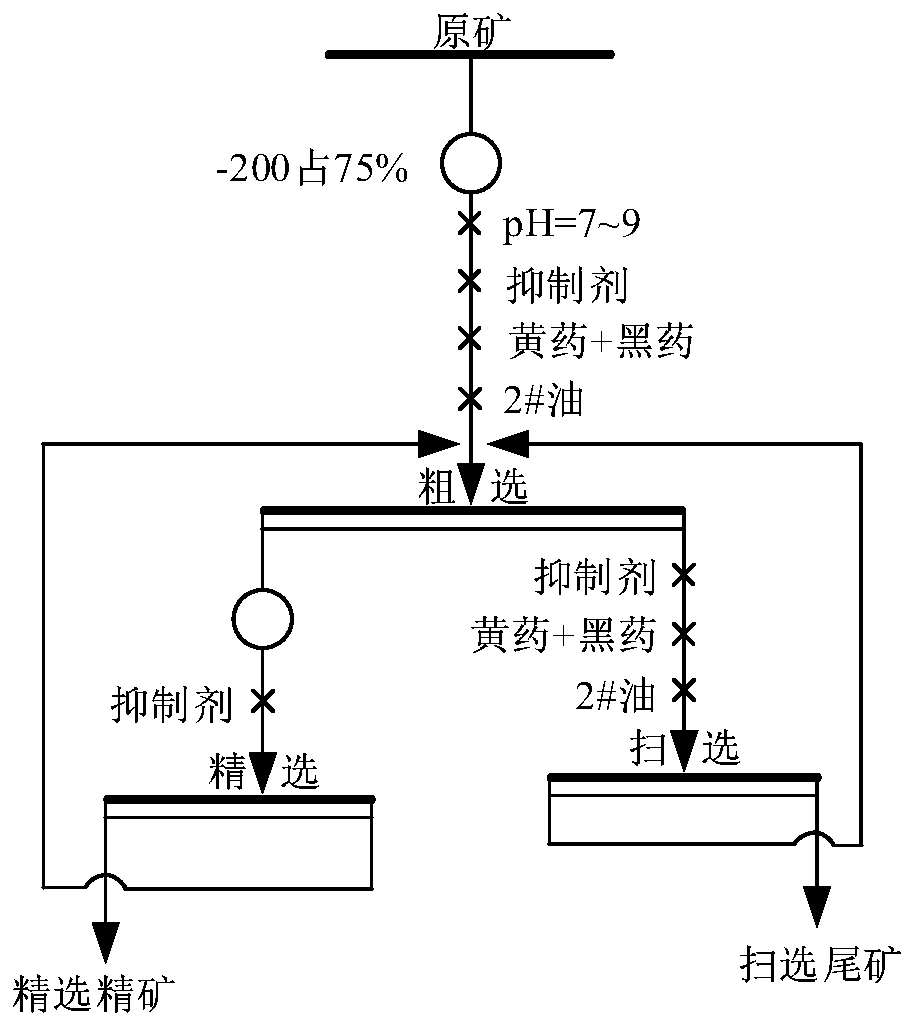

[0039] Add 30g of calcium fluoride and 20g of sodium oleate to 100mL of water, and react in a high-pressure reactor at a temperature of 150°C and a pressure of 10MPa for 1 hour to make a nano-scale colloidal inhibitor, which is used for the flotation of raw ore in Jinchuan No. 1 mining area. Taking the raw ore in Jinchuan No. 1 mining area as the research object, the closed-circuit beneficiation process is returned to the closed-circuit beneficiation process in the order of one-stage grinding, coarse-sweeping, coarse concentrate re-grinding and re-election. The grades of nickel, copper and magnesium oxide before and after beneficiation are shown in Table 3. The flotation collector is used in combination with xanthate + black medicine, the inhibitor is nano-scale calcium fluoride colloid inhibitor, and the foaming agent is 2# oil. The mixing time after adding the nano-colloid inhibitor is 5 minutes, and the stirring intensity is 1600rmp. It can be seen that after figure 2 In ...

Embodiment 3

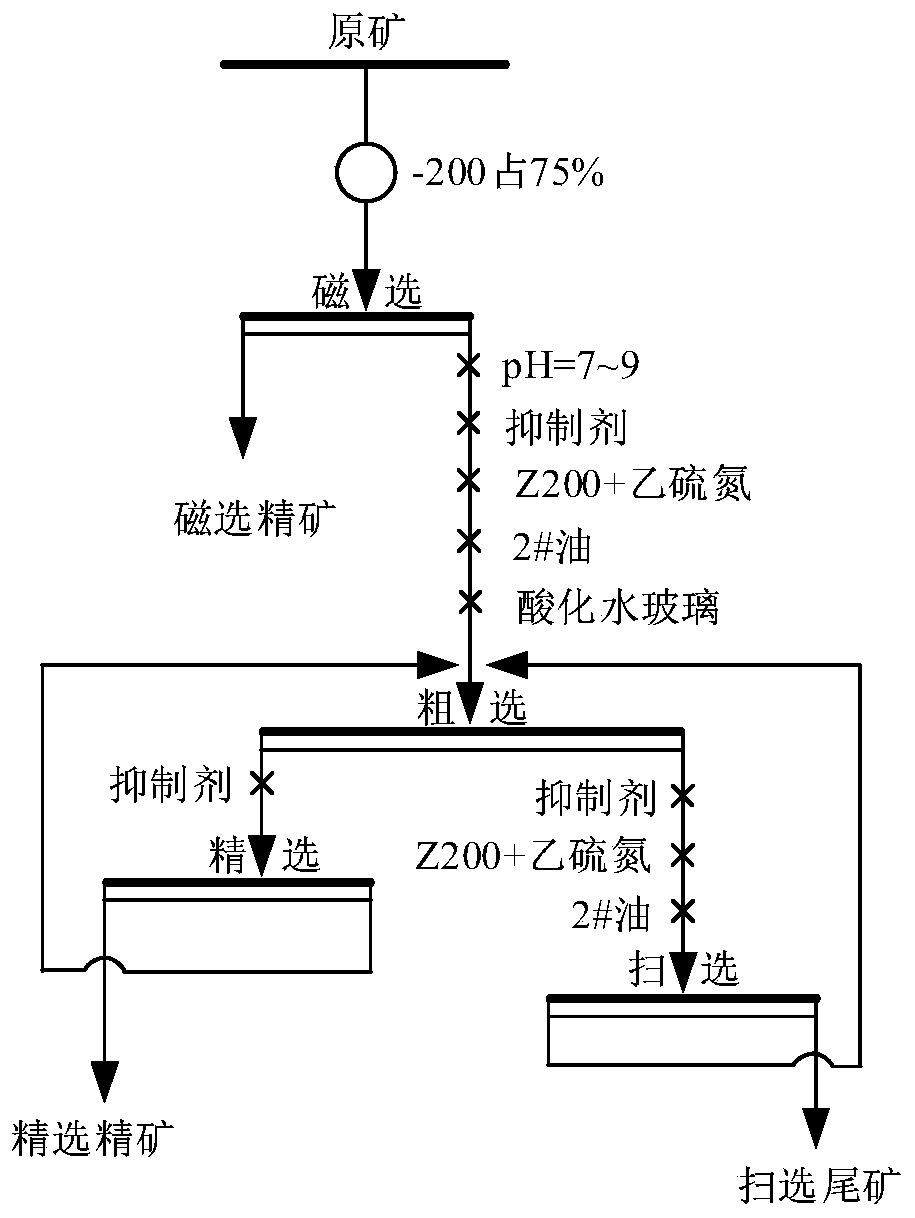

[0043] Take 20g of barium fluoride and 10g of sodium dodecylsulfonate, add 50mL of water, and react for 0.5 hours in a high-pressure reactor with a temperature of 200°C and a pressure of 10MPa to make a nano-scale colloidal inhibitor, which is used for the flotation of raw ore in Jinchuan No. 2 mining area. select.

[0044] The composition analysis and multi-element analysis of the raw ore in Jinchuan No. 2 mining area are shown in Table 4 and Table 5. Choose Z-200+ ethyl disulfide nitrogen, the inhibitor is nano-scale barium fluoride colloidal inhibitor, the foaming agent is 2# oil, and it is used together with acidified water glass. The mixing time after adding the nano-colloid inhibitor is 5 minutes, and the stirring intensity is 1500rmp. The beneficiation process is a closed-circuit process in the order of grinding + magnetic separation + rough, fine, and sweep, such as image 3 shown. Under this condition of collector and inhibitor, the grade and recovery rate of nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com