Base-modified catalyst and method for preparing ethylene through hydrogenating reaction of carbon monoxide

A catalyst and oxide technology, used in catalysts, molecular sieve catalysts, hydrocarbon production from carbon oxides, etc., can solve the problems of affecting application, selectivity lower than 30%, low single selectivity of ethylene, etc., and achieve high selectivity, high The effect of easy separation and high space-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of A component

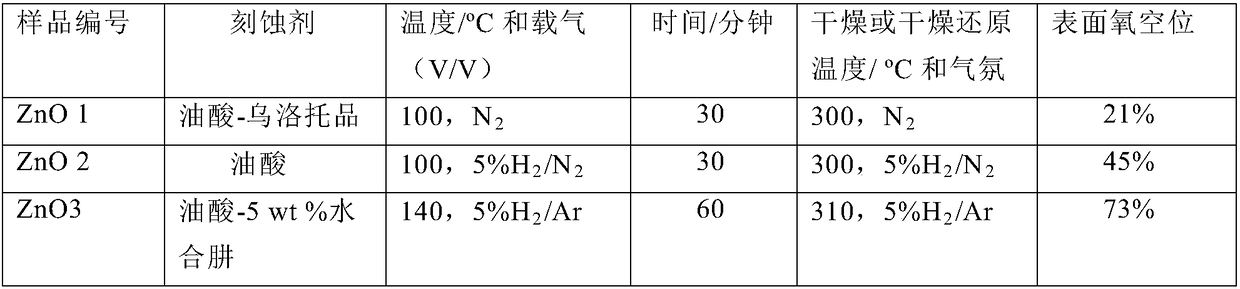

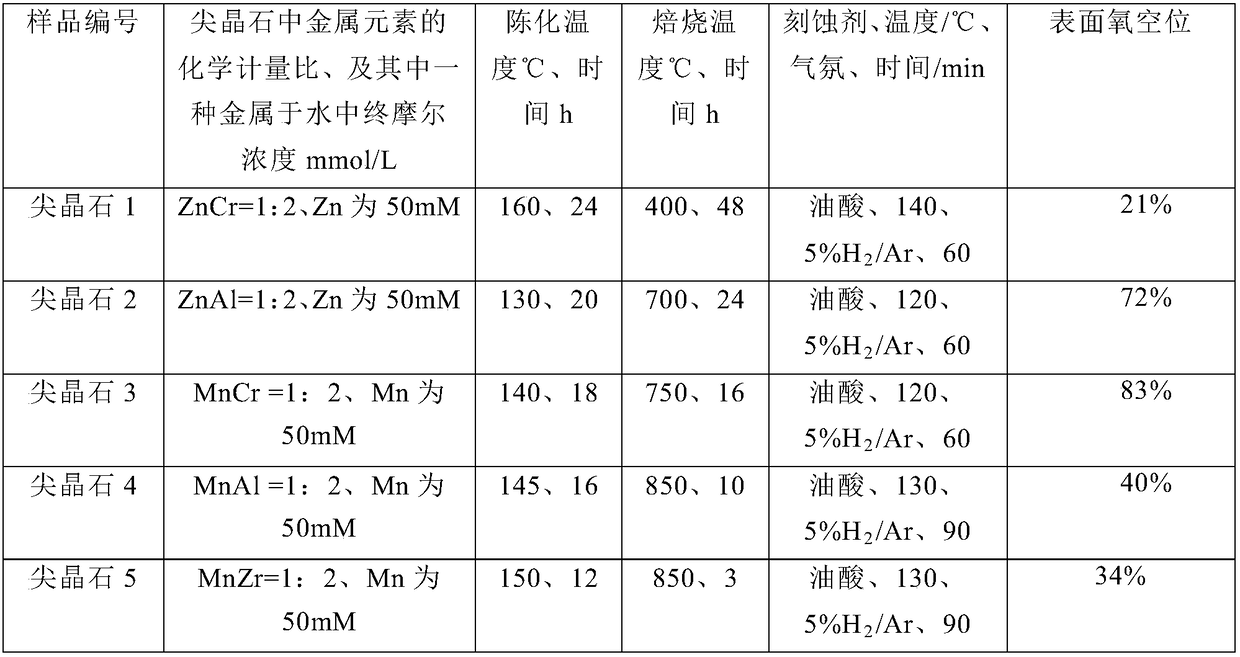

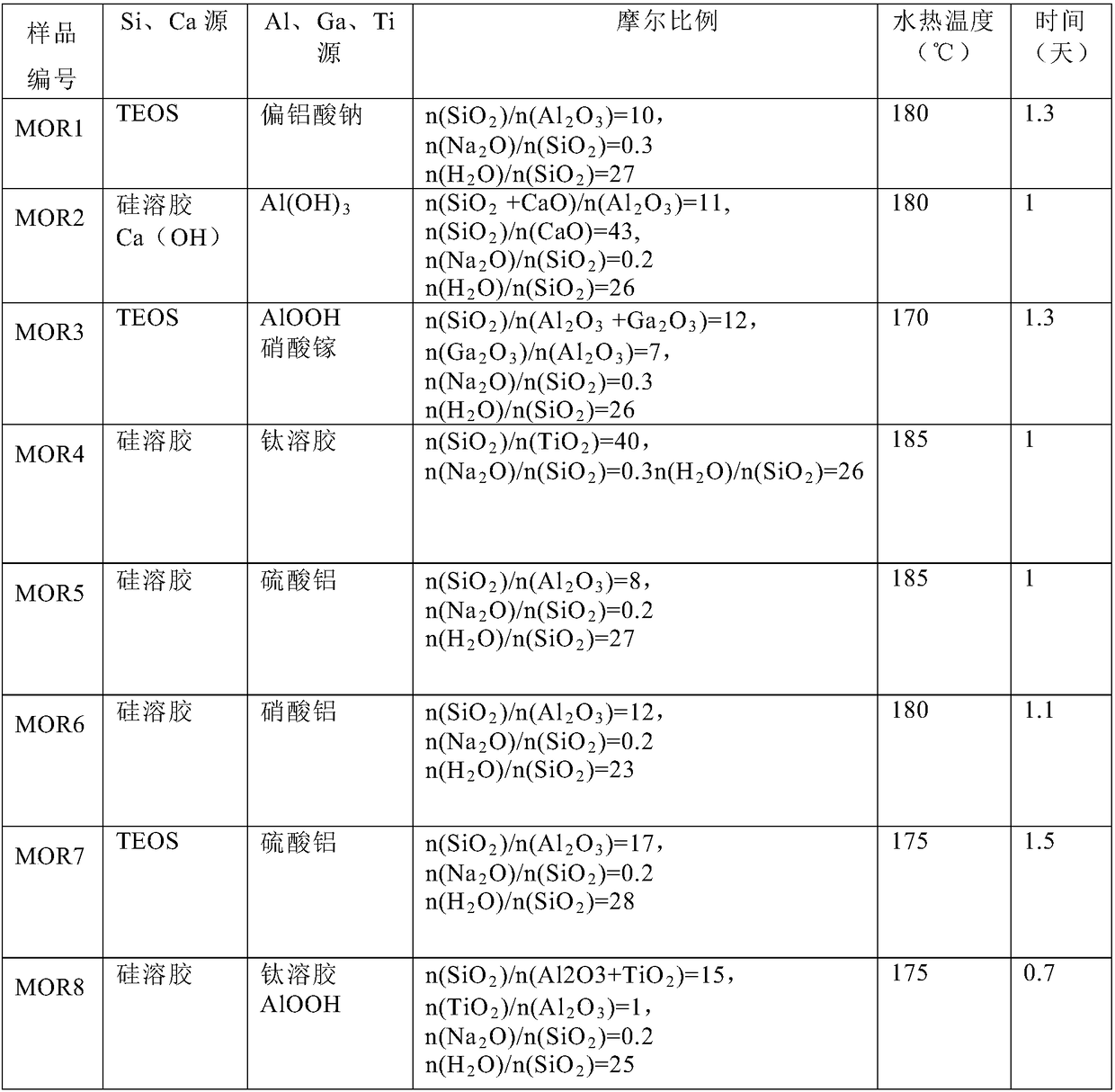

[0026] (1) Etching method to synthesize ZnO material with polar surface:

[0027] (1) Weigh 4 parts, each 0.446g (1.5mmol) Zn(NO 3 )2·6H 2 O in 4 containers, then weigh 0.300g (7.5mmol), 0.480g (12mmol), 0.720g (18mmol), 1.200g (30mmol) NaOH and add them to the above 4 containers in turn, and then measure 30ml each to remove Ionized water was added to 4 containers, and stirred for more than 0.5h to make the solution evenly mixed. The temperature was raised to 160°C, the reaction time was 20 hours, and the precipitate was decomposed into zinc oxide; naturally cooled to room temperature. The reaction solution was centrifuged to collect the precipitate after centrifugation, and washed twice with deionized water to obtain ZnO oxide;

[0028] Get wherein the product of 0.480g (12mmol) NaOH consumption carries out following processing:

[0029] (2) Use etchant such as oleic acid, urotropine, ethylenediamine, ammonia water, hydrazine hydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com