Eclogitic rutile ore sorting method

A technology of rutile ore and beneficiation method, which is applied in the direction of chemical instruments and methods, flotation, wet separation, etc., can solve the problems of single research and development and application of rutile collector, low rutile separation index, high economic cost, etc., and achieve improvement Comprehensive recovery level, improvement of low comprehensive utilization efficiency and low equipment investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

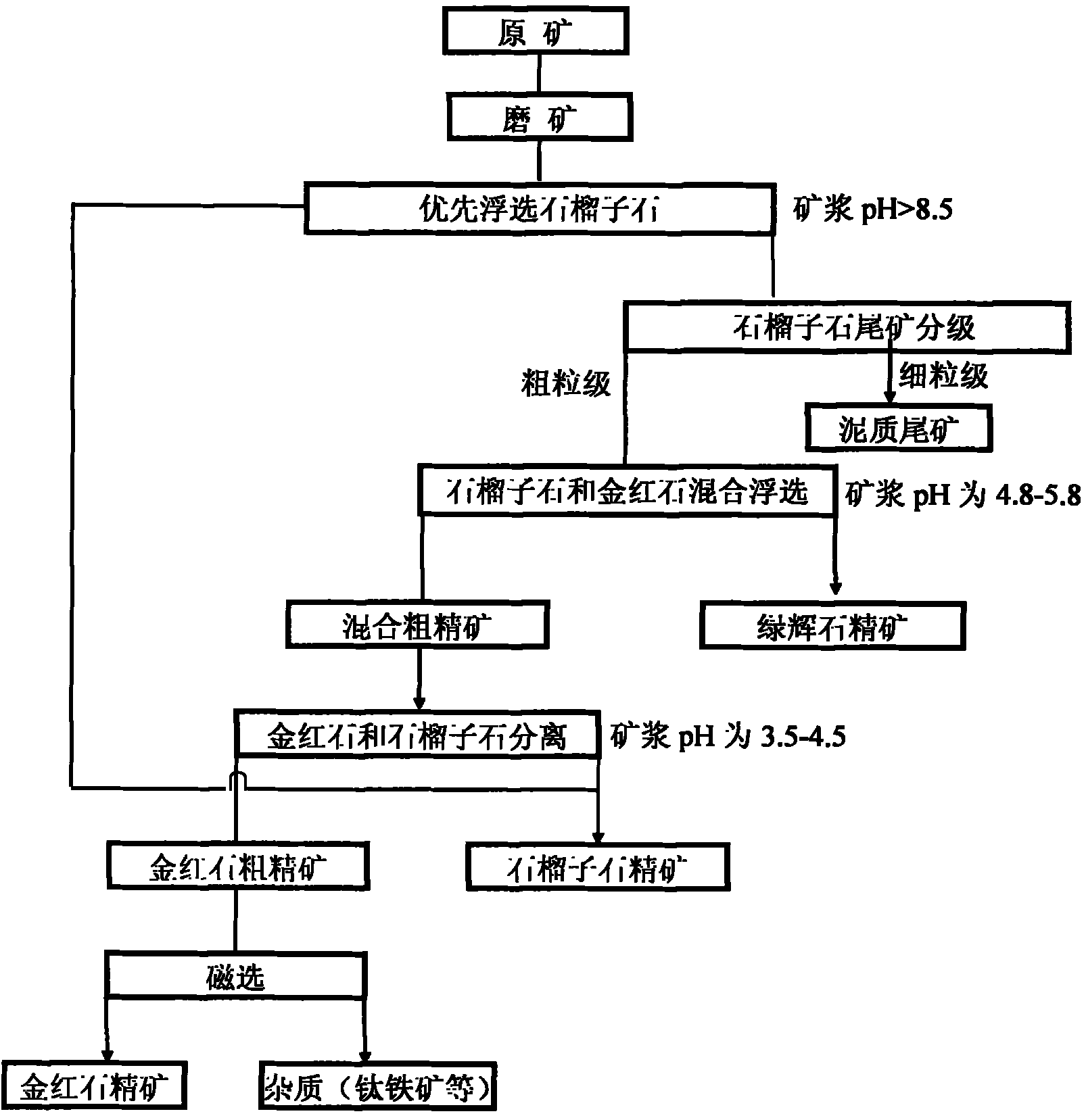

Method used

Image

Examples

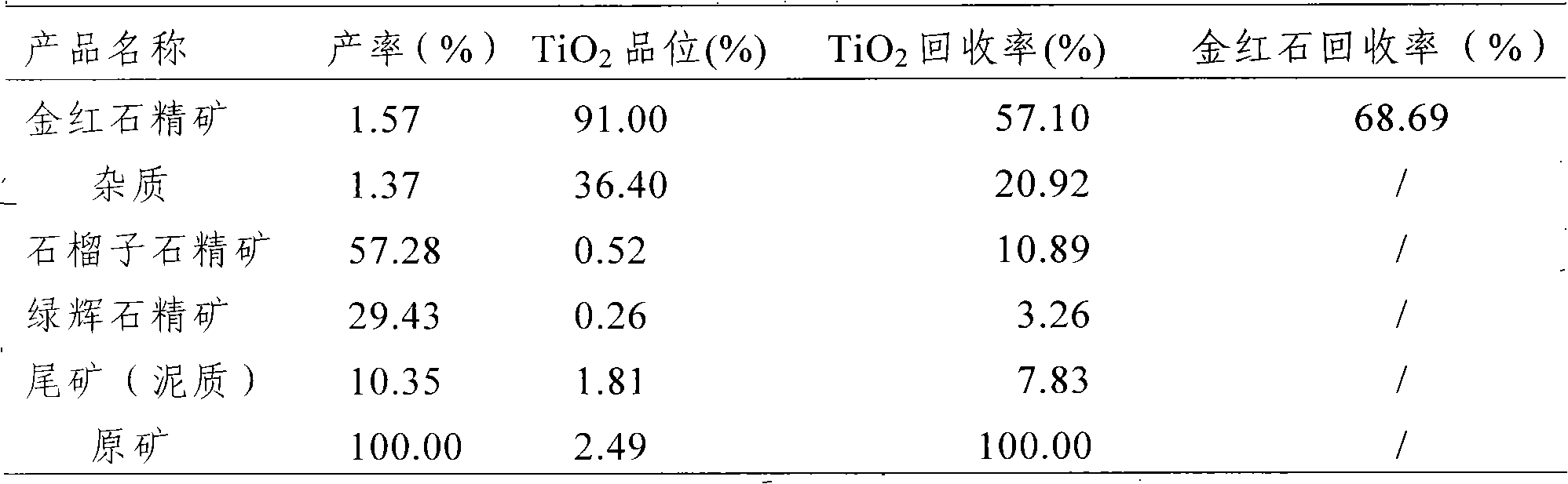

Embodiment 1

[0021] According to the present invention, laboratory small-scale test has been carried out, specifically comprising the following steps:

[0022] Step 1, ore grinding: Grinding the raw ore of rutile with a wet ball mill, the ore grinding to a particle size of -0.074mm, the quality of the rutile ore with a particle size of -0.074mm in the slurry is 31% ( That is, the grinding fineness -0.074mm accounts for 31%);

[0023] Step 2. Prioritize the flotation of garnet: the pulp in step 1 enters the flotation tank, add an alkaline regulator to the pulp, adjust the pH of the pulp to > 8.5, and then add collectors, auxiliary collectors and foaming to the pulp For garnet flotation, the dosage of collector is 100g / ton rutile raw ore, 175g / ton rutile raw ore or 250g / ton rutile raw ore, and the dosage of auxiliary collector is 60g / ton gold Redstone raw ore, 70g / ton rutile raw ore or 80g / ton rutile raw ore, the amount of foaming agent is 15g / ton rutile raw ore, 20g / ton rutile raw ore or 2...

Embodiment 2

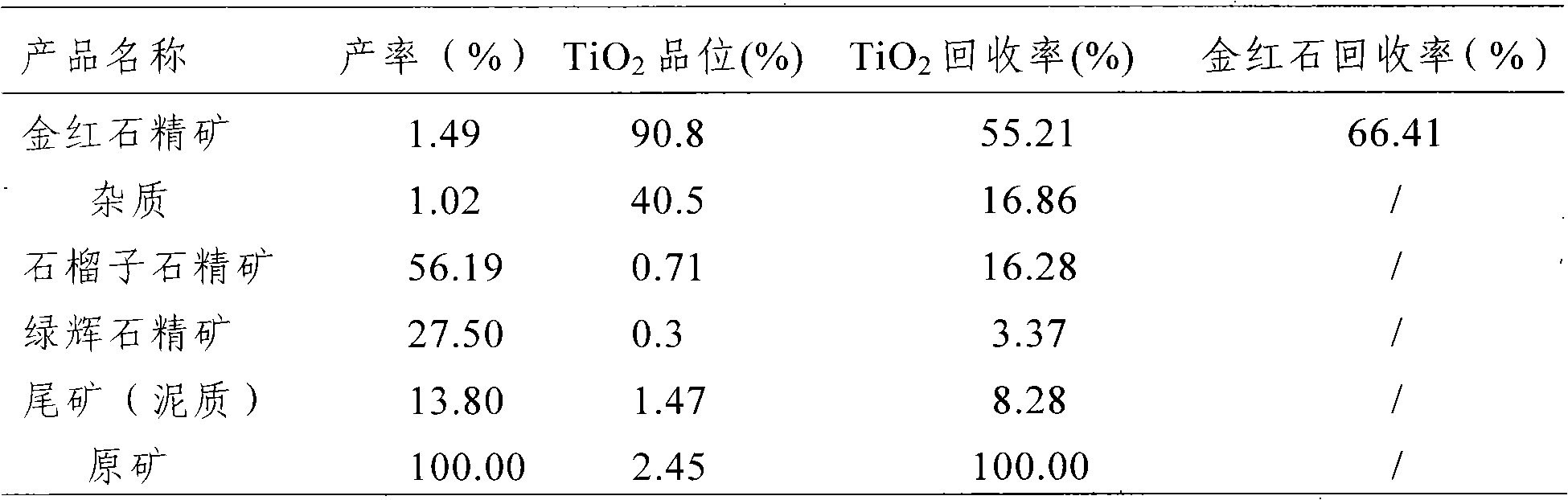

[0034] Carried out laboratory small-scale test according to the present invention, grinding fineness-0.074mm accounts for 45%, other steps are the same as embodiment 1, and test result is shown in Table 2.

[0035] Table 2 The closed-circuit test results of the whole process with the grinding fineness -0.074mm accounting for 45%

[0036]

[0037] In the whole process, the yield of garnet concentrate is 56.19%, the garnet content is about 92%, and the recovery rate of garnet reaches more than 90%.

[0038] In the whole process, the yield of omphacite concentrate is 27.50%, the content of omphacite is 90-92%, and the recovery rate of omphacite reaches more than 85%.

Embodiment 3

[0040] Carried out laboratory small-scale test according to the present invention, grinding fineness-0.074mm accounts for 55%, other steps are the same as embodiment 1, and test result is shown in Table 3.

[0041] Table 3 The closed-circuit test results of the whole process with the grinding fineness -0.074mm accounting for 55%

[0042]

[0043] The yield of garnet concentrate in the whole process is 54.22%, the content of garnet is about 91-95%, and the recovery rate of garnet reaches about 90%.

[0044] In the whole process, the yield of omphacite concentrate is 24.51%, the omphacite content is 91-93%, and the recovery rate of omphacite reaches about 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com