Long flame coal washing system and method

A long-flame coal separation technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low recovery rate of clean coal, low separation efficiency, high washing cost, etc., and achieve clean coal recovery High efficiency, high sorting efficiency, and remarkable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

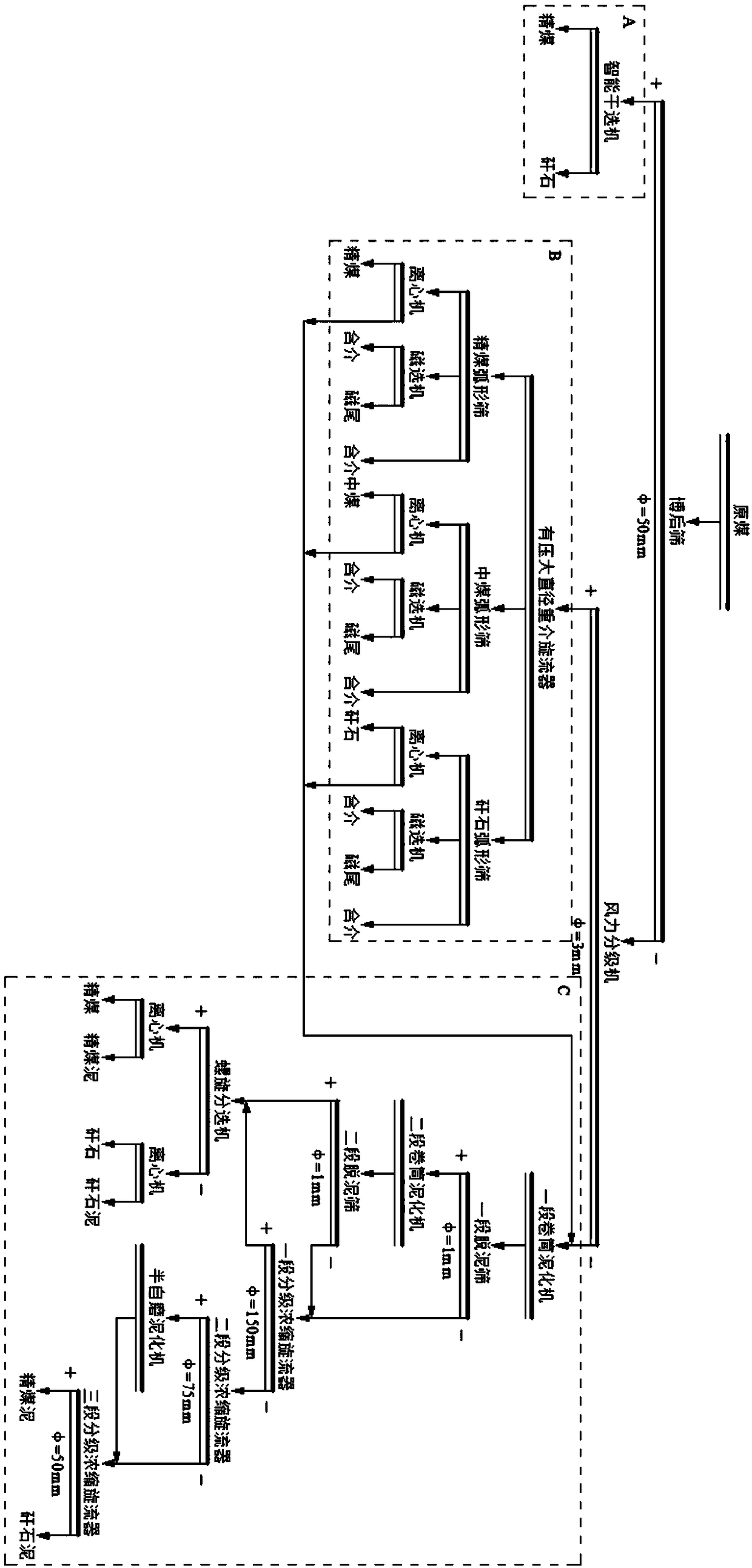

[0033] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0034] A specific embodiment of the present invention, such as figure 1 As shown, a long-flame coal washing system is disclosed, including a dry separation device, a pressurized heavy-medium separation device and a muddy separation device; raw coal enters the dry separation device, the pressurized One of dense medium separation device and mud separation device.

[0035] During implementation, the coarse-grained grade (particle size greater than 50mm) enters the dry separation device, the medium-grained grade (particle size is 3-50mm) enters the pressurized heavy medium separation device, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com