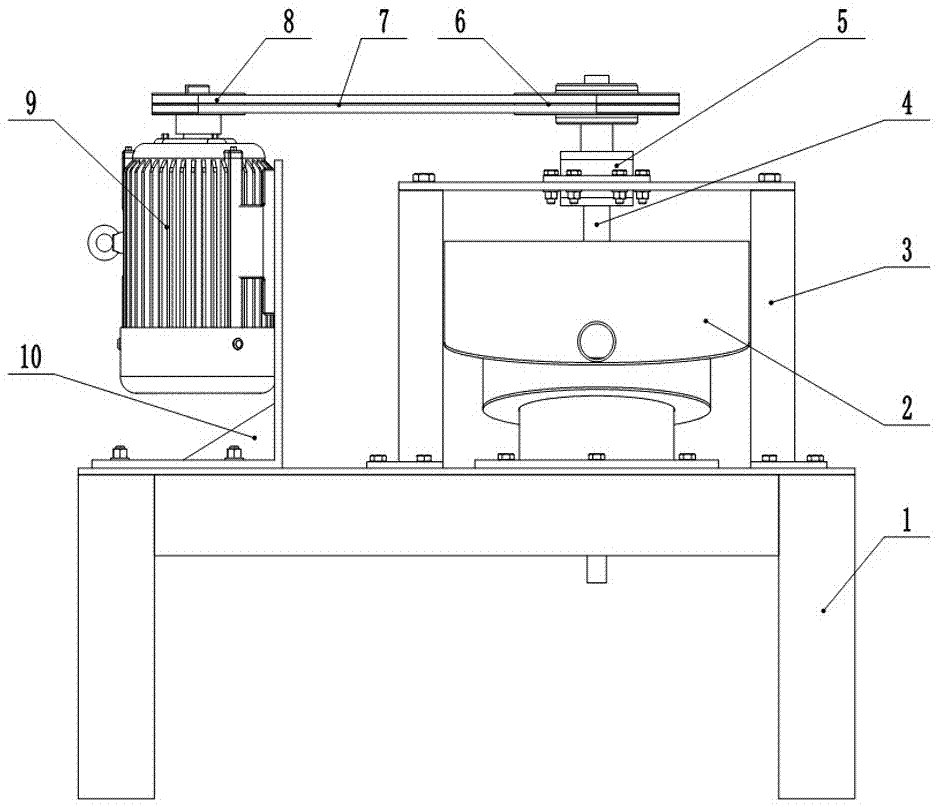

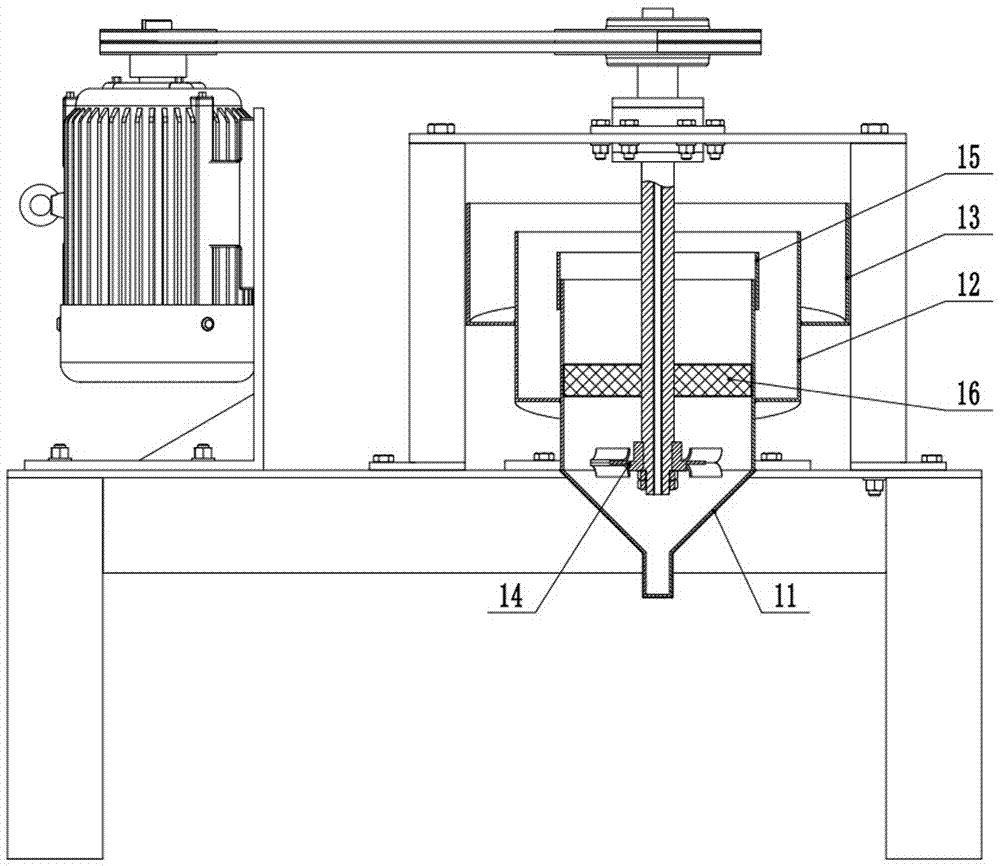

Coarse grain flotation machine

A flotation machine and coarse-grained technology, which is applied in the field of flotation separation of minerals and coarse-grained flotation machines, to achieve the effect of improving the concentrate grade, reducing the flotation time, and reducing the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

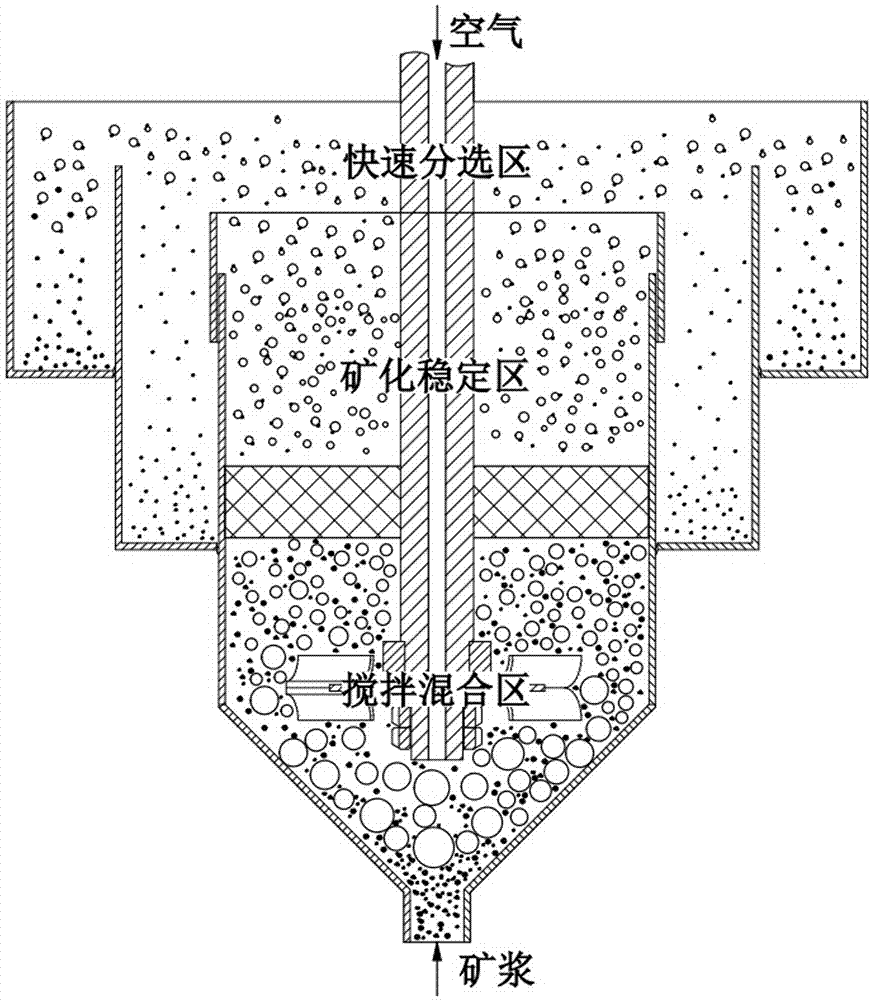

[0030] Embodiment 1: Garnet flotation test:

[0031] A. The raw material, garnet ore, is crushed to -3mm by jaw crusher and roller crusher, and the ore is ground to -0.074mm by conical ball mill, accounting for 30%.

[0032] B. Desliming, using spiral chute gravity separation and desliming, the deslimed material is the flotation raw material.

[0033] C. Slurry adjustment, use a mixing tank to adjust the slurry, and adjust the slurry concentration of the flotation selected raw materials to 50%, the dosage of the agent is as follows: adjuster sulfuric acid, the dosage is 1000g / t, the pH value of the pulp is 4~5, and the collector sodium petroleum sulfonate Combination agent with salicylic hydroxamic acid (the ratio of agent is 3:1), the dosage of agent is 1500g / t. The stirring time was 5 minutes.

[0034] D. Flotation test, start the equipment, open the aeration device, add water to the top of the middle cylinder, adjust the ore discharge valve to keep the water volume in the...

Embodiment 2

[0038] Embodiment 2: kyanite flotation test:

[0039]A. Test sample treatment, kyanite is crushed to -3mm by jaw crusher and roller crusher, and dry-type magnetic separation is carried out by dry-type permanent magnet strong magnetic separator, discarding biotite, Weak magnetic mineral, the magnetic field strength is 850KA / m. Grind the non-magnetic material until the content of -0.074mm accounts for 50%, carry out gravity separation and throw tailings in the spiral chute, discard light minerals such as muscovite and fine mud, and prepare the raw materials for flotation.

[0040] B. Slurry adjustment, use a mixing tank to adjust the slurry, and adjust the slurry concentration of the flotation selected raw materials to 50%, and the dosage of the agent is as follows: 300g / t of citric acid as an adjustment agent, 20g / t of polyacrylamide, and self-developed collector Z-401 The dosage of medicine is 1000g / t. The stirring time was 5 minutes.

[0041] C. Flotation test, start the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com