High-efficiency ore sorting technique for nickel-molybdenum mineral

A nickel-molybdenum ore, high-efficiency technology, applied in the field of high-efficiency beneficiation of nickel-molybdenum ore in complex and refractory black rock series, can solve the problems of difficulty in removing organic carbon, low recovery rate, and low-grade recovered products, and achieve the goal of solving the problem of organic carbon remove difficult effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

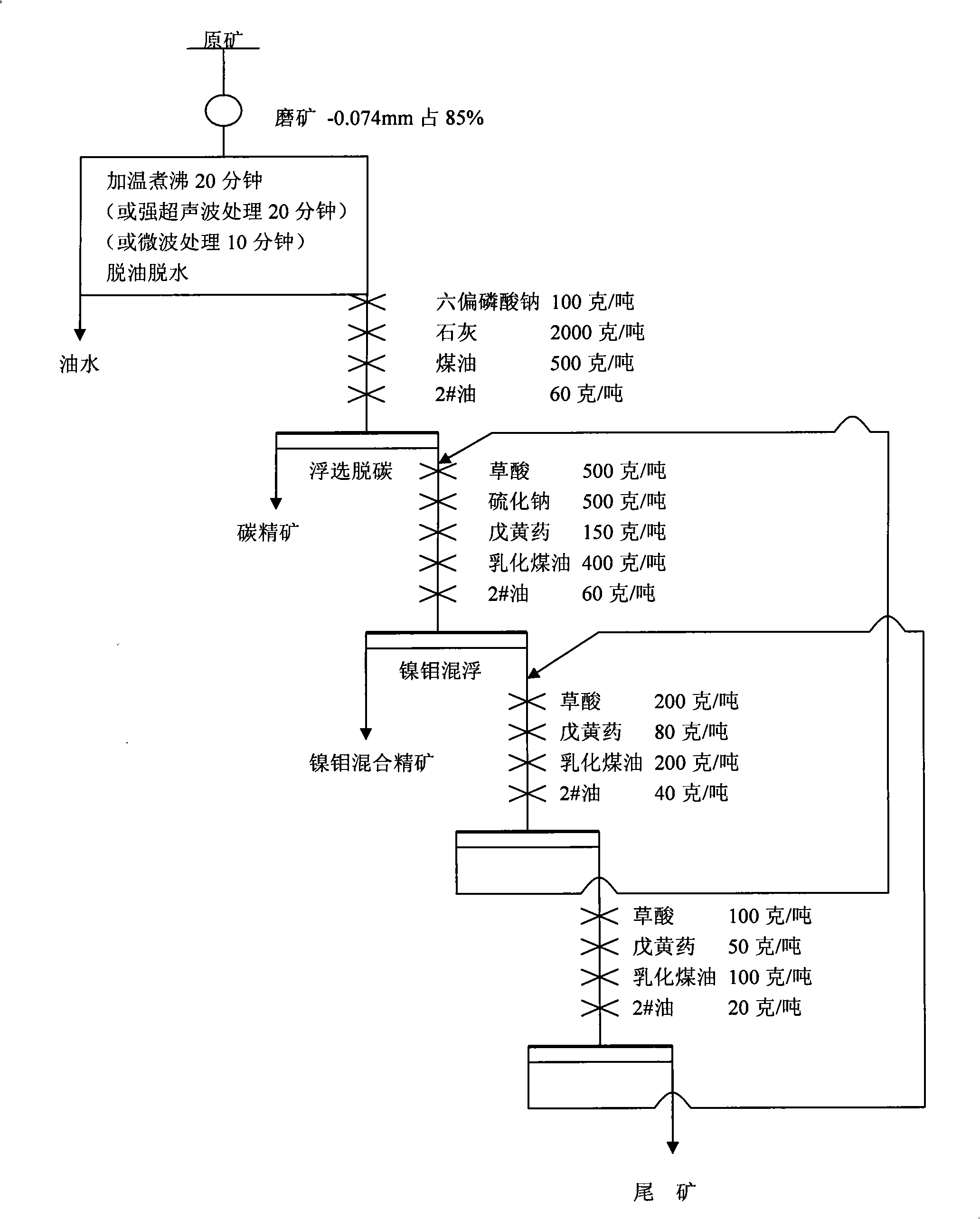

[0022] Embodiment 1: heat treatment decarburization flotation

[0023] Refractory black rock nickel-molybdenum ore containing 0.8% and 0.5% Ni and 0.5% respectively in the original ore, grind to -0.074mm to account for 85%, add fresh water until the pulp concentration is 30%, heat to 100°C and cook for 20 minutes , after standing for 20 minutes, remove the supernatant. Concentrate the pulp to 30%, add 100 g / t sodium hexametaphosphate as dispersion, 2000 g / t lime to suppress nickel and molybdenum, add 500 g / t kerosene as collector, 60 g / t 2# oil as foaming agent , Flotation decarbonization with an inflatable flotation machine. Add 800 g / t oxalic acid listed activator and 500 g / t sodium sulfide as activator, use 700 g / t emulsified kerosene and 280 g / t pentaxanthate to collect nickel-molybdenum ore by flotation, after a rough separation The small-scale closed-circuit test of secondary scavenging can obtain nickel-molybdenum mixed concentrate with Ni and Mo grades greater than 5...

Embodiment 2

[0025] Strong ultrasonic pretreatment decarburization flotation

[0026] The original ore contains 0.8% Ni and 0.5% Mo respectively for refractory black rock series nickel-molybdenum ore. Grinding to -0.074mm accounts for 85%. Add fresh water until the pulp concentration is 30%. 10W / cm 2 1. The power is 400w high-intensity ultrasonic treatment for 20 minutes, and the supernatant is extracted after standing for 8 minutes. Concentrate the pulp to 30%, add 100 g / t sodium hexametaphosphate as dispersion, 2000 g / t lime to suppress nickel and molybdenum, add 500 g / t kerosene as collector, add 60 g / t 2# oil as foam agent, decarbonized by flotation with an inflatable flotation machine. Add 800g / ton of oxalic acid and 500g / ton of sodium sulfide as activators, add 700g / ton of emulsified kerosene and 280g / ton of pentaxanthate to collect nickel-molybdenum ore by flotation. The closed-circuit test can obtain nickel-molybdenum mixed concentrate with Ni and Mo grades of 5.68% and 7.88% re...

Embodiment 3

[0028] Microwave pretreatment decarburization flotation

[0029] The original ore contains 0.8% and 0.5% Ni and Mo respectively, refractory black rock series nickel-molybdenum ore, crushed to -0.074mm to account for 85%, add fresh water to the pulp concentration of 30%, and place it at a frequency of 2450MHz and a power of Treat in 2000w microwave for 10 minutes, stand still for 10 minutes and then remove the supernatant. Concentrate the pulp to 30%, add 100 g / t sodium hexametaphosphate as dispersion, 2000 g / t lime to suppress nickel and molybdenum, 500 g / t kerosene as collector, 60 g / t 2# oil as foaming agent, Flotation decarbonization with inflatable flotation machine. Add 800g / ton of oxalic acid and 500g / ton of sodium sulfide as activators, use 700g / ton of emulsified kerosene and 280g / ton of pentaxanthate to collect nickel-molybdenum ore by flotation. The closed-circuit test can obtain nickel-molybdenum mixed concentrate with Ni and Mo grades of 6.52% and 7.95% respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com