Aviation-grade kerosene from independently produced blendstocks

a technology of aviation-grade kerosene and blendstock, which is applied in the direction of fuels, hydrocarbon oil treatment products, lubricant compositions, etc., can solve the problems of insufficient production of aviation-grade kerosene that is compatible with aviation standards, and the inability to meet the requirements of aviation standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

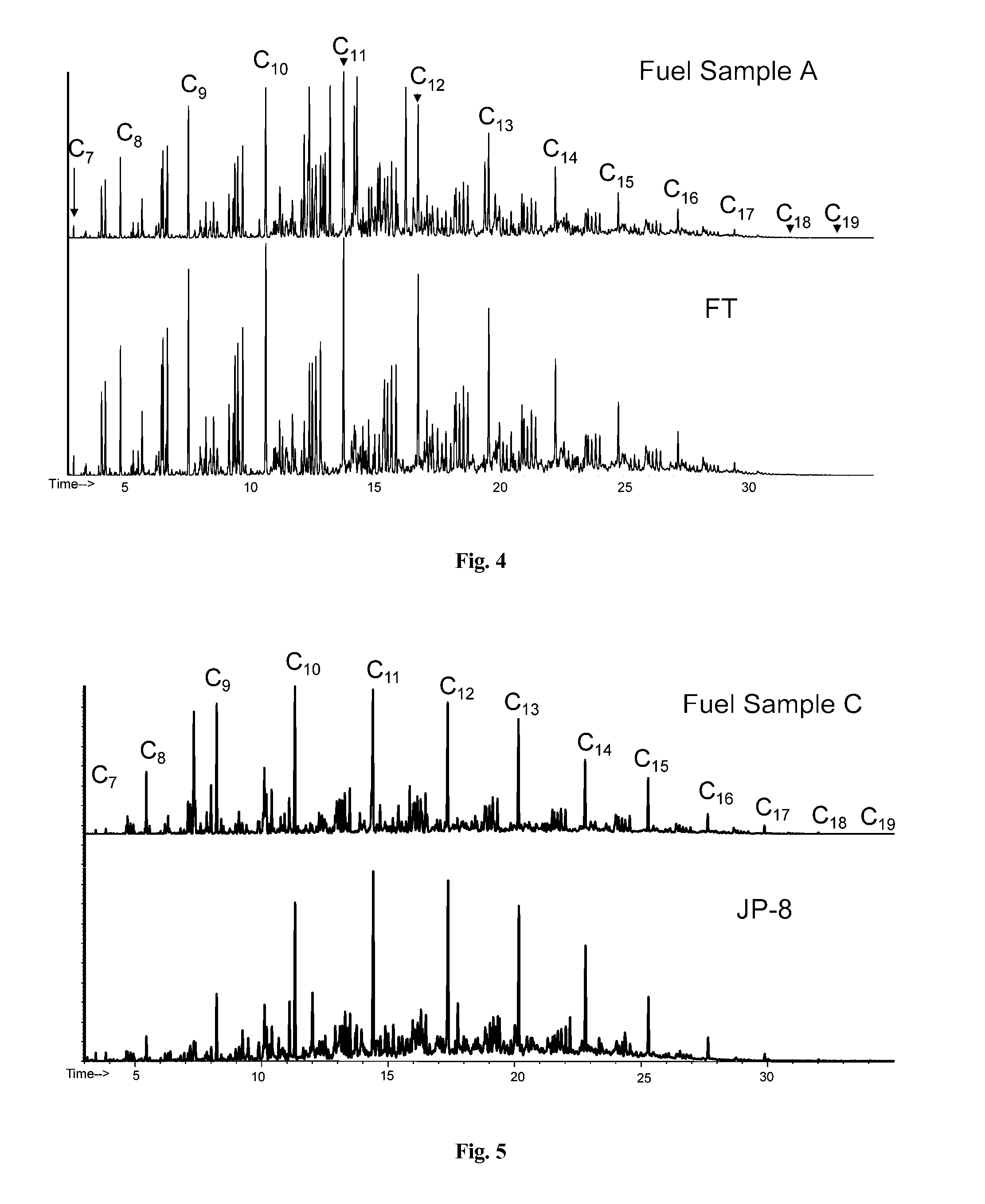

Fuel Sample A

[0063]A FT fuel produced from natural gas and containing iso-paraffinic and normal paraffin hydrocarbons did not comply with density requirement of the JP-8 military specification (MIL-DTL-83133E). In this example, a mixture of aromatic hydrocarbon fluid containing aromatic hydrocarbons ranging in carbon chain length from 8-16, was blended to a concentration of 23% by weight with the FT fuel. A summary of results from Fuel Sample A compared to specification requirements outlined in MIL-DTL-83133E is provided in Table 4.

TABLE 4Results from Jet Fuel Specification Tests ofFuel Sample A Comprising Blend of Aromatic Hydrocarbonand Fischer-Tropsch Derived FuelSpecification TestSample AMilitary SpecAcid Number, mg KOH / gm0.0030.015maxAromatics, vol %19.425vol % maxOlefins, vol %0.05vol % maxSulfur, mass %0.00.30maxHeat of Combustion, Btu / lb1850018400Distillation:10% recovered, ° C.172205maxEndpoint, ° C.274300maxResidue, vol %1.41.5maxLoss, vol %0.41.5maxFlash Point, ° C.48 >38...

example 2

Fuel Sample B

[0065]The same FT fuel as used in Example 1 was blended at 82% wt. with 8% wt. of a mixed aromatic fluid and 10% wt. cycloparaffinic fluid. A summary of Fuel Sample B results from key specification parameters is provided in Table 5.

TABLE 5Results for Key Jet Fuel Specification Tests of Fuel Sample B Comprising Blendof Aromatic and Cycloparaffin Hydrocarbons with Fischer-Tropsch Derived FuelSpecificFreezeFlashHHV,Gravity, g / mLPoint,° C.Point, ° C.MJ / kgMil Spec0.775-0.84−47>38 C.>42.8Specification value isa lower heating valueSample B0.779−61.44846.1Lab analysisFT Fuel0.755−56.74846.6Lab analysis

[0066]As seen in the results in Table 5, the resulting fuel Sample B possessed a MIL-DTL-83133 E specification compliant fuel with a density of 0.779 g / mL.

example 3

Fuel Sample C

[0067]Two hydrocarbon blendstocks, one consisting of normal- and iso-paraffinic hydrocarbon and the second consisting of a mixture of aromatic and cycloparaffinic hydrocarbons, were produced exclusively from crop oil and blended to achieve a fuel sample complying with the requirements of MIL-DTL-83133E. In this example, neither fuel blendstock possessed, on its own, the physical characteristics required by the specification; however, through blending at a ratio of 44% normal and iso-paraffinic blendstock, and 66% aromatic and cycloparaffinic blendstock, the resulting fuel achieved the necessary characteristics. A summary of results from Fuel Sample C compared to specification parameters outlined in MIL-DTL-83133E is provided in Table 6. Data from gas chromatography of Sample C and a typical JP-8 fuel is provided in FIG. 5.

TABLE 6Results from Jet Fuel Specification Tests of FuelSample C Comprising a Blend of Two Discrete HydrocarbonBlendstocks Produced from Crop OilSpeci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com