Method for detecting fault of steel-ball surface

A detection method and a technology of steel balls, which are applied in the direction of optical testing of flaws/defects, measuring devices, and material analysis through optical means, and can solve problems such as misjudgment detection efficiency and missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Method of the present invention comprises the following steps:

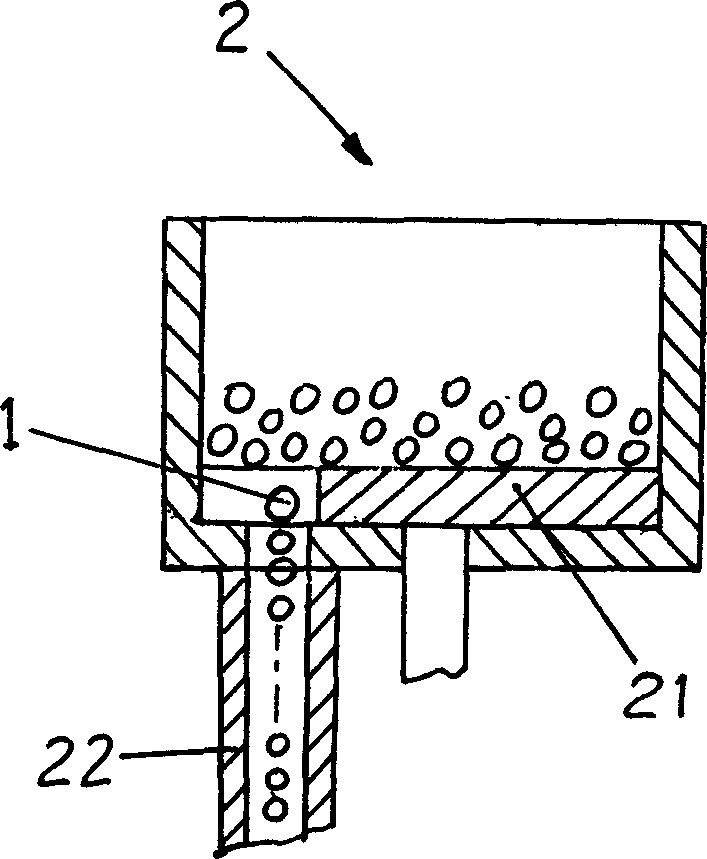

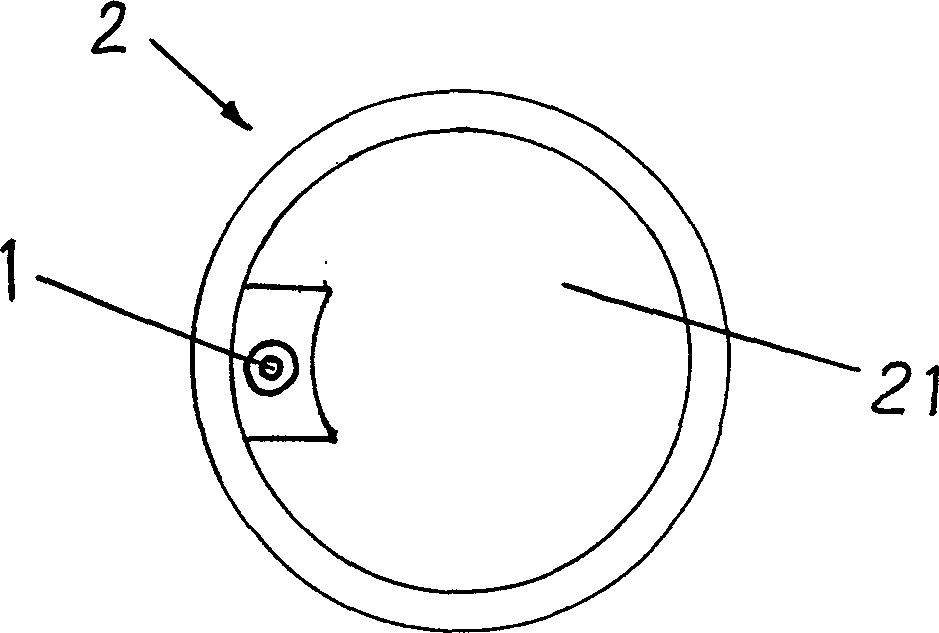

[0016] 1. See figure 1 As shown, put the steel ball 1 to be tested into the feeding mechanism 2;

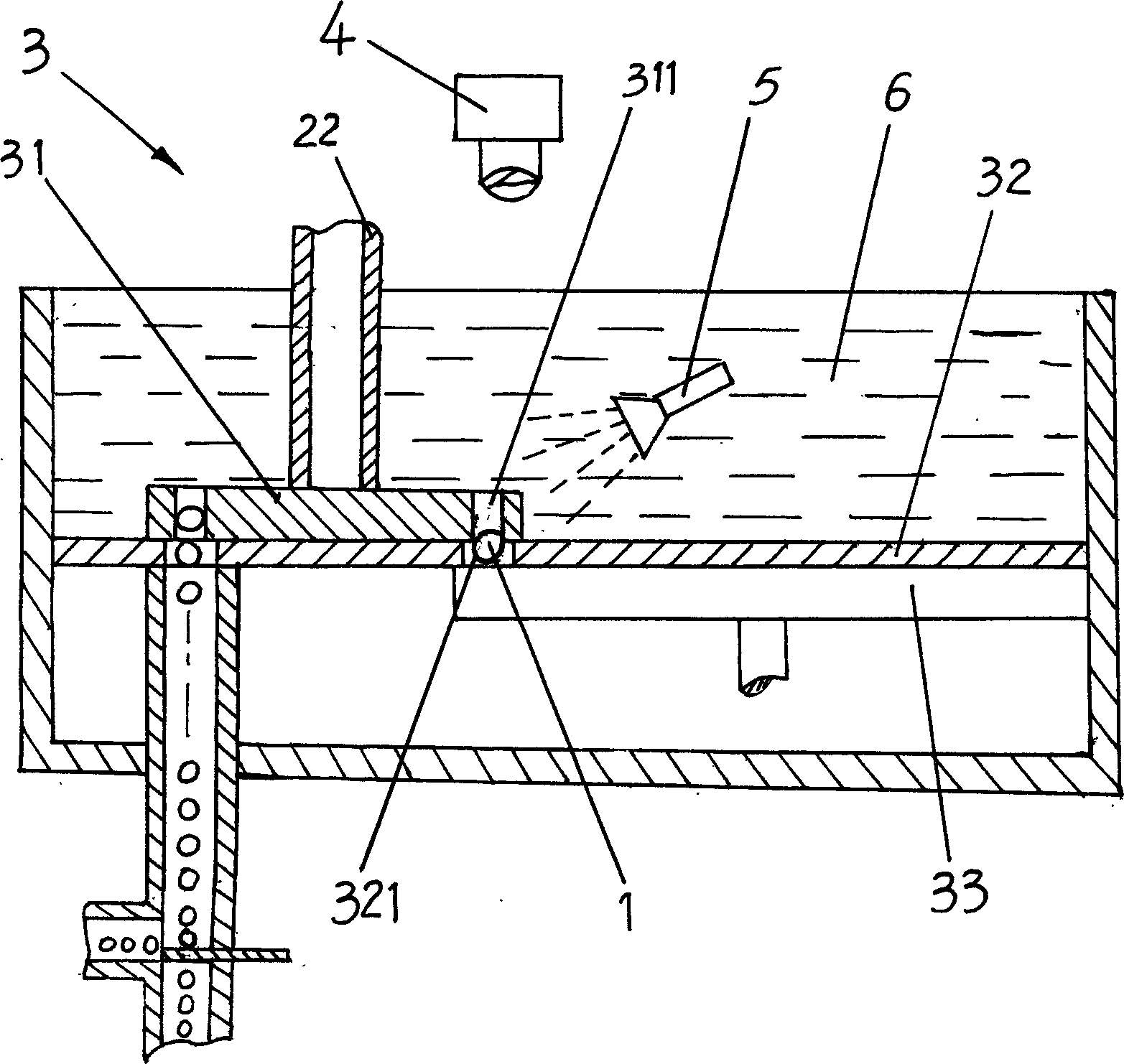

[0017] 2. By the reciprocating rotation of the ball dial 21 in the feeding mechanism 2, the steel balls are smoothly sent from the material guide tube 22 into the hole-shaped detection chamber 311 on the periphery of the feeding turntable 31 in the detection mechanism 3, as image 3 As shown, the feed turntable is made of white light-transmitting material, and a partition 32 is provided under the feed turntable 31 to provide a supporting surface. 321 corresponds to the hole-shaped detection chamber 311 on the feed turntable 31, the feed turntable 31 rotates step by step, and the steel balls 1 are pushed into the holes 321 of the partition 32 in sequence, and the unfolding turntable 33 arranged under the partition 32 acts as The swinging and rotating movement drives the steel ball 1 in the hole 321 of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com