Atomic ore sorting system

A sorting system and radioactive technology, applied in sorting and other directions, can solve the problems of reducing the efficiency of ore sorting, slowing down the transmission speed of the conveyor belt, and short measurement time, so as to prolong the time of measuring radioactive intensity, improve accuracy, and prevent The effect of miscalculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

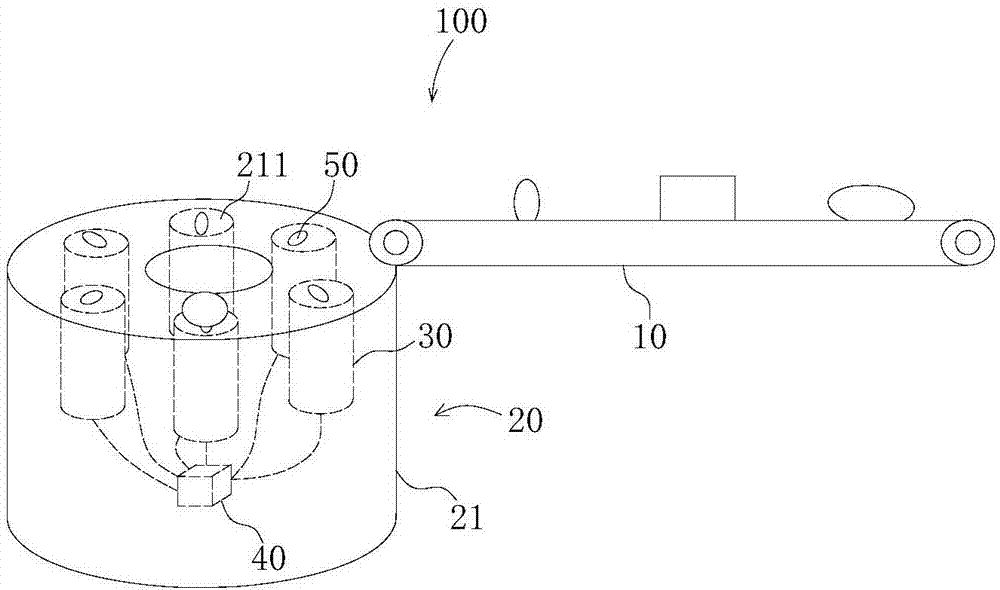

Examples

no. 2 example

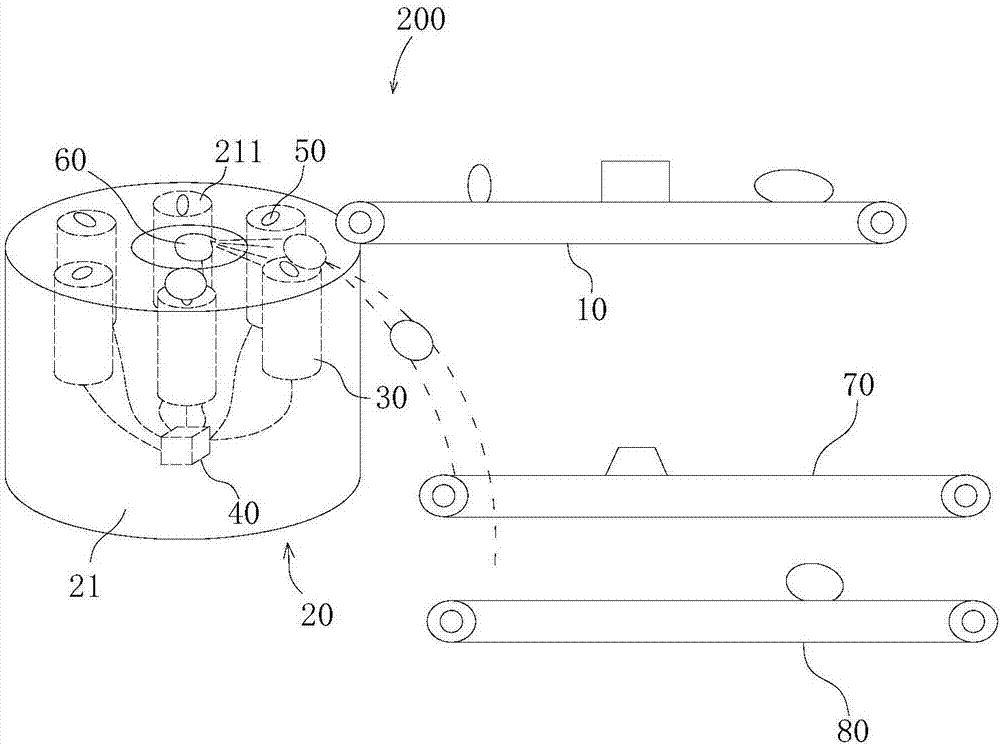

[0033] Please refer to figure 2 , is a schematic composition diagram of another radioactive ore sorting system 200 provided by the embodiment of the present invention. Compared with the first embodiment, the radioactive ore sorting system 200 provided by the second embodiment also includes an air injection valve 60, which is connected with the processor 40, and the air injection valve 60 is used to respond to the control of the processor 40 to the The selected ore blows gas so that the ore to be sorted falls into different preset destinations according to different types. In the present embodiment, the radioactive ore sorting system 200 also includes a concentrate conveyor belt 70 and a tailings conveyor belt 80. When the processor 40 judges that the ore to be sorted is a concentrate, the air injection valve 60 is controlled to blow gas to the concentrate to remove the concentrate. The ore is blown onto the concentrate conveyor belt 70, and when the processor 40 judges that ...

no. 3 example

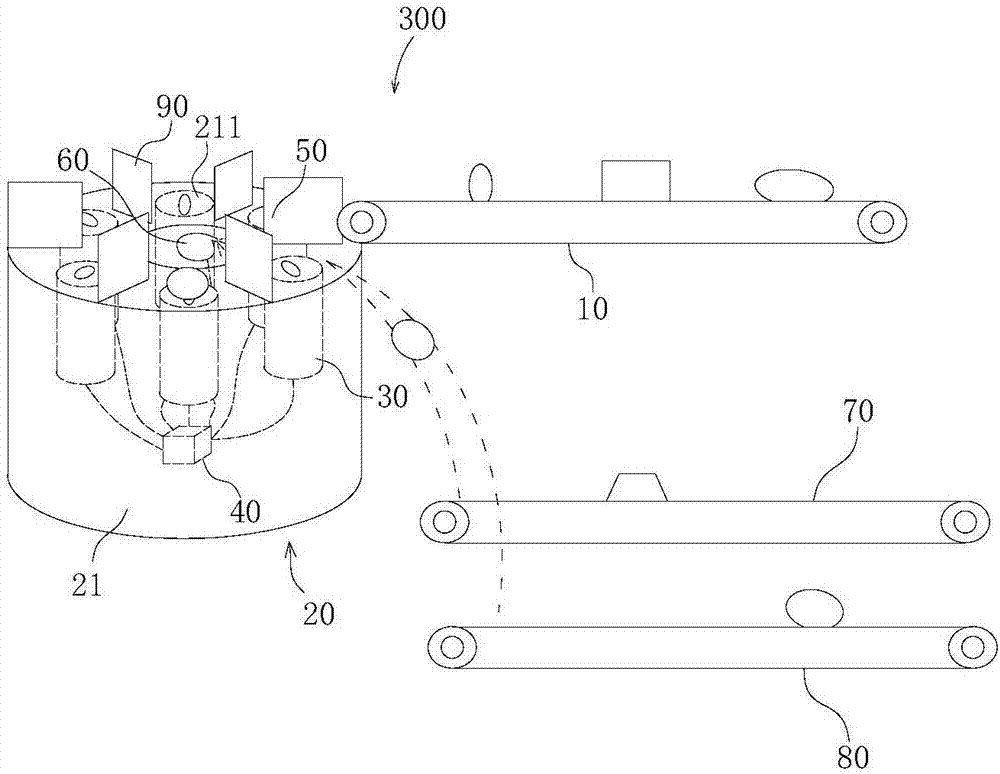

[0036] Please refer to image 3 , is a schematic diagram of the composition of the radioactive ore sorting system 300 provided by the embodiment of the present invention. Compared with the second embodiment, the radioactive ore sorting system 300 also includes a shielding plate 90, and the shielding plate 90 is arranged on two adjacent between measurement areas 211 . Due to the short distance between adjacent measurement areas 211 , the radiation between the ores to be sorted may interfere with each other, making the radioactive intensity detected by the nuclear radiation detector 30 inaccurate. In this third embodiment, the setting of the shielding plate 90 isolates the adjacent measurement areas 211 and prevents the mutual interference of adjacent ores, thereby improving the measurement accuracy of the nuclear radiation detector 30. As preferably, the shielding plate 90 for lead plates.

[0037] In addition, it has been found through research that when the nuclear radiatio...

no. 4 example

[0039] Please refer to Figure 4 , is a schematic diagram of the composition of the radioactive ore sorting system 400 provided by the embodiment of the present invention. The fourth embodiment is roughly the same as the third embodiment, the difference is that the radioactive ore sorting system 400 also includes an ore bin 410 and a vibration feeder. The feeder 420, the ore bin 410 is connected with the vibrating feeder 420, the vibrating feeder 420 is connected with the conveyor belt 10, the ore bin 410 is configured to store the ore to be sorted, and the vibrating feeder 420 is configured to put the ore in the ore bin The ore to be sorted is transported to the conveyor belt 10. In addition, the nuclear radiation detector 30 is equipped with a shielding tube 31 for shielding the interference of adjacent ores, and shielding the surrounding environment of the nuclear radiation detector 30 including natural background, dust and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com