Ore automatic identification and coarse sorting system based on deep learning

An automatic identification and deep learning technology, applied in sorting, neural learning methods, character and pattern recognition, etc., can solve problems such as increasing difficulty, manual participation, property loss, etc., to reduce manual participation, realize full automation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

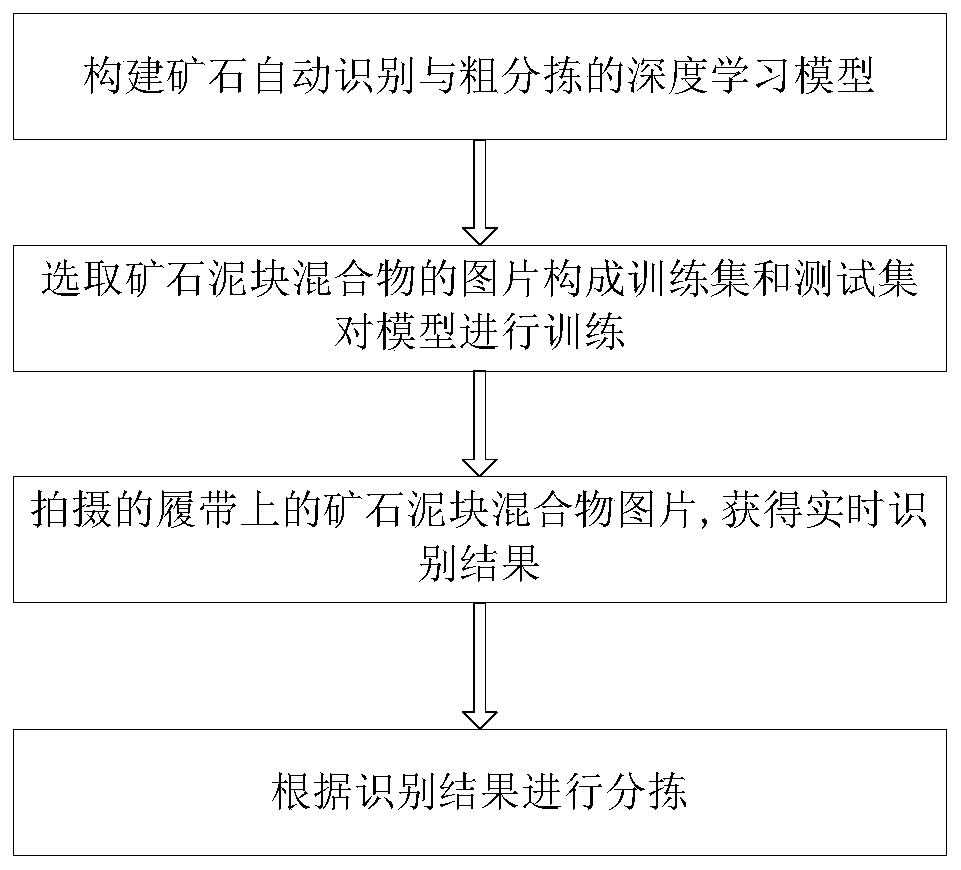

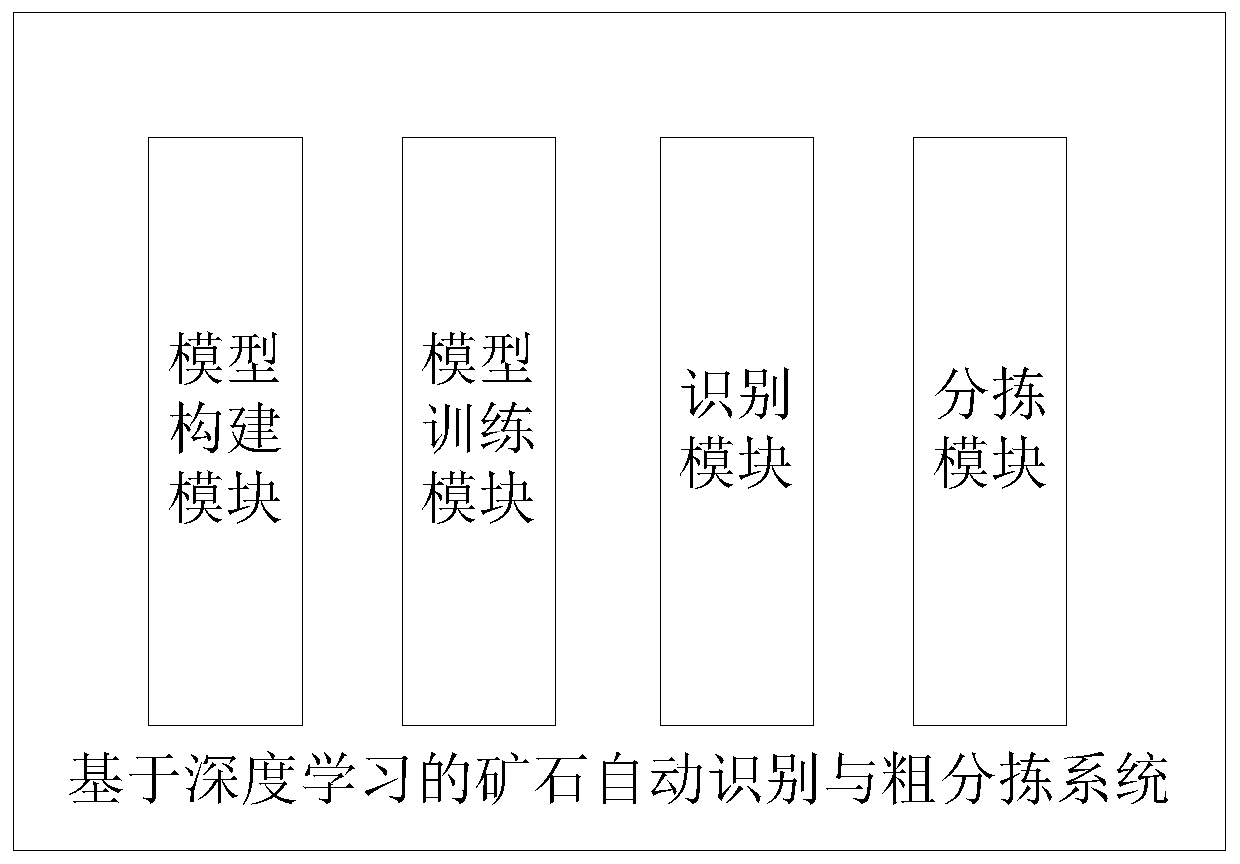

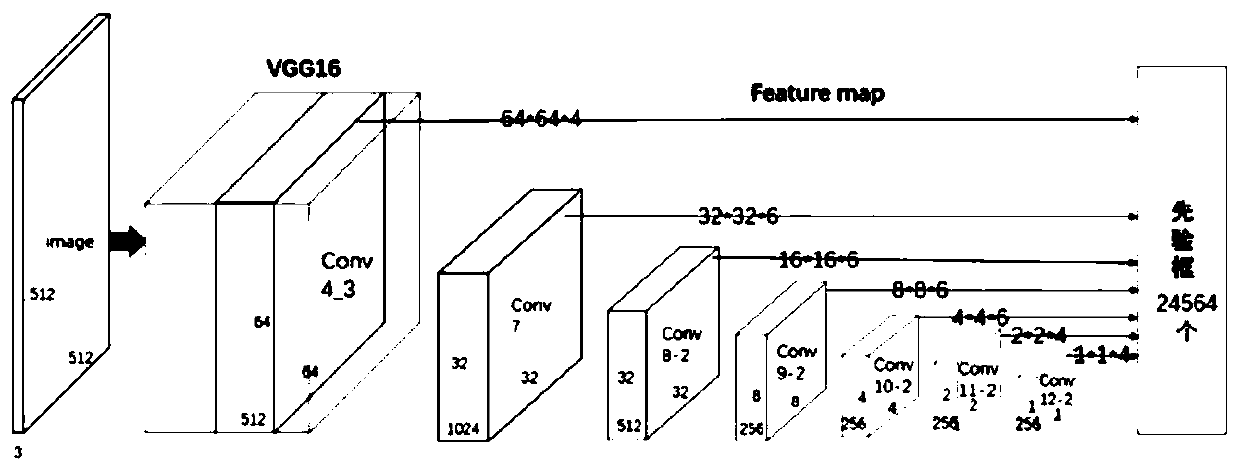

[0039] Such as figure 1 and Figure 4 As shown, a deep learning-based ore automatic identification and rough sorting method, the specific steps are as follows:

[0040] S1. Use a high-pressure water gun to wash the ore mud mixture just sent, and the washing time is generally controlled to 3 minutes;

[0041] S2, the lower computer controls the camera module to take pictures of the ore on the crawler, and transmits it to the upper computer through the network;

[0042] S3. The host computer stores the pictures in the database, and uses the trained deep learning model to identify the pictures, and measures and calculates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com