Automatic spot welding method for battery electrodes

An automatic spot welding and battery electrode technology, applied in resistance welding equipment, welding equipment, welding equipment, etc., can solve the problems of no significant increase in efficiency, deviation of displacement, and high requirements for welding employees with manual participation, and achieve manual participation. Simple and easy to implement, avoid wrong welding or welding damage, low manual participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

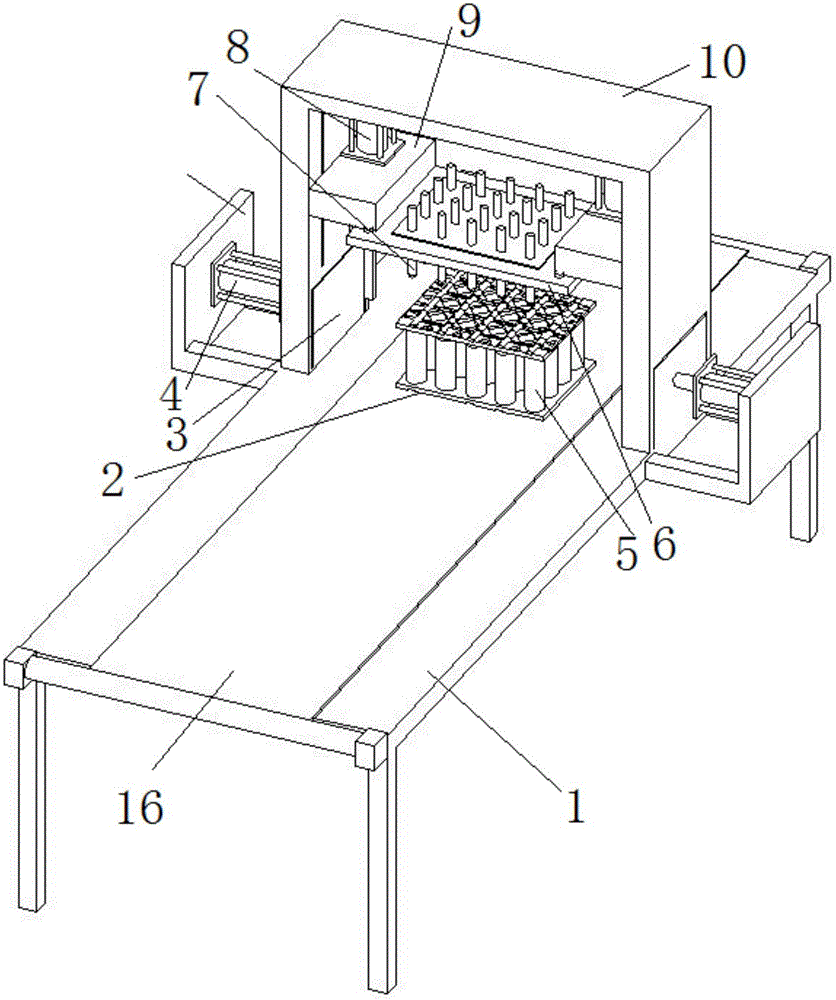

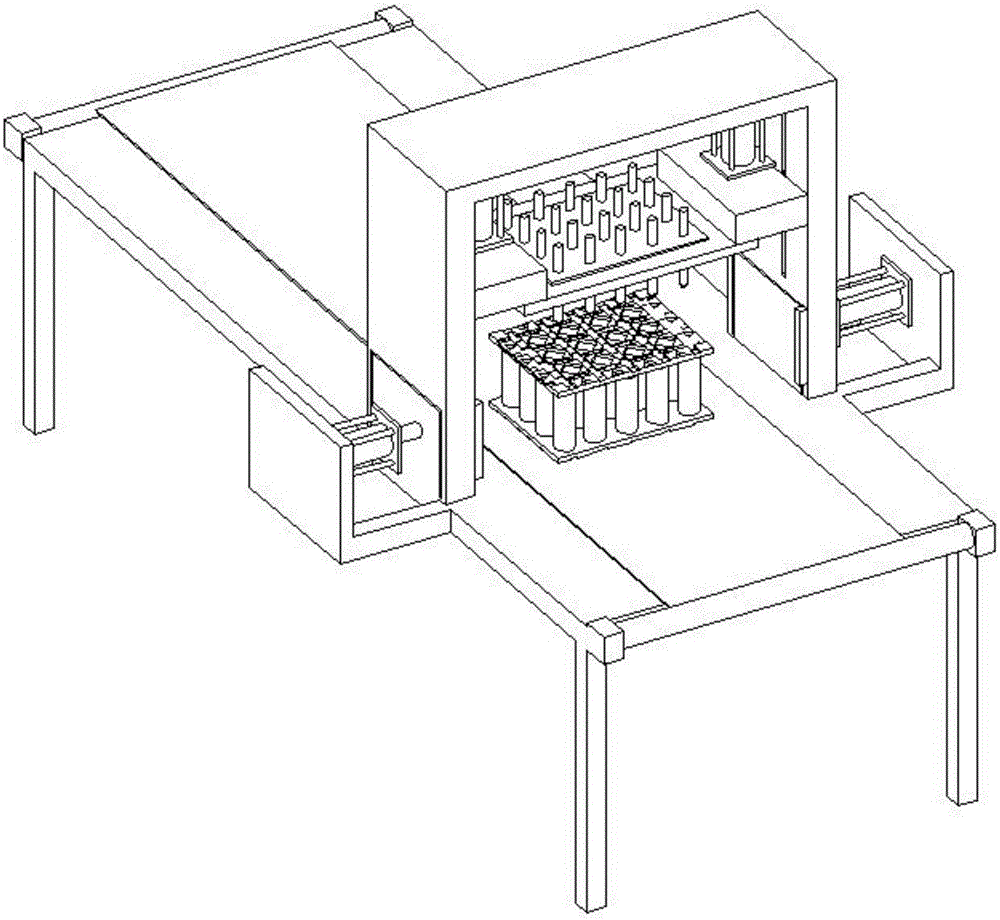

[0019] Such as Figure 1 ~ Figure 3 An automatic spot welding method for battery electrodes is shown. The automatic spot welding machine includes a workbench 1, a battery fixing mechanism 2, a spot welding mechanism, and a positioning and clamping mechanism. The positioning and clamping mechanism includes two oppositely arranged retractable clamping blocks 3. The two clamping blocks 3 are stretched and retracted respectively by the two clamping cylinders 4, and the battery fixing mechanism 2 is arranged between the two clamping blocks 3;

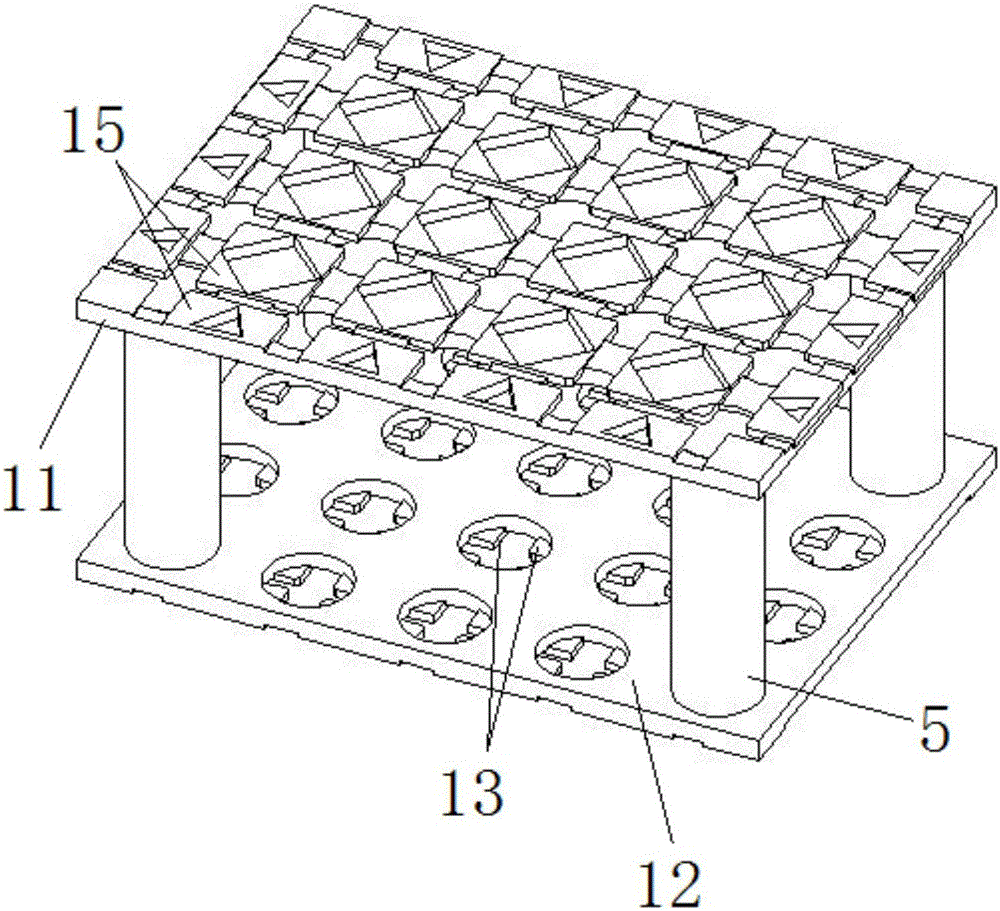

[0020] The battery fixing mechanism 2 is fixed with a plurality of vertical batteries 5, and the electrodes of the batteries to be welded are set upward; 5 are in one-to-one correspondence, and each group of welding pins 7 is arranged above the corresponding battery 5, and the lower pressing plate 6 is driven down by the lower pressing telescopic mechanism. In the pressed down state of the lower pressing plate 6 , the welding pin 7 is in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com