Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Good spinning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

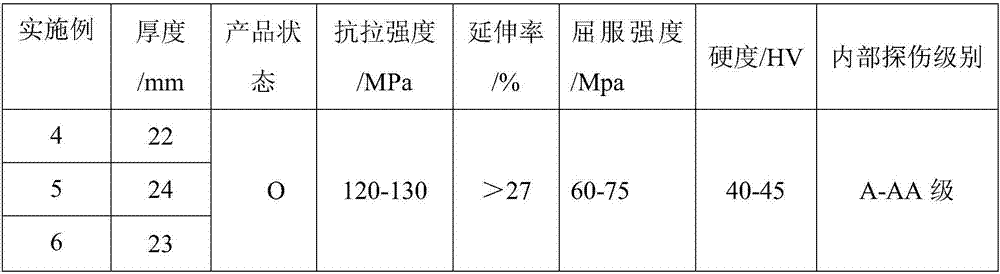

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

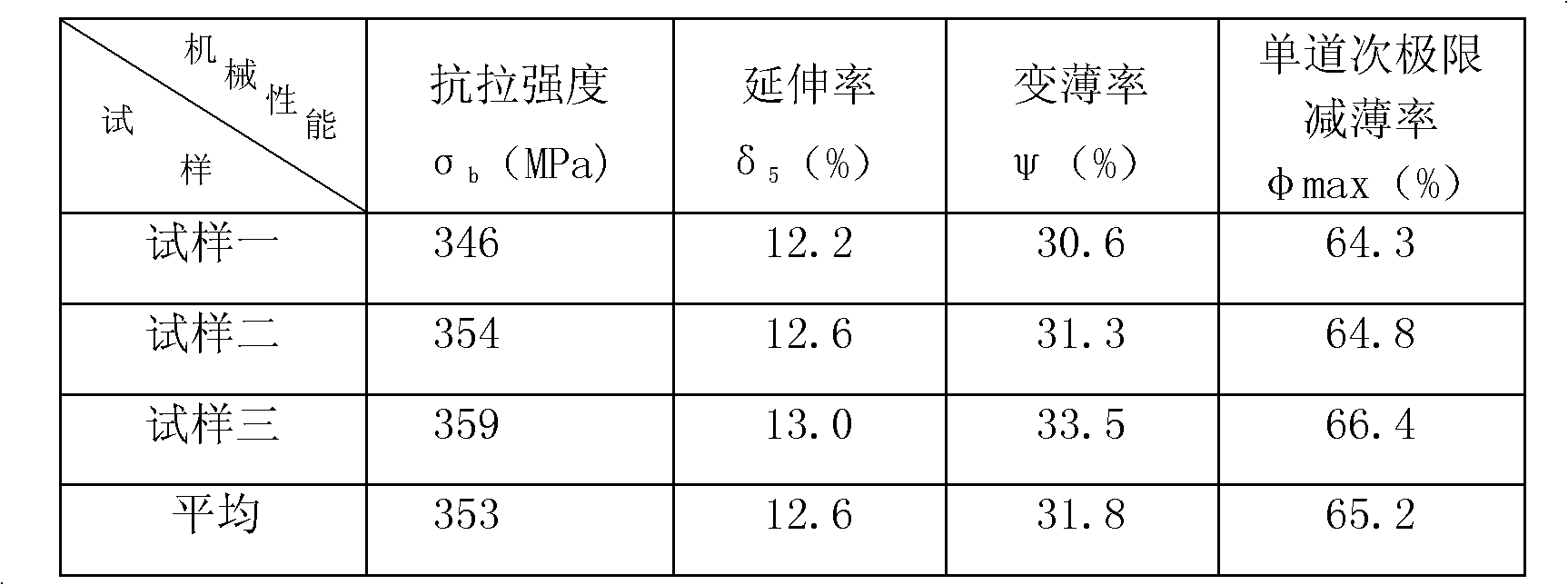

High-toughness ultrahigh-strength D506A steel easy for rotary extrusion and easy to weld and preparation method thereof

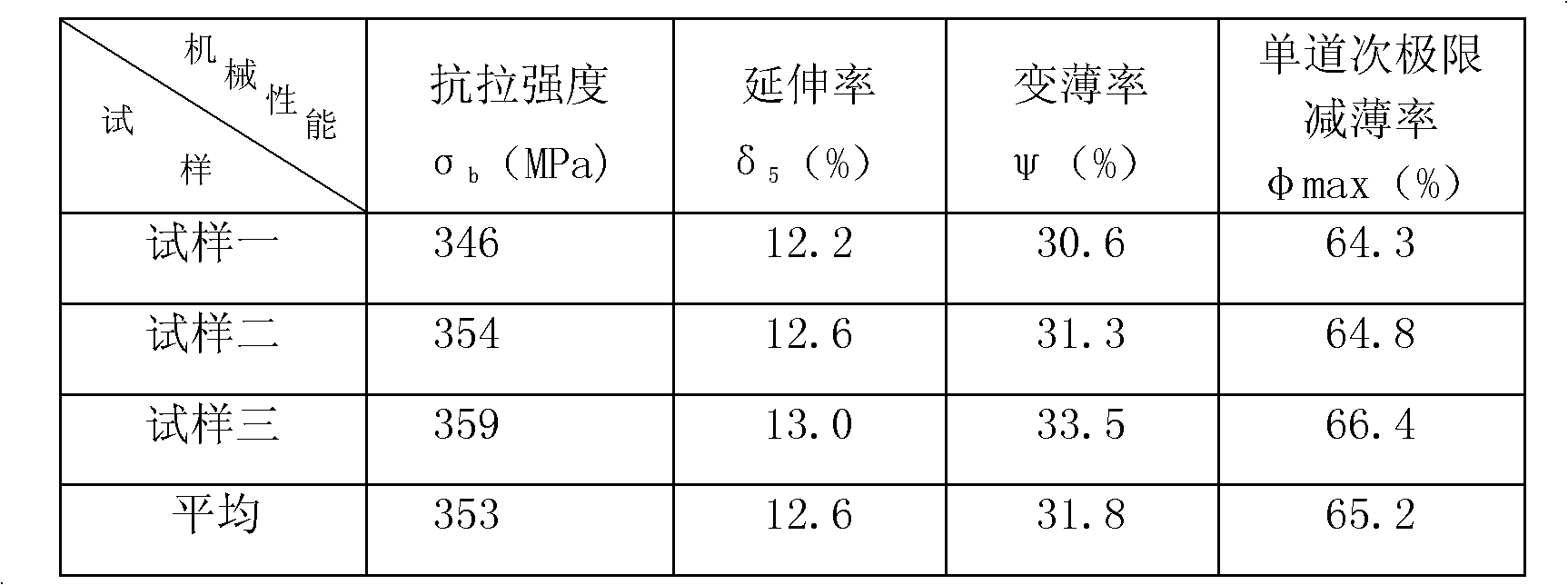

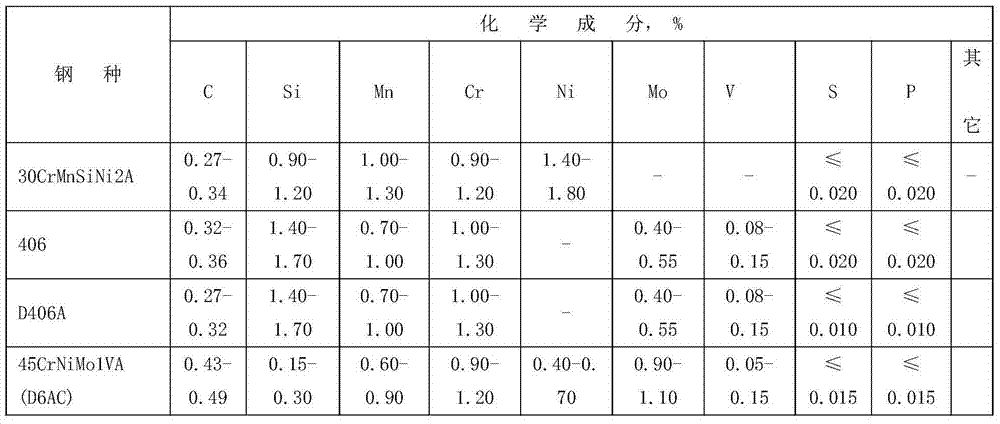

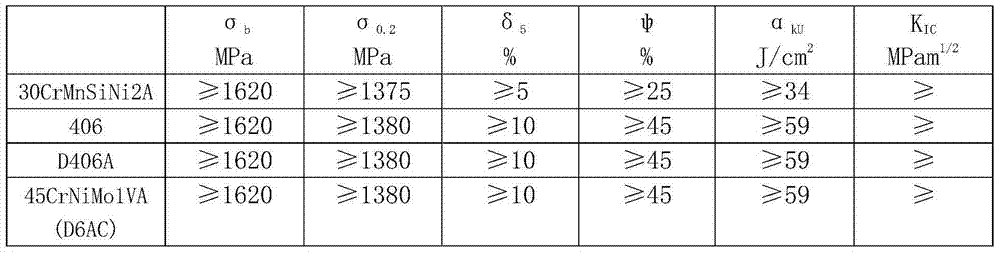

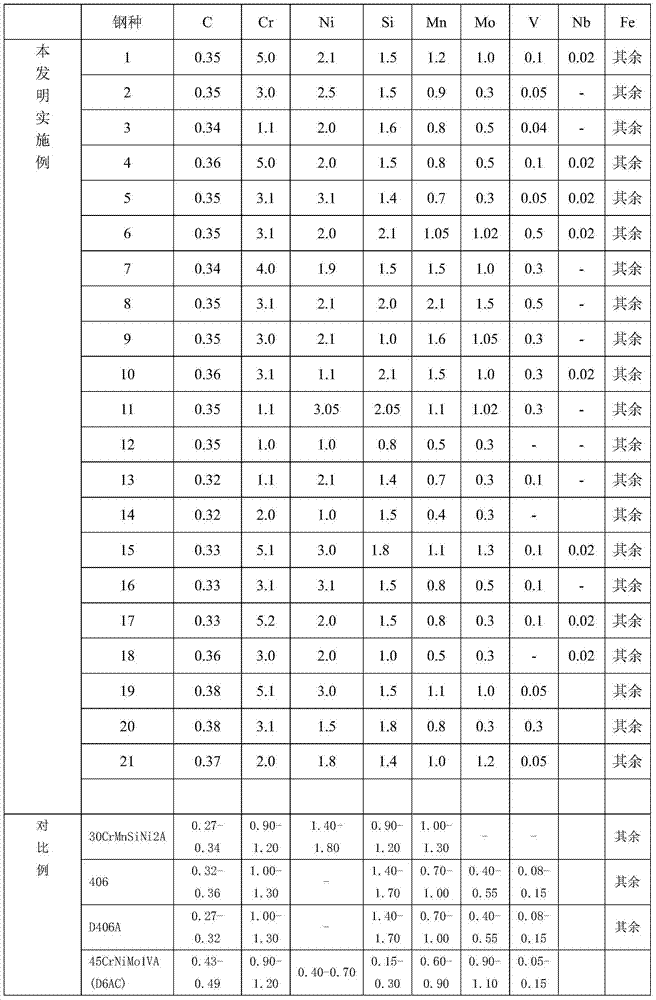

The invention relates to high-toughness ultrahigh-strength D506A steel easy for rotary extrusion and easy to weld and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.32-0.38% of C, 0.50-5.50% of Cr, 0.5-3.5% of Ni, 0.2-2.20% of Si, 0.2-2.2% of Mn, 0.05-1.50% of Mo, 0-0.5% of V, no more than 0.2% of Nb and the balance of Fe and other inevitable impurity elements. Compared with the prior art, the steel has excellent comprehensive performance, high toughness (sigma b>=1800Mpa) and ultrahigh strength (KIC>=90MPam<1 / 2>), and also has excellent weldability, rotary extrusion performance and decarbonization resistance.

Owner:CENT IRON & STEEL RES INST

Al-Mg-Zn aluminum alloy material for aluminum wheel hubs and method for preparing aluminum wheel hub disk

The invention discloses an Al-Mg-Zn aluminum alloy material for aluminum wheel hubs, which comprises 6.0wt%-7.5wt% of Mg, 0.90wt%-1.50wt% of Zn, 0.20wt%-0.70wt% of Mn, 0.05-0.15wt% of Ti, 0.0005wt%-0.005wt% of Be, at most 0.20wt% of Cr, at most 0.20% of Zr, at most 0.10wt% of Cu, at most 0.20wt% of Si, at most 0.30wt% of Fe, and the balance of Al and inevitable impurities. The invention also discloses a method for preparing an Al-Mg-Zn aluminum alloy disk for aluminum wheel hubs. The Al-Mg-Zn aluminum alloy material for aluminum wheel hubs has favorable forging and rotary extrusion properties; and the prepared wheel hub has higher strength and toughness.

Owner:ZHEJIANG GKO IND CO LTD

Automobile crankshaft thickened hub multi-wedge wheel forming technique and tool

The invention discloses an automobile crankshaft thickened hub multi-wedge wheel forming technique and tool. The whole machining process is completed through blanking and punching, shovel spinning formation, stamping formation of arcs and rotary tooth thickening sequentially. A rotary tooth thickening tool for rotary tooth thickening comprises an upper die, a lower die, a positioning core, a cover plate, an unloading plate, an arc rotary wheel, a first pre-spinning wheel, a second pre-spinning wheel and a final formation rotary wheel, wherein the arc rotary wheel, the first pre-spinning wheel, the second pre-spinning wheel and the final formation rotary wheel are used in cooperation sequentially. The automobile crankshaft thickened hub multi-wedge wheel forming technique and tool have the advantages that the machining process is stable, the spinning effect is good, material folding, layering and cracking are not prone to occurring in the forming process, the purpose of integrated formation is achieved, finished products are more stable and firm in structure, and meanwhile the service life is prolonged; and the adopted rotary tooth thickening tool is simple in structure, an obtained pulley groove is smooth in surface and high in precision, the service life of matching belts is prolonged, and meanwhile the production efficiency of products is improved.

Owner:NANTONG FULEDA AUTOMOBILE FITTINGS

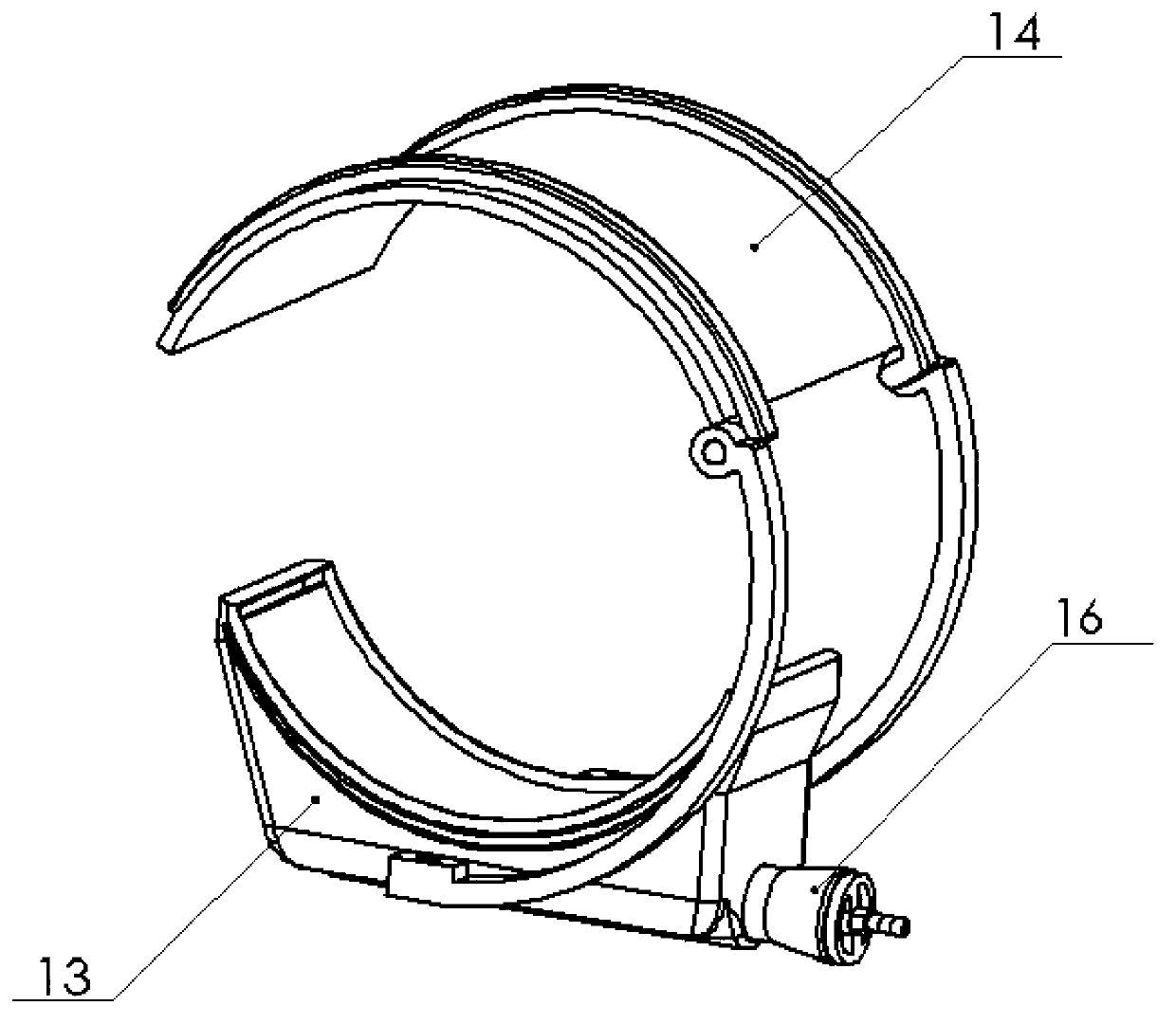

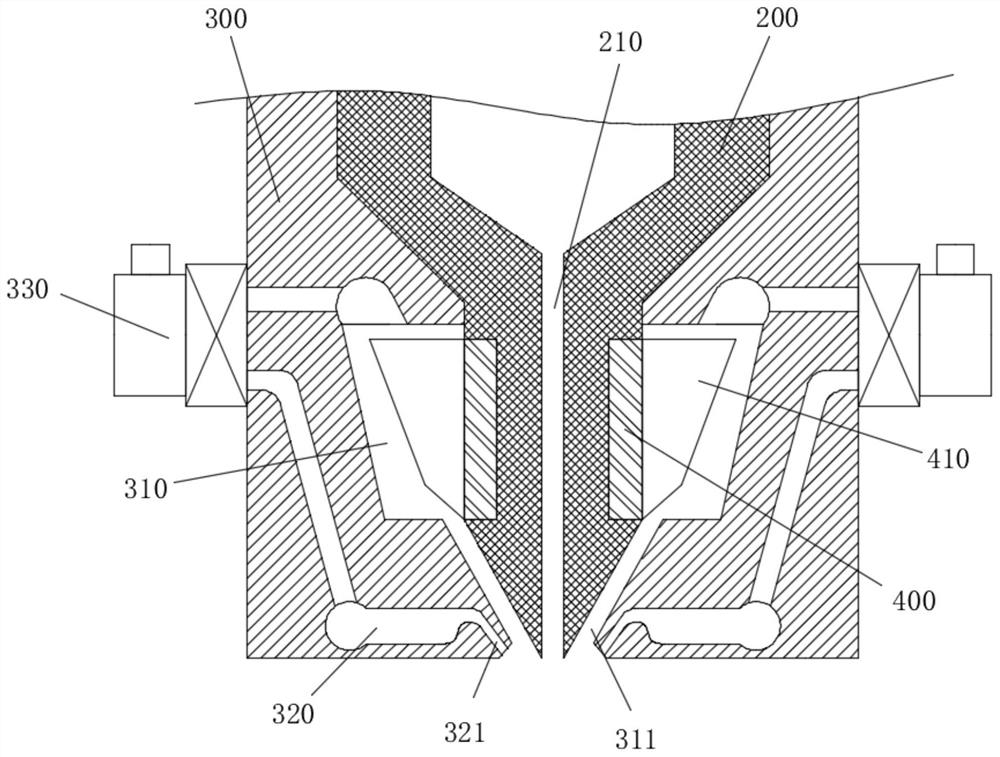

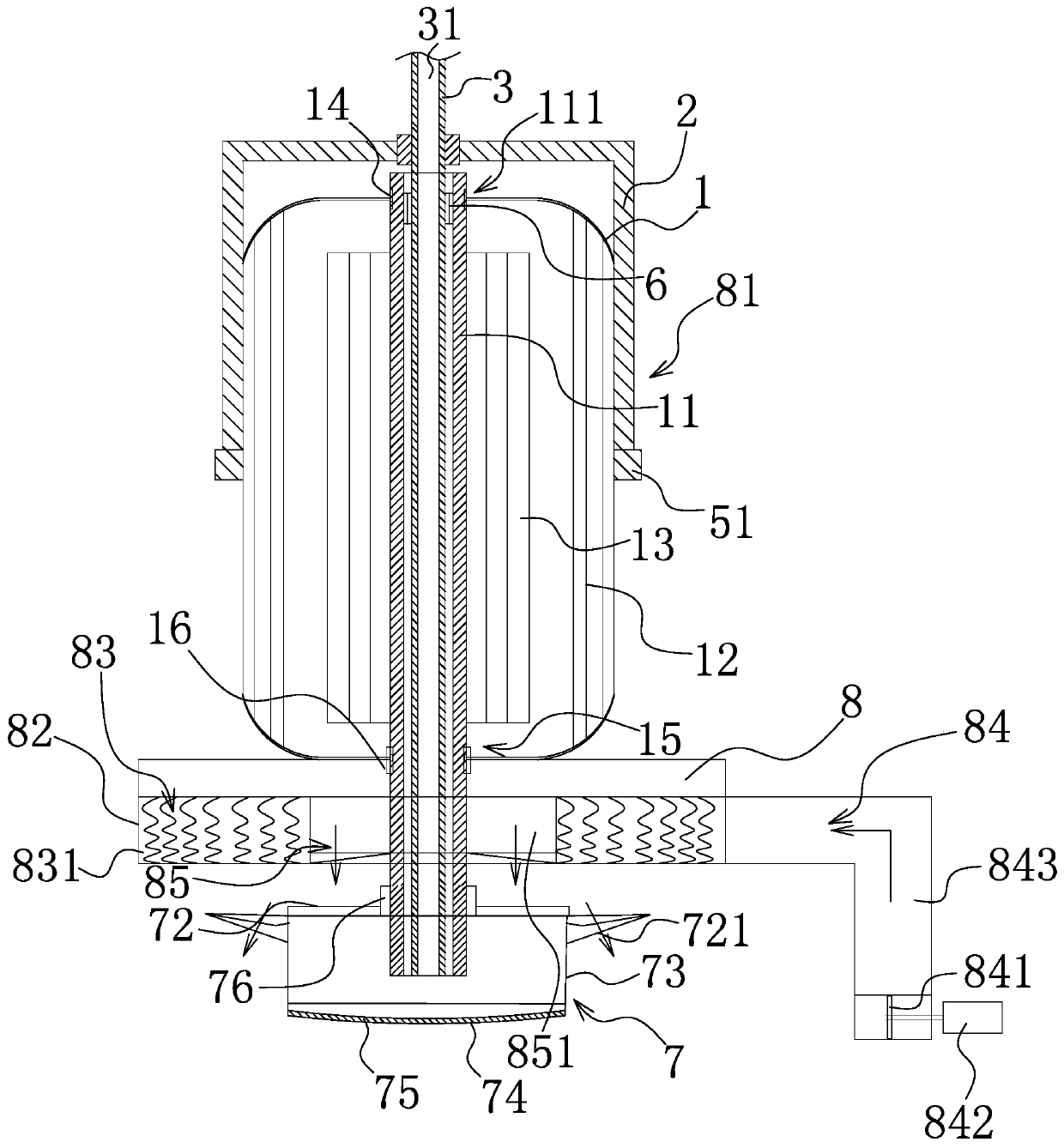

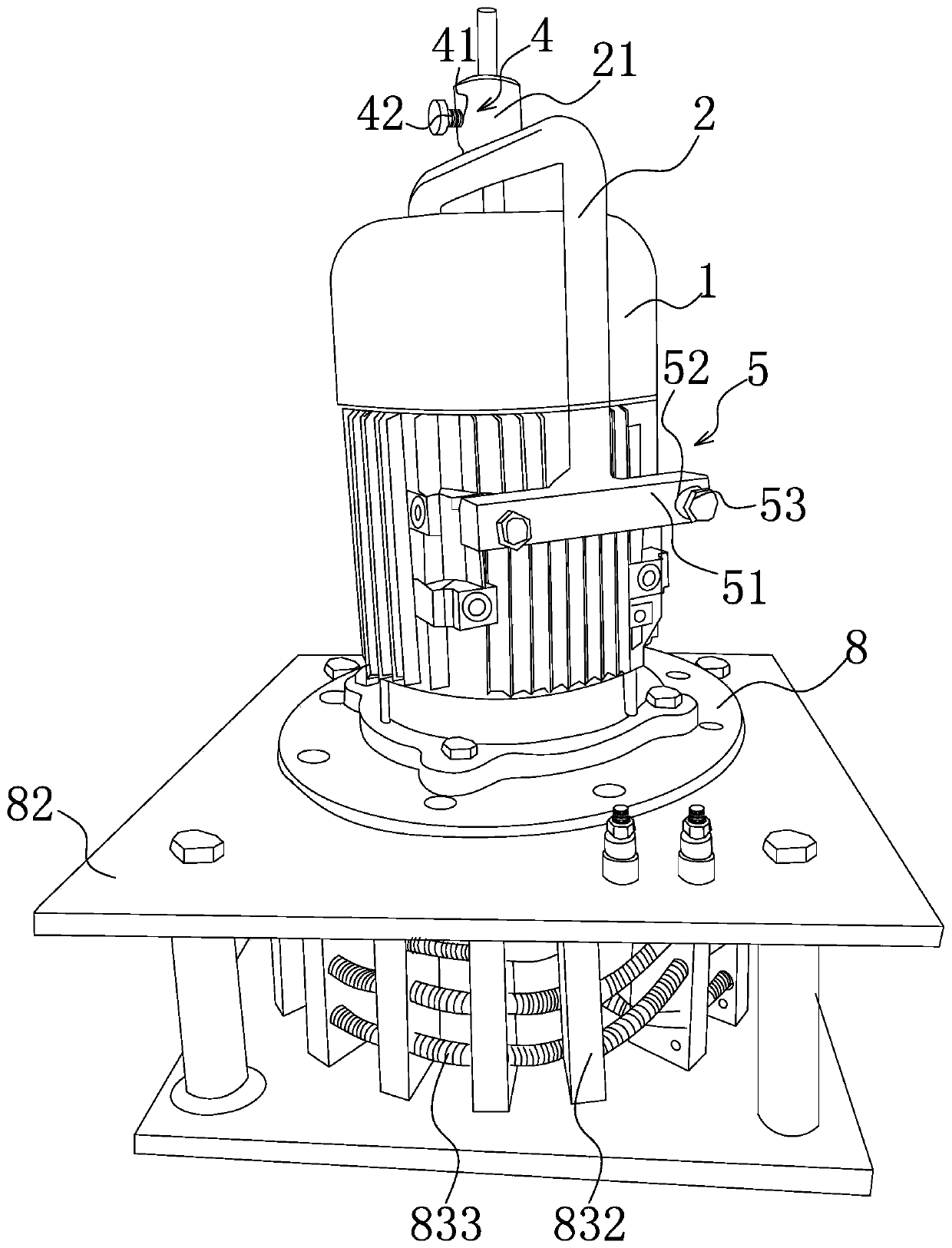

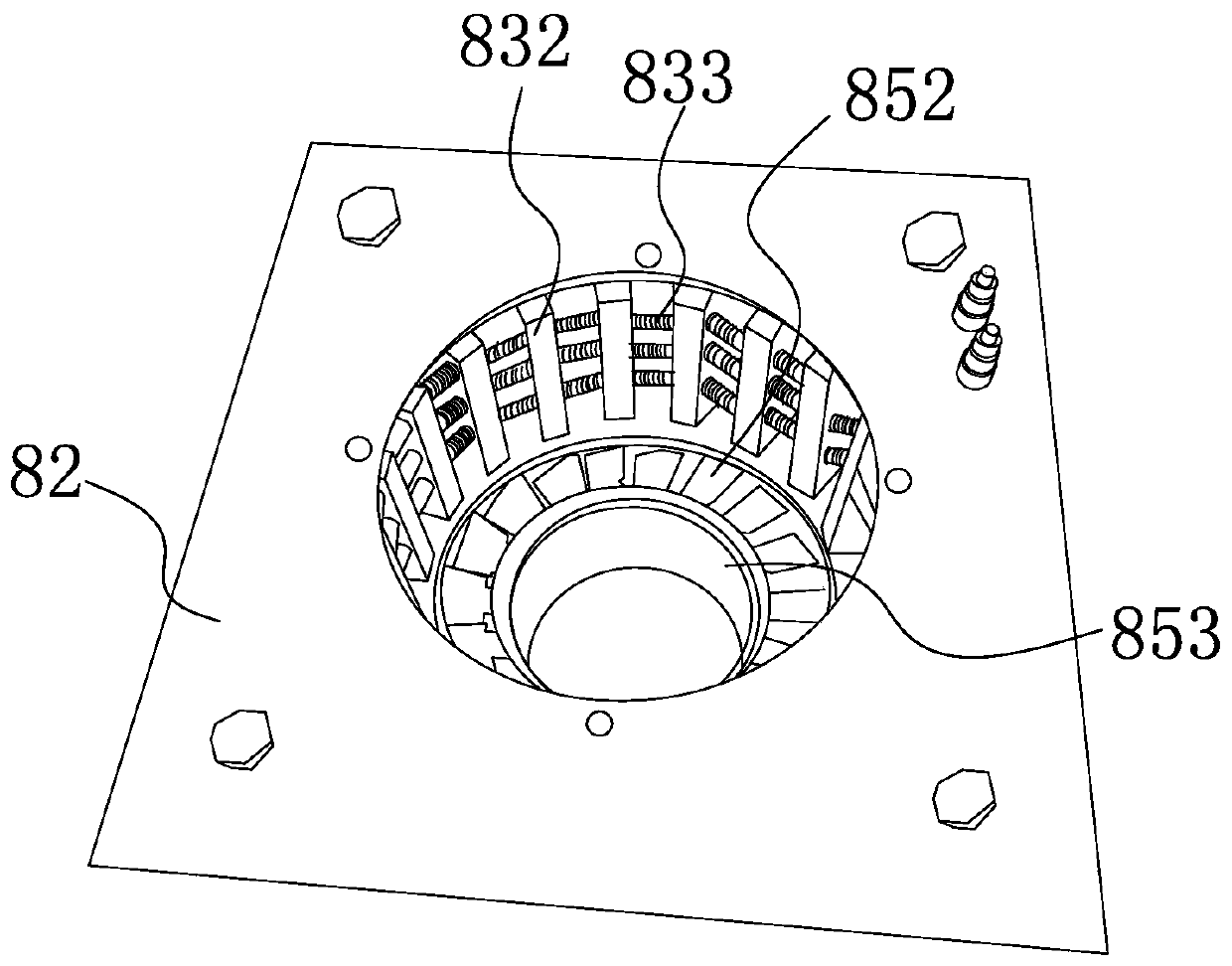

Spinning heating device

ActiveCN103272948ASave energySave time and costShaping toolsGaseous fuel burnerGas heaterEngineering

The invention discloses a spinning heating device which comprises an internal gas heating device and an external heating heat preserving device. The internal gas heating device is arranged inside a spinning mold. The external heating heat preserving device is arranged outside a spinning blank. A main shaft is of a hollow structure. A gas delivery pipe penetrates through the middle of the main shaft to the inner portion of the spinning mold. A three-leaf fire spraying pipe sprays flames to heat the spinning mold so that the spinning blank can be evenly heated. The external heating heat preserving device is composed of an infrared gas heater and a heat preserving cover. According to the spinning heating device, the spinning mold is heated through flames so that temperature of the spinning blank rises, the external heating heat preserving device is used for heat preservation, and therefore spinning force is reduced. The spinning heating device has the advantages of being high in heating speed, capable of saving energy consumption and even in heating.

Owner:SHANGHAI JIAO TONG UNIV

Al-Mg aluminium alloy material for aluminium hub and method for preparing wafer for aluminium hub

The invention discloses an Al-Mg aluminium alloy material for an aluminium hub. The Al-Mg aluminium alloy material for the aluminium hub comprises 7.0-8.0wt% of Mg, 0.40-0.80wt% of Mn, 0.04-0.10wt% of Ti, not greater than 0.15wt% of Cr, not greater than 0.20wt% of Zr, not greater than 0.10wt% of Cu, not greater than 0.10wt% of Zn, not greater than 0.20wt% of Si, not greater than 0.30wt% of Fe, and the balance of Al and inevitable impurities. The invention further discloses a method for preparing an Al-Mg aluminium alloy wafer for the aluminium hub. The Al-Mg aluminium alloy wafer material prepared by the method disclosed by the invention is applied to aluminium alloy hub forging, and capable of realizing the effects of avoiding upsetting and reducing forging times; meanwhile, the Al-Mg aluminium alloy material adopted in the method disclosed by the invention is aluminium alloy which cannot be subjected to heat treatment reinforcement, and the prepared aluminium alloy does not need high-temperature long-time solid solution and aging treatment, so that a production process for the aluminium alloy hub is simplified, the production efficiency is increased, and the energy consumption is reduced.

Owner:ZHEJIANG GKO IND CO LTD

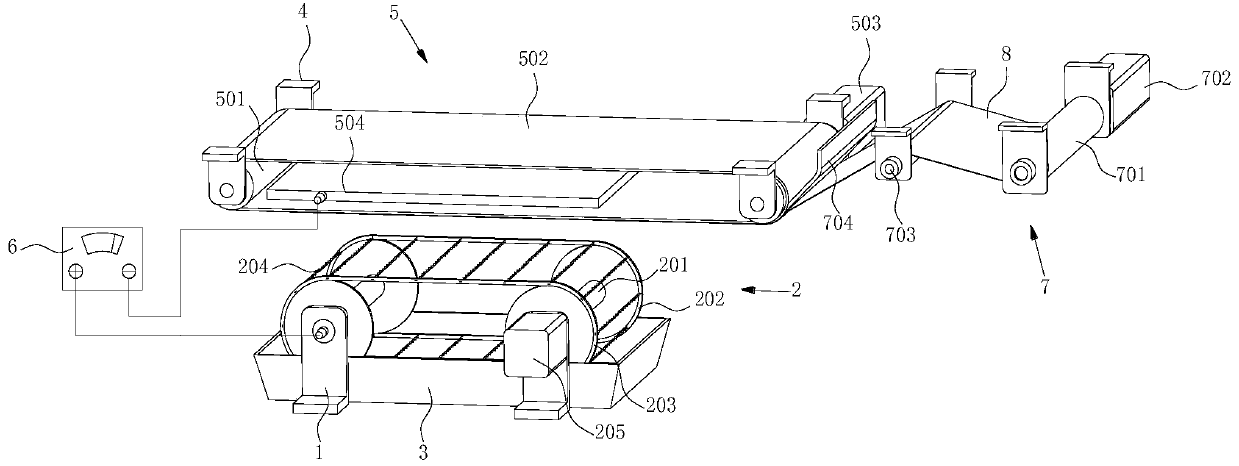

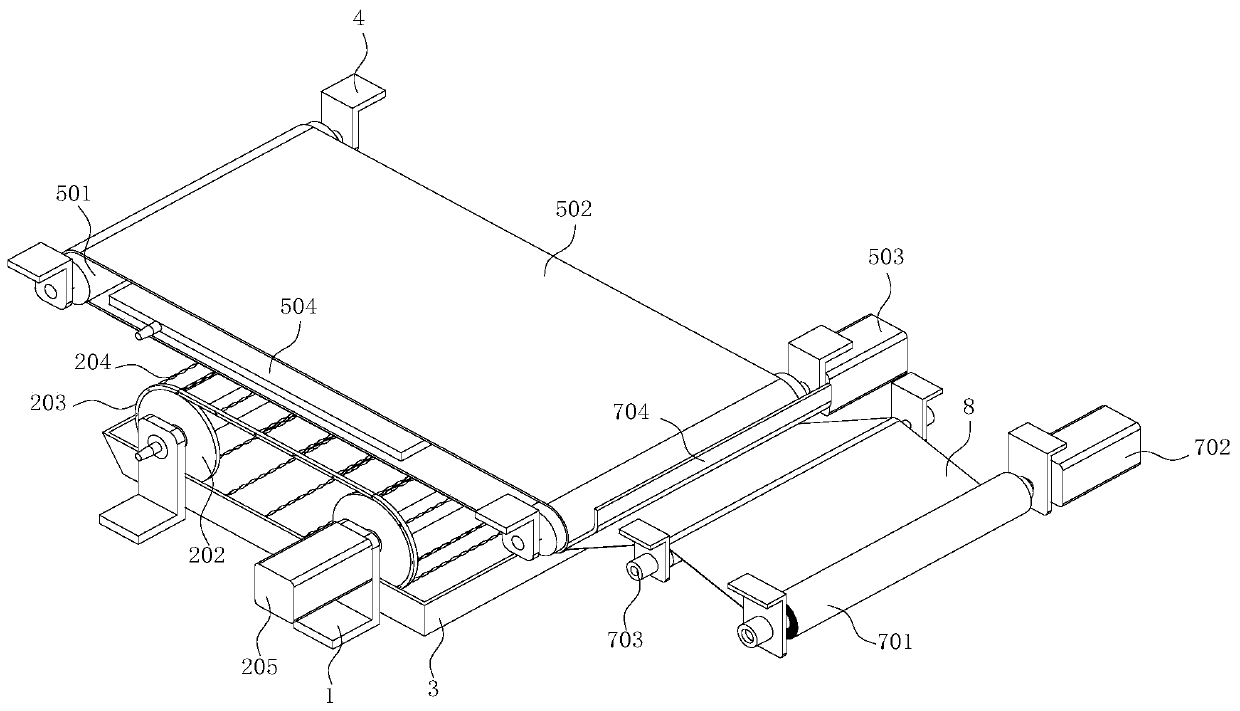

Needleless electrostatic spinning device

InactiveCN109695063AGood spinning effectMeet the requirements of different use casesFilament/thread formingState of artElectrospinning

The invention discloses a needleless electrostatic spinning device, belongs to the technical field of electrostatic spinning and aims at solving the problems that needle heads are easy to block, the quantity of needle heads is limited, the uniformity is poor and a feeding system is complex in the prior art. The needleless electrostatic spinning device comprises a first rack, an emitting device arranged on the first rack, a solution tank arranged below the emitting device, a second rack, a receiving and transmitting device arranged on the second rack, a high-voltage power supply connected between the emitting device and the receiving device and a collecting device matched with the receiving and transmitting device, wherein the emitting device comprises two planes which do vertically-opposite cyclic motion; the solution tank enables the lower plane of the emitting device to be infiltrated therein; the upper and the lower planes of the receiving and transmitting device are oppositely arranged; the collecting device is used for collecting obtained spinning products. The needleless electrostatic spinning device disclosed by the invention has the advantages of simple structure and good continuity; the problems that the needle heads are easy to block, the quantity of the needle heads is limited, the uniformity is poor and the feeding system is complex are solved.

Owner:JILIN AGRICULTURAL UNIV

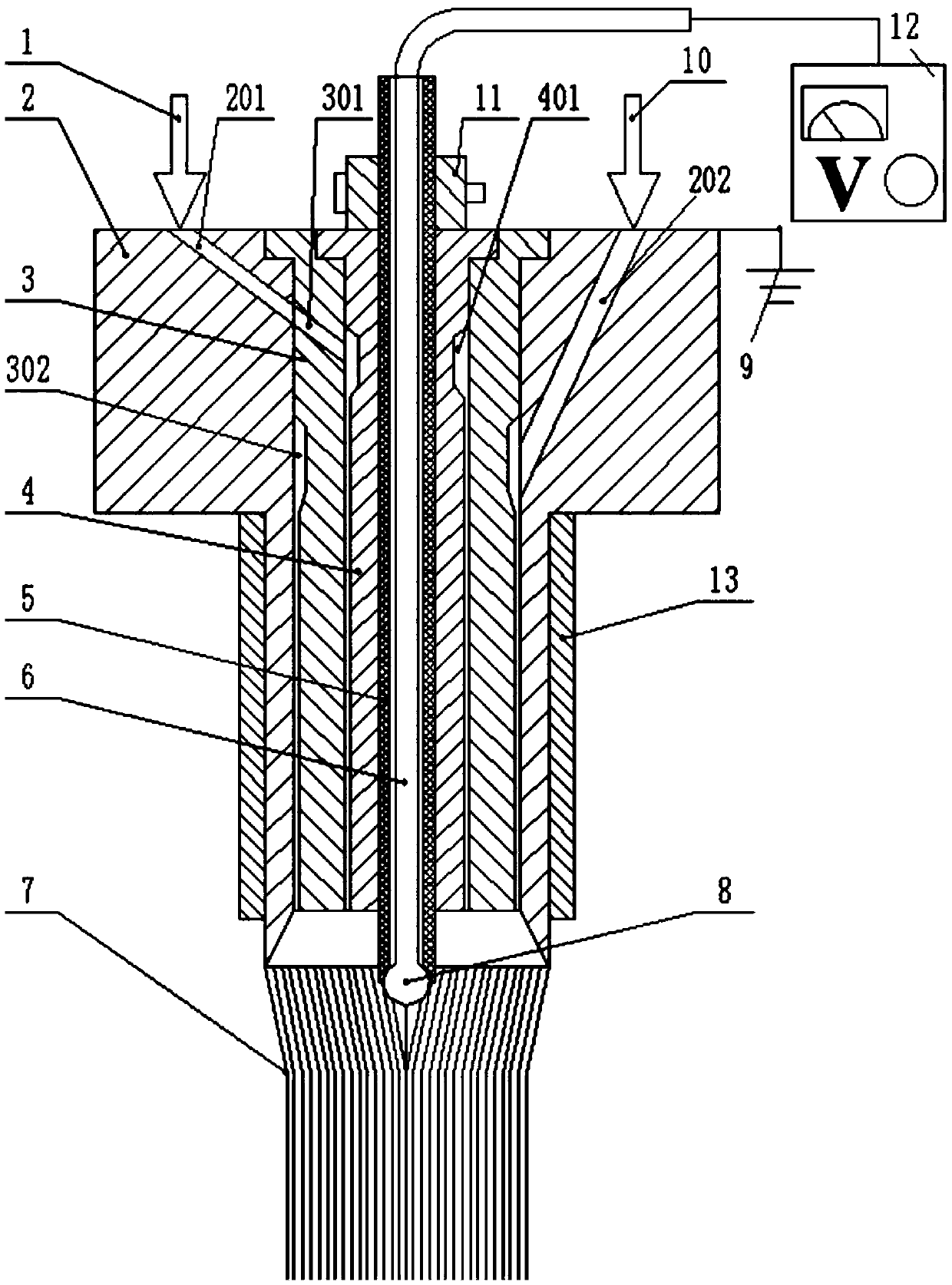

Central point electrode electrostatic spinning device and spinning method

ActiveCN109594135ALift restrictionsAchieve deposition sprayingFilament/thread formingElectricityFiber

The invention discloses a central point electrode electrostatic spinning device and spinning method. The upper part of a second sleeve is fixedly connected with the upper part of a first sleeve; the upper part of a third sleeve is fixedly connected with the upper part of the second sleeve; a straight flow passage I and a straight flow passage II are arranged on the first sleeve; a straight flow passage III is arranged on the second sleeve; one end of the straight flow passage III is communicated with the straight flow passage I; the other end of the straight flow passage III is communicated with a ring-shaped flow passage II; the straight flow passage II is communicated with a ring-shaped flow passage I; an insulating bushing is arranged inside the third sleeve; a wire is arranged inside the insulating bushing; the lower end of the wire is connected with a small metal ball; a locking clamping sleeve is arranged at the upper end of the insulating bushing and clamps the insulating bushing; the wire is connected with a high-voltage electrostatic generator; the first sleeve is connected with a grounding electrode; a heating ring is coated outside the first sleeve. The central point electrode electrostatic spinning device and spinning method have the beneficial effect that fiber deposition spraying on a random object surface can be implemented.

Owner:QINGDAO UNIV OF SCI & TECH

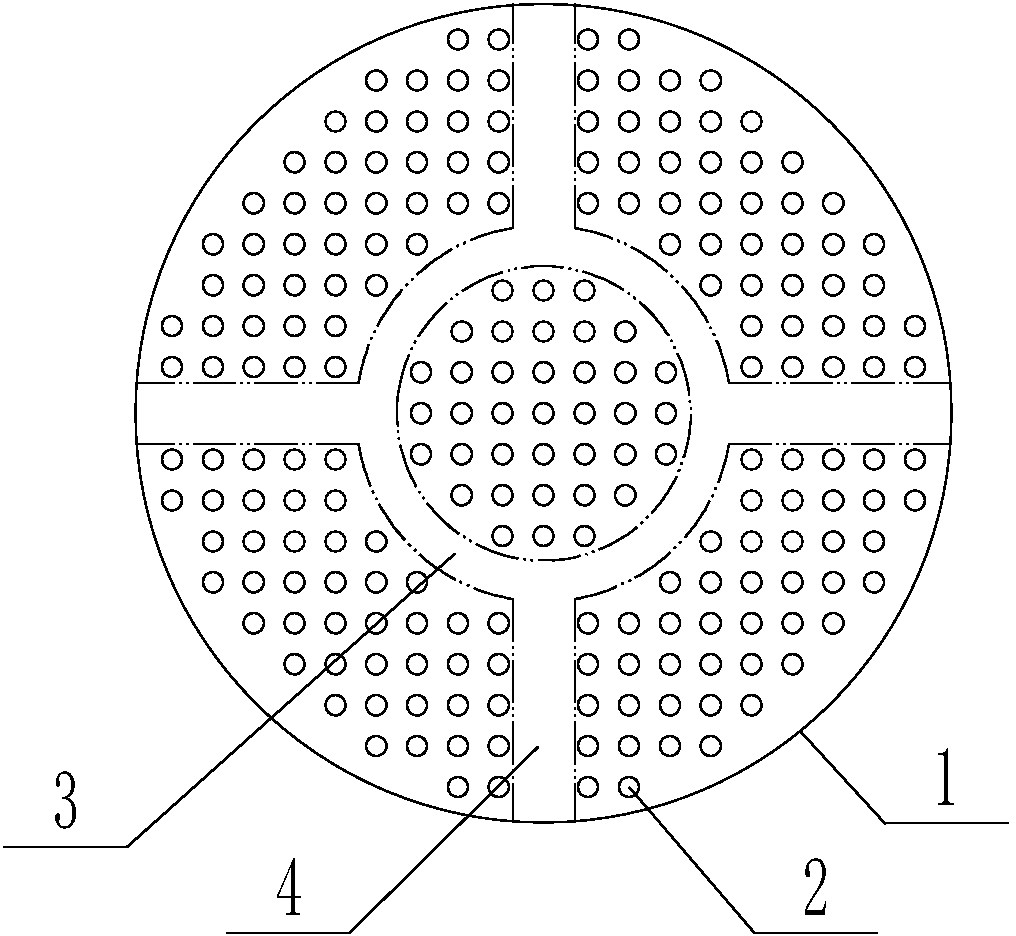

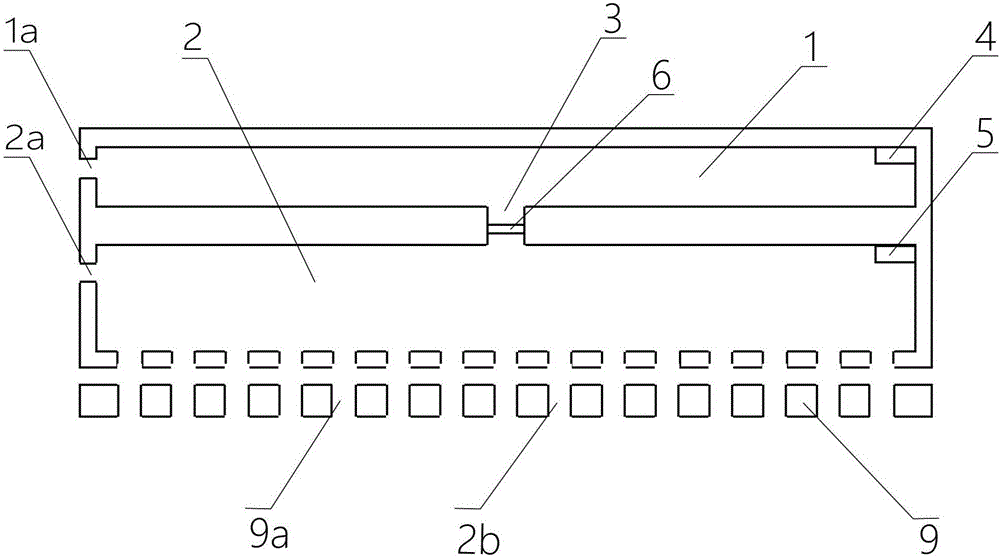

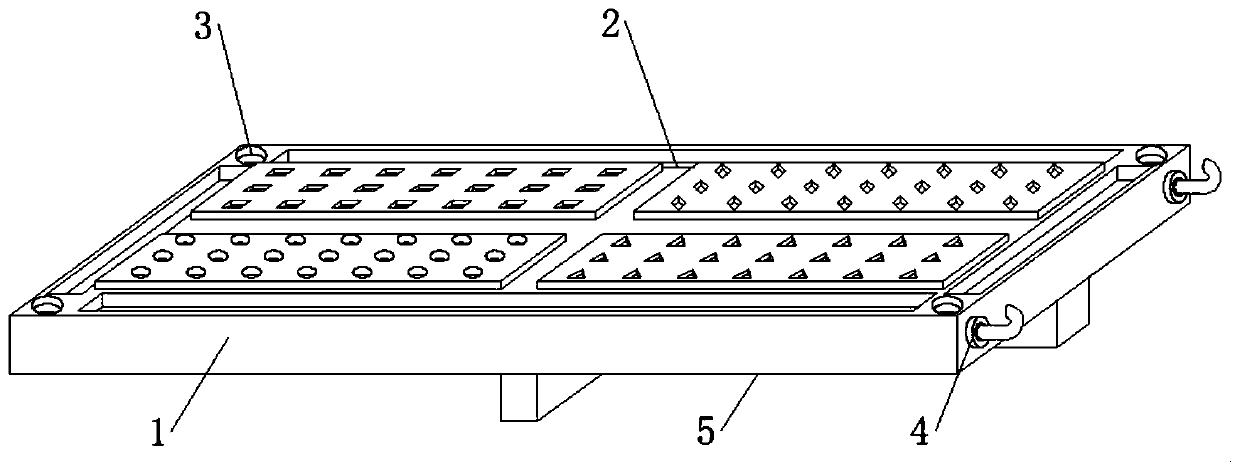

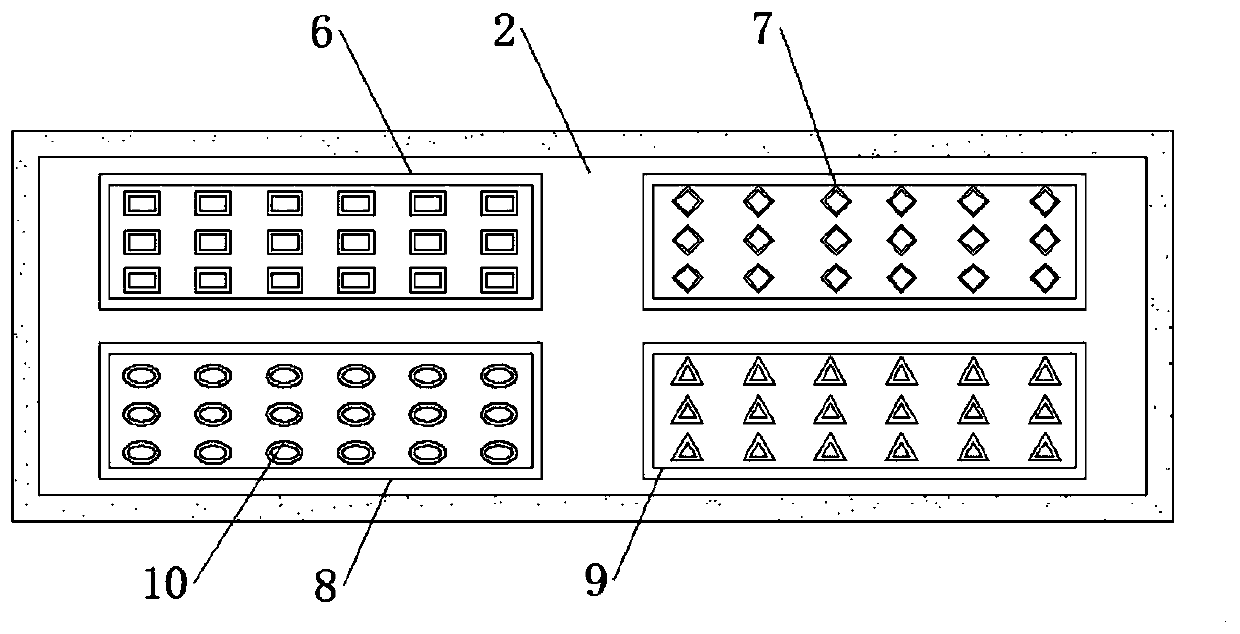

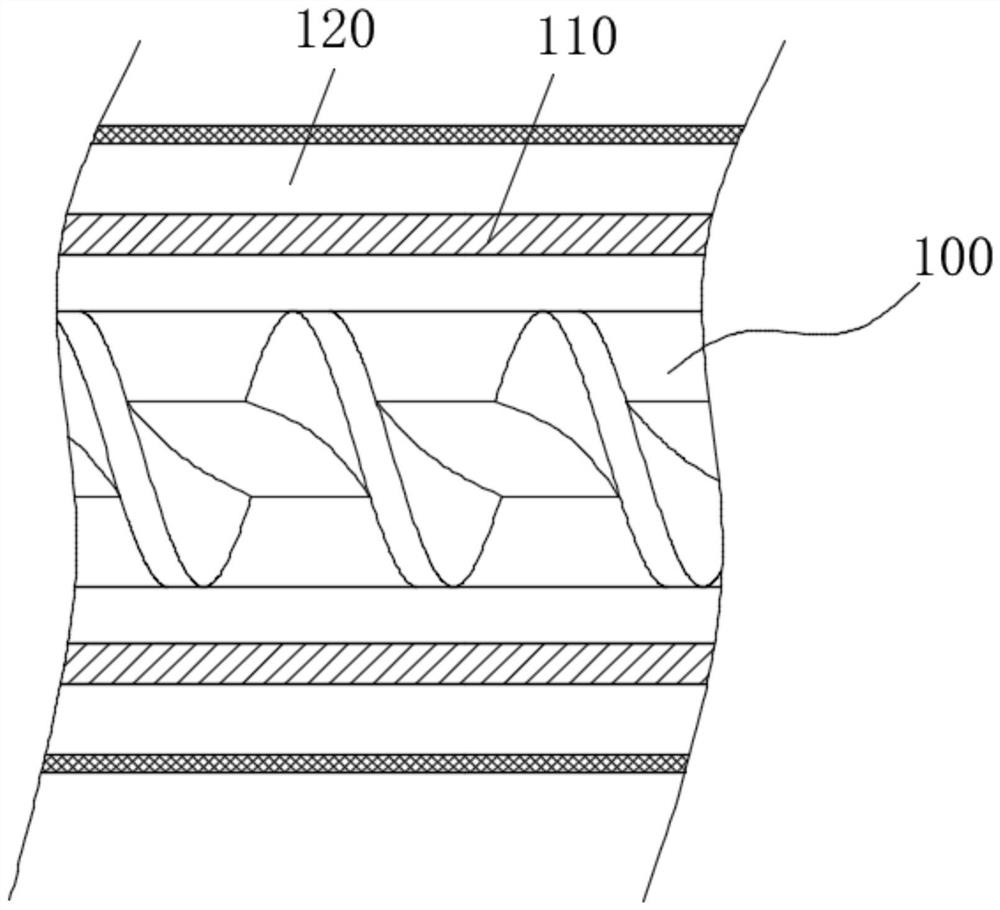

Spinneret plate

InactiveCN103290490AStable crystallinityStable pre-orientationSpinnerette packsEngineeringCrystallinity

The invention relates to a spinneret plate which comprises a spinneret plate body. Spinneret holes are formed in the spinneret plate body, an annular ventilation duct taking the center of the spinneret plate as the center of a circle is arranged on the spinneret plate body, at least one linear ventilation duct is further arranged on the spinneret plate body, and one ends of the linear ventilation ducts are communicated with the annular ventilation ducts while the other ends of the same are communicated with the outside of the spinneret plate body. By the spinneret plate, high-temperature melt sprayed by the spinneret plate can be within a set time period and on a certain spinning line and can be all uniformly cooled to meet process requirements and form stable pre-stretching threads with certain crystallinity and pre-orienting degree, so that spinning effect is better.

Owner:ZHANGJIAGANG ZANXIN SPECIAL FIBER

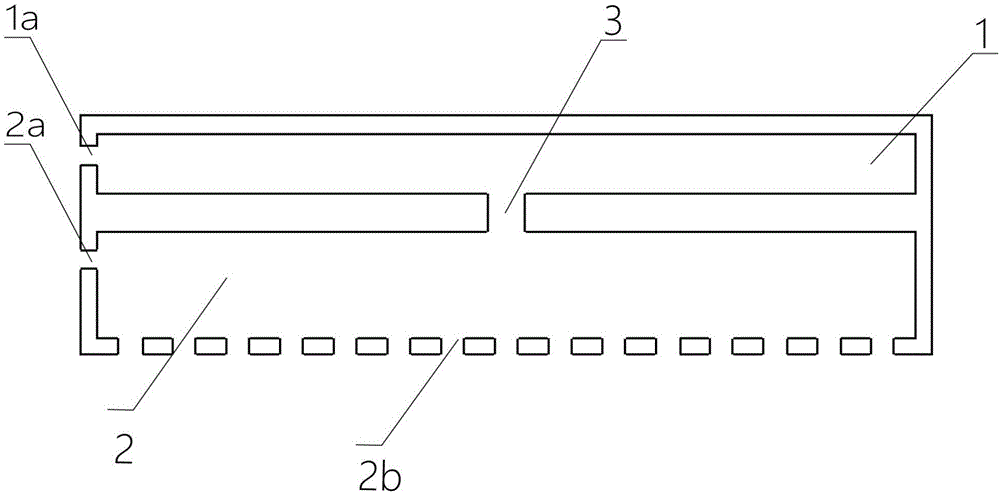

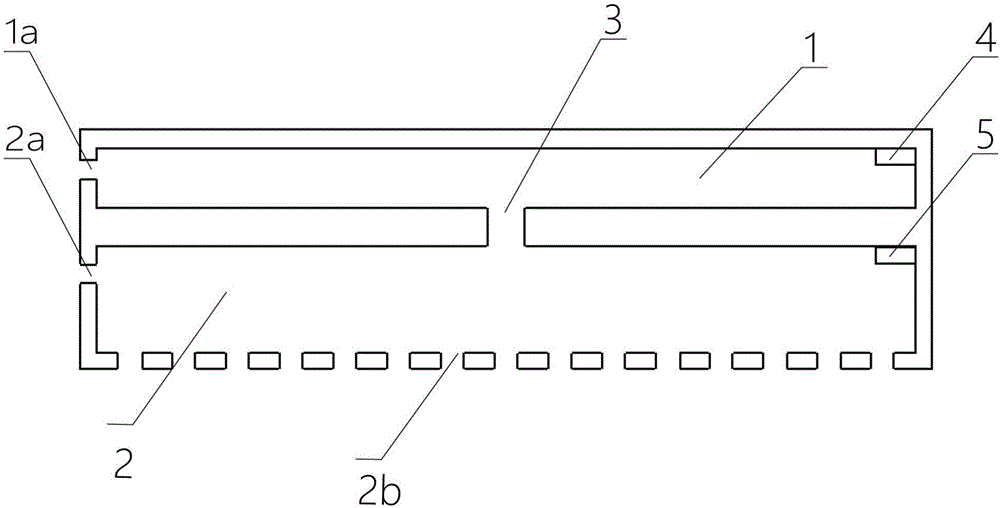

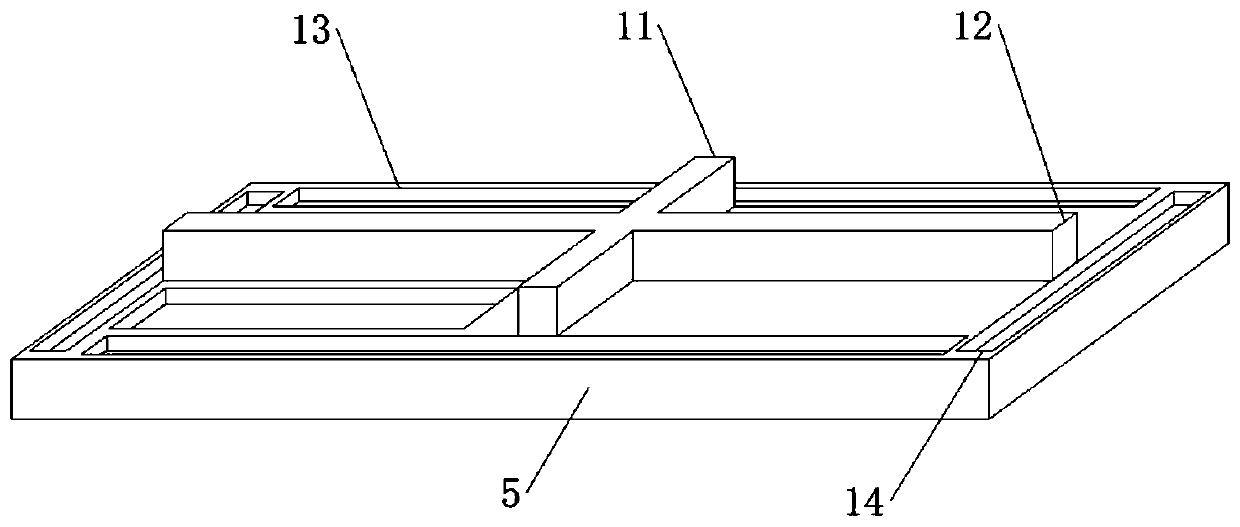

Spinneret plate and spinneret mechanism

InactiveCN106702505AEasy to replaceSpinning is uniform enoughFilament/thread formingElectrospinningEngineering

The invention relates to the field of spinning equipment and discloses a spinneret plate and a spinneret mechanism. The spinneret plate and the spinneret mechanism are used in electrostatic spinning equipment. The spinneret plate comprises a body, the body is internally provided with two layers of cavities from top to bottom, the cavities include the gas cavity and the liquid cavity, a gas inlet is formed in the gas cavity, and a liquid inlet is formed in the liquid cavity. The gas cavity and the liquid cavity are connected through a one-way channel, and the liquid cavity is communicated with a spinneret hole in the bottom of the body; spinneret liquid enters the liquid cavity from the liquid inlet, and gas enters the gas cavity from the gas inlet, enters the liquid cavity through the one-way channel and pushes the spinneret liquid to be sprayed out from the spinneret hole. The spinneret mechanism provided with the spinneret plate has the advantages of being low in cost and convenient to detach.

Owner:SHANGHAI UNIV OF ENG SCI

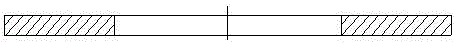

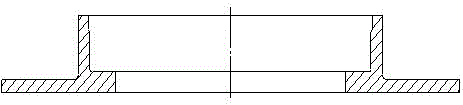

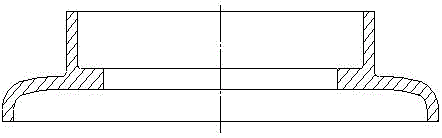

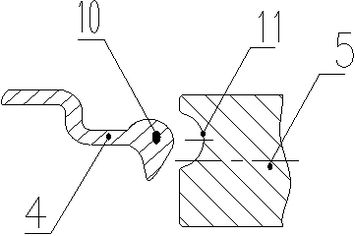

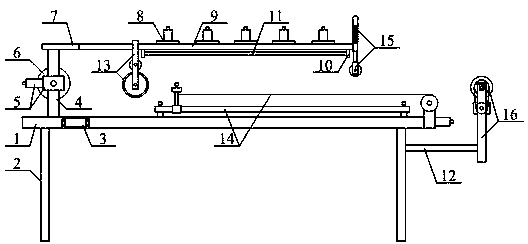

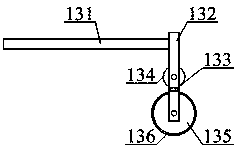

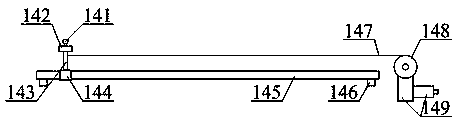

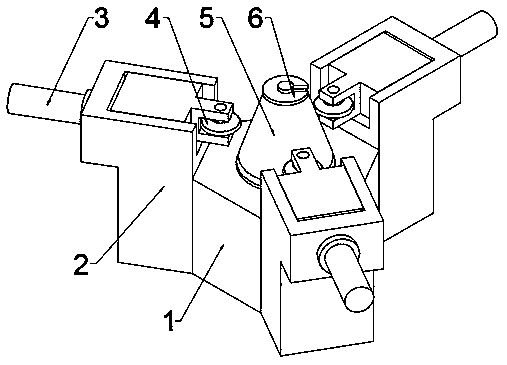

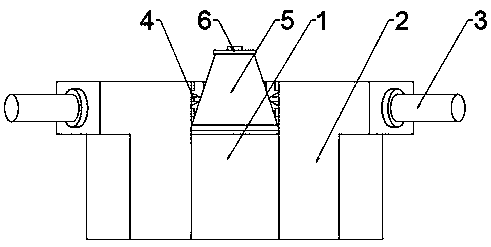

Rotary pressing tooling for manufacturing asymmetric T-shaped rotary pressing belt wheels

InactiveCN102672039ANot easy to foldNot prone to delaminationShaping toolsEngineeringForming processes

The invention relates to a rotary pressing tooling for manufacturing asymmetric T-shaped rotary pressing belt wheels. An upper core mold and a lower core mold are arranged on rotary pressing equipment, a T-shaped thickening rotary wheel, a flat rotary wheel, a preforming tooth rotary wheel and a final forming tooth rotary wheel are respectively arranged on respective rotary wheel shafts, each rotary wheel and the upper and lower core molds are in corresponding arrangement, the work surface of the T-shaped thickening rotary wheel is provided with a groove, and the groove corresponds to a plate material tightly clamped by the upper core mold and the lower core mold. Materials are regulated to uniformly flow towards two sides according to proportions through the contact area between the circular arc of the groove and the material, the material flowing speed is also limited by the groove, the extrusion on the materials is also enhanced in the stack rotation process, the compactness is realized, the cracking and delamination possibilities are reduced, and the forming stability is improved. The flat rotary wheel is mainly used for continuously pushing distributed materials until the inner walls at two T-shaped sides are fully pasted with the upper core mold and the lower core mold through feeding. The rotary pressing tooling has the advantages that the processing process is stable, the rotary pressing effect is good, and conditions of folding, delamination and fracture of the materials cannot occur in the forming process.

Owner:东风襄阳旋压技术有限公司

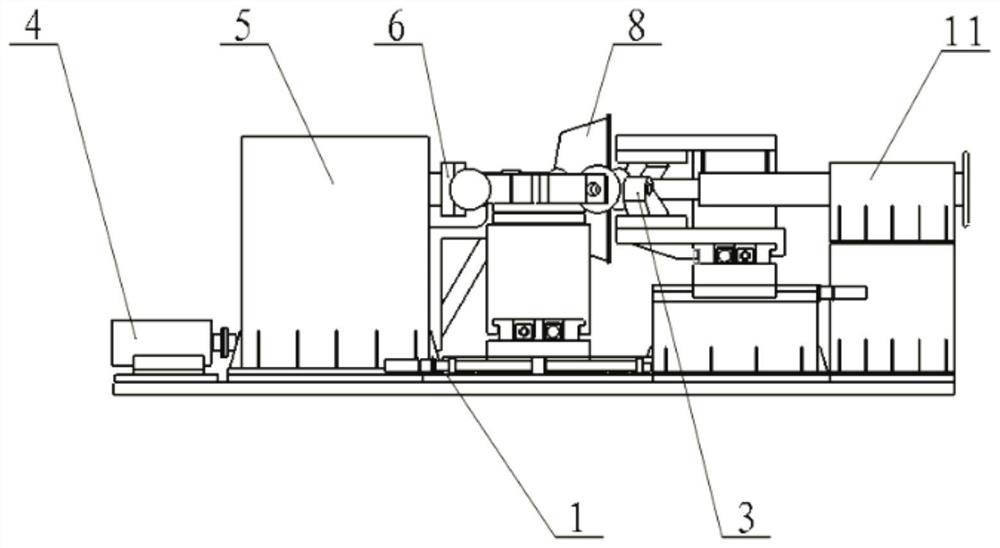

Chemical fiber drawing equipment for textile production

InactiveCN111424355AGuaranteed spinning effectSpinning works smoothlyFilament handlingFibre cleaning/openingElectric machineryTextile production

The invention provides chemical fiber drawing equipment for textile production. The chemical fiber drawing equipment comprises a rack, a stand leg, a control machine, a machine base, a fiber releasingmotor, a fiber releasing wheel, a cross beam, a radiating fan, a radiating frame, a pipe base, a cooling pipe, a connecting seat, a heatable fiber drawing cleaning wheel guiding structure, a fast fiber drawing traction moving machine structure and a buffering type tensioning and guiding conveying wheel structure. According to the chemical fiber drawing equipment, through arranging a mounting base, a support seat, a temperature detection sensor, a heating guiding wheel, a guiding cleaning wheel and a dust cleaning sheet, fiber drawing is favorably guided and cleaned; when the fiber releasing motor drives the fiber releasing wheel to rotate to release fiber, cleaning guiding operation between the heating guiding wheel and the guiding cleaning wheel can be carried out; the dust cleaning sheet can clean dust; at the same time, through fiber heating of the heating guiding wheel, the fire drawing effect is ensured; and the temperature detection sensor can detect the temperature in real timeto ensure smooth fiber drawing operation.

Owner:曹学民

Low base weight high-strength food grade unbleached waxing raw paper

ActiveCN105019297AReduce absorptionReduce air permeabilityWater-repelling agents additionReinforcing agents additionBursting strengthToxic material

The invention relates to a low base weight high-strength food grade unbleached waxing raw paper. The base weight of the waxing raw paper is 20-25g / m<2>, the tightness is 0.7-0.8g / m<2>, the opacity is 60-65%, the air permeability is 0.4-0.5micrometer / Pa.s, the vertical and horizontal tearing strength is 130-140mN, the bursting strength is 85-100KPa, the evenness is 900-925, and the vertical and horizontal average fracture length is 5-8Km. The slurry adopted by the waxing raw paper comprises, by weight, 47-60 parts of softwood pulp, 36-48 parts of hardwood pulp, and 4-6 parts of china clay. The food grade unbleached waxing raw paper provided by the invention has the advantages of low base weight, high strength, high evenness, low absorption, low air permeability and certain opacity, the adopted wood pulp raw materials are not bleached and are not added with fluorescent agent or other toxic ingredients. The obtained waxing raw paper is safe and non-toxic, the production waste liquor has no toxic substance emission. Therefore, the low base weight high-strength food grade unbleached waxing raw paper is in line with the requirements of safety and environmental protection.

Owner:浙江佳维康特种纸有限公司

Vertical spinning machine for tank of cement tanker

InactiveCN110170563AImprove mechanical propertiesEnables a solderless processHollow articlesManufacturing cost reductionAgricultural engineering

The invention discloses a vertical spinning machine for a tank of a cement tanker, and relates to the spinning machine. The vertical spinning machine for the tank of the cement tanker comprises a rack, wherein spinning devices are uniformly distributed on the side surface of the rack and are up-and-down slidably connected to the side surface of the rack; spinning wheels are slidably connected above the spinning devices through hydraulic rods; the movement directions of the hydraulic rods face the middle of the rack; and a fixing mechanism is connected to the inner side of the rack through rotating a drive mechanism. More welding quality problems for traditional tank manufacturing exist, the flaw detection program is complex, and the overall weight problem is hard to solve. Through spinningmanufacturing, a non-welding process of a tank bottom component can be realized, the overall quality is good, light-weight manufacturing can be realized, the manufacturing cost is reduced, and an effective load is increased. Through spinning manufacturing, a mechanical performance of the tank is improved; and a grain structure of a material is changed through spinning, so that the mechanical strength is improved. The vertical spinning machine for the tank of the cement tanker provided by the invention adopts three vertical type rollers for multi-pass spinning so as to be applicable to spinning workpieces in different sizes; and the rollers are hydraulic driven so as to be sufficient in power and good in spinning effect.

Owner:山东京华智能装备有限公司

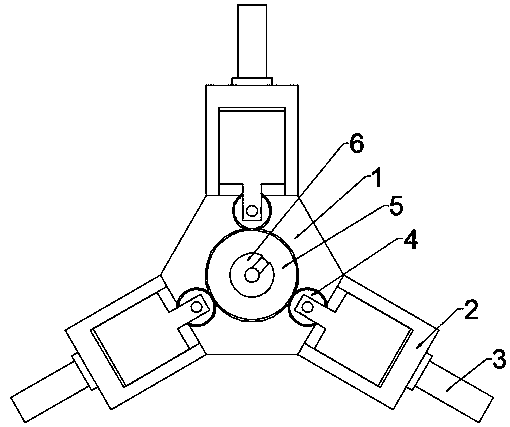

Rotating cutter wheel control structure of rod rolling machine of wheel hub

PendingCN110153261AIncrease freedomIngenious structural designMetal-working apparatusMotor driveBall screw

The invention discloses a rotating cutter wheel control structure of a rod rolling machine of a wheel hub. The rotating cutter wheel control structure comprises a fixed support, a movable support, a first ball screw pair, a second ball screw pair, a first motor, a second motor, a rotating cutter wheel support, a first chain wheel shaft, a second chain wheel shaft and a chain. According to the rotating cutter wheel control structure, the structure is ingenious and reasonable in design, during machining, the second motor drives the chain to run through the second ball screw pair, then the firstchain wheel shaft is driven to rotate, so that the purpose of driving the rotating cutter wheel support to rotate by an angle is achieved, a free shaft is added compared with a traditional spinning machine of the wheel hub, a freedom degree of the spinning machine of the wheel hub is increased, and functions of the rod rolling machine of the wheel hub are expanded, and the rod rolling machine of the wheel hub can be applied to more complex curved surface machining; moreover, the rotating angle can be accurately and effectively controlled through the first motor, the operation is easy, the machining precision is high, the spinning effect is effectively improved, and the product quality is guaranteed; and in addition, the overall structure is compact, the working stability is good, the abrasion is not easy, the service life is long, and wide popularization and application are facilitated.

Owner:江西鼎力旋压装备有限公司

Manufacturing method of high-strength automobile aluminum-alloy rim material

The invention relates to a manufacturing method of a high-strength automobile aluminum-alloy rim material, which relates to a manufacturing method of automobile fitting materials. The manufacturing method comprises the following steps of: preparing materials; smelting; adding a refiner; adjusting components; refining; casting; quenching; carrying out aging treatment; and packaging to prepare the high-strength automobile aluminum-alloy rim material which comprises 0.4-0.8 percent of Si, 0.8-1.2 percent of Mg, 0.16-0.22 percent of Ti, 0.2-0.3 percent of Zn, 0.6-0.8 percent of Fe, 0.15-0.4 percent of Cu, 0.08-0.32 percent of Cr, 0.1-0.2 percent of Mn, 0.02-0.06 percent of RE rare earth, 0.02-0.06 percent of Zr, 0.02-0.06 percent of Sr and the balance of Al. The invention has reasonable process parameter and simple manufacturing method, and the manufactured aluminum-alloy rim material has the advantages of high strength, good mechanical performance and the like and is suitable for being popularized and used in small, medium and large automobiles.

Owner:卢森锴

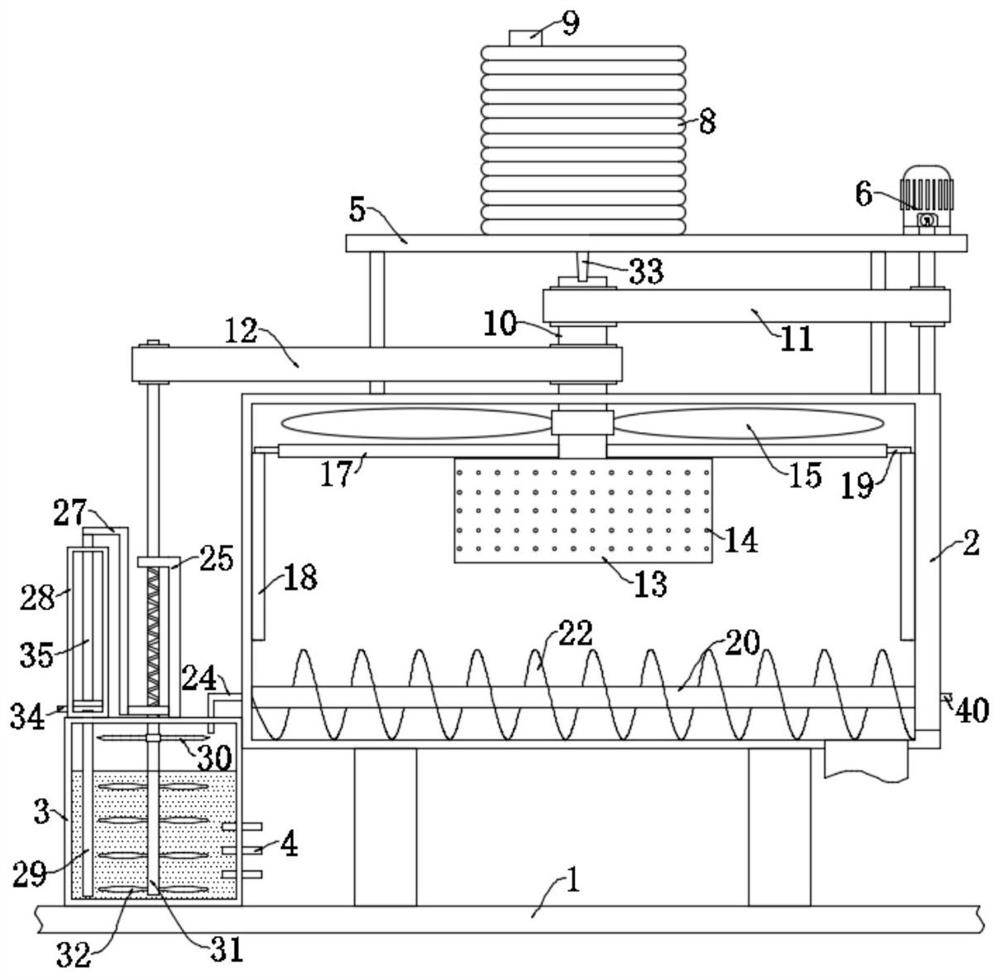

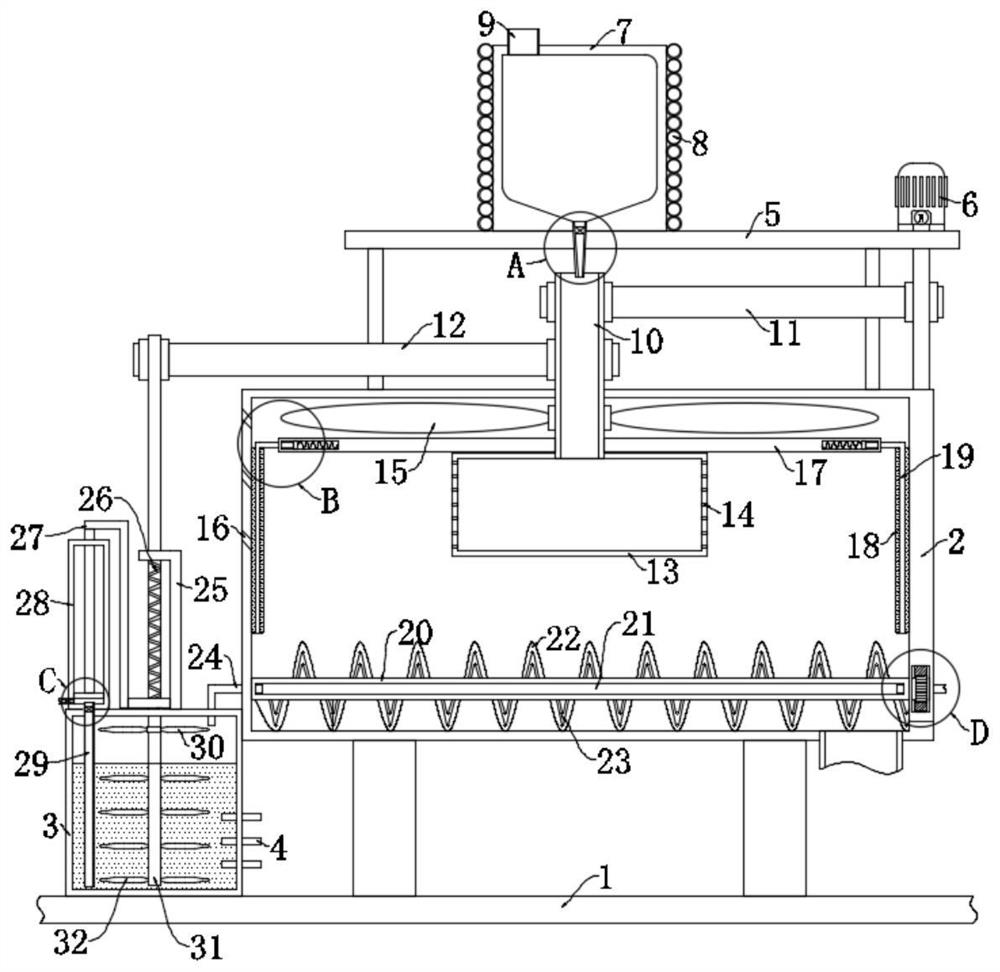

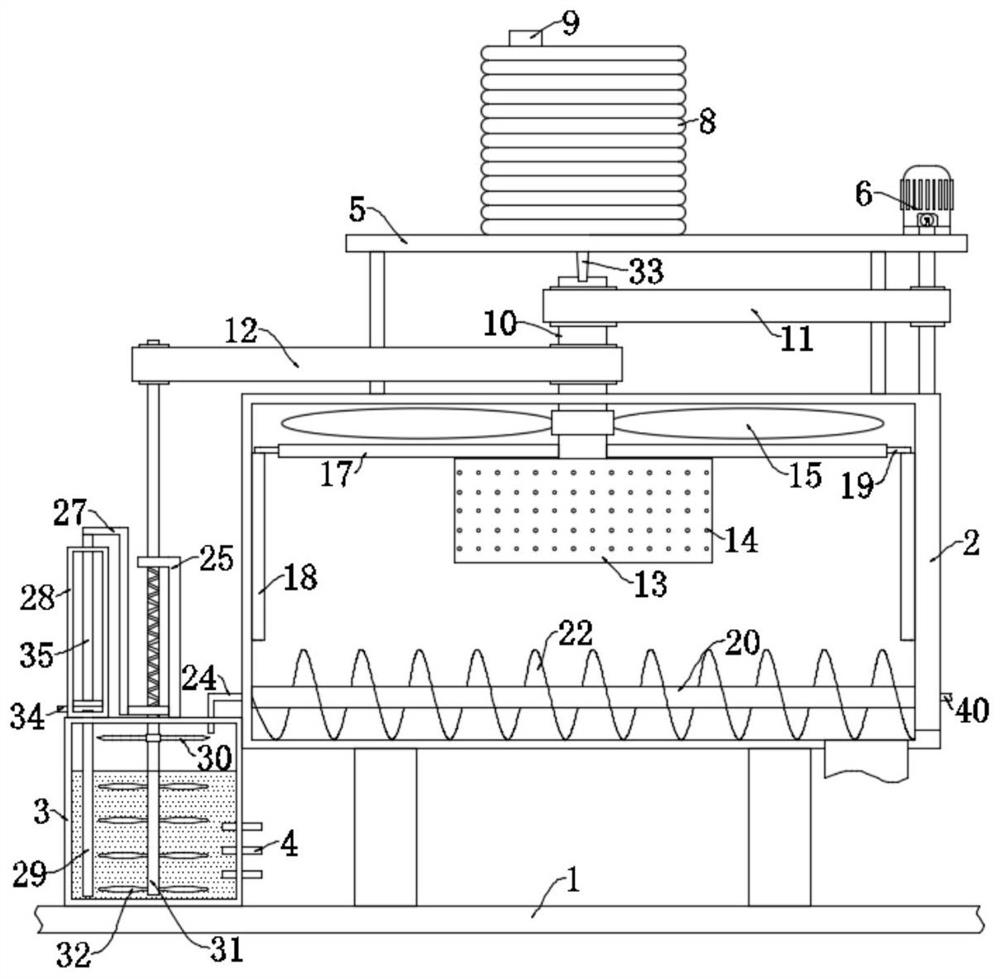

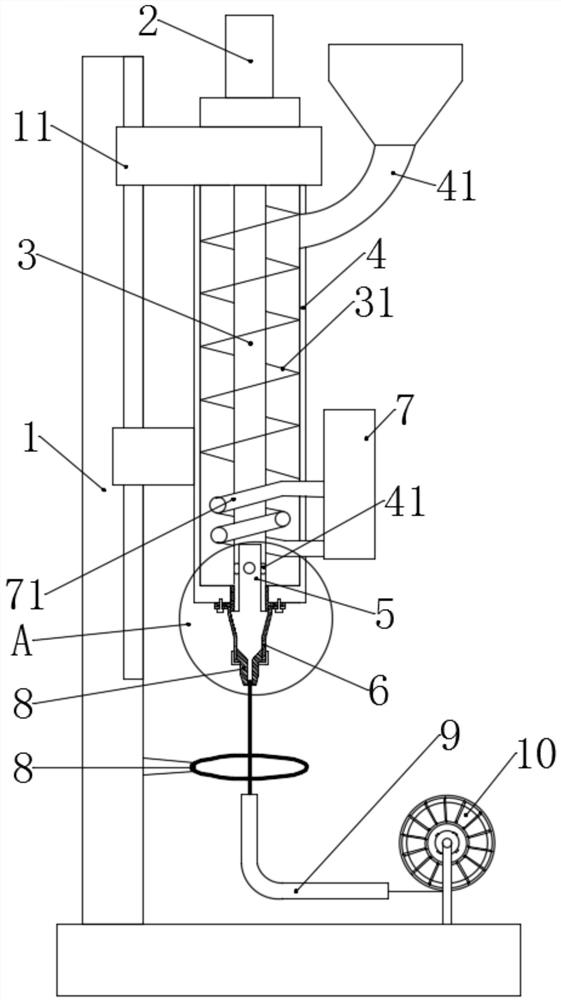

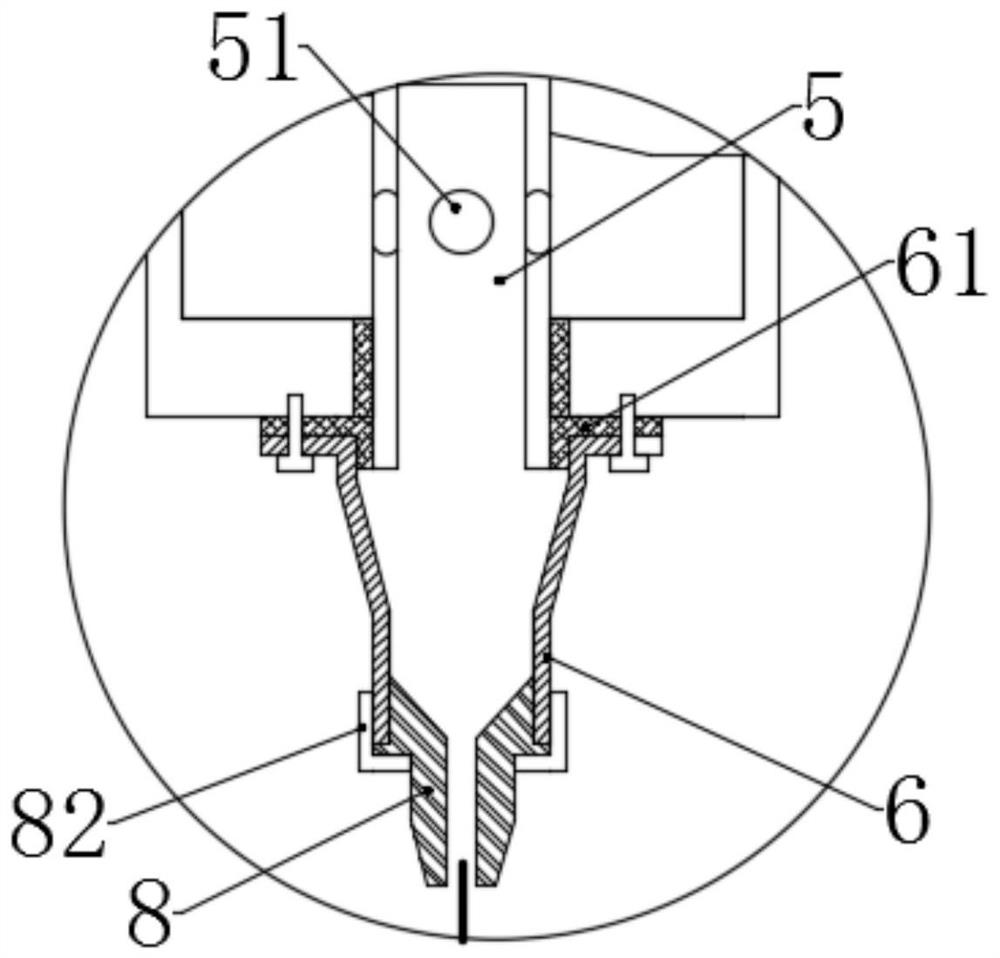

A spinning machine for polycrystalline mullite fiber

ActiveCN112481718BImprove stabilityIncrease temperatureSpinnerette packsInorganic material artificial filamentsEngineeringPhysics

The invention discloses a polycrystalline mullite fiber spinning machine, which comprises a base, a spinning box is fixedly connected to the base through a plurality of supporting legs, a water tank is fixedly connected to the base, and the spinning box A hollow shaft is rotatably connected, and the lower end of the hollow shaft is provided with a spinning mechanism for realizing spinning. The spinning box is fixedly connected with a mounting plate through a support rod. A feeding mechanism for materials is required. Two connecting rods are fixedly connected to the hollow shaft. The connecting rods are provided with a cleaning mechanism for cleaning the inner wall of the spinning box. The spinning box is provided with a discharge port. The spinning box is provided with a conveying mechanism for moving the thrown fiber to the outlet, and the conveying mechanism is provided with a cooling mechanism for cooling the fiber. The invention has the advantages of reasonable structure, good spinning effect, quick cooling, rapid prototyping and resource saving.

Owner:湖州博星科技有限公司

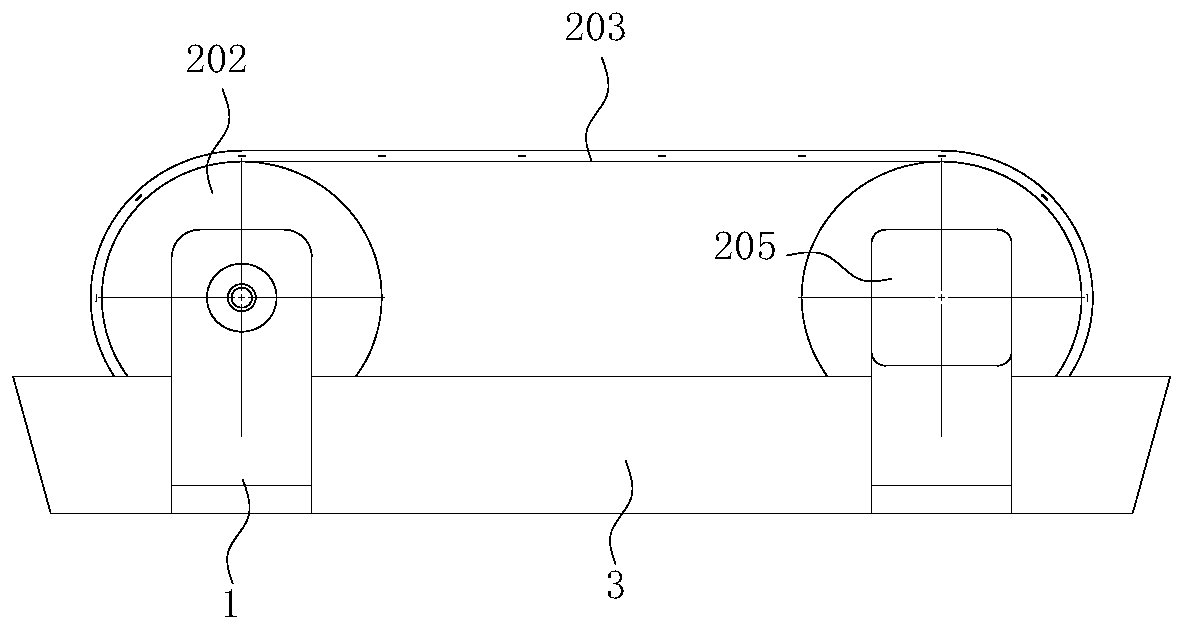

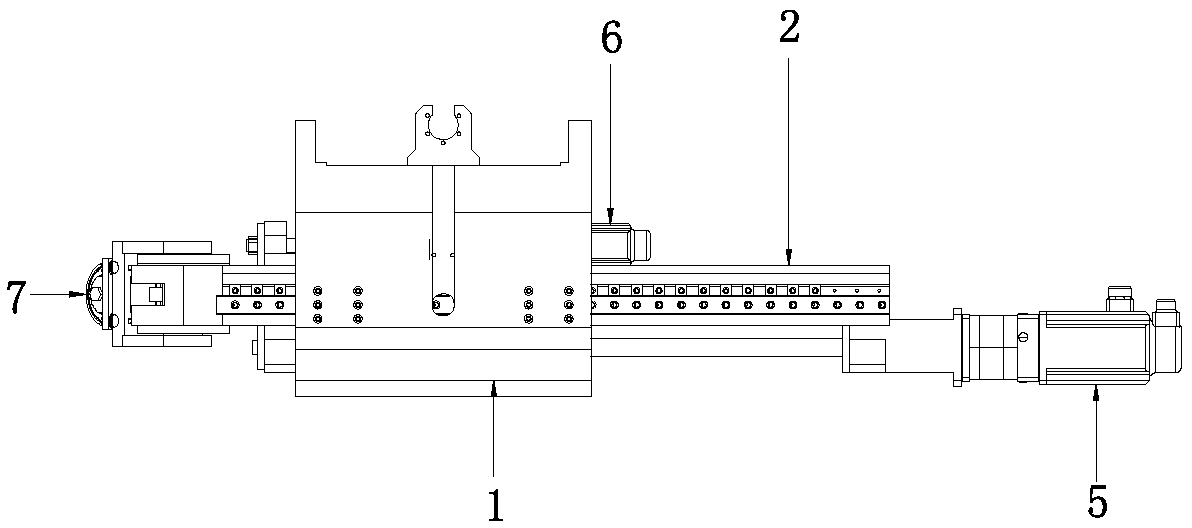

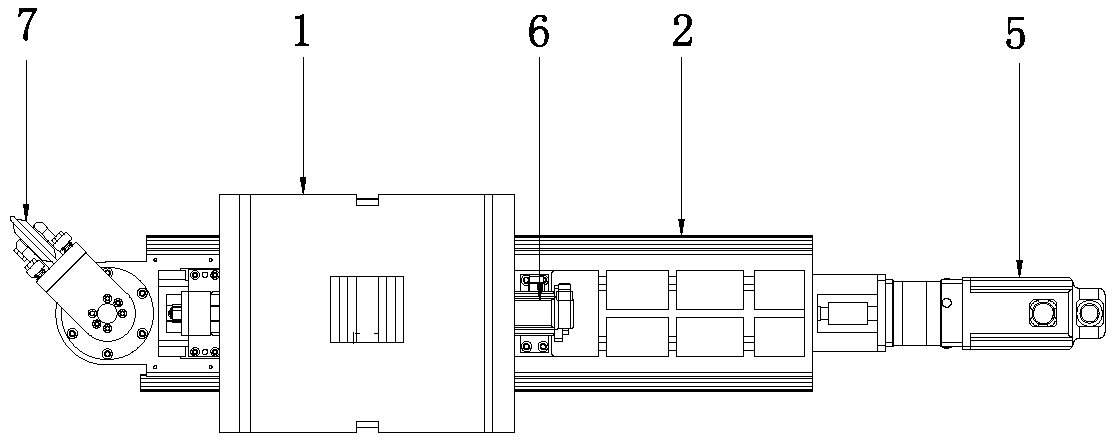

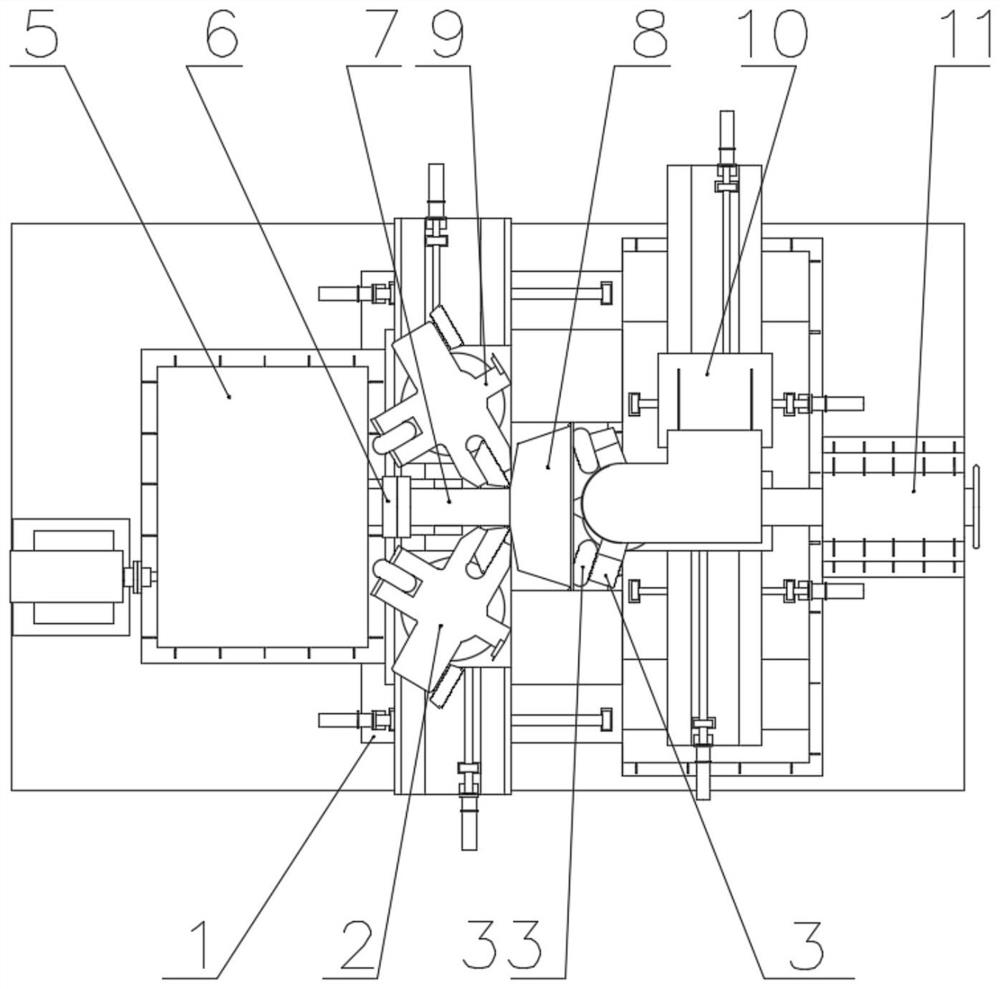

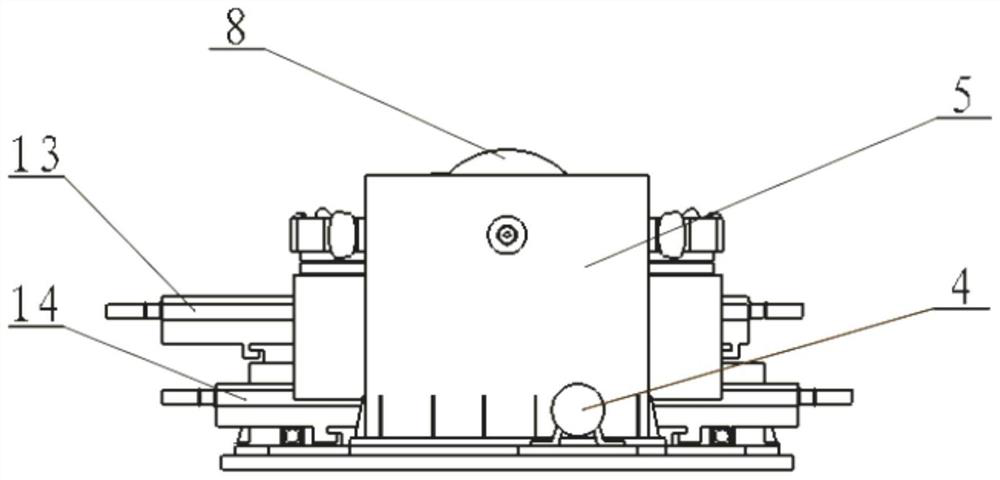

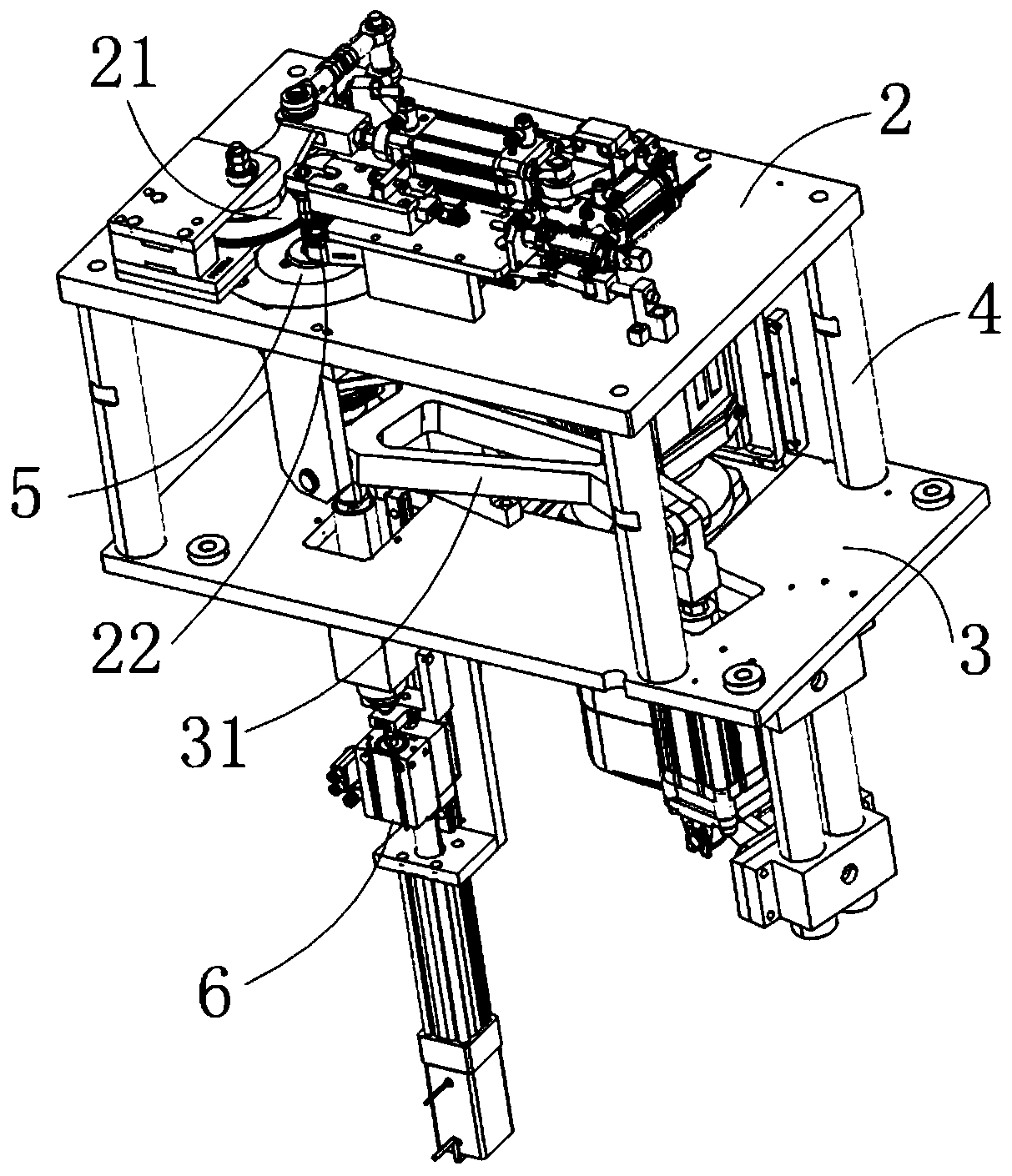

Horizontal type double-pair-wheel multifunctional variable-size composite flexible spinning equipment

ActiveCN112547922ARealize multi-shape processingUniform processing forceOther manufacturing equipments/toolsSpinningEngineering

The invention provides horizontal type double-pair-wheel multifunctional variable-size composite flexible spinning equipment, and belongs to the technical field of flexible spinning equipment. According to the horizontal type double-pair-wheel multifunctional variable-size composite flexible spinning equipment provided by the invention, an outer spinning roller assembly A and an outer spinning roller assembly B are installed on a Y-axis platform, an X-axis platform is arranged below the Y-axis platform, an inner spinning roller assembly A and an inner spinning roller assembly B are installed on a V-axis platform, a U-axis platform is arranged below the V-axis platform, and the X-axis platform and the Y-axis platform are controlled to move in cooperation with the V-axis platform and the U-axis platform through a servo motor and a screw rod; and normal spinning rollers, angle spinning rollers, flanging fixed rollers and cutters are arranged on the two sides of a spinning roller base. According to the horizontal type double-pair-wheel multifunctional variable-size composite flexible spinning equipment provided by the invention, a spindle rotates to drive a spinning workpiece to rotate, and the angles of inner spinning rollers and outer spinning rollers are adjusted through rotating devices at the bottoms of the assemblies, so that the spinning rollers are perpendicular to the surface of the workpiece in the spinning process; the two-axis motion platforms are arranged below the inner spinning roller sets and the outer spinning roller sets and controlled by the servo motor, so that multi-shape machining of a workpiece can be achieved; and two pairs of inner spinning roller sets and two pairs of outer spinning roller sets are arranged to form a double-pair-wheel mode, so thatstress on machining large-size workpieces is balanced, and the spinning effect is good.

Owner:HARBIN INST OF TECH

Spinneret plate for producing super bright flat fibers

The invention discloses a spinneret plate for producing super bright flat fibers. The spinneret plate comprises a spinneret plat body, a spinneret groove and a spinneret plate base. The spinneret groove is fixedly connected on the top of the spinneret plate body; a firs spinneret block is fixedly connected on the surface of the spinneret groove; one side of the first spinneret block is fixedly connected with a second spinneret block; a fourth spinneret block is fixedly connected on the bottom of the second spinneret block; a third spinneret block is fixedly connected on the other side of thefourth spinneret block; the spinneret plate base is fixedly connected on the bottom of the spinneret plate body; and a longitudinal baffle is fixedly connected on the middle part of the bottom of thespinneret plate base. The longitudinal baffle prevents tows of different shapes from being wound together, the accessory fixing holes improve the practicability of the device body, the diversified spinneret mechanisms improve the factory benefits, the hooks improve the convenience of the device body, the smooth spinneret holes improve the quality of the tows and the spinneret plate is suitable forbeing used in fiber spinneret plates and has wide development prospects in the future.

Owner:ANHUI DONGJIN RESOURCE REGENERATION SCI & TECH

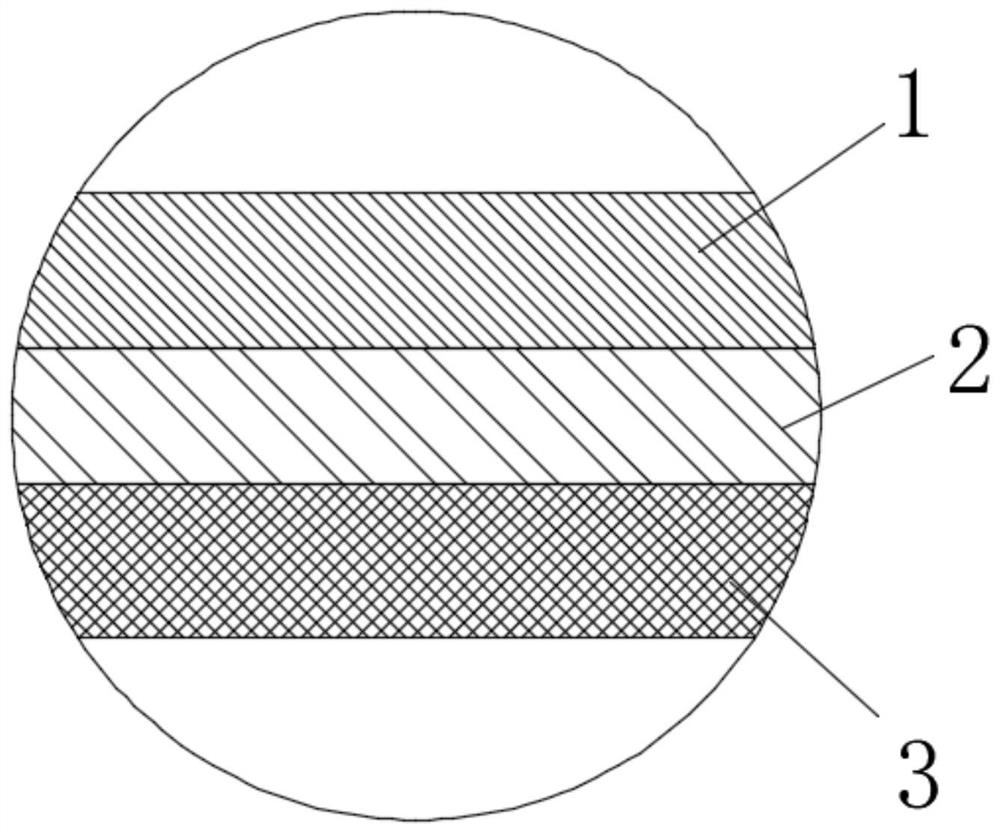

Multi-layer melt-blown non-woven fabric and preparation method thereof

InactiveCN113430711AGood filtering effectSimple processSynthetic resin layered productsTextile/flexible product manufactureWoven fabricHeater Rod

The invention discloses a multi-layer melt-blown non-woven fabric and a preparation method thereof. The multi-layer melt-blown non-woven fabric is formed by compositing an antibacterial outer layer, a filtering interlayer and a hydrophilic inner layer which are arranged in sequence. The multi-layer melt-blown non-woven fabric has the antibacterial function, is resistant to abrasion, durable, good in filtering effect, resistant to water and hydrophilic, is used for making masks, and can be used for a long time; the preparation method of the multi-layer molten non-woven fabric is simple in process and convenient to implement; and a melt-blowing machine for preparing the multi-layer molten non-woven fabric is smooth in spinning, good in spinning effect and concentrated in hot air strength and heat, it is guaranteed that spinning work is stably carried out, the function that a single heating rod heats air and melts materials at the same time can be achieved, the structure is simplified, the use cost is reduced, waste heat utilization of a heating device of a screw extruder can be achieved, and the purpose of preheating the air is achieved.

Owner:宿迁正峰包装材料有限公司

A high-speed drum mechanism and fighting robot

ActiveCN109895119BSimple structureIncrease production capacitySelf-moving toy figuresManipulatorControl engineeringElectric machinery

The invention provides a high-speed drum mechanism and a fighting robot. The high-speed drum mechanism includes a drum main body. A drum blade is arranged on the drum main body. Both sides of the drum main body are rotationally connected with drum mounting seats. A driving motor is arranged in the main body, and the driving motor is suitable for driving the main body of the drum and the blades of the drum to rotate. In the high-speed drum mechanism and fighting robot of the present invention, the driving motor is built into the drum body to realize the driving and rotation of the drum mechanism. The overall structure of this simplified mechanism, when applied to fighting robots, can reduce the setting of the motor installation structure in the robot, making the structure of the robot simpler, which is conducive to the miniaturized production and development of fighting robots, and can protect the driving motor at the same time , where the main body of the drum is provided with a drum blade, so as to achieve a better rotating strike effect.

Owner:玄智(深圳)科技有限公司

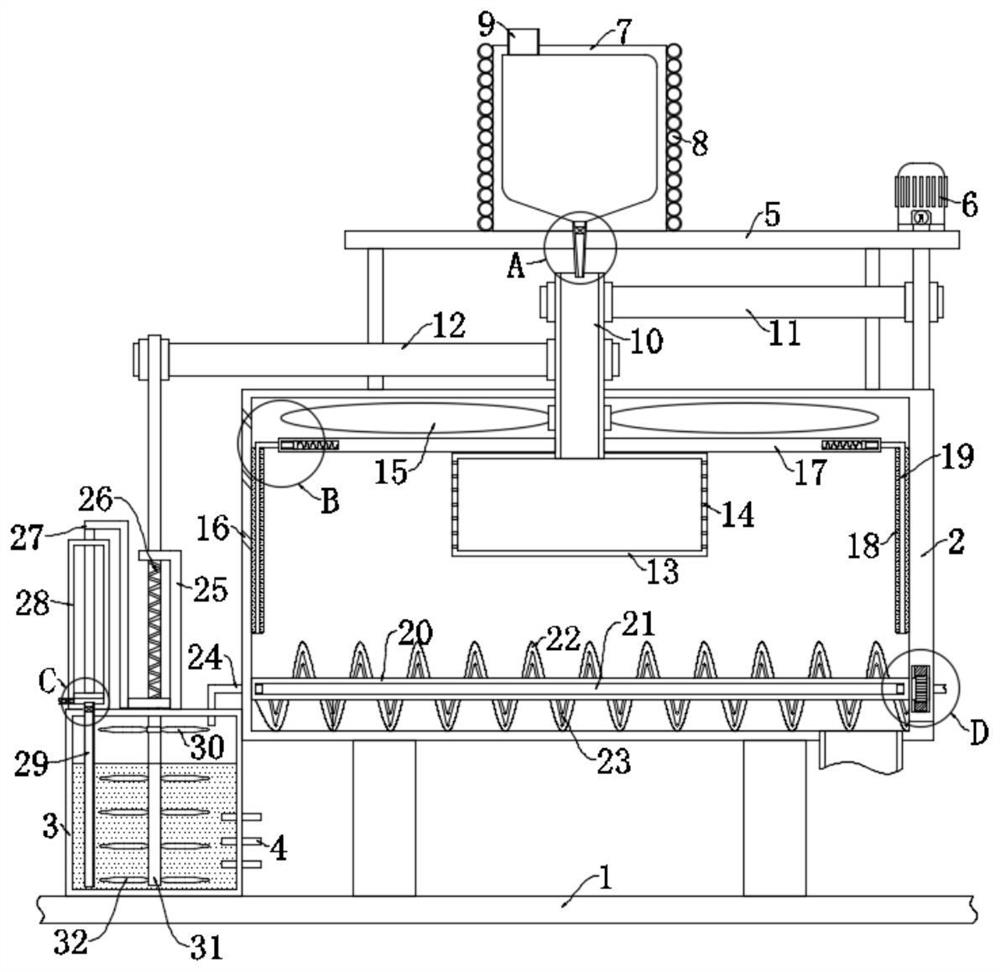

Polycrystalline mullite fiber spinning machine

ActiveCN112481718AImprove stabilityIncrease temperatureSpinnerette packsInorganic material artificial filamentsFiber spinningMaterials science

The invention discloses a polycrystalline mullite fiber spinning machine which comprises a base, wherein a spinning box is fixedly connected to the base through a plurality of supporting legs, a watertank is fixedly connected to the base, a hollow shaft is rotationally connected to the interior of the spinning box, a spinning mechanism used for spinning is arranged at the lower end of the hollowshaft, the spinning box is fixedly connected with an installation plate through a supporting rod, the installation plate is provided with a feeding mechanism used for providing materials needed by thespinning mechanism, the hollow shaft is fixedly connected with two connecting rods, the connecting rods are provided with cleaning mechanisms used for cleaning the inner wall of the spinning box, a discharging port is formed in the spinning box in a penetrating mode, a conveying mechanism used for moving spun fiber filaments to the discharging port is arranged in the spinning box, and a cooling mechanism used for cooling the fiber filaments is arranged in the conveying mechanism. The polycrystalline mullite fiber spinning machine is reasonable in structure, good in spinning effect, high in cooling speed and capable of achieving rapid forming and saving resources.

Owner:湖州博星科技有限公司

Superfine high-density fiber pile fabric

InactiveCN110129957AExcellent adhesionQuality improvementSpinnerette packsSpinning head liquid feederFiberHigh density

The invention discloses superfine high-density fiber pile fabric. Different superfine high-density fibers are prepared by adopting special raw material ratio, the different superfine high-density fibers are combined, adhesive force among the fibers is enhanced by adopting high-quality reasonable pile fabric ratio, dyeing uniformity can be guaranteed while quality is improved, and the problems thatexisting superfine high-density fiber pile fabric is poor in dyeing uniformity, poor in fixation rate and poor in antibacterial property and softness and excellent dyeing uniformity, antibacterial property and fixation rate cannot be considered simultaneously are solved effectively.

Owner:洪泽联合化纤有限公司

Thread throwing device of colloidal silk forming equipment

PendingCN109913962AImprove qualityDry fastSpinning head liquid feederFilament manufactureFiberThermal insulation

The invention relates to a thread throwing device of colloidal silk forming equipment. The technical problem that the design is not reasonable in design. The device includes a thread throwing base, athread throwing motor, a feeding pipe body and a hot air base. The hot air base is internally provided with a heating element, the heating element is connected with a hot air guide structure, a motorshaft and the feeding pipe body pass through the hot air base and extend to the lower portion of the hot air base, the lower end of the motor shaft is connected with a thread throwing disc body, the thread throwing disc body corresponds to the feeding pipe body, the periphery of the thread throwing disc body has a plurality of thread throwing holes, the upper end of the thread throwing disc body is fixedly provided with a hot air blowing structure connected with the motor shaft, and the lower end of the hot air base is provided with a hot air guide out structure corresponding to the hot air blowing structure. The device has the advantages that fiber is stretched further through a hot air system and meanwhile is dried rapidly to prevent bonding with one another, a thermal insulation sheet effectively avoids colloidal solution solidification, the thread throwing holes in the thread throwing disc is not easily blocked, and the prepared silky fiber is very high in quality.

Owner:德清欧康无机材料科技有限公司

Spinning heating device

ActiveCN103272948BSave energySave time and costShaping toolsGaseous fuel burnerGas heaterEngineering

The invention discloses a spinning heating device which comprises an internal gas heating device and an external heating heat preserving device. The internal gas heating device is arranged inside a spinning mold. The external heating heat preserving device is arranged outside a spinning blank. A main shaft is of a hollow structure. A gas delivery pipe penetrates through the middle of the main shaft to the inner portion of the spinning mold. A three-leaf fire spraying pipe sprays flames to heat the spinning mold so that the spinning blank can be evenly heated. The external heating heat preserving device is composed of an infrared gas heater and a heat preserving cover. According to the spinning heating device, the spinning mold is heated through flames so that temperature of the spinning blank rises, the external heating heat preserving device is used for heat preservation, and therefore spinning force is reduced. The spinning heating device has the advantages of being high in heating speed, capable of saving energy consumption and even in heating.

Owner:SHANGHAI JIAO TONG UNIV

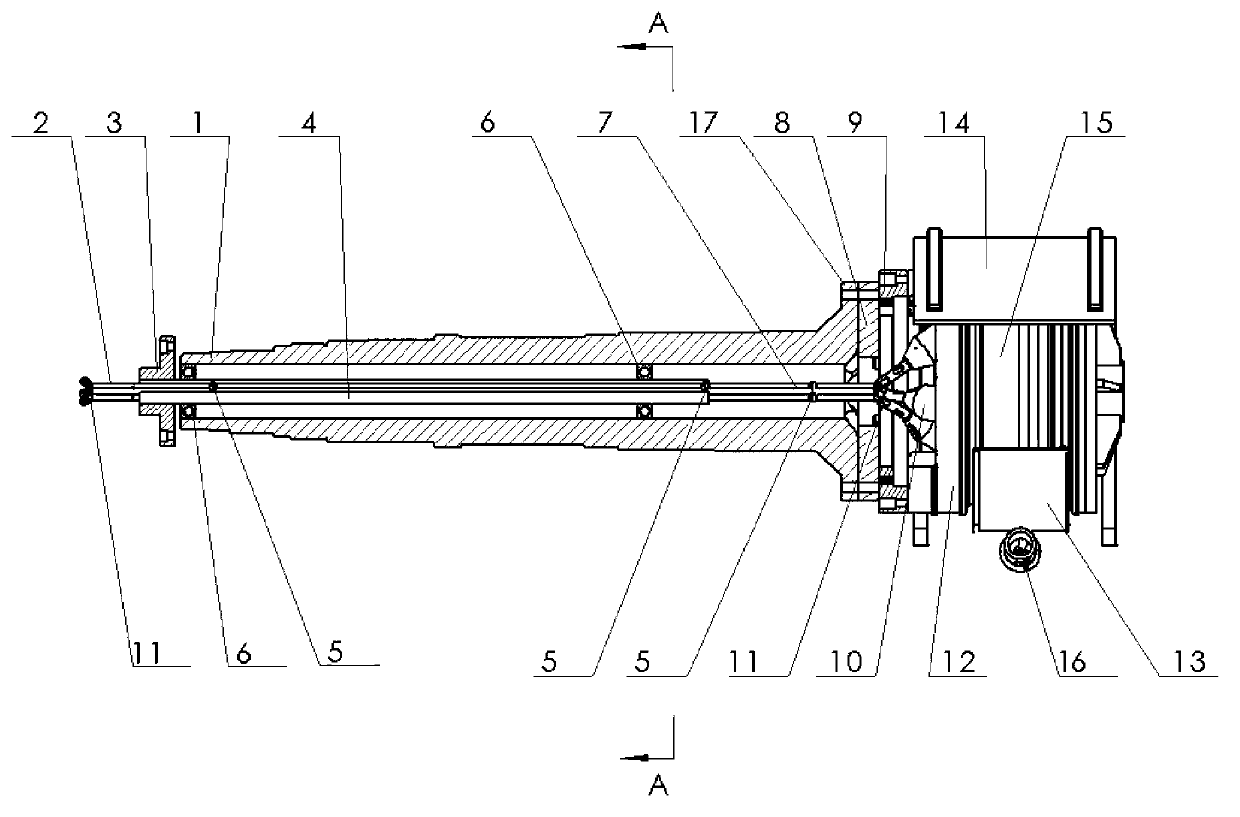

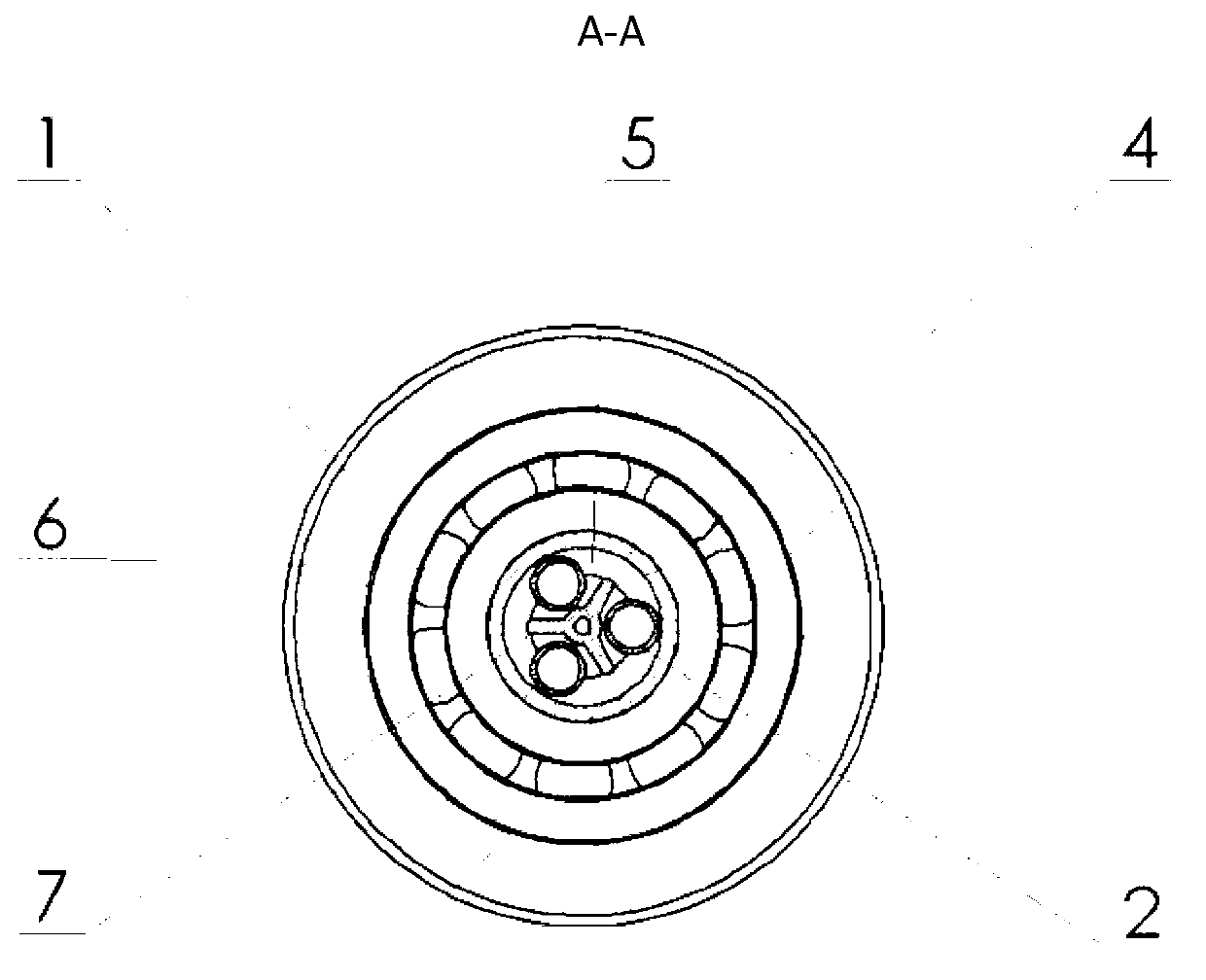

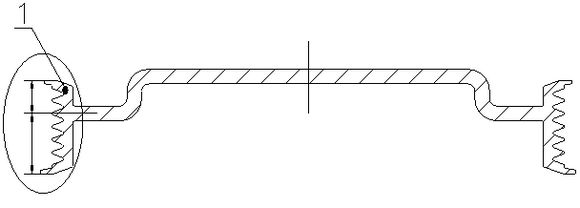

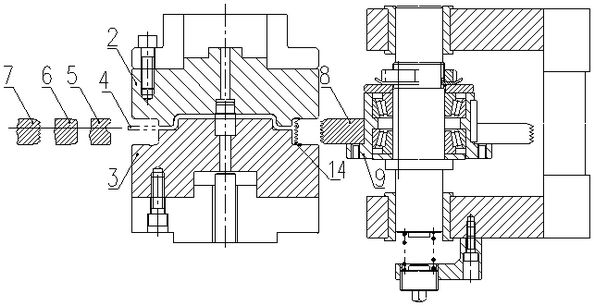

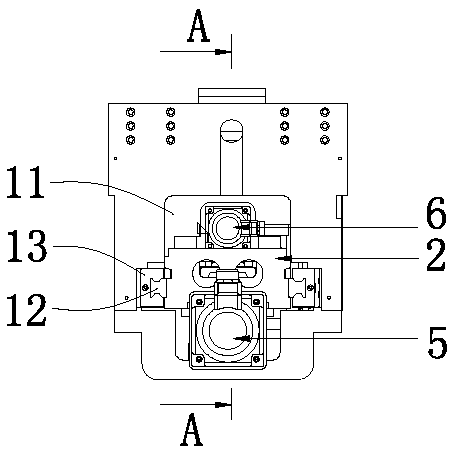

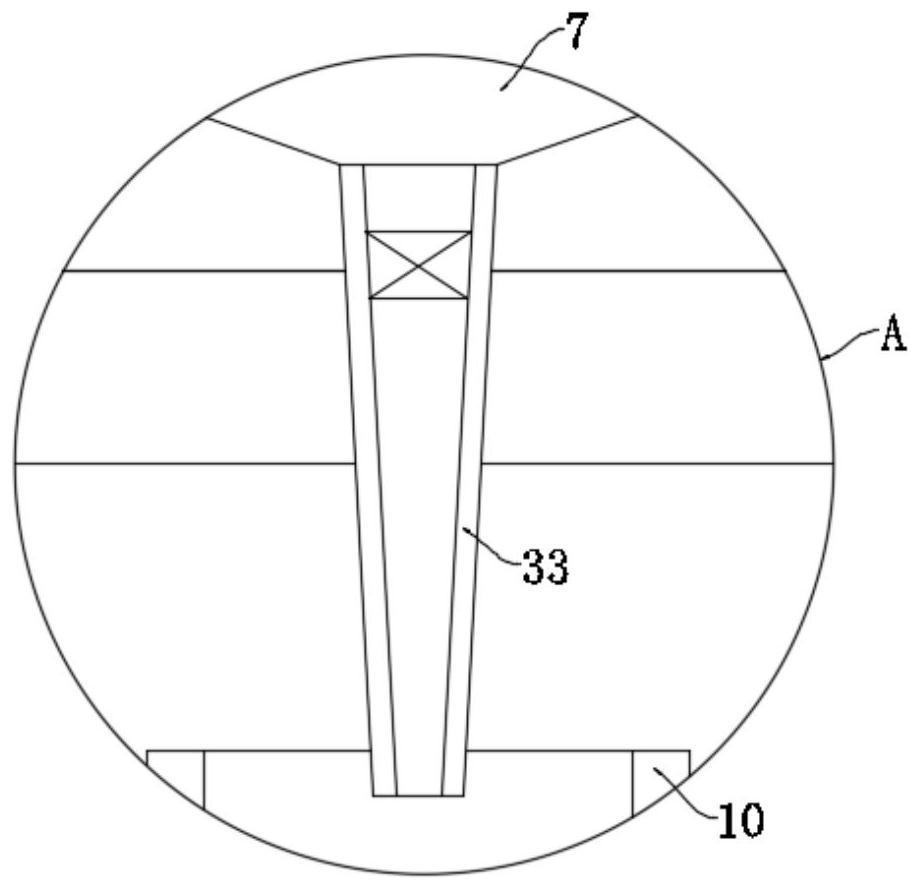

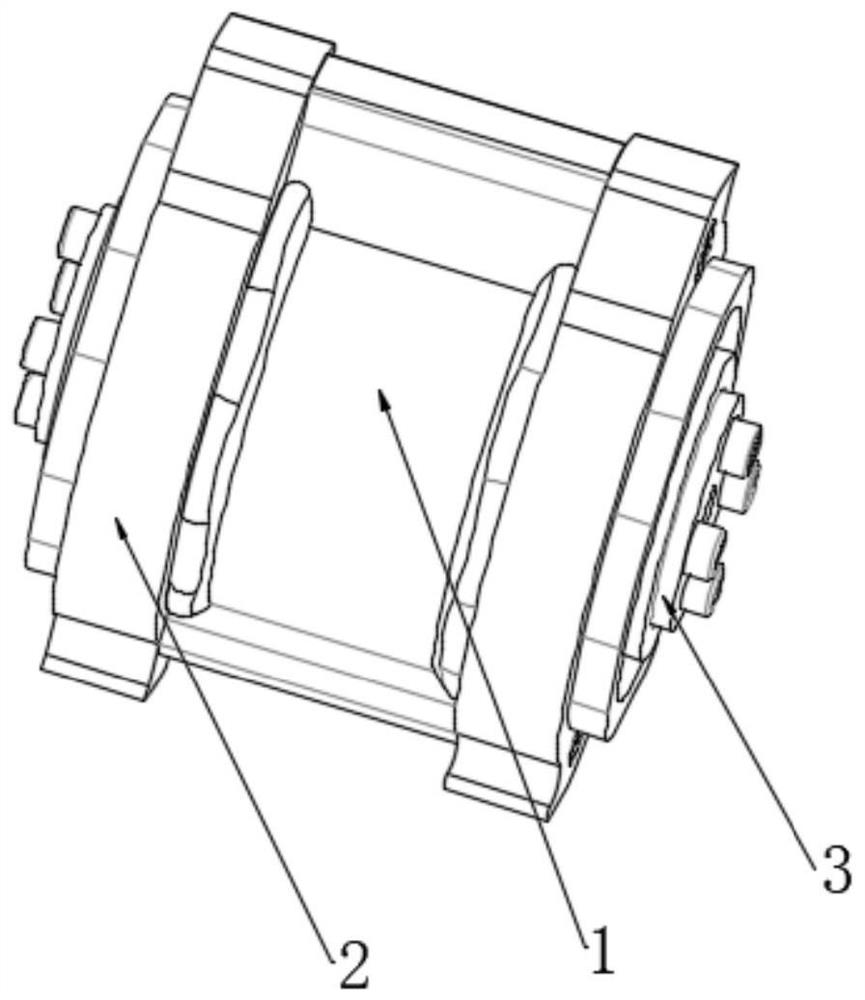

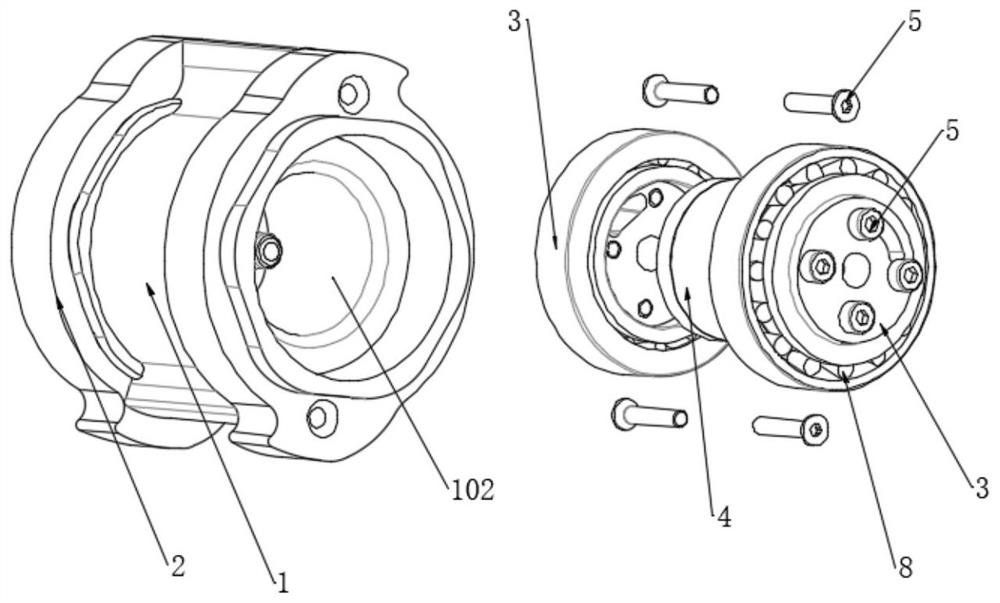

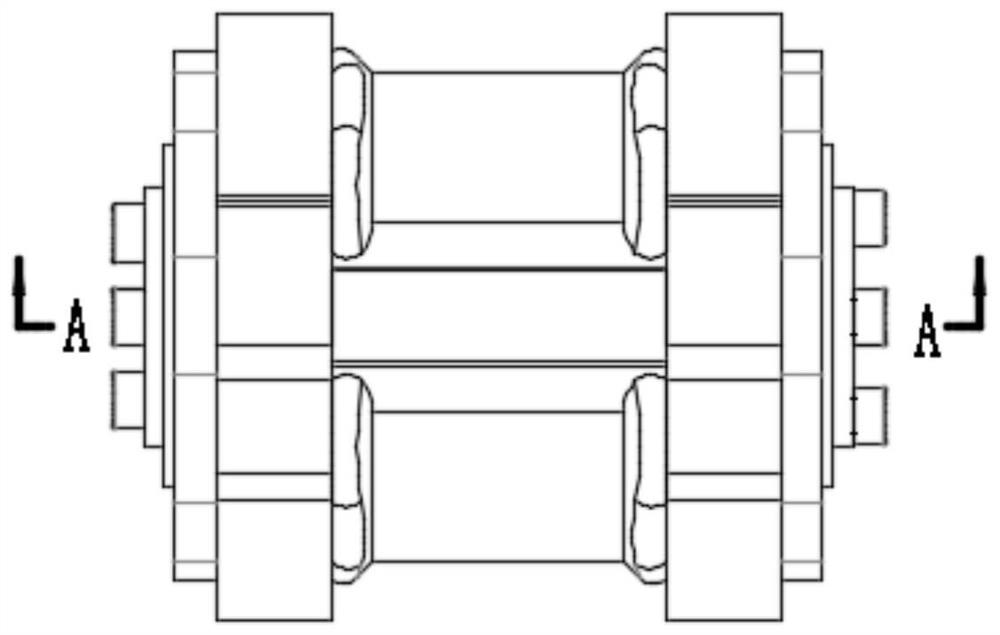

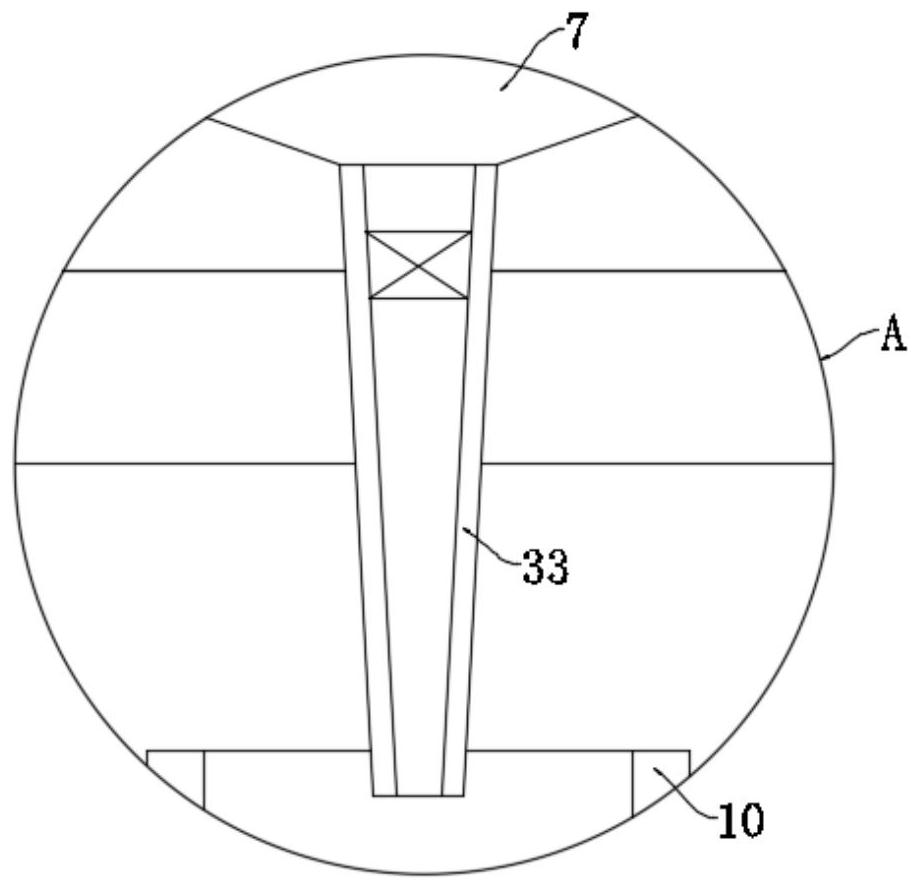

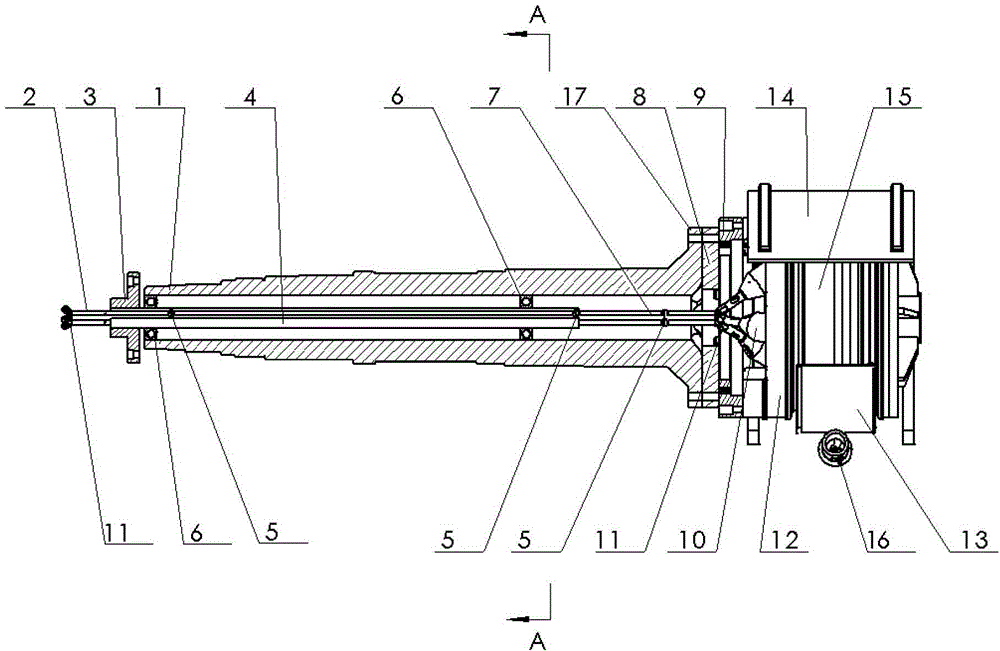

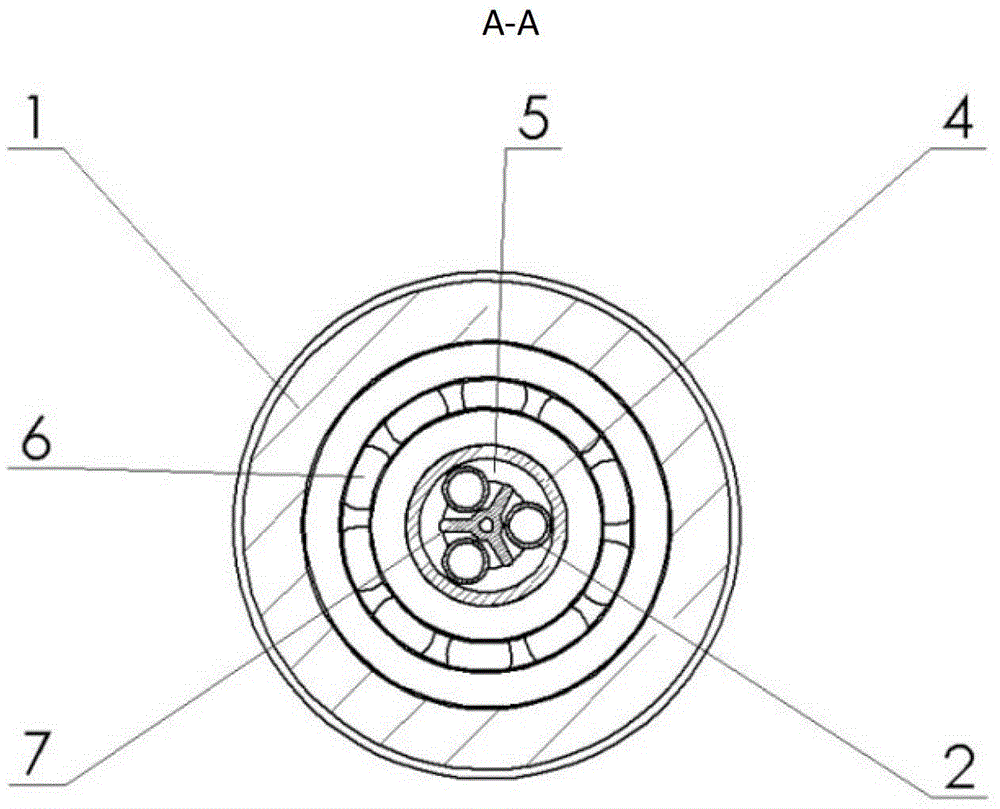

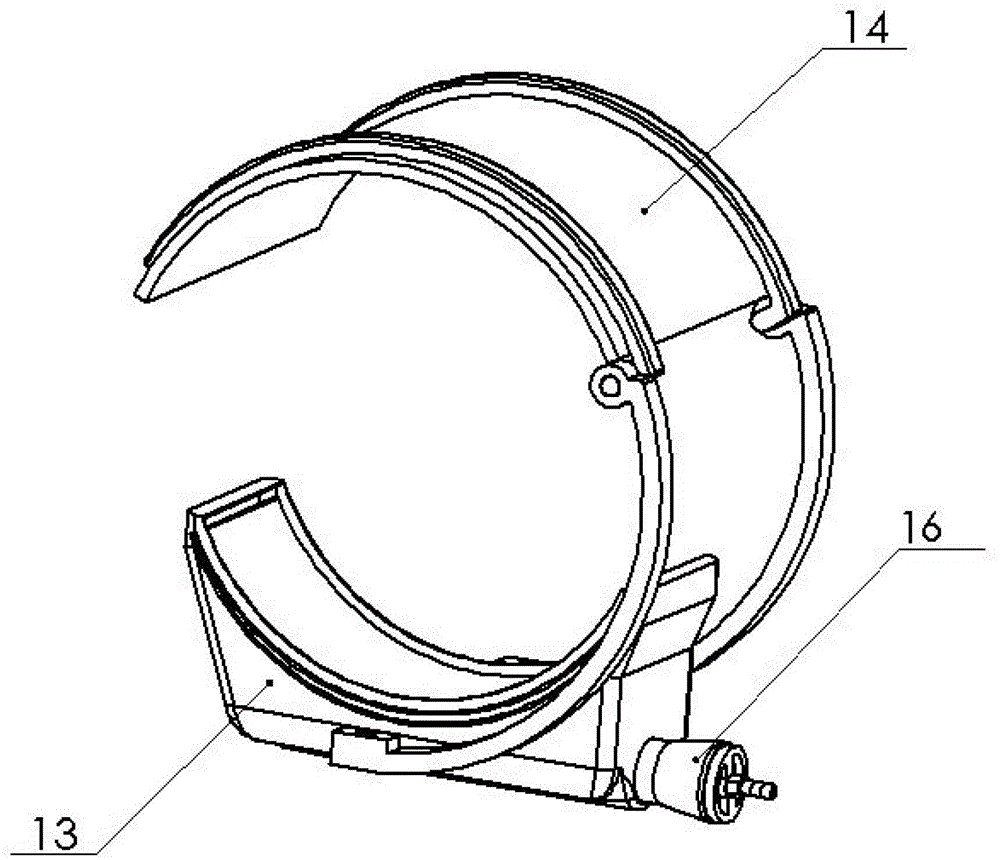

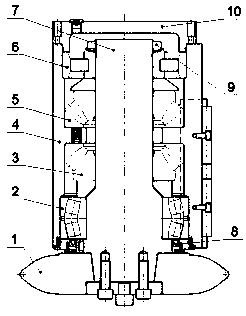

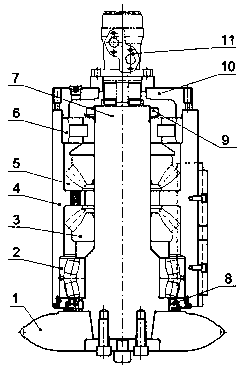

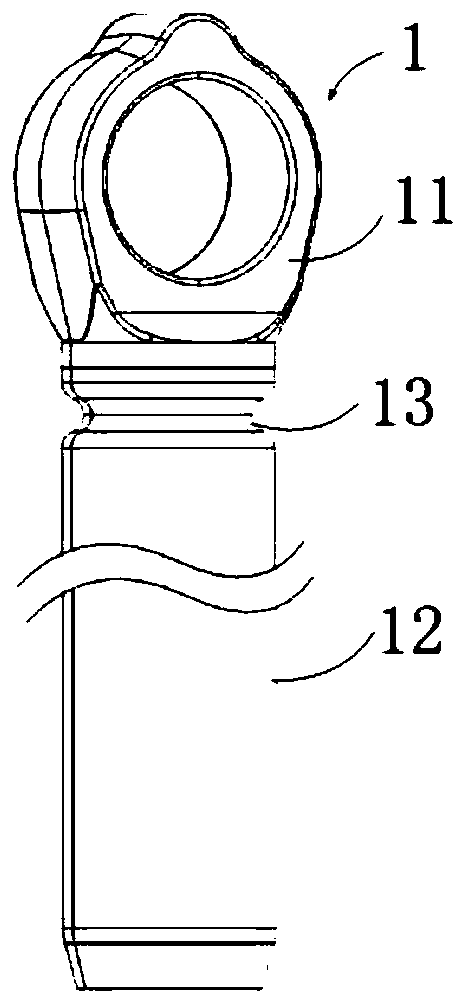

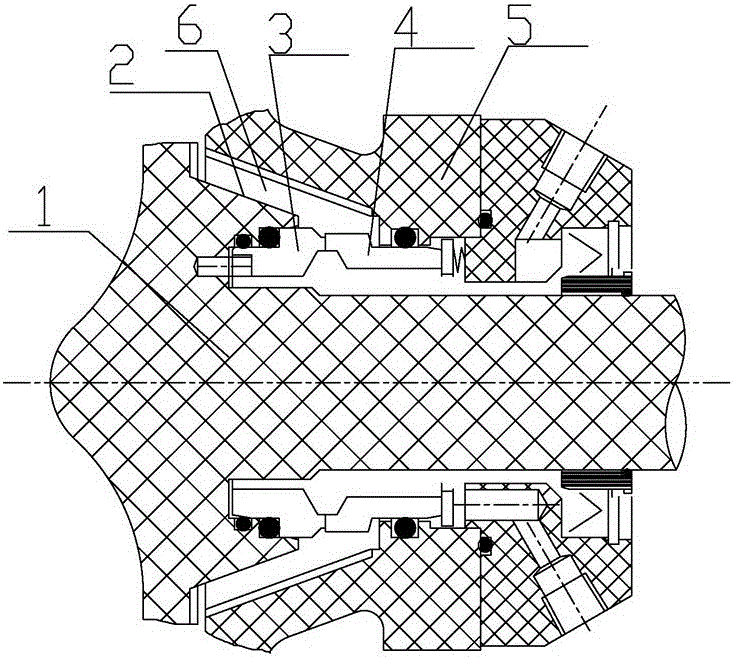

Ultrahigh-load aluminum alloy wheel extrusion-forming and spinning wheel mechanism

The invention discloses an ultrahigh-load aluminum alloy wheel extrusion-forming and spinning wheel mechanism. The ultrahigh-load aluminum alloy wheel extrusion-forming and spinning wheel mechanism comprises a spinning wheel (1), a spinning wheel base (4), a mandrel (7), a locking nut (9), and an upper end cover (10), wherein the mandrel (7) and the upper end cover (10) are fixed by the locking nut (9); the upper end cover (10) is fixedly arranged on the upper end surface of the spinning wheel base (4); and the spinning wheel (1) is fixedly arranged on the mandrel (7) and is sealed by a sealing ring (8). The ultrahigh-load aluminum alloy wheel extrusion-forming and spinning wheel mechanism is characterized in that radial force and axial force, which are borne on the spinning wheel (1), arereleased through a centering bearing I (2), a thrust bearing I (3), a thrust bearing II (5) and a centering bearing II (6) on the spinning wheel (1) through rotation of the mandrel (7). Before the spinning wheel is in contact with a high-speed rotating aluminum alloy wheel, radial force and axial force generated in all extruding and stretching processes are borne in a combined mode through the spinning wheel and a bearing of the spinning wheel, so that rolling precision and service life are guaranteed, and surface smoothness of a spun product is improved.

Owner:江苏天宏智能装备有限公司

A kind of polyglycolic acid spinning assembly

ActiveCN111647958BOuter diameter of wire is smallWell mixedFilament/thread formingFilament-forming treatmentElectric machineryEngineering

The invention discloses a polyglycolic acid spinning assembly, which includes a support and a spiral heating device vertically connected to the support. The spiral heating device includes a heating barrel and a central shaft arranged at the axis of the heating barrel. Hopper, the side of the central shaft is provided with a spiral piece, one end of the central shaft is connected to the motor, the other end is provided with a storage chamber, the storage chamber is provided with a feed port leading to the heating barrel and the end extends to the heating barrel Externally, the lower end of the material storage chamber is connected to the electrostatic nozzle, and the electrostatic nozzle is connected to the high-voltage electrostatic generator. A grounding ring and an air-cooled pipe are arranged in sequence directly below the electrostatic nozzle. The present invention adopts the method of electrostatic spraying to produce filamentous polyglycolic acid. Compared with the traditional extrusion method, the outer diameter of the filaments produced by the present invention can be very small. The present invention implements high-frequency vibration on the polyglycolic acid to be spun through the shock ring, so that the polyglycolic acid liquid is mixed more uniformly, and the indicators in all aspects are more stable, which is beneficial to improving the subsequent spinning effect and efficiency.

Owner:ZHONG HONG NANO FIBER TECH DANYANG

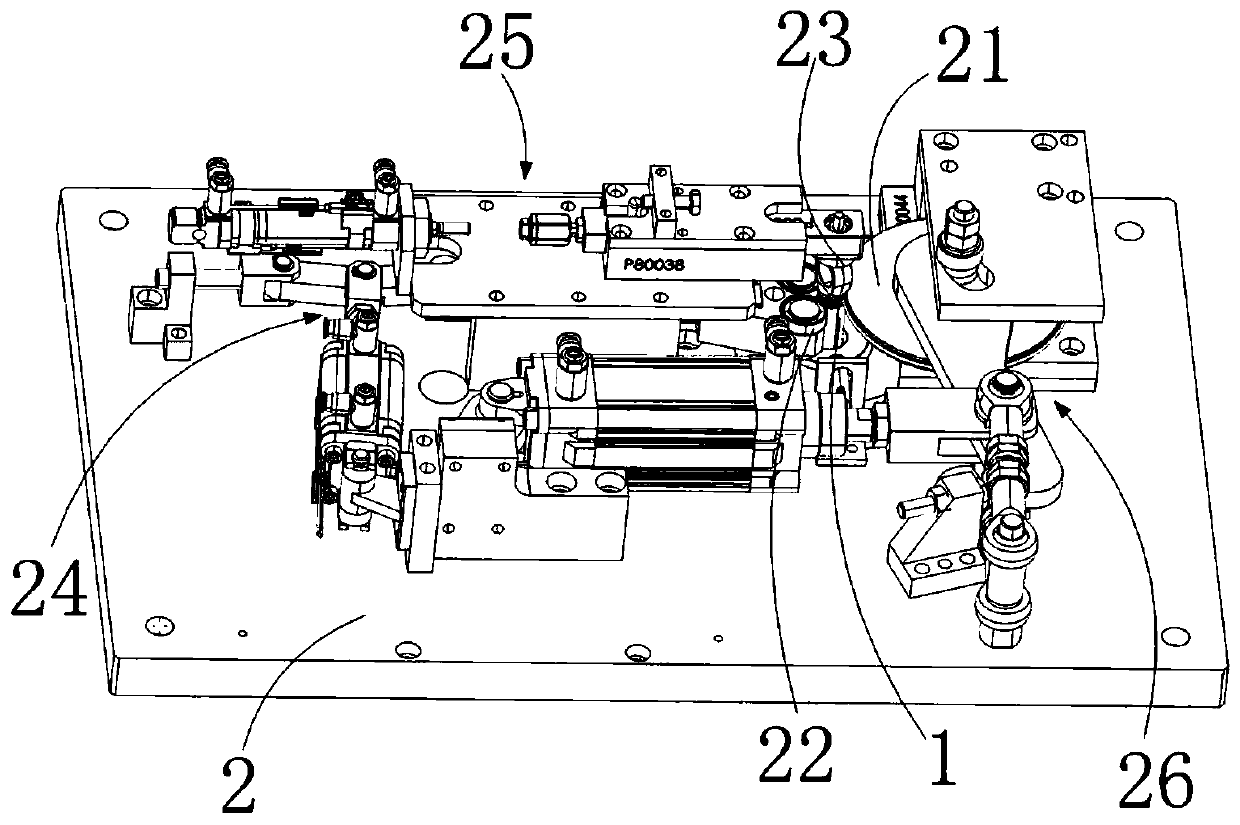

Spinning device

ActiveCN109759489AReduce output forceSqueeze hardMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to the technical field of spinning devices, in particular to a spinning device comprising a spinning wheel (21), a circular wheel (22) and a clamp (5) for fixing a connecting rod(12). The bottom of the clamp (5) is provided with a lifting mechanism (6), the lifting mechanism (6) is used for jacking a product (1) in the clamp (5), and the spinning wheel (21) and the circularwheel (22) are supported by a spinning wheel support mechanism (26) and a circular wheel support mechanism (24) to abut against the connecting rod (12). The spinning device is large in pressing forceand good in spinning effect; the circular wheel support mechanism and the spinning wheel support mechanism adopt the indirect supporting manner, the cylinder output force can be effectively reduced, the cylinder diameter can be correspondingly reduced, the cost is reduced, and the volume is reduced.

Owner:宁波均普智能制造股份有限公司

Sealing cavity of a plastic pump conical rotary noodle machine

ActiveCN103573689BGood spinning effectImprove the use environmentPump componentsPumpsImpellerStrong acids

The invention discloses a conical rotating surface mechanical seal cavity of a plastic pump. The conical rotating surface mechanical seal cavity comprises an impeller and a pump cover, wherein a moving ring is arranged on the impeller, and a static ring is arranged on the pump cover; the rotating surface of the impeller is conical; a conical surface is also formed in the pump cover to be matched with the conical rotating surface; and a seal cavity defined by the pump cover and the rotating surface is conical as well, and the part, close to a vertex angle, of the conical rotating surface is the joint part of the moving ring and the static ring. The conical rotating surface mechanical seal cavity has the benefits as follows: under the working condition that solid particle strong acid media exist, the mechanical seal cavity adopts the conical rotating surface, particles can circumferentially spin along the conical inclined surface and leave the seal surfaces of the moving ring and the static ring through transport motion of the conical rotating surface, the mechanical seal use environment is improved, and nearly hundred times of tests prove that the particle spin separation effect is the best when the angle of the conical surface ranges from 20 degrees to 25 degrees, so that the sealing performance is improved, the service life of the mechanical seal cavity is prolonged, and the life is 20 times longer than that of a conventional externally-mounted mechanical seal cavity.

Owner:HANGZHOU ALKALI PUMP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com