Rotating cutter wheel control structure of rod rolling machine of wheel hub

A technology of control structure and rotary knife, applied in metal processing equipment, etc., can solve the problems that the knife seat does not have the function of adjusting the rotation angle, and it is difficult to meet the requirements of complex curved surface spinning technology, and achieves ingenious structural design, easy control, and working stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

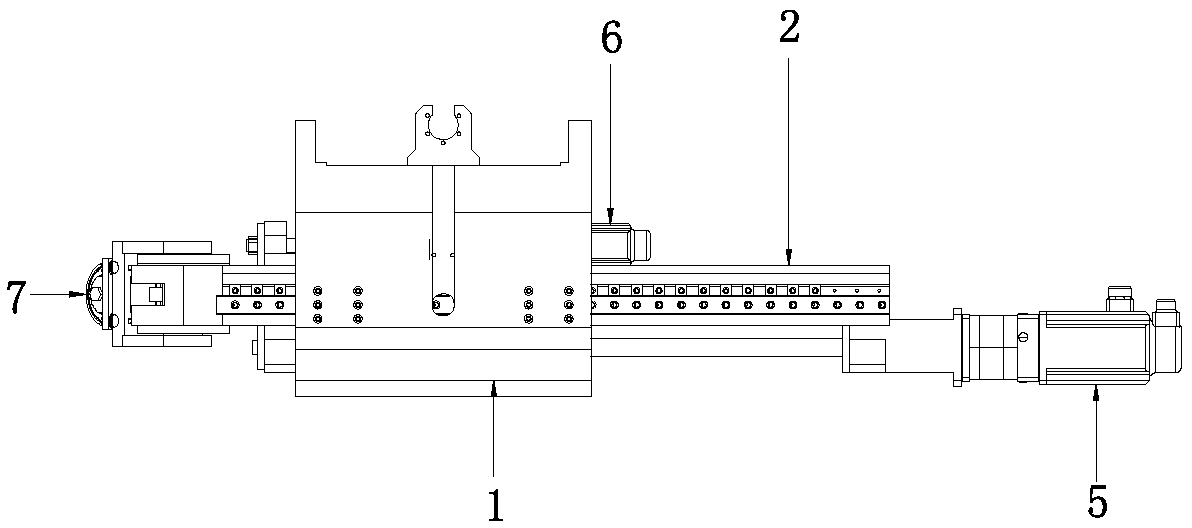

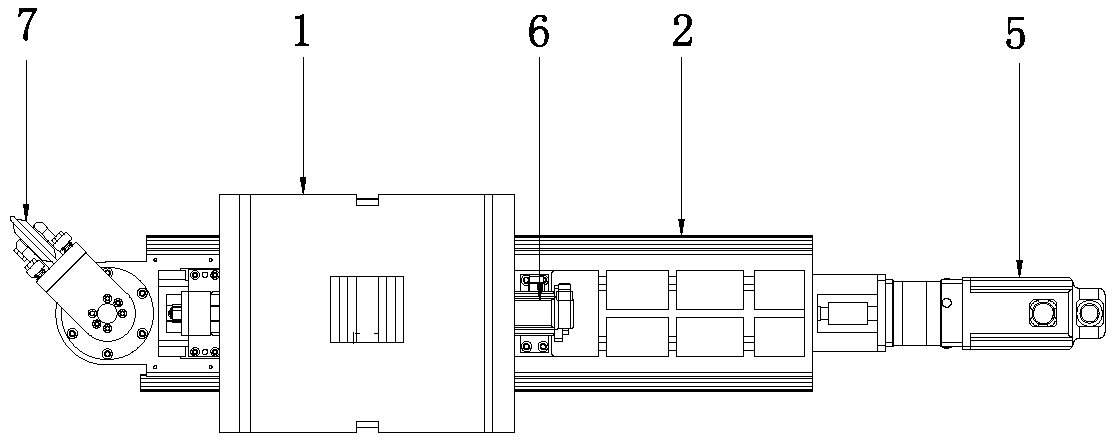

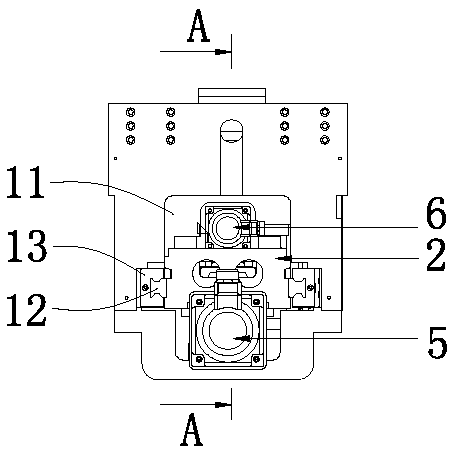

[0021] see Figure 1 to Figure 4 , the present embodiment provides a hub rolling machine rotary cutter wheel control structure, which includes a fixed bracket 1, a movable bracket 2, a first ball screw pair 3, a second ball screw pair 4, a first motor 5, a second Two motors 6, rotary cutter wheel bracket 7, first sprocket shaft 8, second sprocket shaft 9 and chain 10. In this embodiment, both the first motor 5 and the second motor 6 are preferably servo motors. It has the advantages of fast response, high speed, small inertia, smooth rotation, stable torque, and accurate position accuracy. Both the fixed bracket 1 and the movable bracket 2 are preferably cast iron components, which have high structural strength and good stability, and can effectively improve machining accuracy.

[0022] The movable bracket 2 is arranged on the fixed bracket 1 through a slide rail assembly. Specifically, the fixed bracket 1 is provided with a through cavity 11 horizontally penetrating it. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com