High-toughness ultrahigh-strength D506A steel easy for rotary extrusion and easy to weld and preparation method thereof

An ultra-high-strength, easy-to-weld technology, applied in the field of alloy steel, can solve the problems of comprehensive performance gap between strength and fracture toughness, high price, low strength and toughness, etc., and achieve excellent comprehensive performance, high strength and fracture toughness, good spin pressure effect

Active Publication Date: 2015-02-04

CENT IRON & STEEL RES INST

View PDF3 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

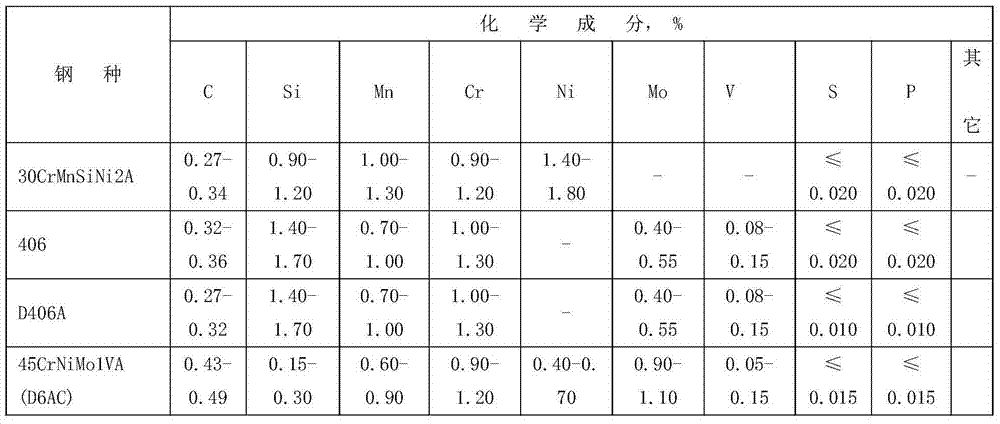

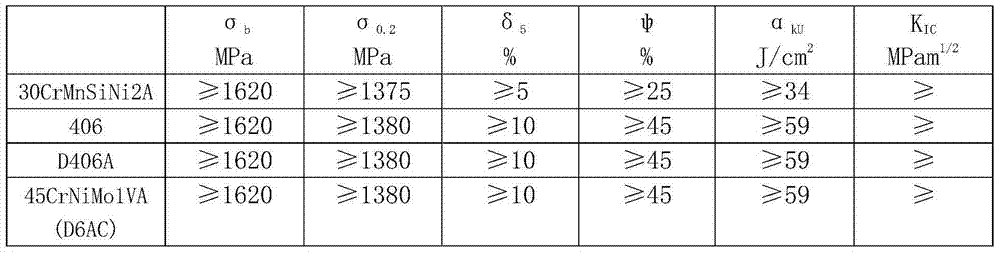

[0003] Early ultra-high-strength steels for high-pressure shells were concentrated on low-alloy ultra-high-strength steels due to cost issues, mainly including 30CrMnSi, 30CrMnSiNi2, 4130, D6AC, D406A, etc., but the strength of these low-alloy ultra-high-strength steels is generally 1600MPa and below ; With the increase of pressure and the decrease of volume weight of high-pressure shell, maraging steel of higher strength level is widely used, the famous ones are C200, C250, C300, T250, etc., the strength is from 1600MPa to 2000MPa, but due to the price Advanced problems have not been able to promote the application

[0008] Although current low-alloy shell steels can provide σ b ≥1620Mpa, K IC ≥80MPam 1 / 2 However, compared with the current demand for components in the aerospace field, there is still a gap in the comprehensive performance of strength and fracture toughness. The strength and toughness are both low, which cannot meet the technical requirements.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

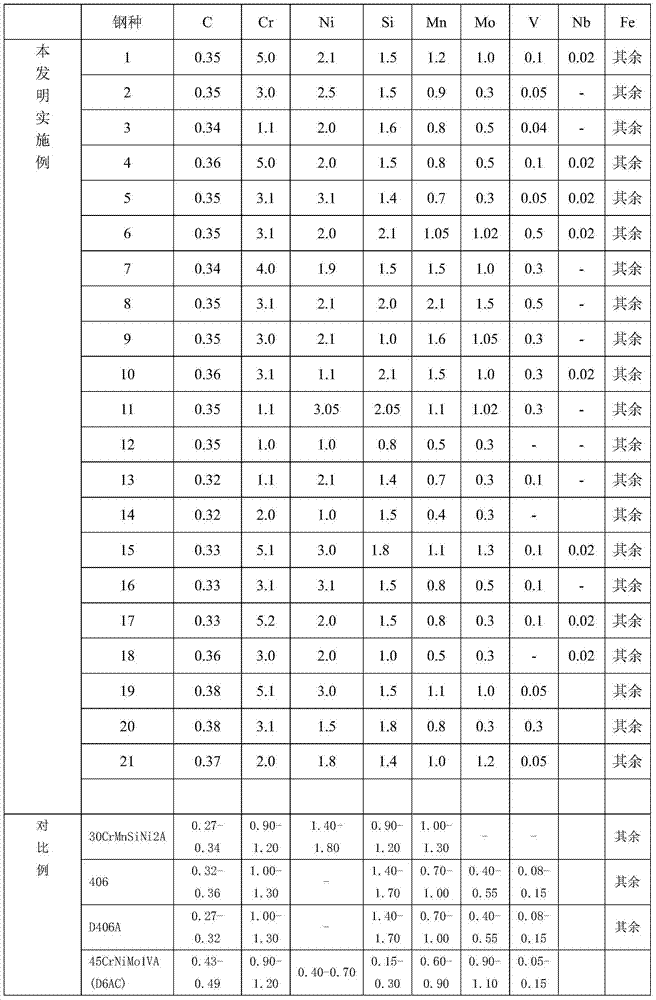

[0029] According to the scope of the chemical composition of the economical high-toughness, easy-spinning and easy-welding ultra-high-strength steel of the present invention, 25 kilograms of vacuum induction furnaces are used to prepare 15 furnaces of alloy ingots of 20 kilograms, and the specific chemical compositions are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to high-toughness ultrahigh-strength D506A steel easy for rotary extrusion and easy to weld and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.32-0.38% of C, 0.50-5.50% of Cr, 0.5-3.5% of Ni, 0.2-2.20% of Si, 0.2-2.2% of Mn, 0.05-1.50% of Mo, 0-0.5% of V, no more than 0.2% of Nb and the balance of Fe and other inevitable impurity elements. Compared with the prior art, the steel has excellent comprehensive performance, high toughness (sigma b>=1800Mpa) and ultrahigh strength (KIC>=90MPam<1 / 2>), and also has excellent weldability, rotary extrusion performance and decarbonization resistance.

Description

technical field [0001] The invention belongs to the technical field of alloy steel, and in particular relates to a high-toughness, easy-spinning and easy-welding ultra-high-strength D506A steel and a preparation method thereof. with σ b ≥1800Mpa and K IC ≥90MPam 1 / 2 With high toughness and ultra-high strength, it has good spinning and welding processability. Background technique [0002] Prior to this, ultra-high-strength steel for high-pressure shells was a special type of ultra-high-strength steel. Due to the needs of the forming process, in addition to maintaining high strength and high toughness, it must be easy to obtain spheroidized structure, low carbon Equivalent and low volatile elements, in order to meet the spinning and welding process requirements. [0003] Early ultra-high-strength steels for high-pressure shells were concentrated on low-alloy ultra-high-strength steels due to cost issues, mainly including 30CrMnSi, 30CrMnSiNi2, 4130, D6AC, D406A, etc., but ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58C22C38/48C22C38/46C22C38/44C21D6/00

CPCC21D1/18C21D1/26C21D6/004C21D6/005C21D6/008C22C38/02C22C38/04C22C38/08C22C38/12C22C38/18

Inventor 王春旭厉勇韩顺刘宪民吴军余天雄李建新黄顺喆方曦惠高列义初敬生纪淑杰庞学东

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com