Superfine high-density fiber pile fabric

A fiber fleece and fleece fabric technology, applied in the direction of fabric, fiber chemical characteristics, textile, etc., can solve the problem of not being able to have both softness, air permeability, moisture permeability, super cool dyeing uniformity, antibacterial property, color fixation rate, Problems such as poor dyeing uniformity and poor antibacterial performance can achieve the effect of ensuring dyeing uniformity, avoiding skin breakage or tearing, and enhancing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

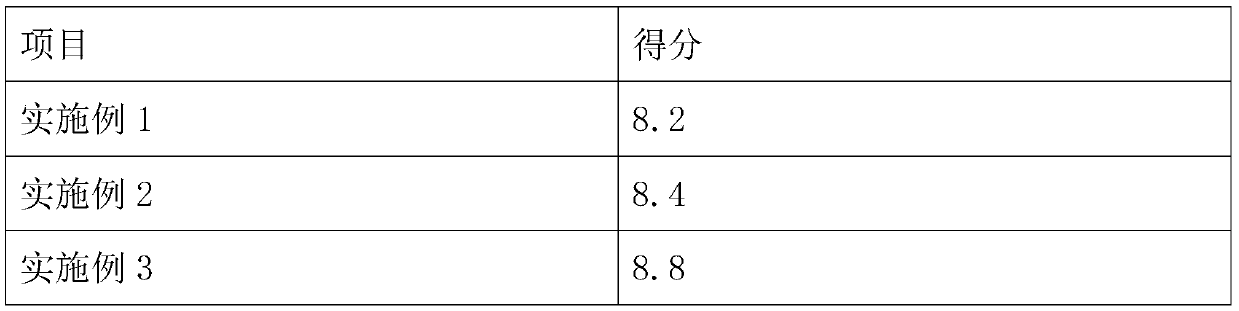

Embodiment 1

[0022] The superfine and high-density fiber fleece fabric of this embodiment includes a surface texture and a bottom texture, the raw material of the surface texture is 50 / 144 modified ultrafine high-density fiber A, and the raw material of the bottom texture is 50 / 72 modified Superfine and high-density fiber B and 50 / 72FDY polyester filament; wherein the mass percentage of modified superfine and high-density fiber A in the fleece fabric is 65%, and the mass percent of modified superfine and high-density fiber B in the fleece fabric It is 30%, and the mass percentage that 50 / 72FDY polyester filament accounts for in the velvet fabric is 5%.

[0023] The core wire diameters of the superfine high-density fiber A and the superfine fiber B are 0.1 micron and 0.7 micron, respectively.

[0024] Wherein, the preparation method of the ultra-fine high-density fiber A is: taking polyester chips and modified materials and putting them into a polyester screw extruder for melt mixing, where...

Embodiment 2

[0029] The superfine and high-density fiber fleece fabric of this embodiment includes a surface texture and a bottom texture, the raw material of the surface texture is 50 / 144 modified ultrafine high-density fiber A, and the raw material of the bottom texture is 50 / 72 modified Superfine and high-density fiber B and 50 / 72FDY polyester filament; wherein the mass percentage of modified superfine and high-density fiber A in the fleece fabric is 70%, and the mass percent of modified superfine and high-density fiber B in the fleece fabric It is 20%, and the mass percentage that 50 / 72FDY polyester filament accounts for in fleece fabric is 10%.

[0030] The core wire diameters of the superfine high-density fiber A and the superfine fiber B are 0.6 micron and 0.6 micron, respectively.

[0031] Wherein, the preparation method of the ultra-fine high-density fiber A is: taking polyester chips and modified materials and putting them into a polyester screw extruder for melt mixing, wherein ...

Embodiment 3

[0036] The superfine and high-density fiber fleece fabric of this embodiment includes a surface texture and a bottom texture, the raw material of the surface texture is 50 / 144 modified ultrafine high-density fiber A, and the raw material of the bottom texture is 50 / 72 modified Superfine and high-density fiber B and 50 / 72FDY polyester filament; wherein the mass percentage of modified superfine and high-density fiber A in the velvet fabric is 73%, and the mass percent of modified superfine and high-density fiber B in the velvet fabric It is 22%, and the mass percentage that 50 / 72FDY polyester filament accounts for in the fleece fabric is 5%.

[0037] The core wire diameters of the superfine high-density fiber A and the superfine fiber B are 0.3 micron and 0.2 micron respectively.

[0038] Wherein, the preparation method of the ultra-fine high-density fiber A is: taking polyester chips and modified materials and putting them into a polyester screw extruder for melt mixing, wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com