Water-retaining thixotropic agent for ready-mixed mortar and preparation method thereof

A technology of ready-mixed mortar and thixotropic agent, applied in the field of building materials, can solve the problems of poor construction, poor water retention, high cost, achieve cohesion and construction smoothness, no VOC, good water retention, improve construction efficiency and The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

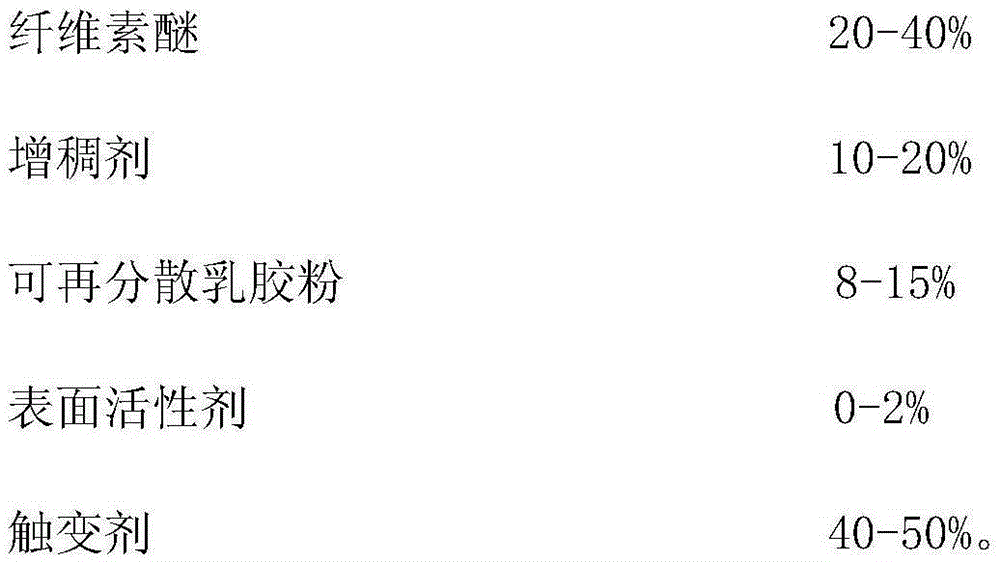

Embodiment 1

[0015]

[0016]

[0017] The water-retaining thixotropic agent prepared according to the mass percentage specified in the above table accounts for 0.08-0.12% of the total mass of the formula raw materials, and it is applied after adding water and stirring evenly. The M5 masonry mortar is mixed with 0.1% of the total mass of water-retaining thixotropic agent, the water retention rate is 92.4%, the consistency loss rate is 20% in 2h, and the compressive strength is 7.1MPa in 28d. This ratio has good construction smoothness, sag resistance and water retention, and effectively controls hollowing and cracking. It is suitable for masonry mortar, plastering mortar and floor mortar for manual work.

Embodiment 2

[0019]

[0020] The water-retaining thixotropic agent prepared according to the mass percentage specified in the above table accounts for 0.1-0.12% of the total mass of the formula raw materials, and it is applied after adding water and stirring evenly. The M10 machine-sprayed surface mortar is mixed with 0.1% of the total mass of water-retaining thixotropic agent, the water retention rate is 94.3%, the 2h consistency loss rate is 16%, and the 28d compressive strength is 13.4MPa. The mortar prepared with this ratio has a low air content, which can significantly improve the "air blocking" phenomenon in the machine spraying process, and has good construction smoothness, sag resistance and water retention, and can effectively control hollowing and cracking. It is suitable for plastering mortar and floor mortar for machine spraying operations.

Embodiment 3

[0022]

[0023] The water-retaining thixotropic agent prepared according to the mass percentage specified in the above table accounts for 0.08-0.12% of the total mass of the formula raw materials, and it is applied after adding water and stirring evenly. The M5 masonry mortar is mixed with 0.1% of the total mass of water-retaining thixotropic agent, the water retention rate is 93.0%, the 2h consistency loss rate is 18%, and the 28d compressive strength is 6.4MPa. This ratio has good construction smoothness, sag resistance and water retention, and effectively controls hollowing and cracking. It is suitable for masonry mortar, plastering mortar and floor mortar for manual work.

[0024] At present, the water retention rate of dry powder mortar using thickened powder can barely reach 88%, and the workability is poor, and it is prone to bleeding, hollowing and cracking. It has the characteristics of high safety, smooth construction and no VOC. It is used in manual work mortar a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com