Autophoresis technology for surfaces of various metal furniture

An autophoresis, metal technology, used in electrophoretic plating, electrolytic coatings, coatings, etc., can solve the problems of poor corrosion resistance of metal surfaces, affecting product quality, unstable processes, etc., to achieve good environmental protection and stable coating process. , Good effect of salt spray test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

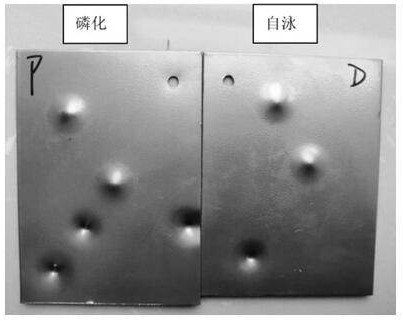

Image

Examples

Embodiment Construction

[0023] The surface self-swimming process of various metal furniture includes the following steps: hang the workpiece→spray pre-degreasing→soaking cleaning→soaking degreasing→spray cleaning→soaking ultrasonic cleaning→self-swimming in the swimming pool→spray water cleaning→baking →Surface electrostatic powder spraying→baking and solidification→cooling→workpiece blanking; Among them, in the self-swimming tank self-swimming process, the raw materials of the self-swimming liquid in the self-swimming tank are all water-based materials, including polymer acrylic acid, solid powder, Stabilizers and defoamers, when depositing, add automatic deposition chemical reaction materials to the bath, when self-swimming, immerse the workpiece in the self-swimming tank, the chemical reaction materials corrode the surface of the workpiece, and the partially dissolved Fe ions and The solid powder reacts to form a solid powder to precipitate and deposit on the surface of the metal workpiece to form ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com