Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

264results about How to "Strong rust resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof antiseptic wearproof nano paint, preparation method, use method and application thereof

ActiveCN101643612APrevent penetrationStrong rust resistanceLiquid surface applicatorsAnti-corrosive paintsEpoxyPolyamide

The invention discloses a waterproof antiseptic wearproof nano paint, a preparation method, a use method and application thereof. The paint has a middle layer, a surface layer or a bottom layer, a middle layer and a surface layer outwards orderly from the contact surface of a metal substrate surface; each layer comprises components by weight percent: the bottom layer comprises 10% to 25% of epoxysolution, 10% to 25% of polyamide solution, 50% to 78% of zinc powder and 2% to 10% of ferrous phosphorus powder; the middle layer comprises 15% to 30% of epoxy solution, 10% to 28% of polyamide solution, 42% to 70% of micaceous iron oxide, 2% to 10% of ferrous phosphorus powder and 2% to 8% of talcum powder; the surface layer comprises 25% to 50% of modified epoxy resin solution, 20% to 44% of polyamide solution, 5% to 20% of carborundum, 0.5% to 3% of nano carborundum and 10% to 25% of alumina and proper defoaming agents are added respectively to each layer of paint. The paint largely enhances the waterproof, antiseptic and wearproof performance of substrate, largely prolongs the service life and has good market prospect and practical popularization value.

Owner:广州汤普新材料有限公司

Metal surface cleaning solution

The invention relates to a metal surface cleaning solution which is prepared by following raw materials of, by weight percentage, sulfuric acid, hydrochloric acid, a high polymer composite enhanced active agent, sodium dodecyl benzene sulfonate, urotropin, sodium silicate, citric acid, urea, industrial salt, triethanolamine and water. The cleaning solution can completely clean up various greasy dirt, rust and scale cinder attached on a metal surface effectively, and protective film can forms on the metal surface after being cleaned so as to prevent metal from rusting and oxidizing in a certain period. Waste water of a used cleaning solution can be reused after being recovered, precipitated and filtered.

Owner:杨恒春

Grinding fluid for metal processing and preparation method thereof

InactiveCN109536263AWith carrying capacityImprove permeabilityLubricant compositionChemical reactionHigh pressure

The invention relates to the field of metal cutting additives, in particular to a grinding fluid for metal processing and a preparation method thereof. According to a technical scheme adopted by the invention, the grinding fluid for metal processing is composed of the following components by weight percentage: 5-15% of a PH value stabilizer, 3-5% of a surfactant, 5-10% of a water-borne lubricant,5-15% of an antirust agent, 4-8% of a coupling agent, 0.2-1% of a bactericide, 0.1-1% of a defoamer, 1-3% of a corrosion inhibitor, 0.2-0.4% of a settling agent, and the balance deionized water. The invention has the advantages that: the grinding fluid for metal processing adopts triethanolamine oleate as the surfactant, has good permeability and wettability, is conducive to entering a high temperature and high pressure working face, and at the same time is also a lubricant, the molecule has strong polar groups, can achieve strong adsorption with the metal surface, and chemical reaction can becarried out to form a firm physical absorption film and chemical reaction film with certain carrying capacity.

Owner:上海加美实业有限公司

Corrosion-inhibition type water-based metal cleaner

The invention discloses a corrosion-inhibition type water-based metal cleaner. The corrosion-inhibition type water-based metal cleaner comprises the following raw materials in parts by weight: 15-30 parts of coconut diethanolamide, 5-12 parts of octyl phenol polyoxyethylene ether, 3-10 parts of alkyl benzene sodium sulfonate, 7-15 parts of sodium xylene sulfonate, 5-10 parts of citric acid, 4-12 parts of sodium citrate, 1-4 parts of polyvinyl chloride latex, 0.5-3 parts of non-ionic polyacrylamide, 4-10 parts of sodium carbonate, 15-30 parts of hydrophilic alcohol, 3-6 parts of instant modified sodium disilicate, 15-30 parts of dodecanedioic triethanolamine, 2-5 parts of N-lauroyl sarcosine triethanolamine, 3-8 parts of mercaptobenzothiazole sodium, 1-5 parts of a defoaming agent, 1-5 parts of a fungicide, 30-40 parts of soft water and 100-150 parts of water. The corrosion-inhibition type water-based metal cleaner disclosed by the invention is strong in detergency, good in anti-rusting property, less in environment-friendly pollution, high in cleaning speed, less in residues after cleaning, good in stability and capable of being used in hard water.

Owner:CHAOHU GUANGFENG METAL PROD

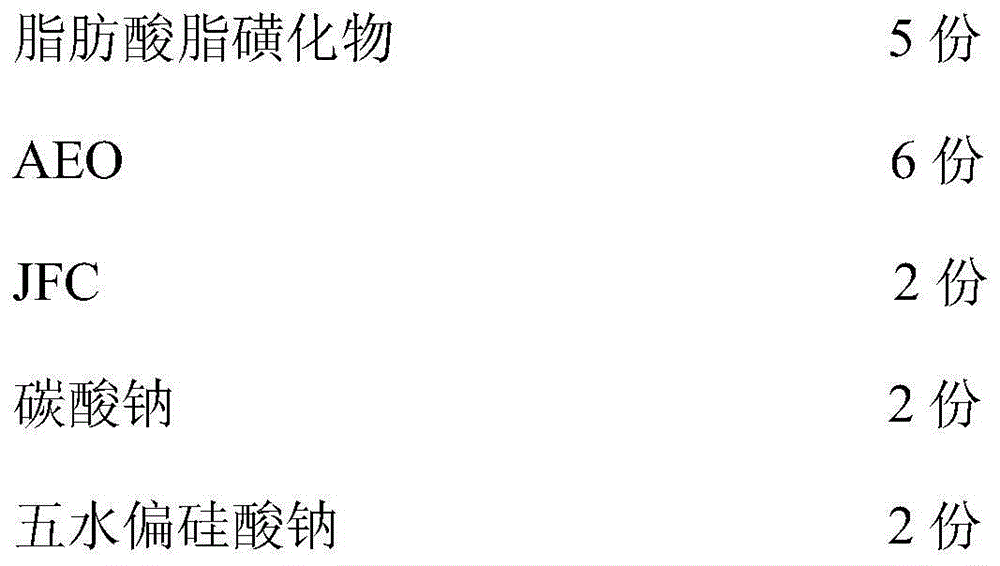

Normal-temperature water-based non-phosphorus rust-proof cleaning agent for heavy oil

InactiveCN104313622AHigh degreasing efficiencyImprove natural degradation performanceWater basedSodium metasilicate

The invention discloses a normal temperature water-based non-phosphorus rust-proof cleaning agent for heavy oil. The rust-proof cleaning agent comprises an anionic surfactant, a nonionic surfactant and auxiliaries, wherein the mass ratio of the anionic surfactant to the nonionic surfactant to the auxiliaries is (1.5-4): (1.5-4): 1. The cleaning agent comprises the following components in parts by weight: 5 parts of sulfonated fatty acid ester, 6 parts of AEO (alcohol ethoxylate), 2 parts of JFC, 2 parts of sodium carbonate, 2 parts of sodium metasilicate pentahydrate, 2 parts of EDTA (ethylene diamine tetraacetic acid) disodium and 3 parts of dimer acid-modified water-based acrylate. The cleaning agent disclosed by the invention has a relatively high natural degradation effect and overcomes the defect that common cleaning agent has the cleaning function only at a medium temperature or relatively high temperature and the cleaning agent disclosed by the invention has a relatively high cleaning effect at normal temperature. In addition, the cleaning agent disclosed by the invention further overcomes the defect that the existing cleaning agent is poor in anti-rust performance.

Owner:HEFEI QIANFENG LUBRICATION TECH

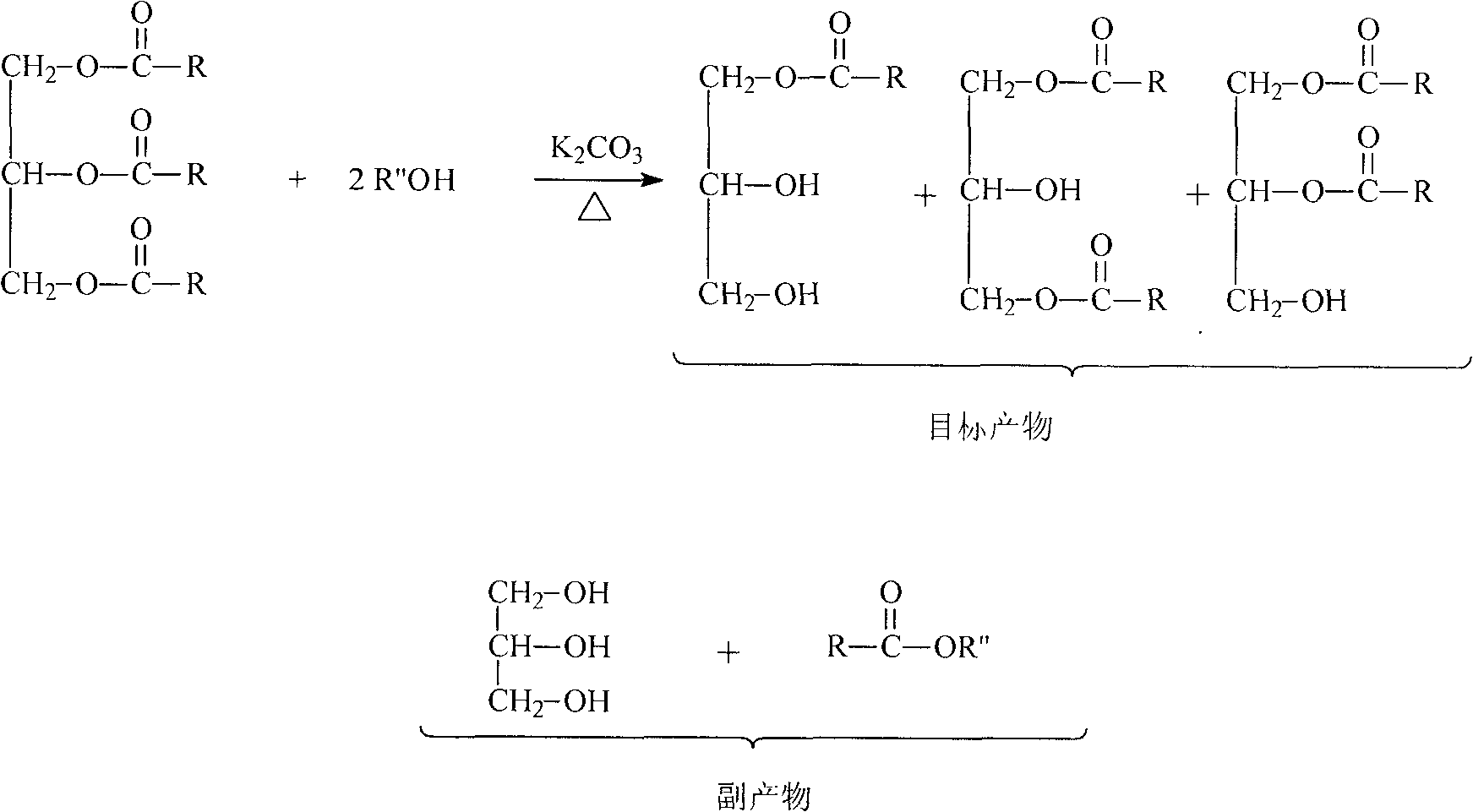

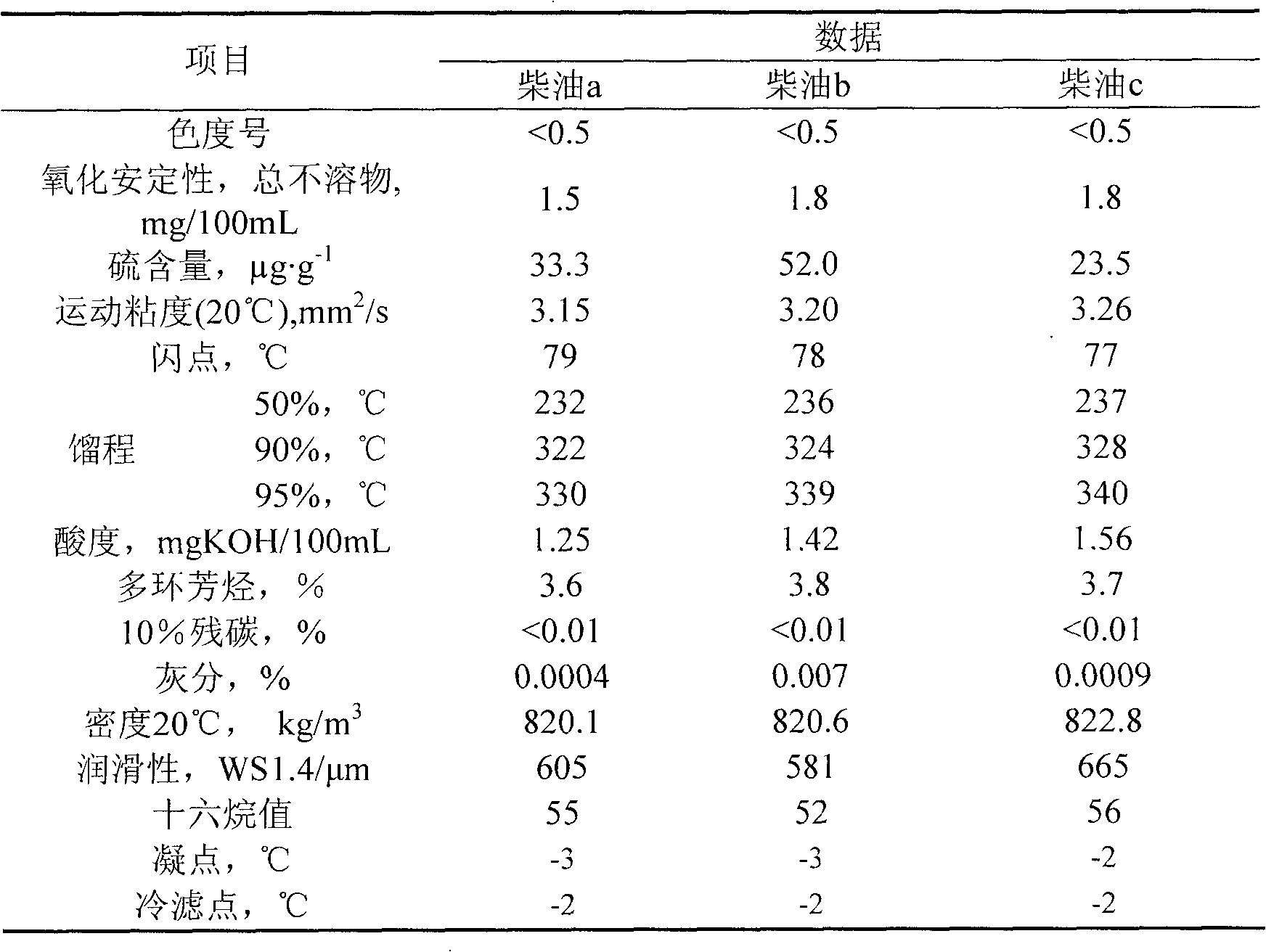

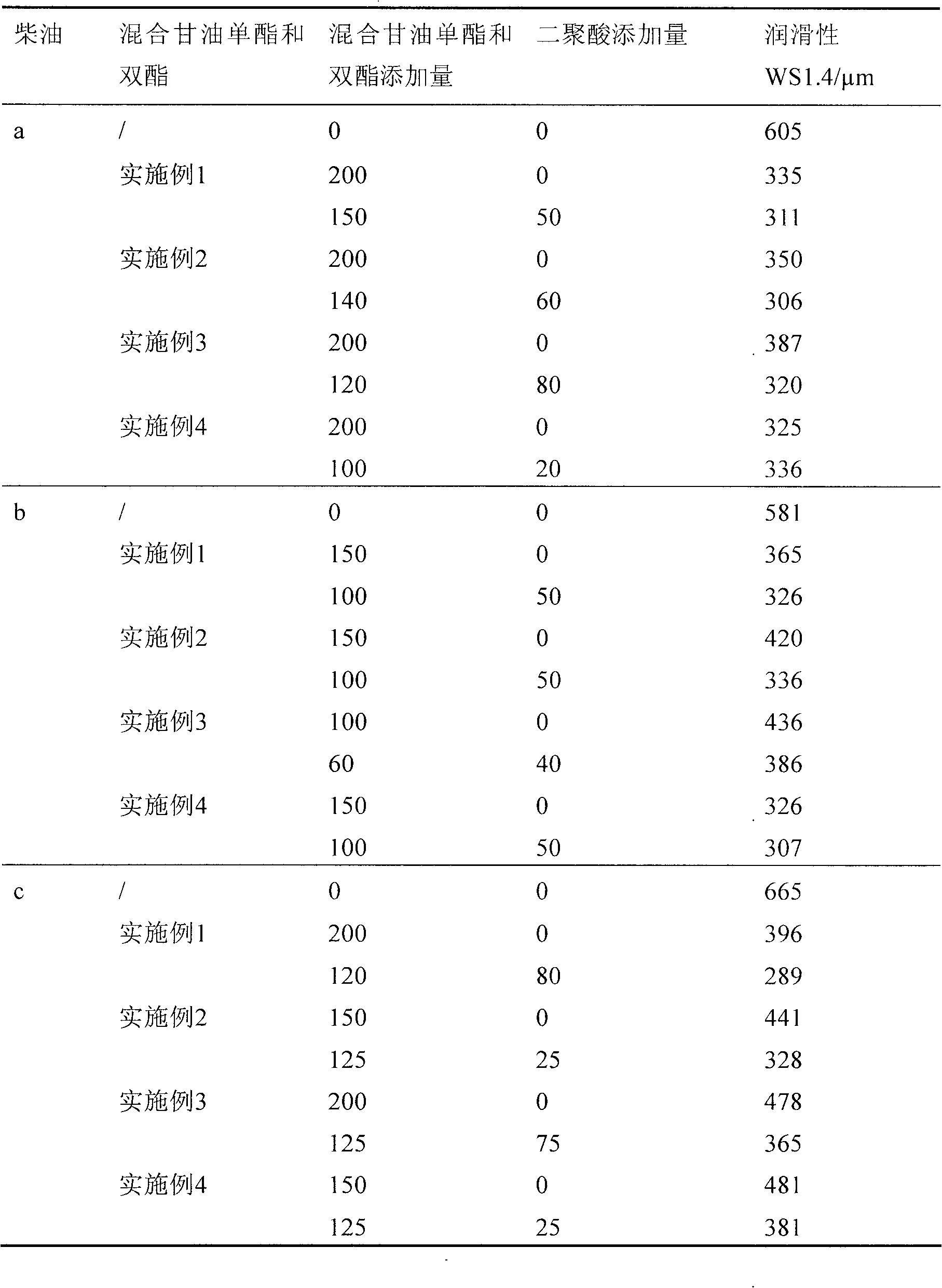

Improver for lubricating performance of low-sulfur diesel oil and preparation process thereof

InactiveCN101787318AImprove solubilityReduce frictionLiquid carbonaceous fuelsFuel additivesOil and greaseCompound a

The invention relates to an addictive formed by compounding a glycerol single-double ester mixture and dimeric dibasic acid and used for improving the lubricating performance of low-sulfur diesel oil and preventing the wear of a pump, caused by combusting a fuel with poor lubricating performance through a diesel engine. The glycerol single-double ester is synthesized by catalyzing natural grease to react with alcohol compounds by taking inorganic base as a catalyst; and the glycerol single-double ester and a dual-ester mixer are compounded with the dimeric dibasic acid to obtain a series performance improver which has a favorable synergistic effect for improving the lubricating performance of low-sulfur diesel oil. Under the condition that the addition is 125-250mug.g<-1>, the improver has the effect which is remarkably superior to that of an imported agent for improving the lubricating performance of the low-sulfur diesel oil and hardly influences the oxidation stability and the low-temperature flowability of diesel oil. Meanwhile, the improver has no counteraction on a diesel oil stabilizer and a diesel oil flowing improver.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Micro-emulsified water-soluble cutting fluid and preparation method thereof

InactiveCN104312707AImprove cooling effectStrong rust resistanceAdditivesMaterial resourcesSkin irritant

The invention discloses micro-emulsified water-soluble cutting fluid and a preparation method thereof. The micro-emulsified water-soluble cutting fluid comprises the following components in percentage by weight: 6-15 percent of base oil or oiliness agent, 2-5 percent of nonionic surfactant, 5-10 percent of anionic surfactant, 5-8 percent of mixed alkylol amine, 10-15 percent of antirust agent, 0.08-0.1 percent of copper alloy corrosion inhibitor, 0-0.5 percent of ethylenediamine tetraacetic acid tetrasodium salt, 0.1-0.2 percent of antifoaming agent and the balance of water. The micro-emulsified water-soluble cutting fluid prepared by the invention is high in cooling property, antirust property and hard water resistance and hardly deteriorates or stinks, the product can inhibit fungi, bacteria and moulds very well without adding any special bactericide, the service life of the product is prolonged, and harm of the bactericide to skin irritation is avoided. The cutting fluid is reasonable in formula, multiple surfactants and aids are utilized, the provided cutting fluid is diluted with water according to a general ratio of 1:20 before being used, the antirust time of a single product exceeds 180 hours, the use of the product is not influenced even if the tank is not replaced within a year according to customer response, the manpower and material resources needed in the process of replacing the tank are saved, and the cost is saved.

Owner:无锡库帕油品有限公司

Special environment-friendly complete-synthesis cutting fluid for drilling stainless steel and preparation method thereof

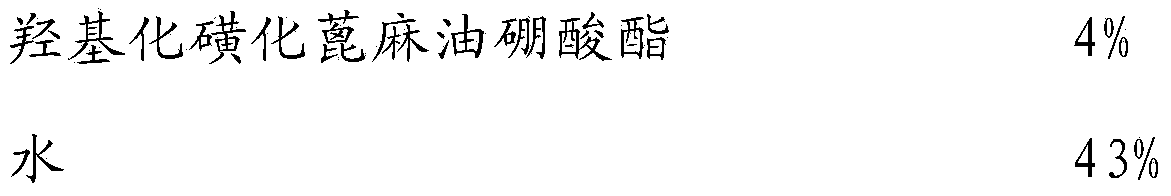

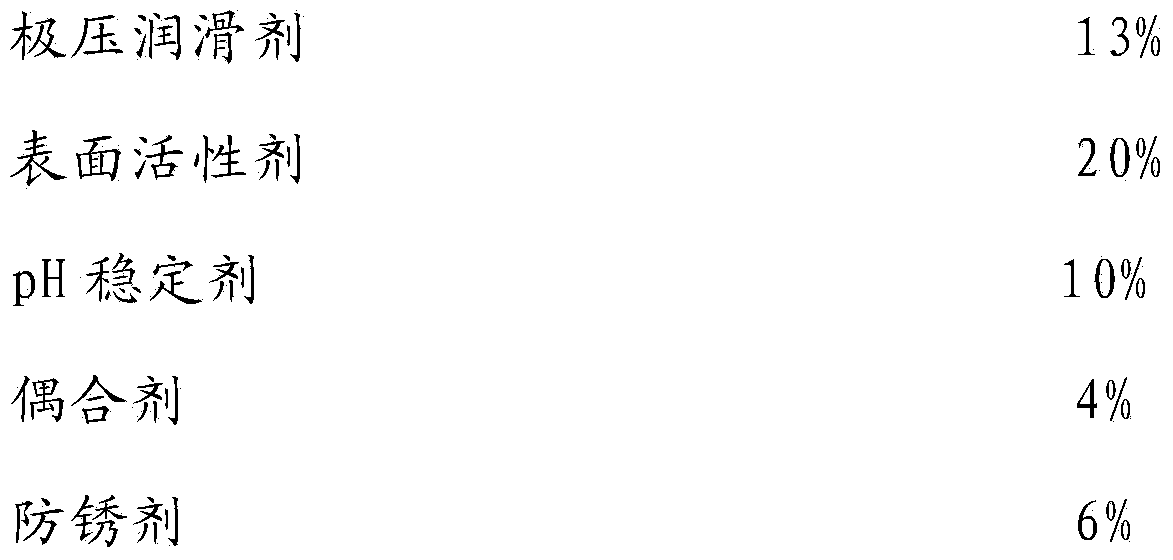

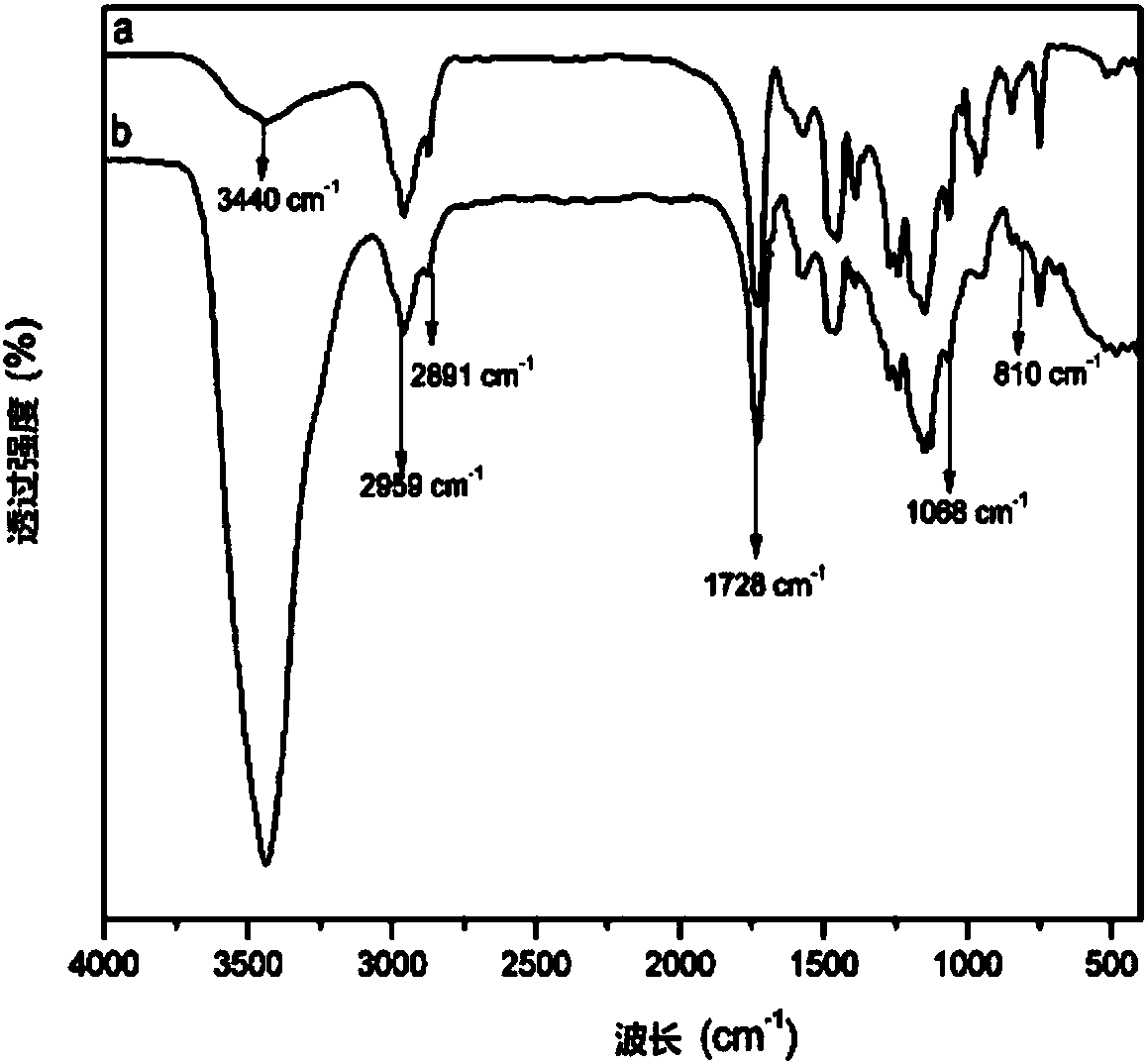

ActiveCN103805329AImprove stabilityStrong rust resistanceLubricant compositionSurface-active agentsMIXTURE COMPONENT

The invention discloses a special environment-friendly complete-synthesis cutting fluid for drilling stainless steel and a preparation method thereof. The preparation method comprises the following steps: mixing and stirring 10 to 15 percent of extreme-pressure lubricant, 3 to 5 percent of hydroxylation sulfonation castor oil borate and water for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain a mixed component A; mixing and stirring 5 to 15 percent of pH stabilizer, 5 to 8 percent of antirust agent and water for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain a mixed component B; uniformly mixing and stirring 15 to 25 percent of surface active agent and 3 to 5 percent of coupling agent at the normal temperature and normal pressure to obtain a mixture component C; adding the mixed component A, the mixed component B and the mixed component C into a reaction kettle and stirring and mixing for 10 minutes to 1 hour at the temperature of 30 to 80 DEG C to obtain the product. The prepared product is good in lubricating property, washing property, antirust property and cooling property, long in service life and environment-friendly.

Owner:GUANGZHOU LANDNOK CHEM TECH

Application, composite anti-rusting pigment and parathion method of calcium phosphate aluminum silicate

ActiveCN104212222AImprove rust resistanceReduce manufacturing costAnti-corrosive paintsCalcium silicateCalcium biphosphate

The invention discloses application, a composite anti-rusting pigment and a parathion method of calcium phosphate aluminum silicate. The anti-rusting pigment comprises, by weight, 50-75 parts of aluminum phosphate, 5-15 parts of aluminum silicates, 5-15 parts of calcium silicate, 10-30 parts of filler and 0.1-5 parts of additive. The parathion method of the calcium phosphate aluminum silicate composite anti-rusting pigment comprises the following steps of mixing at least three materials including the aluminum silicate, the calcium silicate and the aluminum silicate of all raw materials with water, keeping the temperature to be in a range from 20 DEG C to 100 DEG C, and continuously performing stirring 1.5-12 hours; adding the remaining materials into the mixture to be mixed evenly, and then performing centrifugal dewatering, drying and smashing. The anti-rusting pigment has the advantages of being non-toxic, environment-friendly and efficient and can completely take the place of red lead, zinc chrome and other traditional toxic heavy metal anti-rusting pigments used in industrial coatings.

Owner:GUANGXI XINJING TECH

Water-based environment-friendly rust removal and prevention film covering liquid and production process thereof

The invention discloses water-based environment-friendly rust removal and prevention film covering liquid and a production process thereof. The water-based low-VOC environment-friendly rust removal and prevention film covering liquid is prepared by adding coalescing agent, base material wetting agent, import antifoaming agent and other pollution-free auxiliaries with tannic acid as rust removal and prevention agent and vinyl multi-copolymerization emulsion as film forming material. Raw materials of the liquid are easy to obtain, rust removal labor is saved, anti-corrosion performance is high, and safety, environment protection and acid and alkali corrosion resistance are achieved.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Waterborne polyurethane severe corrosion-resisting primer and preparation method thereof

ActiveCN108250927AInhibitionEliminate Bubble ProblemsAnti-corrosive paintsPolyurea/polyurethane coatingsWaxEmulsion

The invention provides a waterborne monocomponent polyurethane severe corrosion-resisting primer and a preparation method thereof. The primer is prepared from waterborne monocomponent polyurethane emulsion, a rust resisting pigment, a coalescing agent, a defoaming agent, a thickening agent, optional wax emulsion, physical filler, a dispersing agent and deionized water. The waterborne corrosion-resisting primer provided by the invention has the advantages of high antirust ability, excellent corrosion resistance, as well as high adhesion and good water resistance of the whole paint film; in addition, the whole paint film has excellent waterproof and antifouling properties and a metal base material is strengthened.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

Water-based heavy-duty single-component on-rust primer, and preparation method and application thereof

The invention discloses a water-based heavy-duty single-component on-rust primer, and a preparation method and application thereof. The water-based heavy-duty single-component on-rust primer is composed of deionized water, a main conversion agent, an auxiliary conversion agent, a penetrant, a film forming assistant, an antifreezing agent, a preservative, a thickener, a filler, a defoaming agent, a dispersing agent, a pH regulator, a film forming material and a substrate wetting agent. The temperature of the used substrate can not be too high, the humidity can not be greater than 85%, the one-time spray coating can not be too thick, and the position for electric welding is reserved. The product is stored at 5-40 DEG C in a ventilating cool dry place, and the construction temperature is preferably 10-40 DEG C. The primer can be applied by brush coating, roller coating, air spraying or airless spraying, the particular mode can be selected according to the on-site construction environment and climate conditions, and brush coating and airless spraying are suggested if conditions permit.

Owner:山东兴鲁化工股份有限公司

Waterborne alkyd paint and preparation method thereof

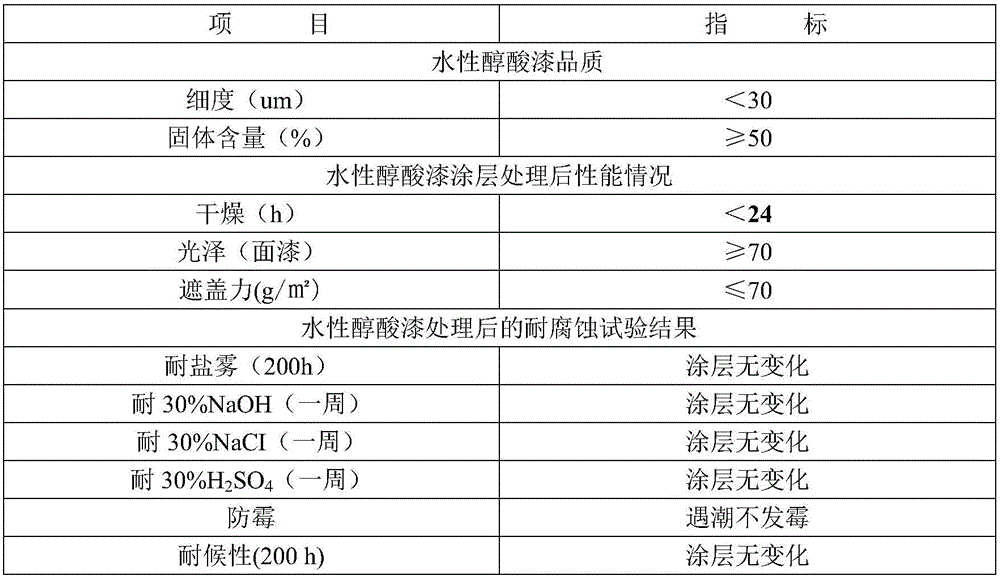

InactiveCN106280933AQuality improvementImprove adhesionAnti-corrosive paintsPolyester coatingsLacquerOil paint

The invention relates to the technical field of oil paint and especially relates to a waterborne alkyd paint and a preparation method thereof. The waterborne alkyd resin, titanium dioxide flour, barium sulfate, ferrotitanium flour, waterborne dispersing agent, defoamer, antirust agent, thickener and water are selected and coordinated, so that the acquired waterborne alkyd paint has quality stability, high adhesive force, higher antirust capacity and higher covering capacity; the expulsion rate in the steel structure can be reduced; the anticorrosive period of the steel structure can be prolonged.

Owner:NANFENG HOUSE KEEPING ELECTRIC APPLIANCES ZUNYI

Microemulsion type water-soluble metal cutting fluid and preparation method thereof

ActiveCN107446681ASimple preparation processEasy to useLubricant compositionAntioxidantCarboxylic salt

The invention provides a microemulsion type water-soluble metal cutting fluid and a preparation method thereof. The cutting fluid is prepared from the components in percentage by weight: 5 to 40 percent of base oil A, 3 to 10 percent of surface active agent B, 2 to 27 percent of stabilizer C, 0.1 to 3 percent of extreme pressure agent D, 0.1 to 5 percent of sterilizing agent E, 0.5 to 3 percent of metal antioxidant F, 1 to 3 percent of defoaming agent H, 0.5 to 2 percent of hard water resistance agent G, 1 to 5 percent of sinking agent K, and the balance of distilled water, wherein the stabilizer is a mixture of primary amine and tertiary amine, and can be reacted with the base oil to generate alkanolamine carboxylate, and the mass ratio of the base oil and the stabilizer is 3 to (1 to 2). The cutting fluid has the advantages of superior lubricating property, good corrosion resistance, high stability, long service cycle and the like.

Owner:许勇 +1

Wear-resistant pressure-resistant epoxy paint and preparation method thereof

The invention discloses a wear-resistant pressure-resistant epoxy paint, which is characterized by being prepared from the following raw materials by weight: 70-75 parts of E-42 epoxy resin, 2-3 parts of ethylene glycol ethyl etheracetate, 10-12 parts of polyamide resin, 10-12 parts of asphalt, 1-2 parts of 2-methylimidazole, 10-14 parts of phenolic resin, 2-3 parts of dicyandiamide, 16-19 parts of talcum powder, 5-6 parts of barium metaborate, 1-2 parts of nano aluminum oxide, 1-2 parts of dibenzoyl peroxide, 10-12 parts of xylene, 4-5 parts of vinyl acetate, 7-9 parts of ethyl acetate and 3-4 parts of a dispersant. The dispersant involved in the invention improves optical performance, realizes even dispersion of the paint and maintains the stability of the paint. The wear-resistant pressure epoxy paint provided by the invention has the advantages of extremely strong corrosion resistance, rust resistance andsaline-alkaline tolerance on metal, high hardness, wear resistance, pressure resistance and difficulty in brittle fracture, makes up the insufficiencies of a traditional epoxy paint; in addition, the wear-resistant pressure-resistant epoxy paint has simple preparation technology and is particularly suitable for back protection for a metal plate.

Owner:WUHU HONGKUN AUTO PARTS

Preparation method of long-acting water replacement type hard membrane corrosion inhibitor for aircrafts

The invention relates to a long-acting water replacement type hard membrane corrosion inhibitor for aircrafts, and a preparation method thereof. The long-acting water replacement type hard membrane corrosion inhibitor is characterized by comprising the following raw materials by weight: 20-30 parts of a film forming agent, 30-40 parts of base oil, 1-10 parts of a corrosion inhibition additive, 5-10 parts of a dewatering additive, 1-5 parts of an antioxidant, 1-5 parts of a plasticizing agent, 1-5 parts of an emulsifier, 0.1-0.5 part of a color adjusting agent, and 5-10 parts of an auxiliary solvent. The prepared long-acting water replacement type hard membrane corrosion inhibitor has the following advantages that: the corrosion inhibitor has functions of strong rust resistance, long durability, good salt spray resistance, good dampness heat resistance and the like of the general corrosion inhibitor, further has characteristics of high flash point and low weight gain, meets aircraft flying requirements, has the strong permeability so as to easily penetrate and immerse into the overlapping and riveted structure of the aircraft, has the strong water replacement performance so as to replace the fine liquid droplet in the structural micropore, and concurrently provides corrosion protection functions for a variety of metals.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Metallic antirust agent

InactiveCN101748417AStrong ability to degrease and decontaminateStrong rust resistanceHazardous substancePolyethylene glycol

The invention discloses a water-soluble metallic antirust cleaner, which is characterized in that the metallic antirust cleaner comprises the following raw materials in parts by weight: 4-8 parts of peregal, 2-6 parts of polyethylene glycol, 2-6 parts of oleic acid, 6-15 parts of triethanolamine, 2-3 parts of sodium nitrite, 0.5-1.2 parts of benzotriazole and 0.5-1.2 parts of silicone defoamer. The metallic antirust cleaner has the advantages of: 1. not containing harmful materials such as trichloroethane, carbon tetrachloride and the like, not damaging high-altitude ozone layer and not polluting the environment; 2. having strong degreasing and decontaminating abilities and having no bad effect on nonferrous metals; 3. having strong antirust capability; and 4. having strong anti-foaming property and generating no overflow phenomenon under high pressure.

Owner:TIANJIN SANNONGJIN TECH

Fabricating method of stainless cast iron cooker

ActiveCN101518410AStrong anti-rust abilityOvercome rust easilyLiquid surface applicatorsCooking vesselsCast ironEveryday object

The invention provides a fabricating method of a stainless cast iron cooker, which belongs to the technical field of the fabrication of daily goods and solves the problems of higher cost, lower rigidity, poorer wearing property and corrosion resistance, shorter service life, and the like. The fabricating method of the stainless cast iron cooker comprises the following steps: A. forming; B. nitrogen stainless treatment; and C. oil finish. The invention has the advantages of good rust prevention property, high safety performance, good iron supplementation effect, favorable rigidity and wearing property, long service life, and the like.

Owner:杭州蜗牛实业有限公司

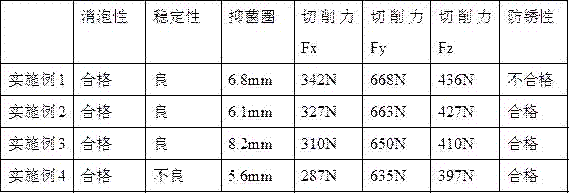

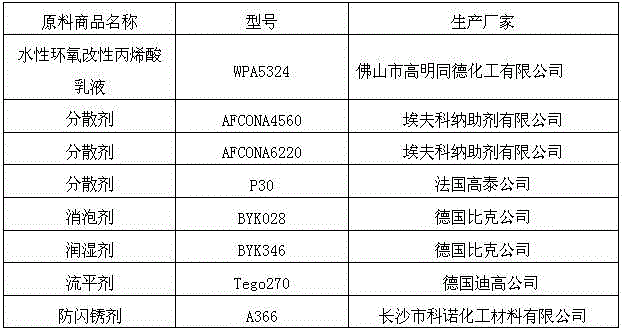

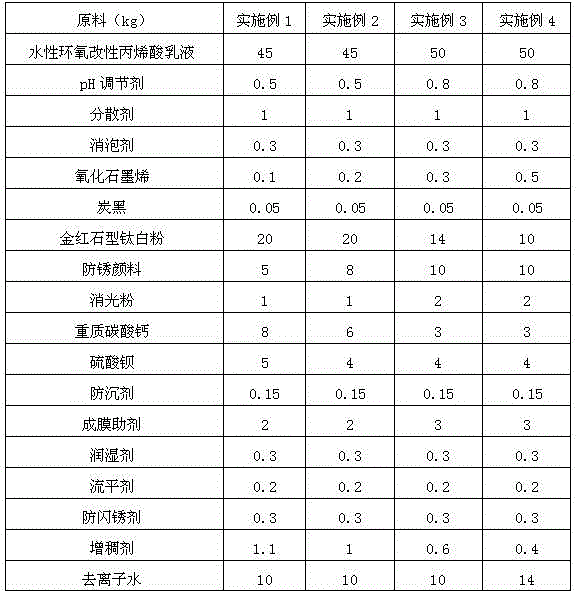

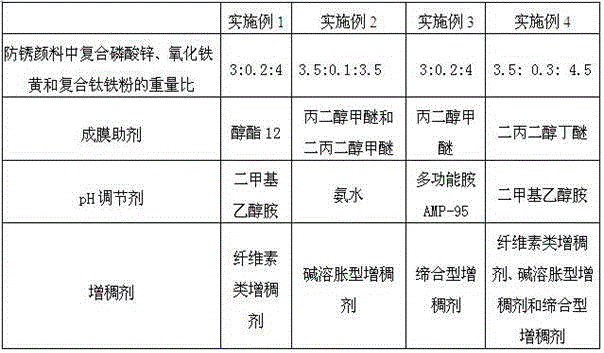

Acrylic water-based paint for motor shells and preparation method thereof

The invention discloses an acrylic water-based paint for motor shells and a preparation method thereof, relating to the technical field of metal water-based paints. The acrylic water-based paint for motor shells comprises the following raw materials in parts by weight: 45-50 parts of acrylic modified resin, 0.4-0.8 part of pH regulator, 0.6-1.5 part of dispersing agent, 0.3-0.5 part of defoaming agent, 0.01-0.5 part of graphene oxide, 0.05-3 parts of carbon black, 10-20 parts of rutile titanium white, 2-10 parts of antirust pigment, 0.5-4 parts of matting powder, 0.5-8 parts of ground calcium carbonate, 3-8 parts of barium sulfate, 0.05-0.15 part of anti-settling agent, 2-3 parts of film forming aid, 0.1-0.5 part of wetting agent, 0.1-0.5 part of leveling agent, 0.1-0.5 part of flash-rust inhibitor, 0.1-1.2 parts of thickener and 6-16 parts of deionized water. The water-based paint has the advantages of favorable antirust effect, quick air-drying, high adhesive force and high hardness; and by using water as the diluter, the water-based paint satisfies the environmental requirements, and is harmless to the human body.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water soluble metal anti-rust cleaning agent

InactiveCN1990913AStrong ability to degrease and decontaminateStrong rust resistanceOzone layerHazardous substance

The invention relates to a water soluble metallic antirust cleaner, which is characterized in that: it comprises following components with certain proportion by weight: peregal 4-8 units, polyethylene glycol 2-6 units, oleic acid 2-6 units, triethanolamine 6-15 units, sodium nitrite 2-3 units, benzotriazole 0.5-1.2 units, and Silicone defoaming agent 0.5-1.2 units. The advantages of this invention comprises: (1) containing no trichloroethane and carbon tetrachloride, which will destroy ozone layer and pollute environment; (2) strong ability to remove fat and dirty, no bad influence to color metal; (3) good performace of preventing rust; (4) strong ability to resist foam.

Owner:天津市怡佳商贸有限公司

Environment-friendly anti-rust oil for bearing

ActiveCN106635343ASuper rust resistanceAnti-salt spray corrosion performanceBase-materialsChemistryEther

Owner:上海森帝润滑技术有限公司

Metal printing technology for food metal can

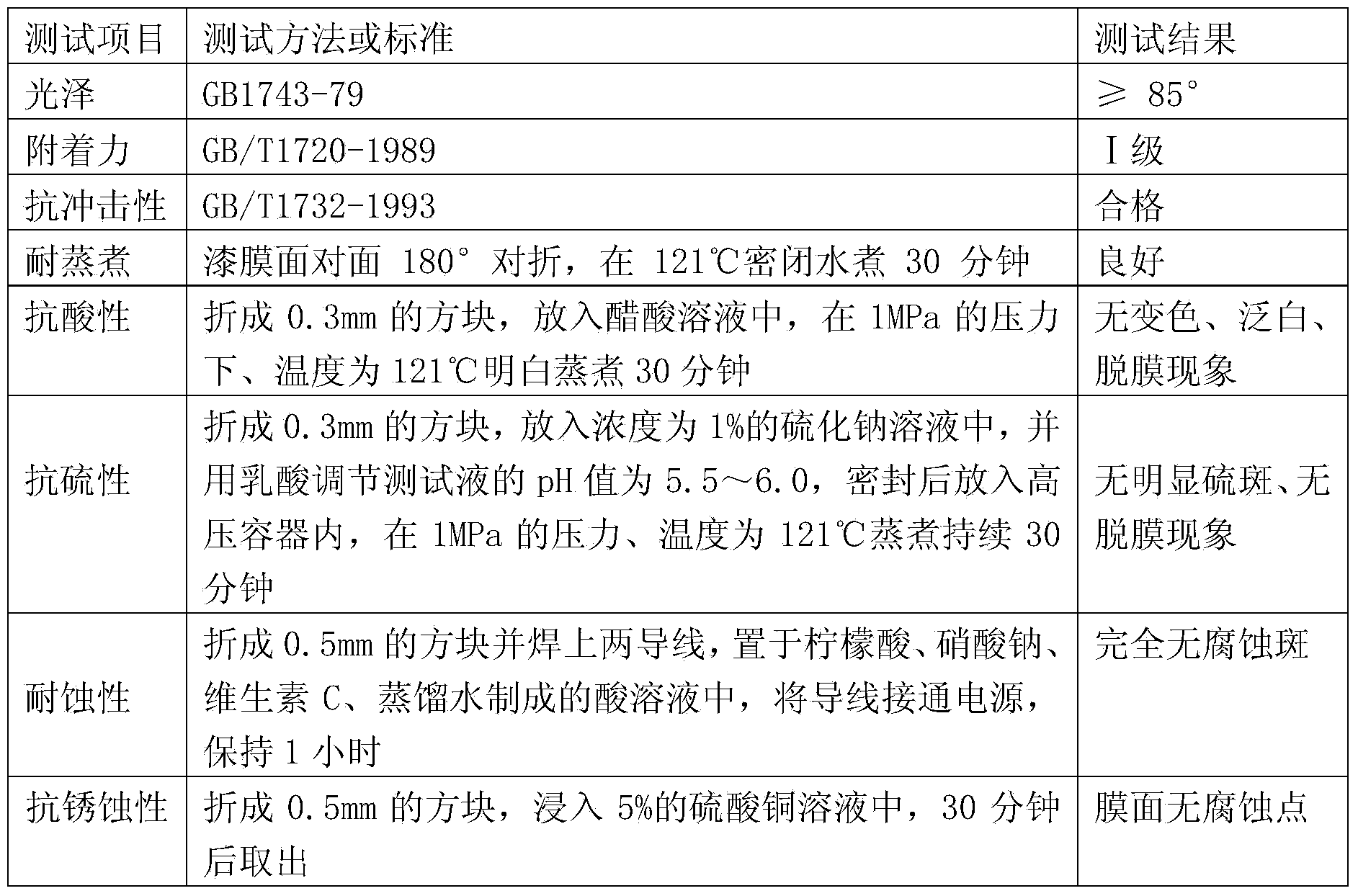

ActiveCN103847268AShorten the timeStrong rust resistanceOther printing apparatusPrinting after-treatmentSulfurThermal printing

The invention belongs to the field of metal printing, and more particularly relates to a metal printing technology for a food metal can. The metal printing technology for the food metal can comprises the following steps of designing, plate making, substrate processing, steel-plate surface rust prevention, steel-plate base-color processing, painting of white coating oil, steel-plate lustering, steel-plate shading, and steel-plate detection and package. According to the metal printing technology provided by the technical scheme of the invention, the capabilities of resisting sulfur corrosion, resisting acid etching and resisting rust cession are better; the time of the whole metal printing technology is shorter, and the operation is easier to control.

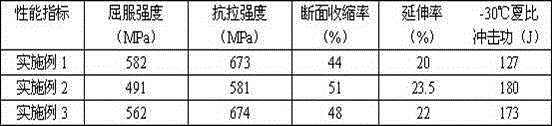

Flux core powder for manufacturing seamless self-shielded welding wire

ActiveCN103949795AArc stabilizationArc blowing force is largeWelding/cutting media/materialsSoldering mediaCopper platingRare earth

The invention relates to flux core powder for manufacturing a seamless self-shielded welding wire. The skin of the seamless self-shielded welding wire adopts a mild steel strip, and the flux core powder is synchronously added to the mild steel strip on line. 100 parts of flux core powder comprises the ingredients: 35-50 parts of barium lithium fluoride, 3-5 parts of magnesium fluoride, 0-4 parts of sodium fluoride, 1-3 parts of calcium fluoride, 4-12 parts of iron oxide red, 1-3 parts of rare earth fluoride, 4-8 parts of metal manganese, 10-18 parts of aluminium magnesium alloy, 6-10 parts of metal nickel, 0.5-2 parts of metal zirconium, and the balance of iron powder. All the materials are mixed and stirred uniformly according to a customary method, so that the flux core powder is obtained; the mild steel strip is curled to form a linear seamed cylinder by roller molding, and the linear seamed cylinder wraps the flux core powder; the linear seamed cylinder is manufactured into a semi-finished product seamless self-shielded welding wire by using high-frequency induction or contact bond; the semi-finished product seamless self-shielded welding wire is subjected to annealing and reducing, and is subjected to copper plating, and then the seamless self-shielded welding wire is prepared. In order to prevent the flux core power from absorbing moisture, the skin can be subjected to copper plating, and thus, the rust resistance of the seamless self-shielded welding wire is improved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Water-based heavy-duty single-component primer, as well as preparation method and application thereof

InactiveCN106811040AIncreased sealing performanceAnti-rust for a long timeAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryHeavy duty

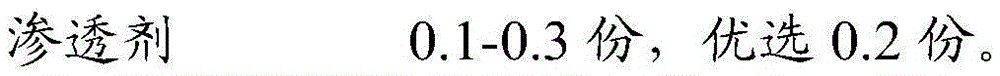

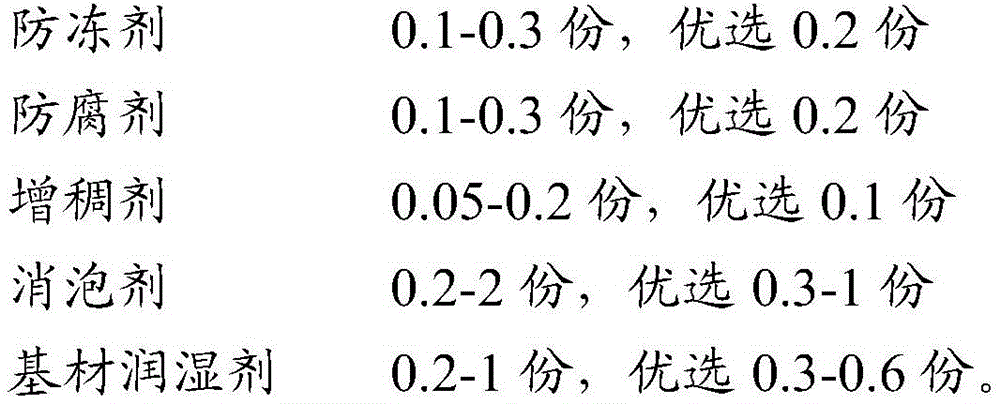

The invention relates to a water-based heavy-duty single-component primer, which is prepared from the following components in parts by mass: 18 to 33, preferably 20 to 30, parts of de-ionized water, 1.5 to 10, preferably 2 to 8, parts of a coalescing agent, 6 to 12, preferably 8 to 10, parts of an anti-rust pigment, 3.5 to 17, preferably 5 to 15, parts of filler, 0.3 to 1.2, preferably 0.5 to 1.0, part of a dispersant, 0.08 to 0.4, preferably 0.1 to 0.3, part of a pH regulator, 38 to 75, preferably 40 to 70, parts of a film former, 7 to 11, preferably 8 to 10, parts of a complexing agent and 0.1 to 0.3, preferably 0.2, part of a penetrant. The invention also provides a preparation method and application of the water-based heavy-duty single-component primer.

Owner:杨卫兵

Calcium monofluorophosphate rust-proofing powder

InactiveCN101182417AEasy to useExcellent performanceAnti-corrosive paintsChemical inhibitorsLacquerPhosphate

Owner:武汉市大汉科技发展有限公司

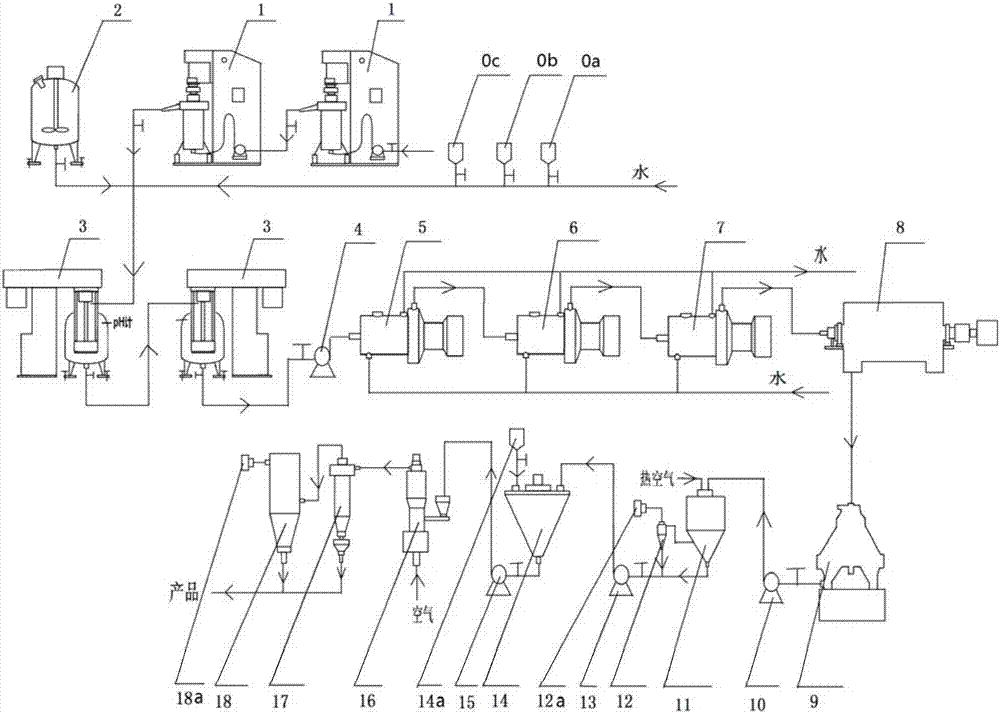

A continuous production method and production device of nano-zinc phosphate antirust pigment

InactiveCN105694570BImprove uniformityMinimize impact on product qualityAnti-corrosive paintsPigment treatment with macromolecular organic compoundsThree levelAutomatic control

The invention provides a nanometer zinc phosphate antirust pigment continuous production method and device. Zinc oxide and phosphoric acid are used as raw materials, under the synergistic effect of multiple auxiliaries such as a template agent and a dispersing agent, the contact reaction surface between zinc oxide and phosphoric acid is continuously updated by means of three-level serial grinding, particle shape and size control is conducted, and nanometer zinc phosphate antirust pigments with a uniform particle size are obtained by means of dehydration, spray drying, modification and smashing. Full-automatic control is adopted, production is convenient and fast, the obtained nanometer zinc phosphate antirust pigments are uniform in particle size and stable in product quality, and the antirust performance is improved by 20% compared with existing imported zinc phosphate.

Owner:GUANGXI UNIV FOR NATITIES

Antibacterial flame-retardant paint and preparation method thereof

InactiveCN104962148AImprove antibacterial propertiesImprove the bactericidal effectEpoxy resin coatingsPolyvinyl butyralZinc borate

The invention relates to antibacterial flame-retardant paint. The antibacterial flame-retardant paint consists of the following substances in parts by weight: 6 to 10 parts of glycidyl acrylate, 15 to 30 parts of trumpet shell powder, 8 to 16 parts of aluminium triphosphate, 10 to 25 parts of antibacterial nano titanium dioxide, 8 to 10 parts of coconut oil fatty acid diethanol amide, 4 to 10 parts of precipitated barium sulfate, 12 to 20 parts of polyvinyl butyral, 0.5 to 1 part of superfine acrylate rubber powder, 0.1 to 0.5 part of isophorone diisocyanate, 5 to 15 parts of epoxy acrylic resin and 1 to 3 parts of zinc borate. The antibacterial flame-retardant paint preparation process is carried out under the normal temperature and normal pressure, no novel device is needed, the process is simple, and the production cost is low. After the antibacterial flame-retardant paint is used, not only is the surface antibacterial performance of the material effectively improved, but also the flame-retardant performance is relatively good.

Owner:饶烨

Special paint for food can and preparation method thereof

ActiveCN103409035AStrong anti-corrosion abilityStrong rust resistanceAnti-corrosive paintsEpoxy resin coatingsSolventBenzene

The invention belongs to and relates to the technical field of can processing, and particularly relates to in-can paint for a can pack and preparation thereof. The special paint for a food can comprises the following components in percentage by mass: 30-70% of resin, 2-3% of amino, 0.5-2% of curing agent, 0.5-2% of surface accelerator and 56-67% of solvent. The special paint for a food can only contains an extremely small amount of benzene, and has no toxic action on human bodies. The paint provided by the invention has very high corrosion resistance and rust resistance, favorable acid resistance and sulfidation resistance, and high resistance to elevated temperatures. The paint provided by the invention is simple and quick in storage method and high in production efficiency.

Owner:蚌埠飞浦科技包装材料有限公司

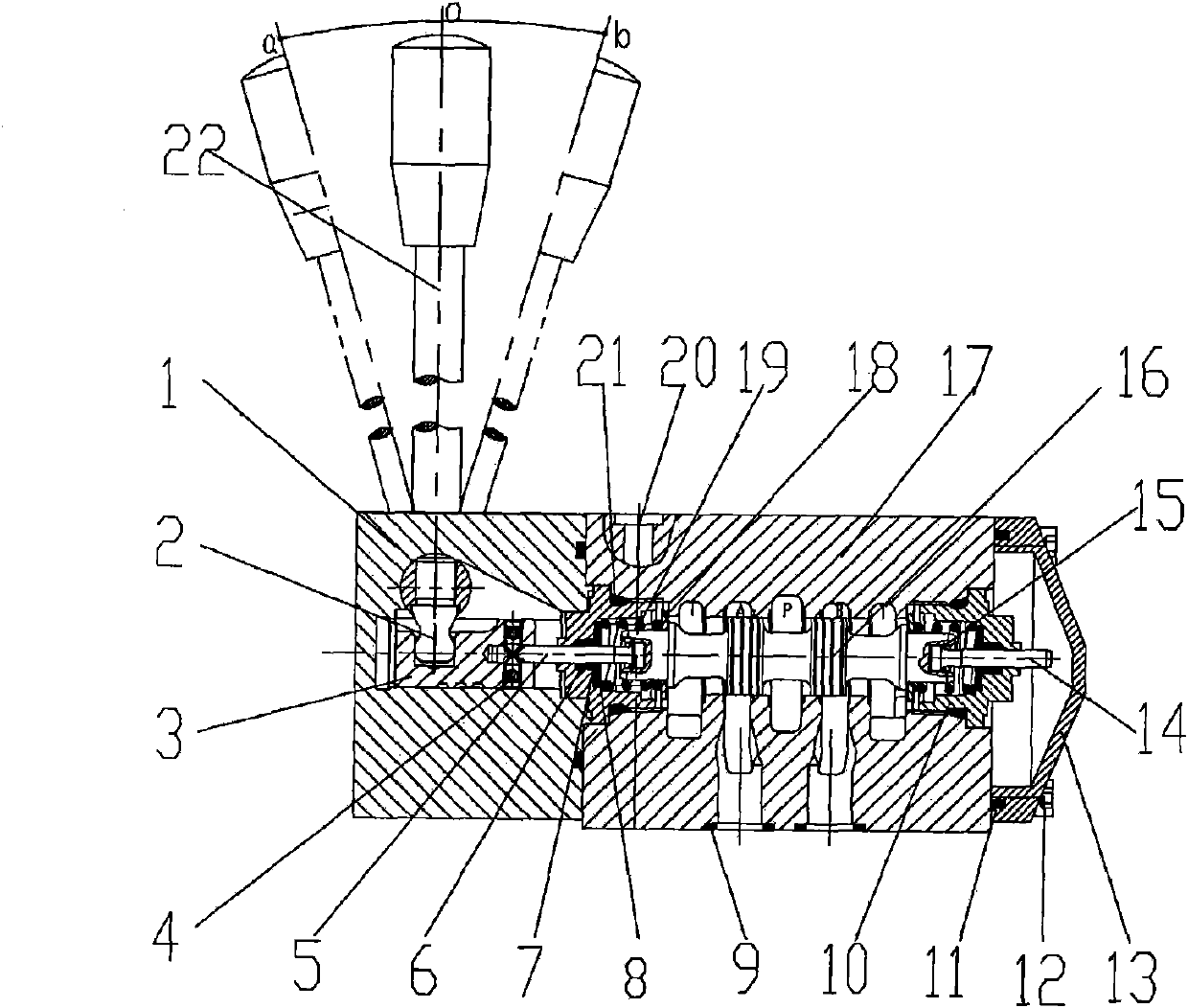

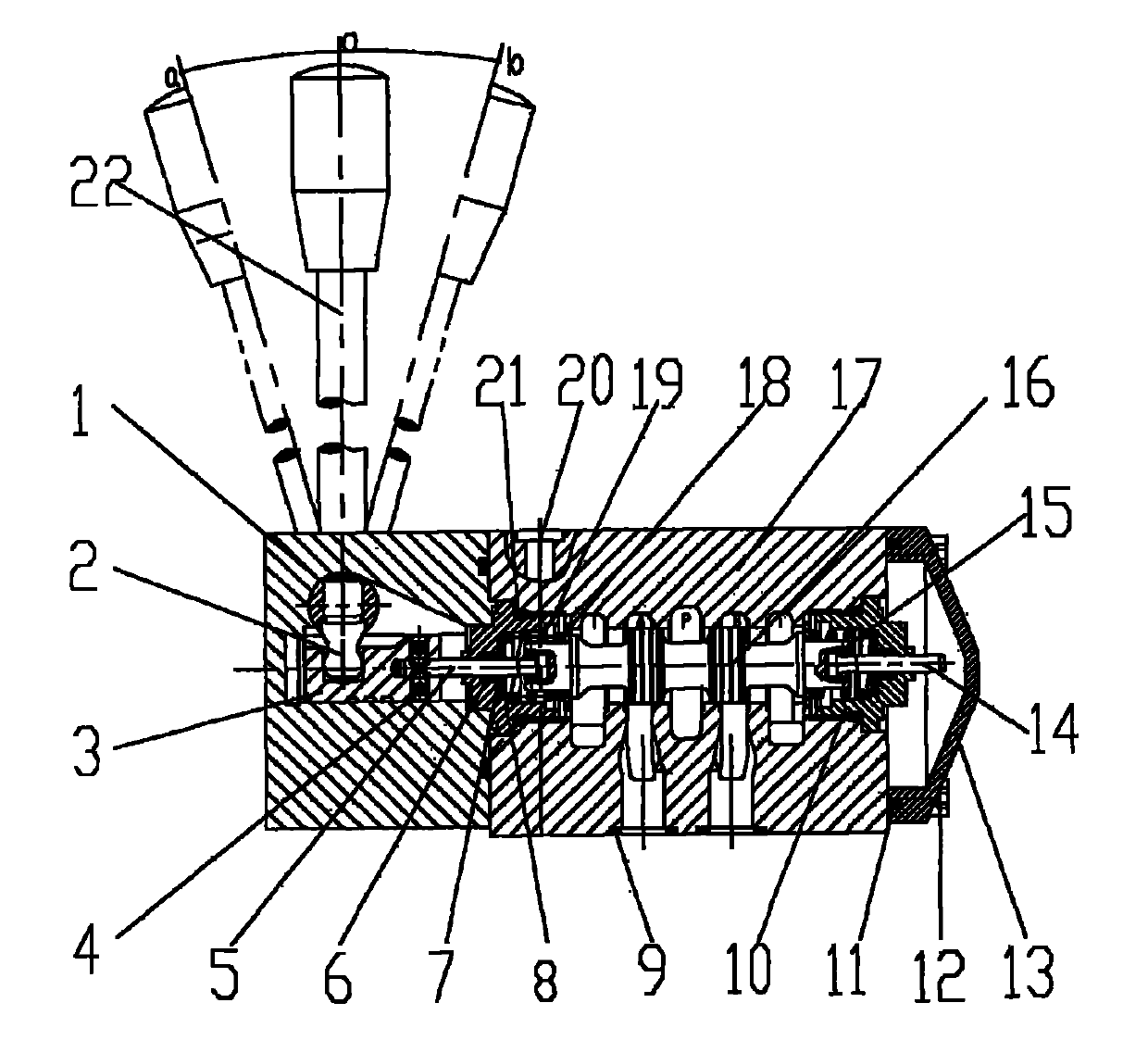

Manual reversing valve for ship

InactiveCN102563120ASmall rotational frictionStrong rust resistanceOperating means/releasing devices for valvesMultiple way valvesEngineeringCopper

The invention discloses a manual reversing valve. A valve core is driven to move by rotation of a handle, so that connection and disconnection of oil ports are determined, and the required functions are obtained; and the oil sealing reliability of the valve core in the moving process is ensured by an effective sealing form. Leakage of oil and intrusion of dust and moisture are effectively prevented by a sealing ring at each position. A valve body, a front cover and a rear cover of the valve are obtained by casting, so that the machining time is greatly reduced. Parts such as a copper bush, a hinge shaft, a pin, a push rod, a locking screw and the like for forming a manual mechanism are placed in the front cover. The valve core, a retainer ring, a spring, a gasket, a sealing element, an end face screw cover and the like are arranged in the valve body. The rear cover plays a role in water proofing and dust resistance.

Owner:SHANGHAI LIXIN HYDRAULIC

Foamless cleaning agent and preparation method thereof

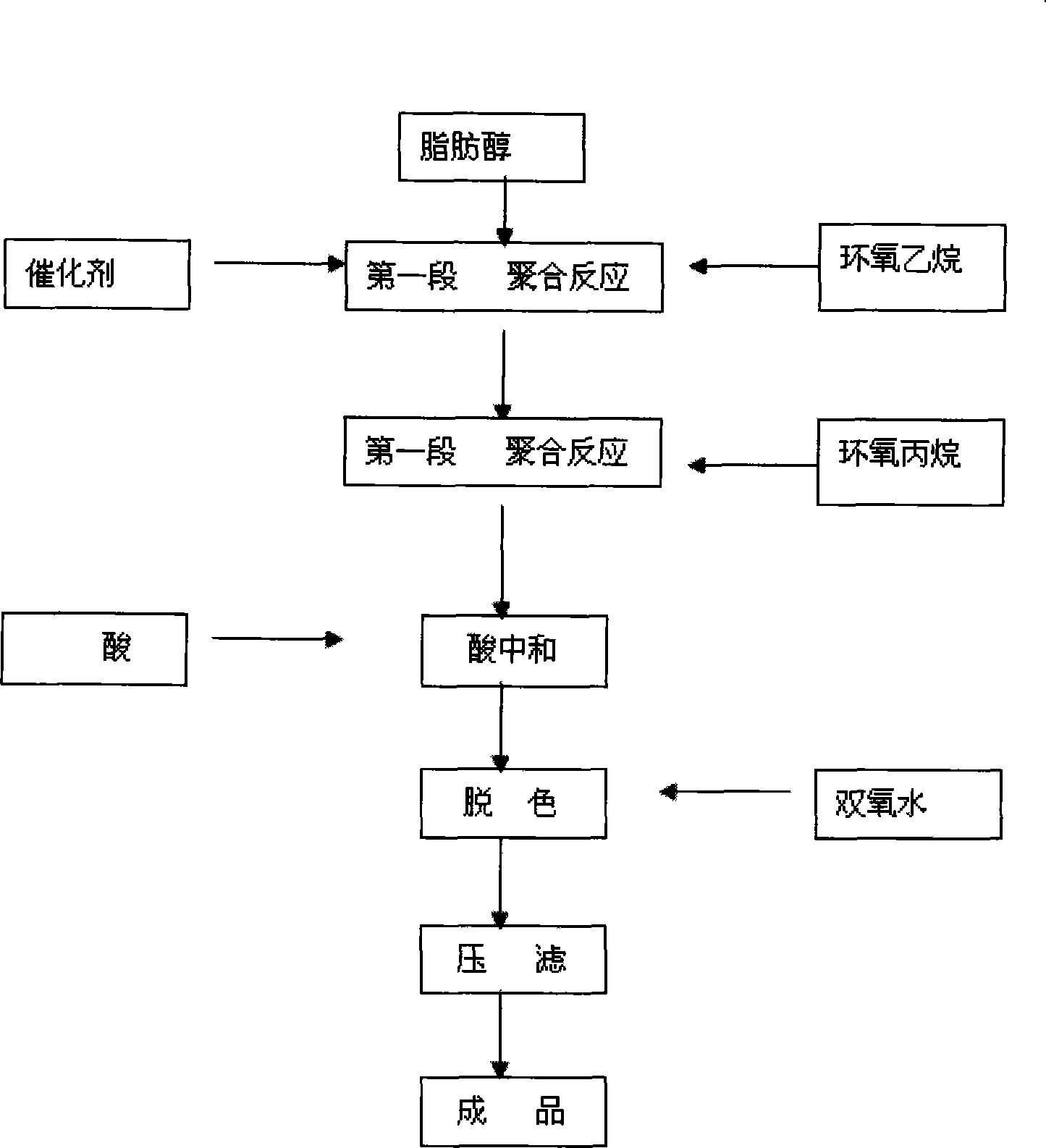

InactiveCN101186862AEasy to cleanEfficient removalNon-ionic surface-active compoundsEpoxyHuman environment

The invention relates to a foamless detergent which is aliphatic alcohol polyether synthesized by an external recycle unit and which is composed of aliphatic alcohol, epoxy ethane and propylene oxide. By the employment of the detergent of the invention, various oils and resembling oil materials can be easily removed from a plurality of adsorbates. The detergent substitutes for normal series products of ODS and APEO which are harmful to human environment, and has the advantages of toxic-free property and environment preservation. The invention has outstanding properties, including humectation, emulsification, dispersion, solubilization and the like, and thereby the invention is an environment-friendly detergent which is high in efficiency, acid-free, high in wetting property and high in detergency.

Owner:大连广会科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com