Foamless cleaning agent and preparation method thereof

A cleaning agent and cleaning agent technology, applied in the field of non-foaming cleaning agent and its preparation, can solve the problems of not easy to degrade, the cleaning agent environment is polluted, and easily corroded parts, etc., and achieves bright and hard coating, wide application range, biological good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

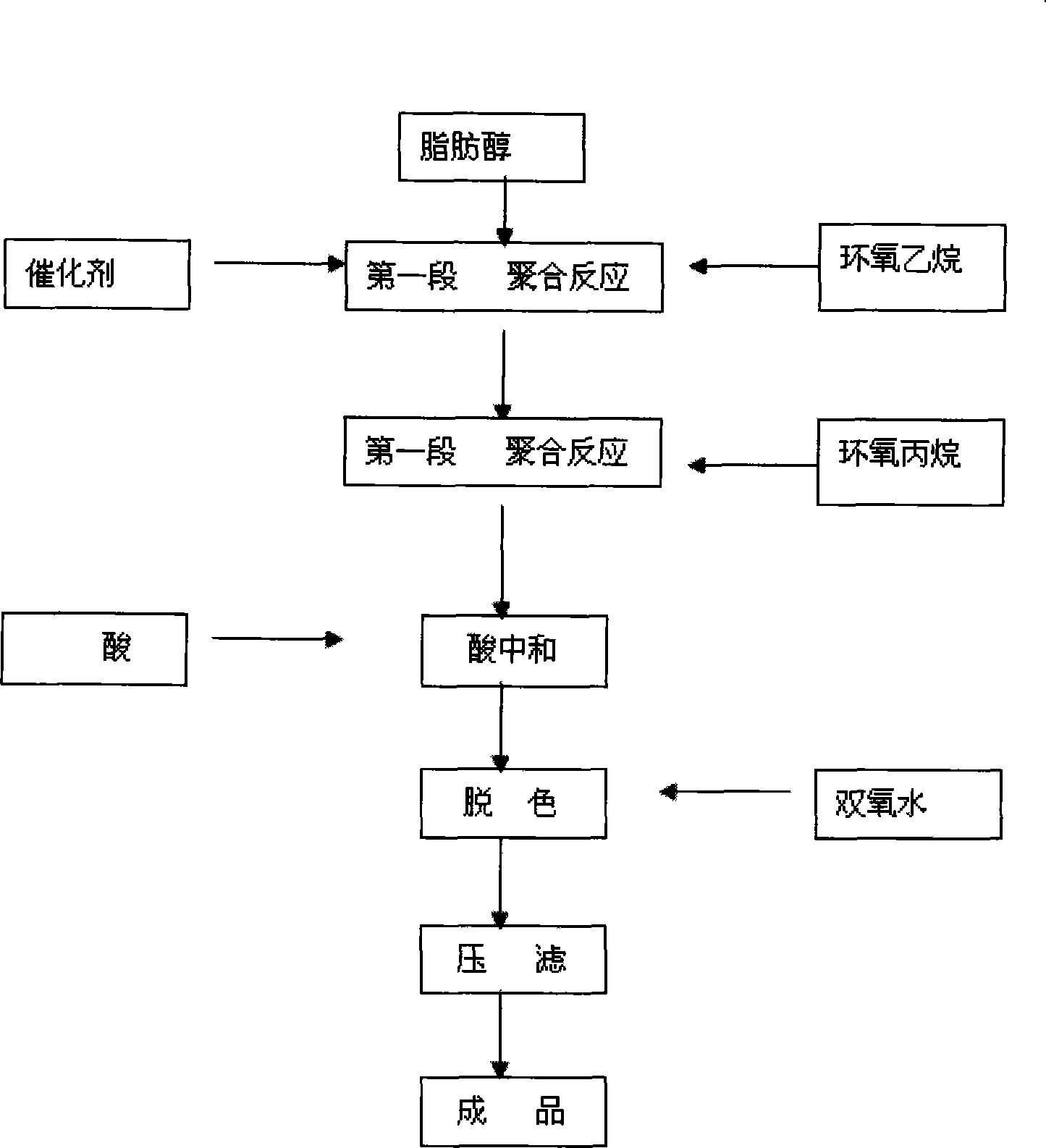

Image

Examples

Embodiment 1

[0026] Raw material weight ratio:

[0027] C 12-14 Fatty alcohol: ethylene oxide: propylene oxide = 1: 1.875: 1.66

[0028] Preparation:

[0029] 1. Put C 12-14 Fatty alcohol, ethylene oxide, and propylene oxide are successively fed into the circulation reactor for polymerization reaction, the reaction pressure is controlled below 0.3Mpa, and the reaction temperature is 150°C±10°C.

[0030] 2. Product refining: Neutralize with acid for 20 minutes at 50°C, then decolorize with hydrogen peroxide at 70°C for 0.5 hours. Then press filter at 100°C to get the finished product.

[0031] Physical properties:

[0032] Viscosity: 220mm 2 / s; Cloud point: 38.5°C; PH value 5.8

[0033] This product has strong emulsifying performance and is suitable for cleaning heavy dirt on various metal surfaces. It has obvious cleaning effects on butter, vegetable oil and gear oil. Adding this product to the pickling process in the electroplating industry can effectively remove oil stains, make...

Embodiment 2

[0035] Raw material weight ratio:

[0036] C 12-14 Fatty alcohol: ethylene oxide: propylene oxide = 1: 2.2: 1.84

[0037] Preparation:

[0038] 1. Put C 12-14 Fatty alcohol, ethylene oxide, and propylene oxide are successively passed into the circulation reactor for polymerization reaction, the reaction pressure is controlled below 0.3Mpa, and the reaction temperature is 160°C±10°C.

[0039] 2. Product refining: Neutralize with acid for 20 minutes at 60°C, then decolorize with hydrogen peroxide at 70°C for 0.5 hours. Then press filter at 100°C to get the finished product.

[0040] Physical properties:

[0041] Viscosity: 250mm 2 / s; Cloud point: 42°C; PH value 6.0.

[0042] This product is suitable for cleaning oil, dust and other organic pollution on the surface of bearings, tools, measuring tools, cutting tools, gears and other metal products. It has strong degreasing ability and strong antirust performance.

Embodiment 3

[0044] Raw material weight ratio:

[0045] C 12-14 Fatty alcohol: ethylene oxide: propylene oxide = 1: 2.5: 2.0

[0046] Preparation:

[0047] 1. Put C 12-14 Fatty alcohol, ethylene oxide, and propylene oxide are successively passed into the circulation reactor for polymerization reaction, the reaction pressure is controlled below 0.3Mpa, and the reaction temperature is 160°C±10°C.

[0048] 2. Product refining: Neutralize with acid for 20 minutes at 60°C, then decolorize with hydrogen peroxide at 70°C for 0.5 hours. Then press filter at 100°C to get the finished product.

[0049] Physical properties:

[0050] Viscosity: 285mm 2 / s; Cloud point: 45°C; PH value 6.0

[0051] This product is suitable for processes requiring low-foam or no-foam cleaning, especially automatic cleaning, spray cleaning, in-situ cleaning and high-pressure cleaning. Such as automatic tableware washing and rinsing in hotels, restaurants and canteens; cleaning of beer bottles, beverage bottles and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com