Waterborne polyurethane severe corrosion-resisting primer and preparation method thereof

A water-based polyurethane and anti-corrosion primer technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as health and environmental threats, and achieve excellent waterproof and anti-fouling, low wear, and strong slip resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0063] Embodiment A: Preparation of modified water-based one-component polyurethane emulsion

[0064] Prepare raw materials: water-based one-component polyurethane emulsion adopts MT, organosilicon intermediates adopt Dow Corning

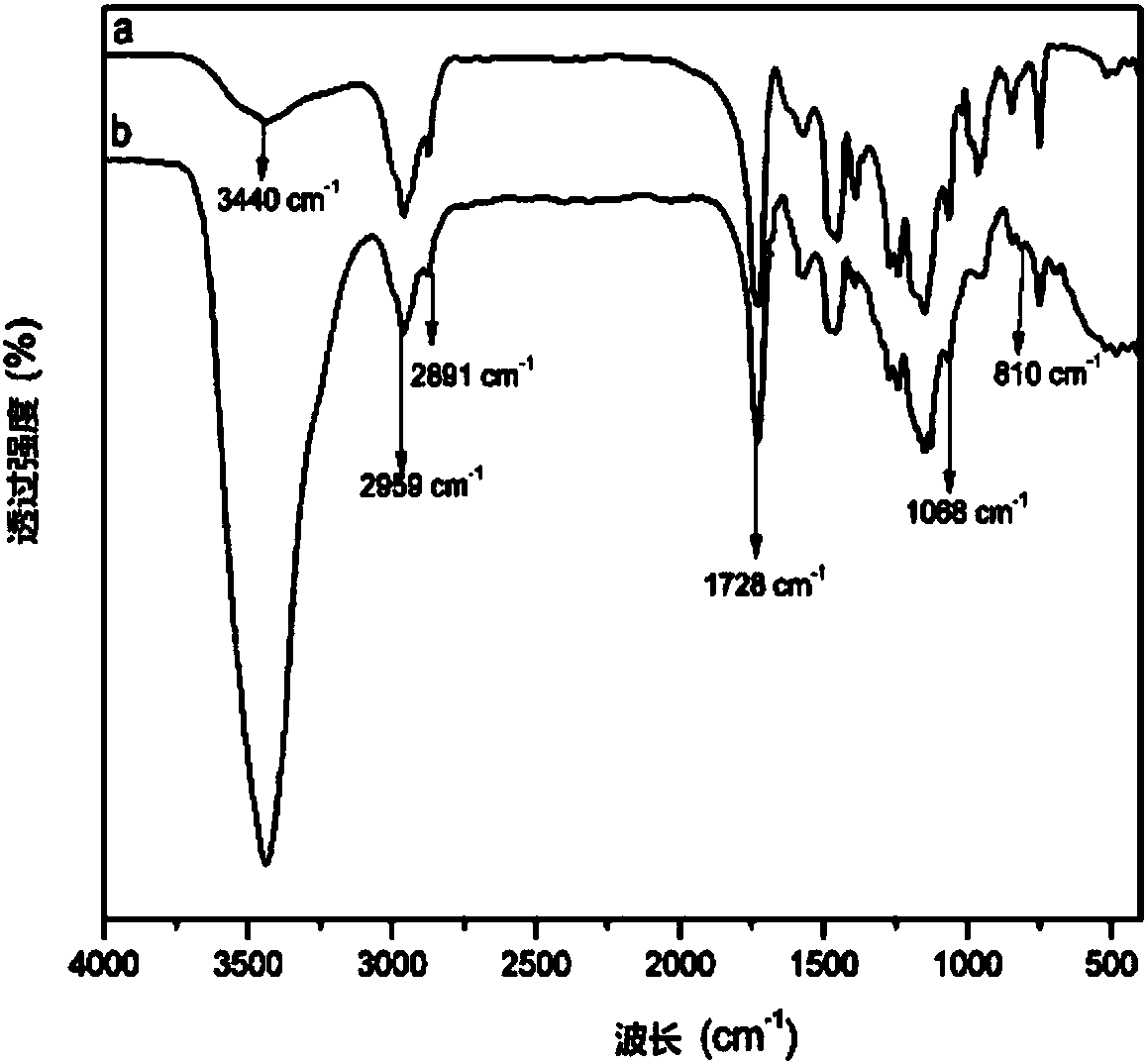

[0065] Add water to the water-based one-component polyurethane emulsion, adjust the pH value to 8-9 with ethanolamine, add the organic silicon intermediate while stirring, and place it for 8-16 hours (room temperature) after the addition, and it can be used immediately. Infrared absorption spectrum as figure 1 Shown, where a is the spectrum of polyurethane, b is the spectrum of silicone modified polyurethane, 3440cm -1 It is the vibration absorption peak of the silicon-oxygen bond, and the peak intensity in Figure b is greater.

Embodiment B

[0066] Example B: Preparation of Surface Calcium Ionized Silica

[0067] Prepare 3-aminopropyltriethoxysilane, ethanol, deionized water, 25% ammonia water, anhydrous calcium chloride, PAA-Br, dichloromethane and other raw materials, and prepare them according to the following steps:

[0068] Disperse a certain amount of silicon dioxide in a mixed solution of ethanol: water = 5: 1 by ultrasonic waves, then add 25% ammonia water and 3-aminopropyltriethoxysilane, stir at 25°C for 24 hours, filter, wash, Vacuum drying for 10 hours to obtain A;

[0069] Disperse A in dichloromethane and NaHPO 4 -NaH 2 PO 4 (pH=6) into the mixed solution, add PAA-Br, 0°C, 10min, then warm up to 25°C, stir for 24h, centrifuge, wash, and vacuum dry for 10h to obtain A 1 ;

[0070] Will A 1 Disperse in deionized water, add 3% CaCl 2 , stirred for 24h, centrifuged, washed, and vacuum-dried for 10h to obtain the surface calcium ionized silica A 2 .

Embodiment 1

[0072] Embodiment 1: Preparation of water-based one-component polyurethane heavy anticorrosion primer

[0073] Prepare each raw material: 300g water-based one-component polyurethane emulsion (covestro company's MT), 100g wax emulsion (AD62 of GSM Company), 150g deionized water, 60g film-forming aid (dipropylene glycol butyl ether of Dow Company), 200g body filler (1250 mesh ground calcium carbonate of Linkou Omiya Company) , 100g anti-rust pigment (SZP-391 of HALOX Company), 20g thickener (RHEOLATE 150 of Hemingsi Company), 40g defoamer (SIN02 of Sol Company), 30g dispersant (OROTAN of Dow Company) TM 731A).

[0074] Then proceed as follows to prepare:

[0075] Add deionized water, dispersant, and defoamer to the agitator, and stir for 10 minutes at 600 rpm;

[0076] Under stirring conditions, add film-forming aids, fillers, anti-rust pigments, about 10g thickener, increase the speed to 1200 rpm, continue stirring for 30-50 minutes, and stop stirring when the fineness reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com