Ultraviolet light or electron beam-cured resin composition for blue-ray disc

A technology of electron beam curing and resin composition, which is applied in the field of ultraviolet light or electron beam curing resin composition for Blu-ray discs, and can solve the problems of poor stability, reliability and stability of data reading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

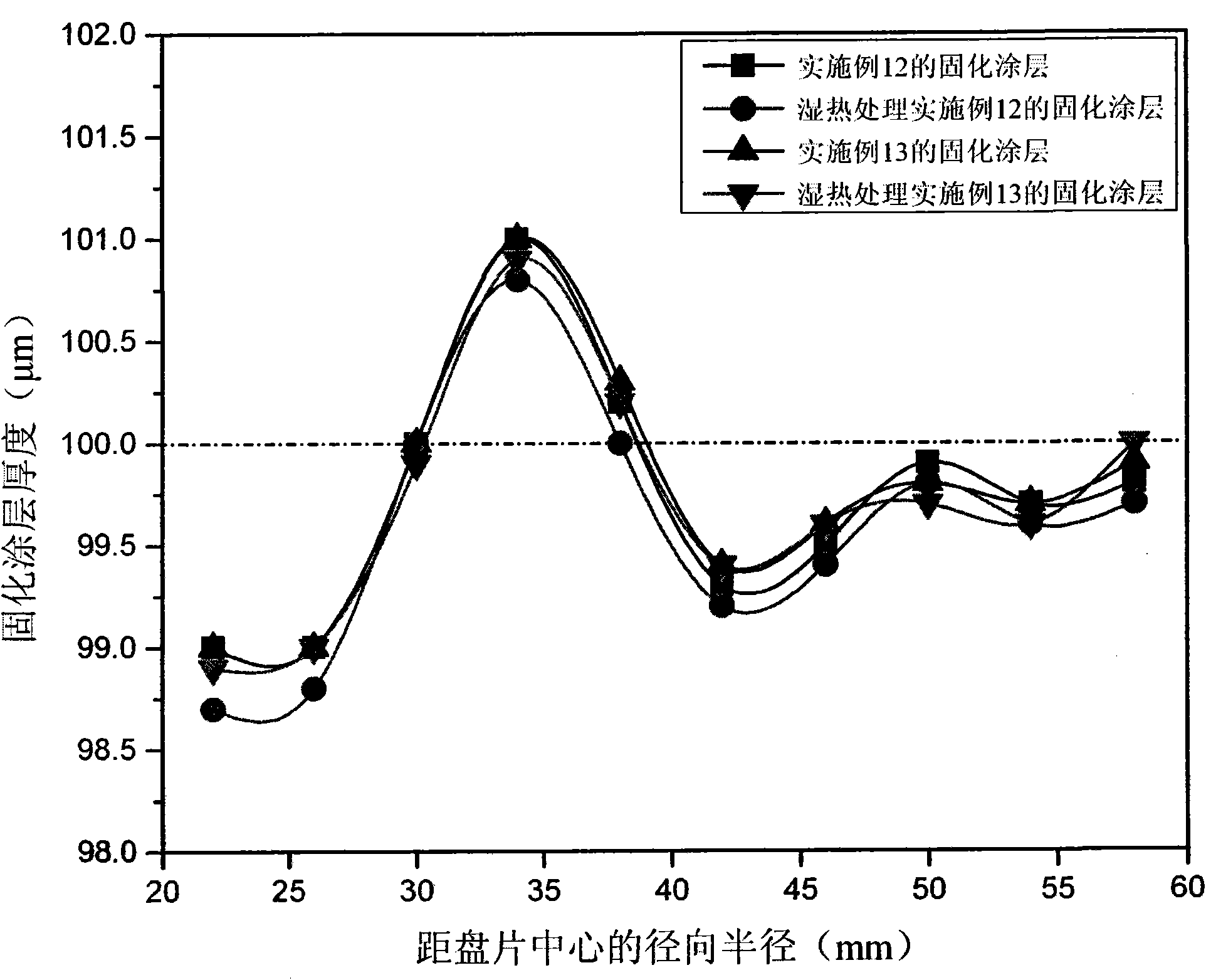

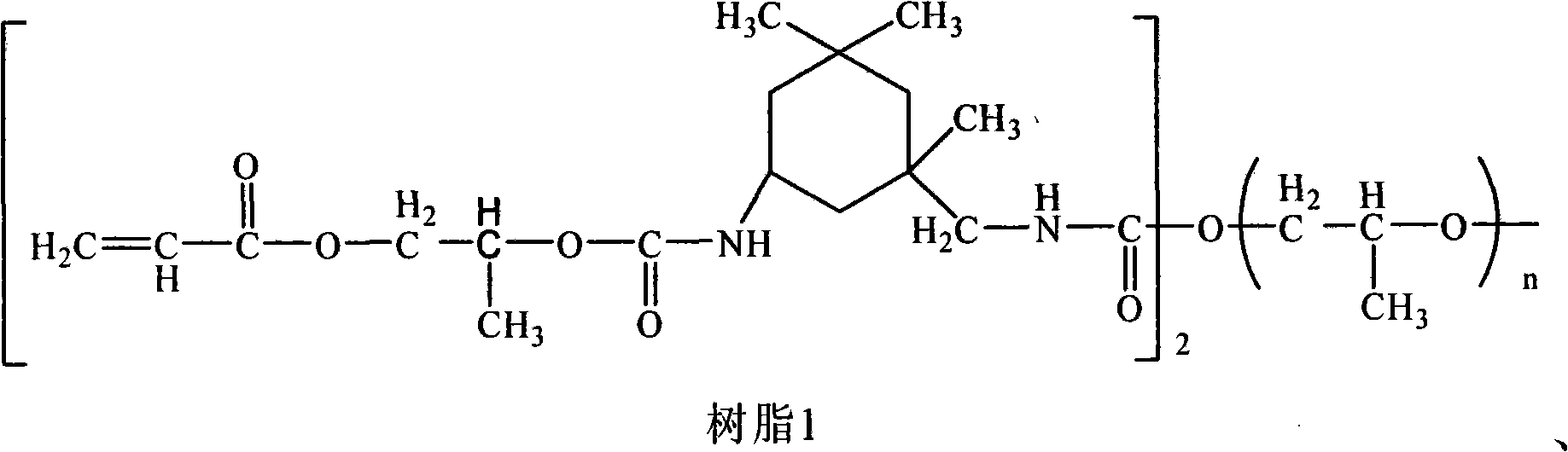

[0057] Based on the weight part of resin 1, 20 parts by weight of resin 1 having the aforementioned structure, 20 parts by weight of isobornyl acrylate, 15 parts by weight of tetrahydrofurfuryl acrylate, 2 parts by weight of Irgacure184, 2 parts by weight of Put Irgacure 651, 1 part by weight of TEGO Flow 300, 2 parts by weight of vinyl tris (β-methoxyethoxy) silane and 0.2 parts of NANOBYK 3601 into a container with a stirrer, stir and mix evenly, use The cured resin composition was prepared by filtering through a filter cloth with a pore size of 0.1 μm. The cured resin composition obtained above was spin-coated on a polycarbonate substrate sputtered with a metal reflective layer by using a coater to form a coating with a thickness of about 100 μm. Curing by UV radiation (energy is 600mJ / cm 2 ) and perform performance evaluation.

Embodiment 2

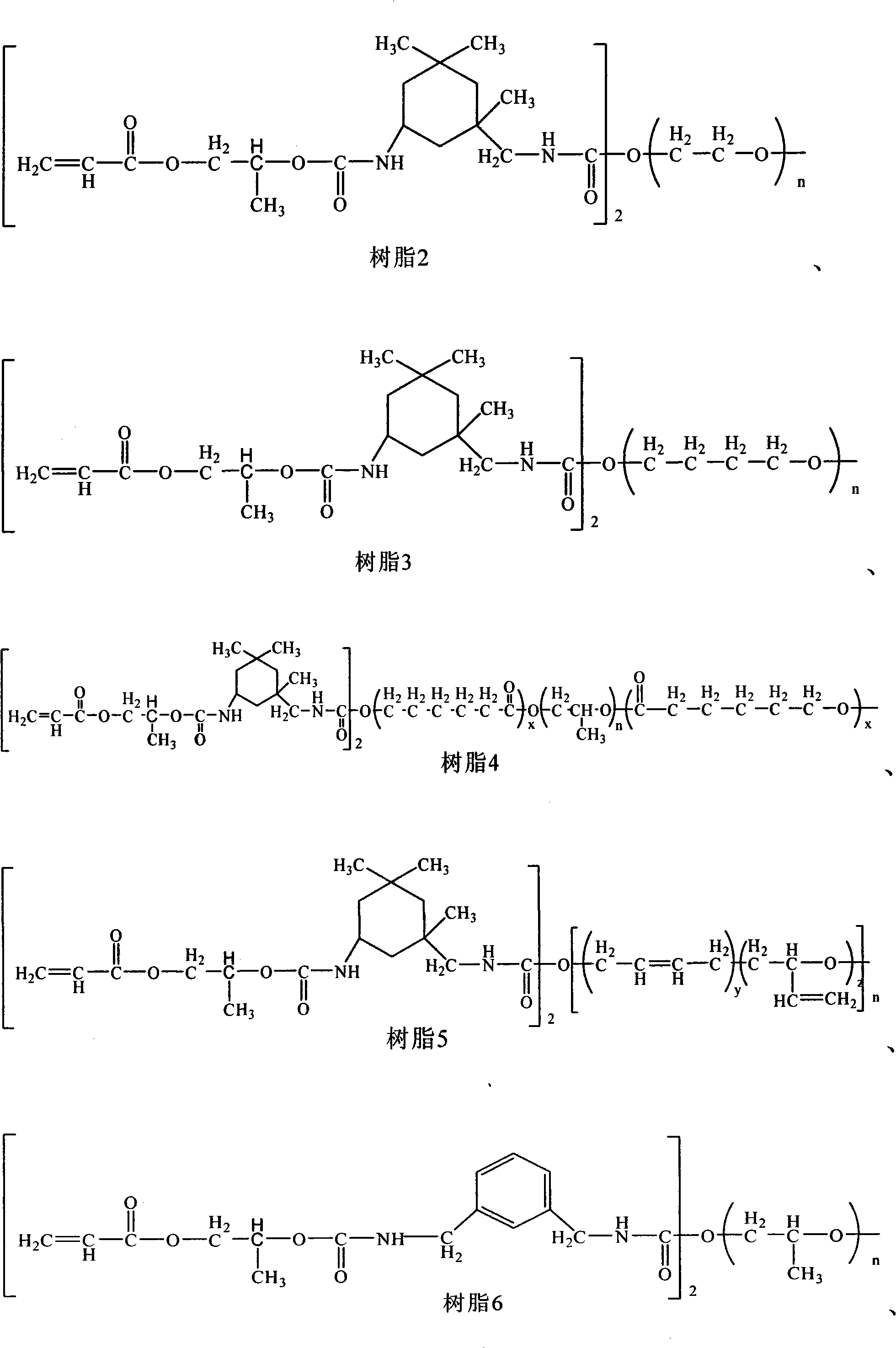

[0059] Based on the parts by weight of resin 2, 40 parts by weight of resin 2 having the aforementioned structure, 15 parts by weight of 2-phenoxyethyl acrylate, and 5 parts by weight of ethoxylated trimethylolpropane triacrylate , 5 parts by weight of trimethylolpropane triacrylate, 2 parts by weight of Darocur 1173, 3 parts by weight of Irgacure 651, 0.2 parts by weight of TEGO Glide 450 and 1 part by weight of vinyltrimethoxysilane coupling agent Put it into a container with a stirrer, stir and mix evenly, and filter through a filter cloth with a pore size of 0.1 μm to prepare a cured resin composition. The cured resin composition obtained above was spin-coated on a polycarbonate substrate sputtered with a metal reflective layer by using a coater to form a coating with a thickness of about 100 μm. Curing by UV radiation (energy is 300mJ / cm 2 ) and perform performance evaluation.

Embodiment 3

[0061] Based on the parts by weight of resin 3, 50 parts by weight of resin 3 having the aforementioned structure, 30 parts by weight of 2-phenoxyethyl acrylate, 15 parts by weight of tetrahydrofurfuryl acrylate, and 8 parts by weight of three Methylolpropane triacrylate, 6 parts by weight of Irgacure 184, 2 parts by weight of Irgacure 651, 0.2 parts by weight of TEGO Glide 450 and 5 parts by weight of vinyltrimethoxysilane coupling agent are put into a container with agitator , stir and mix evenly, and filter through a filter cloth with a pore size of 0.1 μm to prepare a cured resin composition. The cured resin composition obtained above was spin-coated on a polycarbonate substrate sputtered with a metal reflective layer by using a coater to form a coating with a thickness of about 100 μm. Curing by UV radiation (energy 100mJ / cm 2 ) and perform performance evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com